Fine grain strengthening and toughening double-medium-step quenching cooling method for steel

A step-by-step quenching and cooling method technology, applied in the field of steel heat treatment, can solve the problems of difficult to meet the quality and technical indicators at 1/2T of large-section steel parts, large energy and resource consumption, and serious pollution, so as to shorten the construction period and protect the environment , The effect of reducing the yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

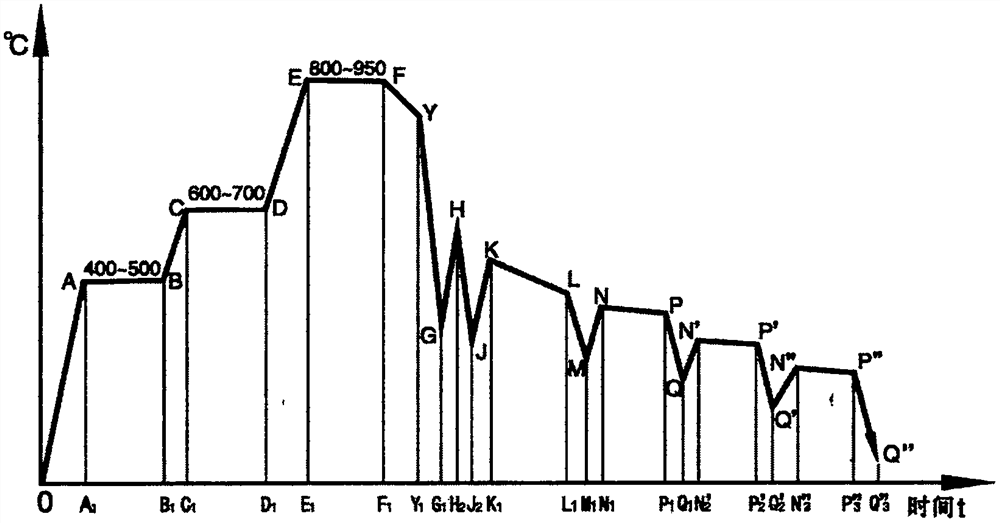

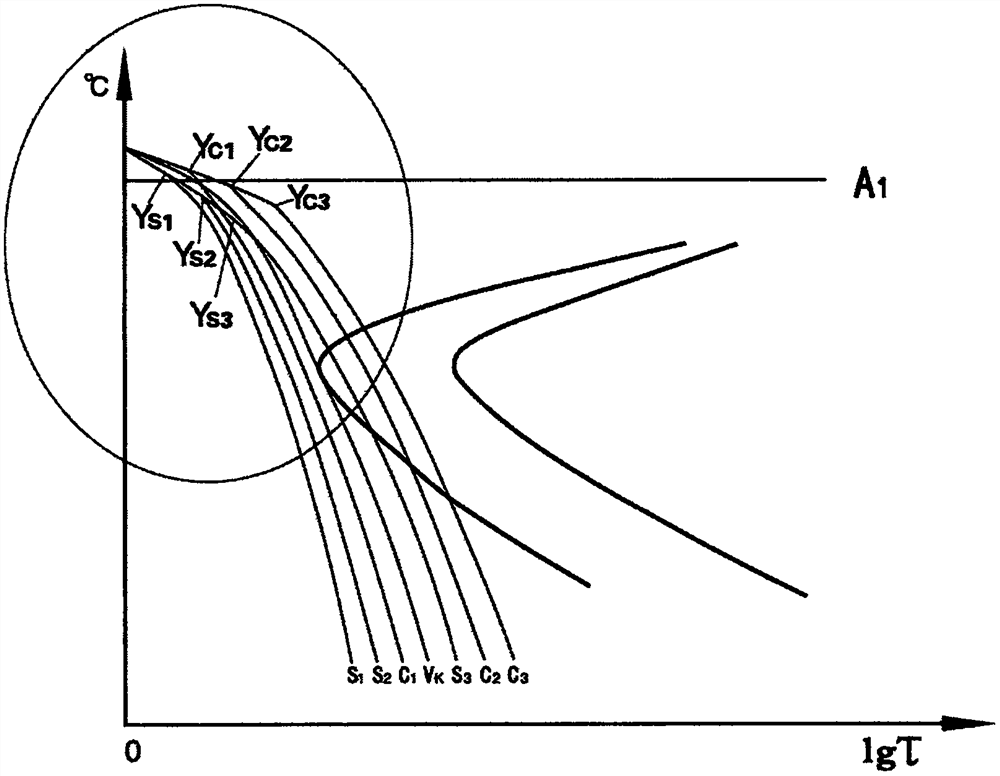

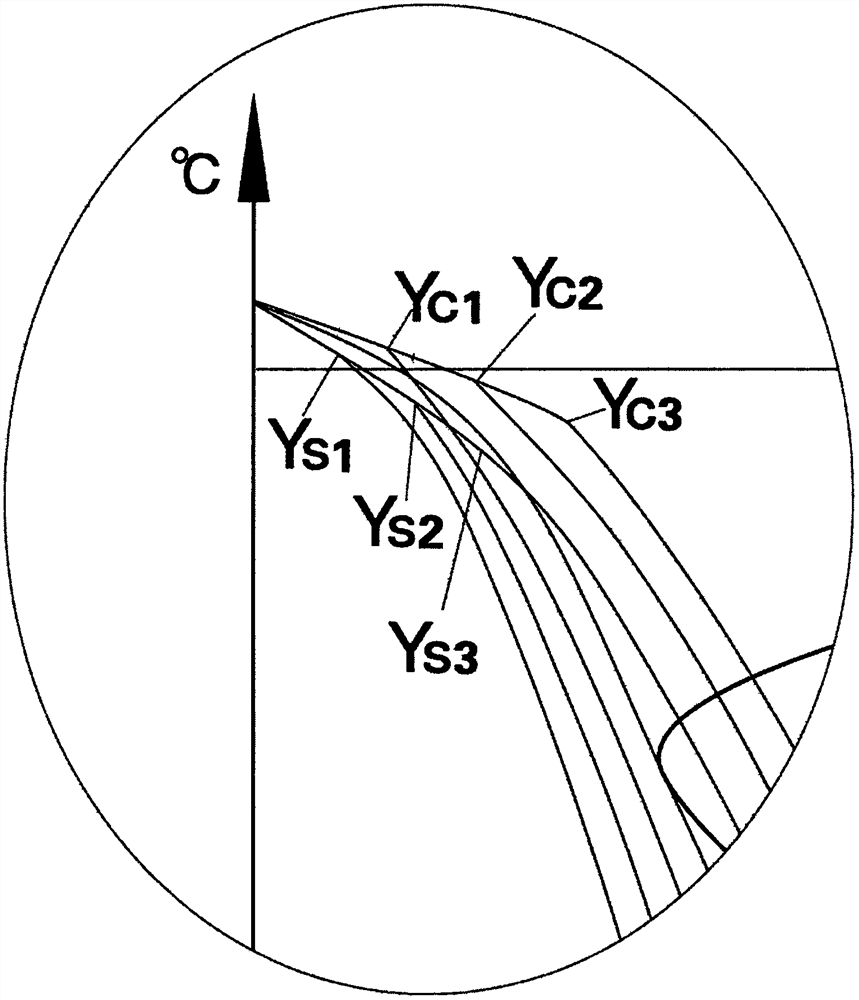

[0048] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0049] The invention will now be described in detail with reference to several preferred embodiments illustrated in the accompanying drawings. In the following description, several specific details are set forth in order to enable a thorough understanding of the invention, but it is clear Skilled artisans may practice the present invention without some or all of these specific details; in some instances, well-known process steps have not been described in detail in order to avoid unnecessarily obscuring the present invention .

[0050] The difficulty coefficient of heat treatment is that after the steel is austenitized (the austenite transformation is completed, the temperature field of the steel is uniform, the austenite grains cannot grow, and the cost is low), it is cooled in water, and its core is 1 / 2T. Cool below Ar 1 At a certai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com