Flexible electronic component and manufacturing method thereof

A technology of electronic components and manufacturing methods, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem of damage to electronic components, decrease in the yield rate of flexible substrates, and the yield rate of flexible electronic components. Problems such as decline, to achieve the effect of improving the manufacturing yield rate and high manufacturing yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

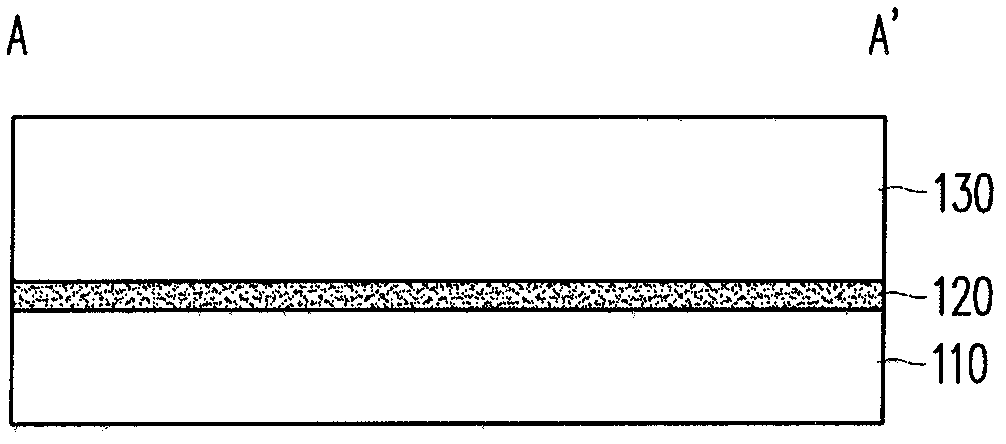

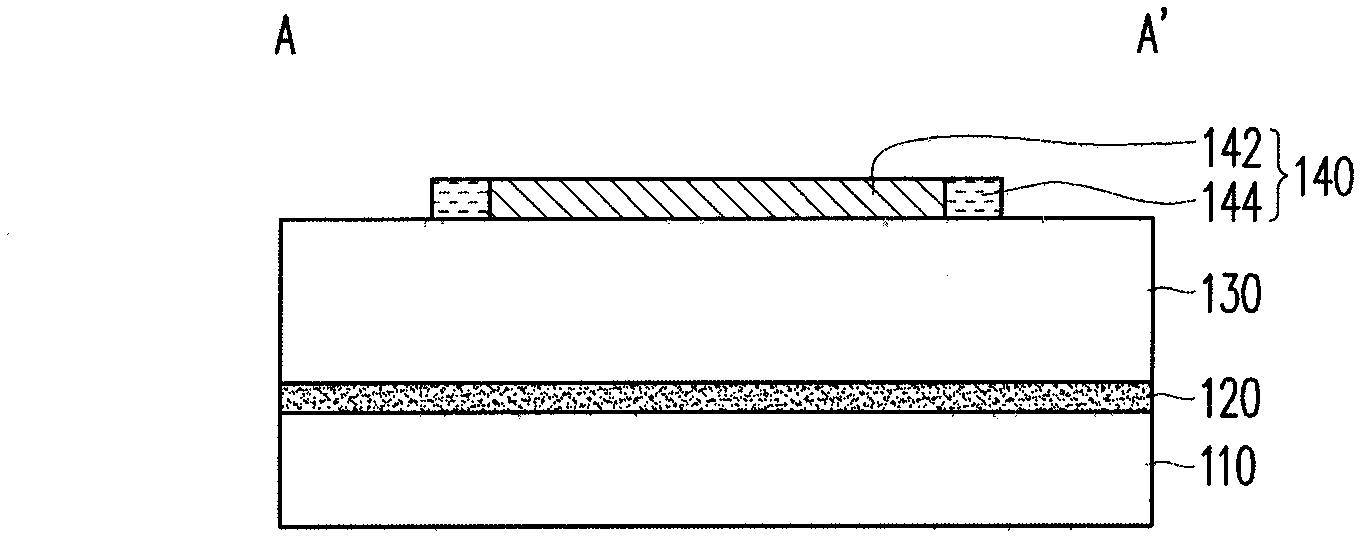

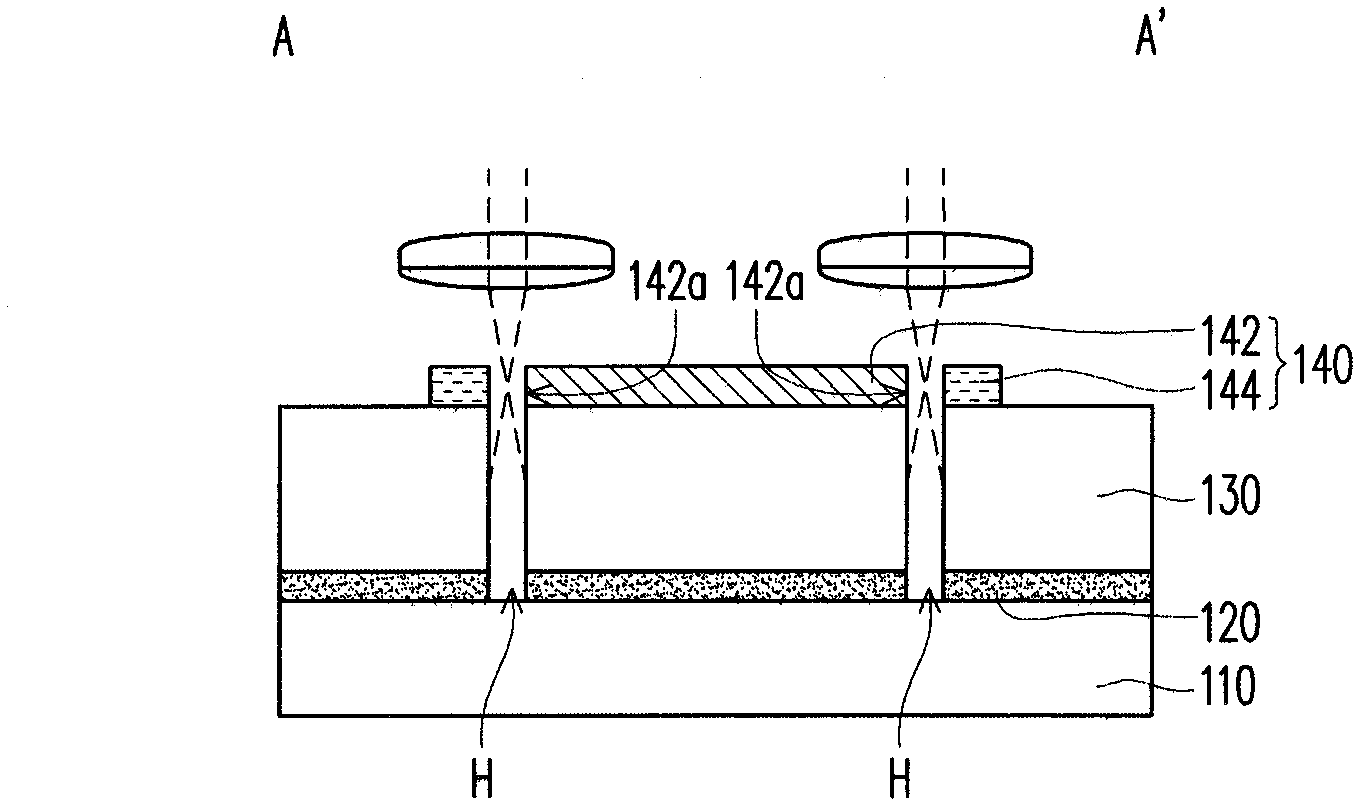

[0035] Figure 1A to Figure 1H is a schematic cross-sectional view of the manufacturing process of a flexible electronic component according to an embodiment of the present invention, and Figure 2A to Figure 2F It is a schematic top view of the manufacturing process of the flexible electronic component according to an embodiment of the present invention. In detail, Figure 1A to Figure 1D as well as Figure 1E to Figure 1F According to Figure 2A to Figure 2D The section line AA' and Figure 2E to Figure 2F is shown by the section line BB'. The following will match Figure 1A to Figure 1H as well as Figure 2A to Figure 2F , to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com