Column wearing plate, steering frame and railway truck

A wear plate and bogie technology, which is applied to bogies, railway car body parts, devices for lateral relative movement between the underframe and the bogie, etc. Longevity and wear prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

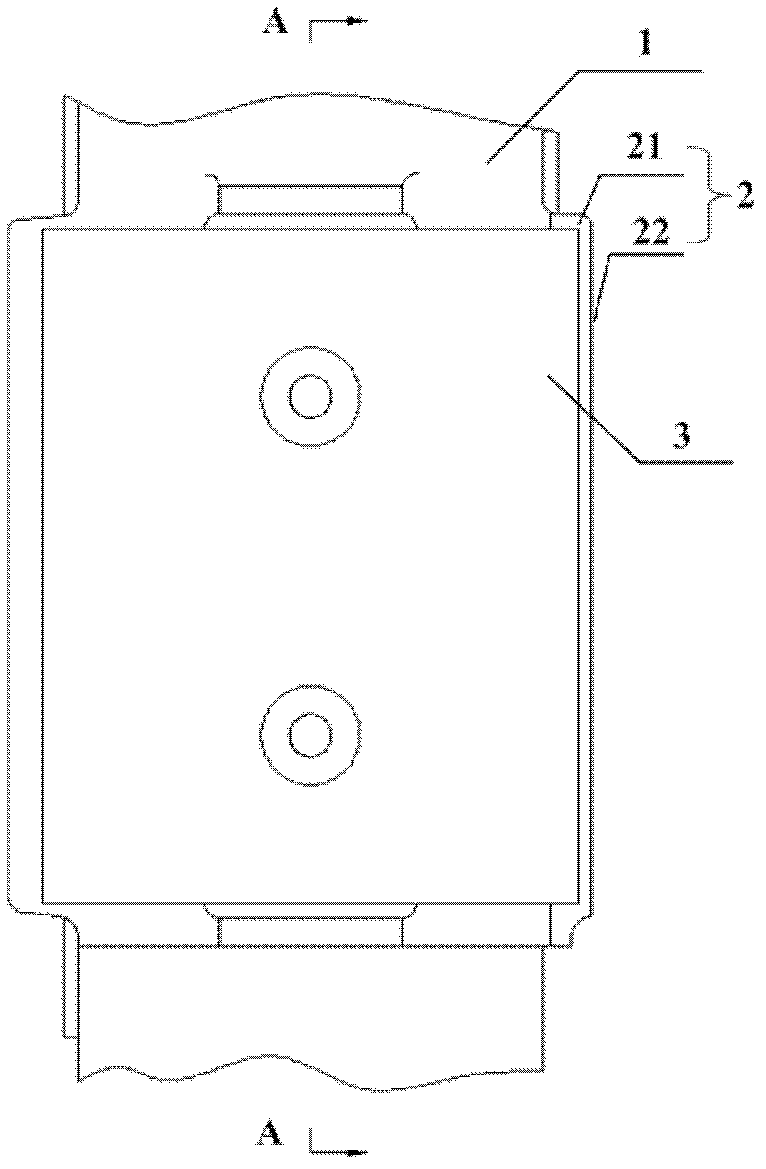

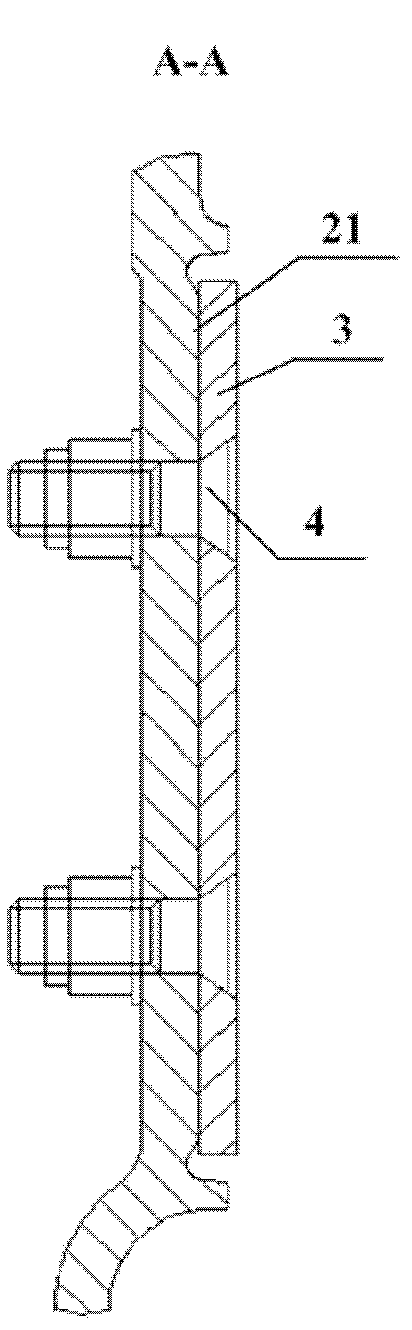

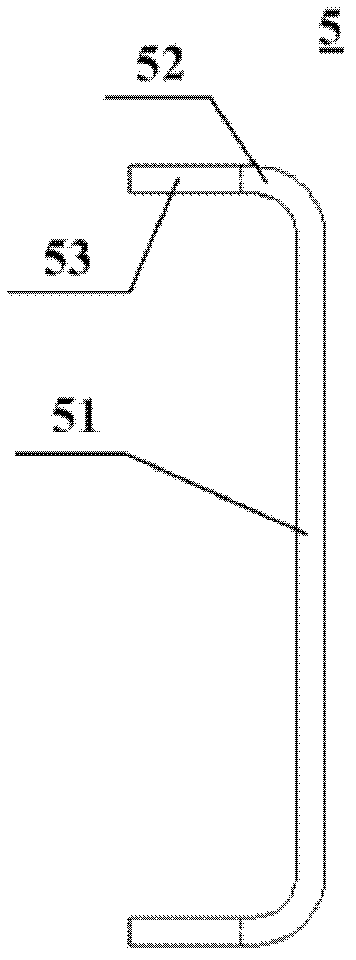

[0026] see Figure 2a with Figure 2b , Embodiment 1 of the present invention provides a column wear plate, which is used to be installed on the side frame of the bogie, specifically, installed on the bolster block of the side frame. The column wear plate 5 includes a groove bottom 51, and two groove sides 52 oppositely arranged on the groove bottom 51, the groove bottom 51 and the two groove sides 52 form a concave shape, and the concave shape is used to cover the bottom surface of the bolster block and sideways.

[0027] The shape of the bottom of the groove depends on the shape of the bottom surface of the bolster block. In the prior art, the bottom surface of the bolster block is generally rectangular, and the bottom of the groove is also rectangular. The two groove sides are relatively arranged on the two rectangular sides of the groove bottom, and the wear plate of the whole column is concave. The two groove sides can be arranged on the bottom of the groove symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com