Preparation method for 3D printing support material based on photoinduced reversible micelles

A technology of 3D printing and supporting materials, applied in the field of 3D printing, can solve problems such as inseparable support, affecting the shape of parts, production deviation, etc., to achieve the effect of improving fluidity, not easy to warp products, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

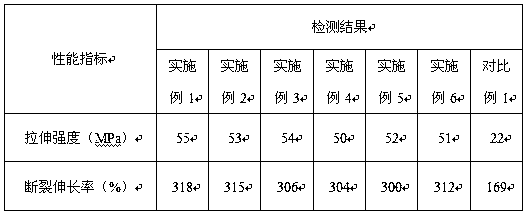

Examples

Embodiment 1

[0031] The preparation of 3D printing support material based on light-induced reversible micelles, the steps are as follows:

[0032] a. Mix polystyrene microspheres with a particle size of 2-5 μm and sodium lauryl sulfate solution with a mass concentration of 0.25%, disperse ultrasonically for 30-60 minutes, add dibutyl phthalate, swell for 6 hours, and then Add toluene to continue swelling for 5-8 hours, continue to add styrene, divinylbenzene, and dibenzoyl peroxide, and swell for another 12 hours, centrifuge the product, separate, add dichloromethane to the separated microspheres, and extract for 24 hours , washed three times with methanol, filtered, and vacuum-dried at 60°C for 15 hours to obtain hollow porous polymer microspheres;

[0033] The mass ratio of polystyrene microspheres, sodium lauryl sulfate solution, dibutyl phthalate, toluene, styrene, divinylbenzene, and dibenzoyl peroxide is 5:1.5:4:6:5 :0.5:0.2;

[0034] b. In a fluidized bed, spray a crosslinking age...

Embodiment 2

[0039] The preparation of 3D printing support material based on light-induced reversible micelles, the steps are as follows:

[0040] a. Mix polystyrene microspheres with a particle size of 2-5 μm and sodium lauryl sulfate solution with a mass concentration of 0.25%, disperse ultrasonically for 60 minutes, add dibutyl phthalate, swell for 5 hours, and then add toluene Continue to swell for 6 hours, continue to add styrene, divinylbenzene, and dibenzoyl peroxide, and swell for another 15 hours. Centrifuge and separate the product. Add dichloromethane to the separated microspheres, extract for 25 hours, and then use methanol Washing 4 times, filtering, and vacuum drying at 60°C for 14 hours to obtain hollow porous polymer microspheres;

[0041] The mass ratio of polystyrene microspheres, sodium lauryl sulfate solution, dibutyl phthalate, toluene, styrene, divinylbenzene, and dibenzoyl peroxide is 5:1.2:3:6:4 :0.8:0.3;

[0042] b. In a fluidized bed, spray a crosslinking agent ...

Embodiment 3

[0047] The preparation of 3D printing support material based on light-induced reversible micelles, the steps are as follows:

[0048] a. Mix polystyrene microspheres with a particle size of 4 μm and sodium lauryl sulfate solution with a mass concentration of 0.25%, ultrasonically disperse for 51 minutes, add dibutyl phthalate, and swell for 7 hours, then add toluene to continue swelling 6h, continue to add styrene, divinylbenzene, dibenzoyl peroxide, and then swell for 13h, centrifuge and separate the product, add dichloromethane to the separated microspheres, extract for 24h, and wash with methanol for 3 times, filter, and vacuum dry at 60°C for 16 hours to obtain hollow porous polymer microspheres;

[0049] The mass ratio of polystyrene microspheres, sodium lauryl sulfate solution, dibutyl phthalate, toluene, styrene, divinylbenzene, and dibenzoyl peroxide is 8:0.5:4:7:4 :0.7:0.3;

[0050] b. In a fluidized bed, spray a crosslinking agent and hydroxyazobenzene into the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com