Touch control panel, touch control module and laminating method therefor

A touch module and touch panel technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the impact of expanding the accuracy of touch panel detection, poor optical effect, distance and medium Changes in electrical coefficients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

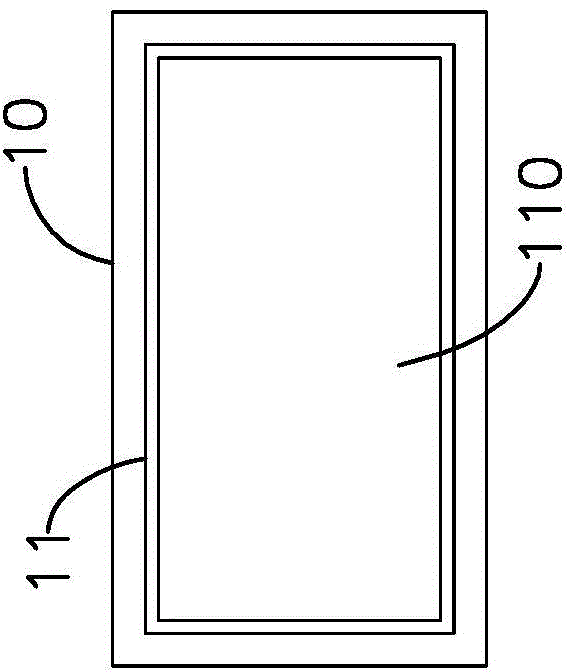

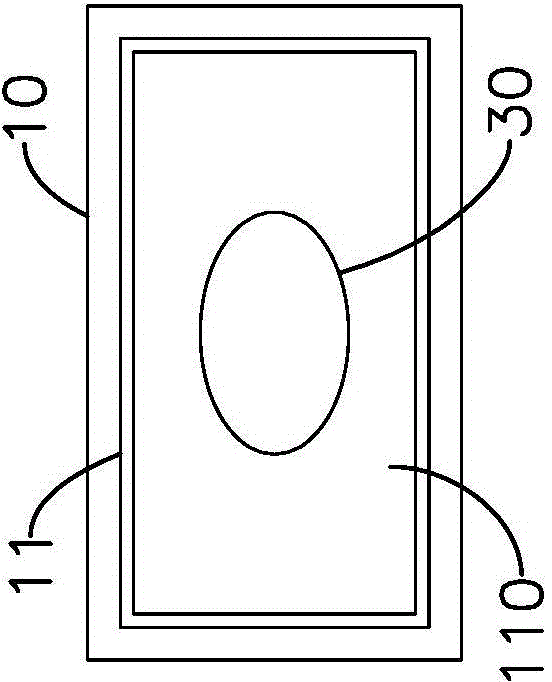

[0082] The technical means adopted by the present invention to realize the intended invention purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0083] Regarding the bonding method of the present invention, it can be applied to the bonding of touch modules or touch panels. In the following embodiments, the touch module is used as the implementation object to illustrate the bonding method. Regarding the bonding of touch panels Basically adopt the same method, and its implementation details will be described in detail later.

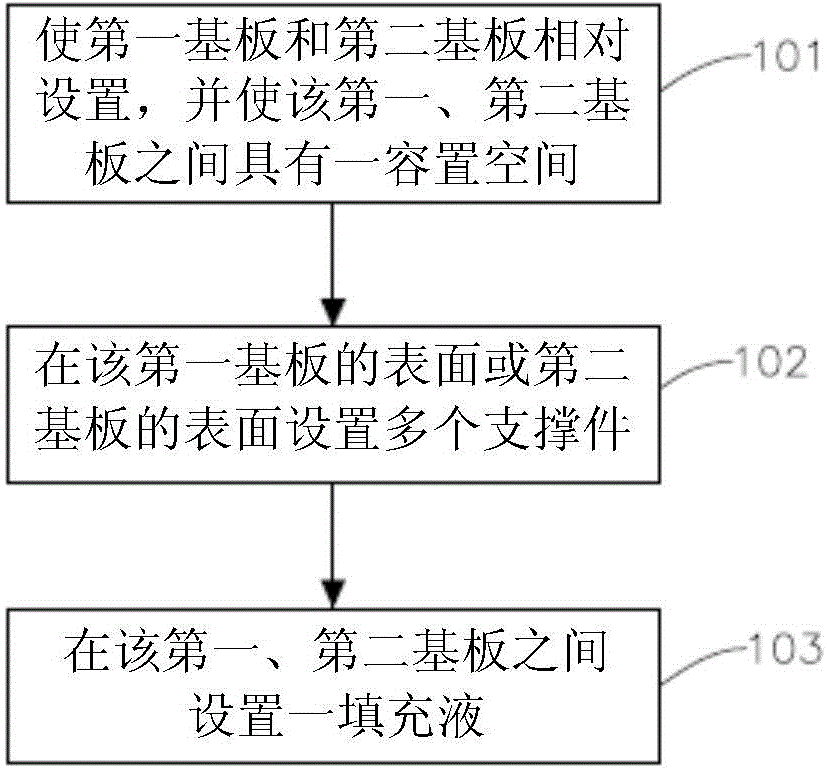

[0084] Please refer to figure 1 Shown is a basic flow chart of the bonding method of the present invention, which comprises the following steps:

[0085] Arranging a first substrate and a second substrate facing each other, and providing an accommodating space (101) between the first and second substrates;

[0086] setting a plurality of supports (102) on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com