Two-way stretching light diffusion film and preparation method thereof

A light-diffusing film and biaxial stretching technology, applied in optics, nonlinear optics, diffuser elements, etc., can solve problems such as potential safety hazards and environmental damage from organic solvents, and achieve human and environmental health and environmental protection, not easy to warp and heat High effect of shrinkage and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

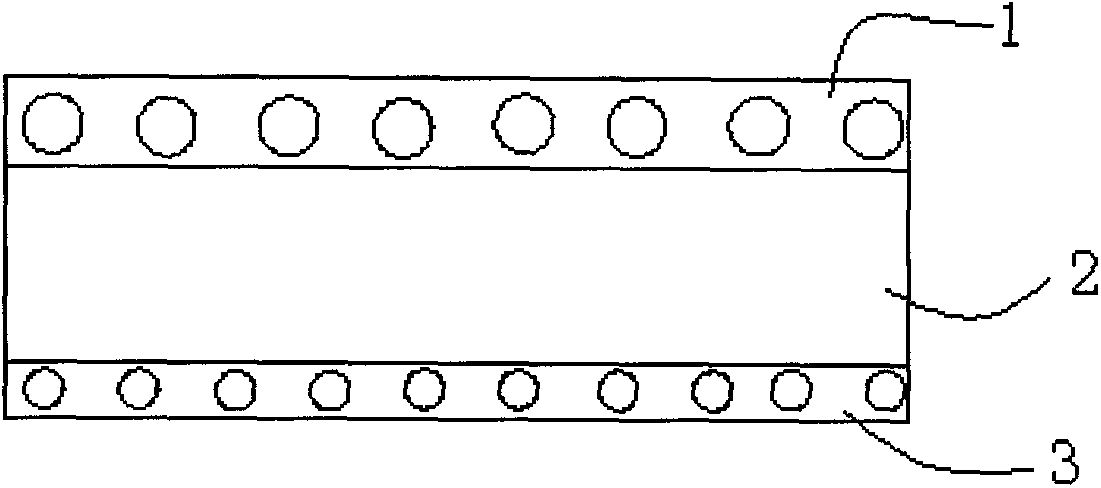

[0029] refer to figure 1 , a biaxially stretched light diffusion film, the biaxially stretched light diffusion film is composed of a diffusion layer 1, a support layer 2 and an anti-adhesion layer 3, the diffusion layer 1 covers the upper surface of the support layer 2, the The anti-adhesion layer 3 is covered on the lower surface of the support layer 2;

[0030] The support layer is PET; the diffusion layer is composed of the following components:

[0031] PET: 100 parts by mass;

[0032] Cationic antistatic agent: 0.01 parts by mass;

[0033] The floating series model produced by 3M Company (Minnesota Mining and Manufacturing Company) is the glass microsphere of H50 / 10000: 1.5 parts by mass;

[0034] Described anti-adhesion layer is made up of following components:

[0035] PET: 100 parts by mass;

[0036] Silica particles: 0.8 parts by mass;

[0037] Cationic antistatic agent: 0.1 parts by mass.

[0038] In this embodiment, the particle diameter of the glass microsph...

Embodiment 2

[0047] refer to figure 1 , a biaxially stretched light diffusion film, the biaxially stretched light diffusion film is composed of a diffusion layer 1, a support layer 2 and an anti-adhesion layer 3, the diffusion layer 1 covers the upper surface of the support layer 2, the The anti-adhesion layer 3 is covered on the lower surface of the support layer 2;

[0048] The support layer is PET; the diffusion layer is composed of the following components:

[0049] PET: 100 parts by mass;

[0050] Anionic antistatic agent: 0.8 parts by mass;

[0051] Glass beads of the floating series model H50 / 10000 produced by 3M: 1.5 parts by mass;

[0052] Described anti-adhesion layer is made up of following components:

[0053] PET: 100 parts by mass;

[0054] Silica particles: 0.08 parts by mass;

[0055] Anionic antistatic agent: 0.8 parts by mass.

[0056] In this embodiment, the particle diameter of the glass microspheres is 1-10 μm, and the particle diameter of the silicon dioxide pa...

Embodiment 3

[0065] refer to figure 1 , a biaxially stretched light diffusion film, the biaxially stretched light diffusion film is composed of a diffusion layer 1, a support layer 2 and an anti-adhesion layer 3, the diffusion layer 1 covers the upper surface of the support layer 2, the The anti-adhesion layer 3 is covered on the lower surface of the support layer 2;

[0066] The support layer is PET; the diffusion layer is composed of the following components:

[0067] PET: 100 parts by mass;

[0068] Nonionic antistatic agent: 1.5 parts by mass;

[0069] Glass beads of the floating series model H50 / 10000 produced by 3M: 0.8 parts by mass;

[0070] Described anti-adhesion layer is made up of following components:

[0071] PET: 100 parts by mass;

[0072] Silica particles: 0.2 parts by mass;

[0073] Nonionic antistatic agent: 1 part by mass.

[0074] In this embodiment, the particle diameter of the glass microspheres is 30-40 μm, and the particle diameter of the silicon dioxide par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com