Functional electroplating process of copperplates of crystallizers

A technology of mold copper plate and electroplating process, which is applied in the field of chemical engineering, can solve the problems of affecting the amount of steel passing through the copper plate, affecting the production efficiency of a continuous casting machine, and accumulating internal stress of the coating, so as to shorten the electroplating production cycle and omit sandblasting. Process, the effect of reducing the probability of peeling off the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Process flow:

[0019] Chemical degreasing→insulation→electrodegreasing→concentrated acid leaching→electroplating into the tank→out of the tank

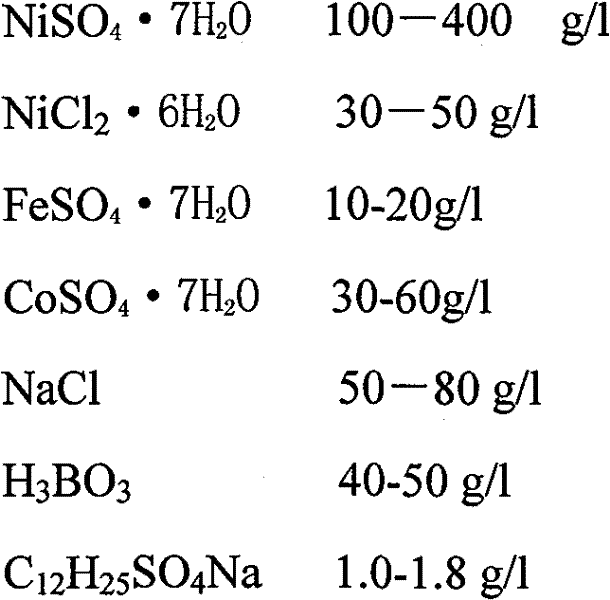

[0020] 2. The composition of the sulfate bath is:

[0021]

[0022] Additive A1, 30ml / l, additive A1 is an aqueous solution of sodium benzenesulfinate and saccharin, wherein the mass percent of sodium benzenesulfinate is 10%, the mass percent of saccharin is 30%, and the rest is water;

[0023] Additive A2: 80ml / l, the additive A2 is an aqueous solution of butynediol, and the mass percentage of butynediol is 32%.

[0024] The plating parameters are:

[0025] Temperature: 35-70°C Cathode area: Anode area = 1:2

[0026] pH value: 1.5-5.0 Current density: 1.0-5.0 A / dm 2 .

Embodiment 2

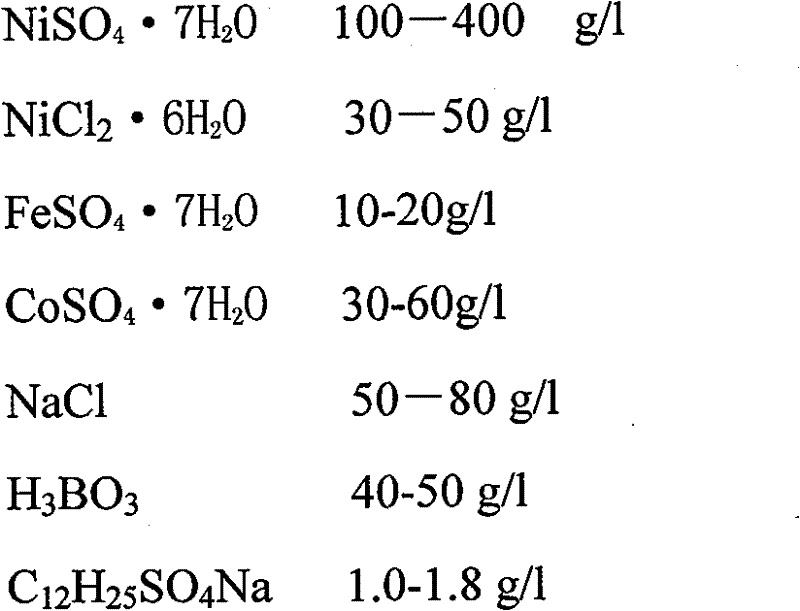

[0028] The composition of sulfate bath is:

[0029]

[0030] Additive A1, 20ml / l, additive A1 is an aqueous solution of sodium benzenesulfinate and saccharin, wherein the mass percent of sodium benzenesulfinate is 20%, the mass percent of saccharin is 35%, and the rest is water;

[0031] Additive A2: 70ml / l, the additive A2 is an aqueous solution of butynediol, and the mass percentage of butynediol is 35%.

[0032] Process flow and electroplating parameters are the same as in Example 1.

Embodiment 3

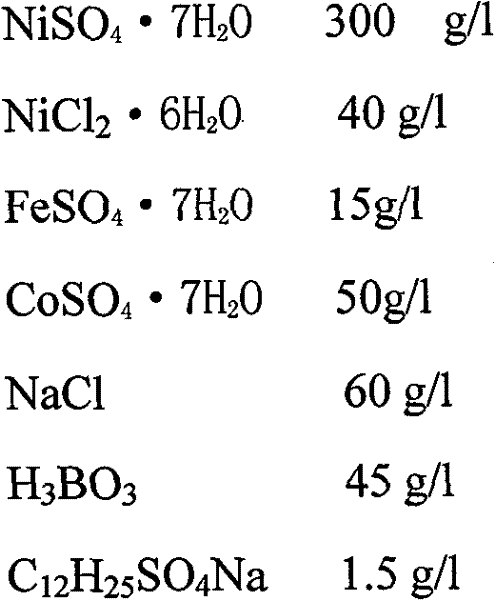

[0034] The composition of sulfate bath is:

[0035]

[0036] Additive A1, 40ml / l, additive A1 is an aqueous solution of sodium benzene sulfinate and saccharin, wherein the mass percentage of sodium benzene sulfinate is 30%, the mass percentage of saccharin is 40%, and the rest is water;

[0037] Additive A2: 90ml / l, the additive A2 is an aqueous solution of butynediol, and the mass percentage of butynediol is 40%.

[0038] Process flow and electroplating parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com