Aluminum nitride single crystal composite substrate and preparation method, application and stress and/or polarization control method thereof

A composite substrate and aluminum nitride technology, which is applied in the semiconductor field, can solve the problems of inability to control the stress state of the substrate, high cost, and high quality repeatability requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

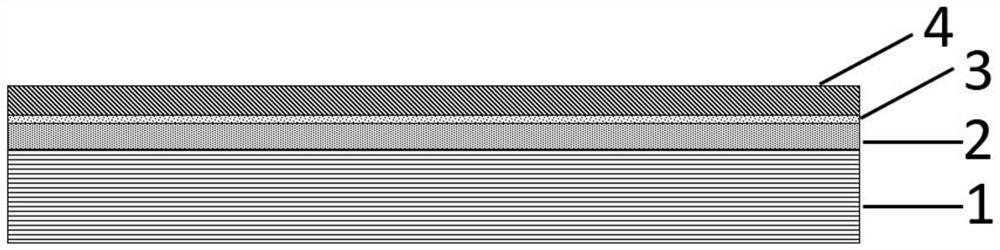

[0083] Nano-patterns were prepared on the surface of single-crystal aluminum nitride substrate by Ar ion low-energy irradiation, and then AlN epitaxial thin film was grown by MOCVD on the substrate to obtain a high-quality aluminum nitride single-crystal composite substrate template with tensile stress.

[0084] The manufacturing method of the stress-adjustable high-quality aluminum nitride template of the present embodiment includes the following steps:

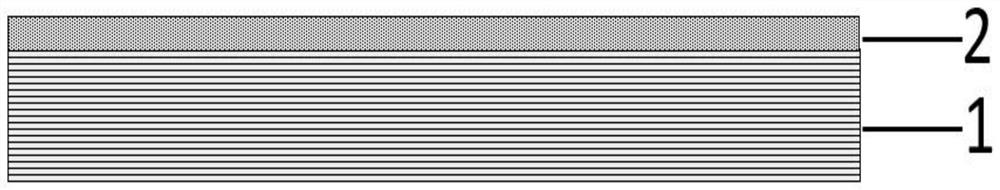

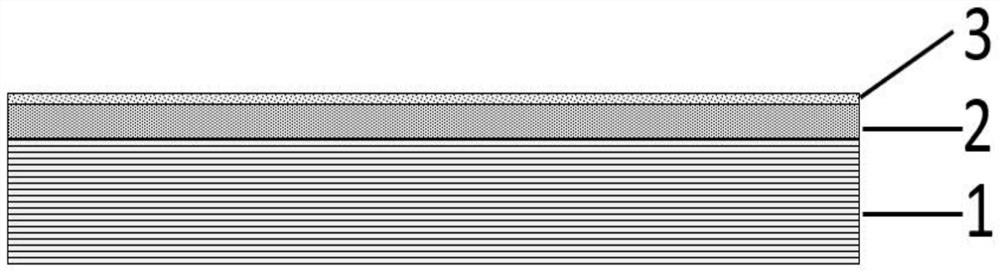

[0085]1) Select a c-plane aluminum polar AlN single crystal substrate with a thickness of 600 μm. Perform chemical ultrasonic cleaning with acetone as the cleaning solution for 10 minutes, and use nitrogen to dry the surface to remove organic and non-polar contamination on the surface, so that the surface is clean, such as figure 1 shown. exist figure 1 , the structure includes an aluminum nitride homogenous substrate 1 and an AlN single crystal 2 .

[0086] 2) annealing the cleaned single crystal aluminum nitride templat...

Embodiment 2

[0091] In this embodiment, a nano-pattern is prepared on the surface of an aluminum nitride single crystal composite substrate template on a sapphire substrate by low-energy irradiation of Ne ions, and then an AlN epitaxial film is grown on the sapphire substrate using MOCVD as a substrate to re-grow an AlN epitaxial film with tensile stress. Aluminum nitride single crystal composite substrate template on sapphire substrate.

[0092] The manufacturing method of the stress-adjustable high-quality aluminum nitride template of the present embodiment includes the following steps:

[0093] 1) Select a high-temperature annealed AlN single crystal template with c-plane sapphire as the substrate, and perform chemical ultrasonic cleaning with acetone as a cleaning solution for 10 minutes, and use nitrogen to dry the surface to remove the surface organic and its non-polar contamination, so that the surface is clean.

[0094] 2) Use high-temperature annealing to anneal the high-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com