A kind of preparation method of cemented carbide coated cutting tool and coated cutting tool

A cemented carbide and coating technology, applied in the direction of metal material coating technology, coating, metal processing equipment, etc., can solve the problem of difficult to achieve thick film coating, and achieve improved hardness, good wear resistance, and improved bonding. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

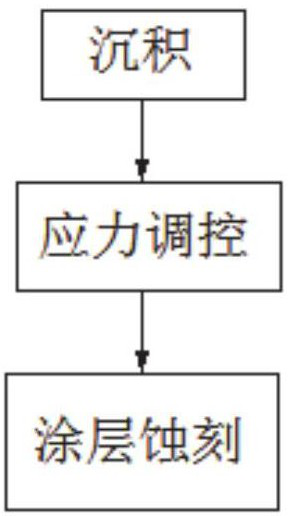

[0037] The present embodiment provides a method for preparing a cemented carbide coating tool, wherein deposition, stress regulation, and coating surface etching operations are cyclically used on the tool substrate until a cemented carbide coating with a desired thickness and internal stress level is obtained;

[0038] Wherein, the deposition step can use the prior art to carry out the coating of the AlxTi1-xN coating. The stress regulation step is to apply one or more thermal cycles to the tool that has deposited a coating of a certain thickness, so that the temperature is raised from the deposition temperature to the first set temperature and then lowered to the second set temperature, in order to make the AlxTi1-xN coating. The layer undergoes thermal cycling for atomic self-diffusion and stress relaxation, which is beneficial to eliminate defects generated during the coating process. The coating surface etching operation is to perform inert gas etching on the coated surfac...

Embodiment 2

[0055] This embodiment provides a coated cutting tool, which is prepared by the method described in the first embodiment.

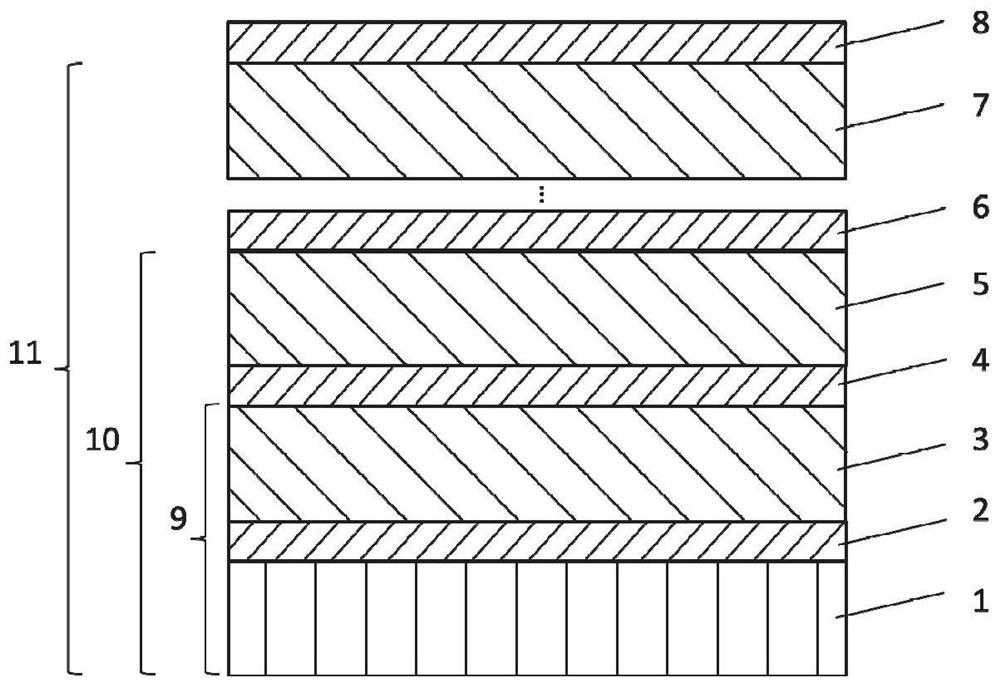

[0056] like figure 2 As shown, a base body 1 is included, and the surface of the base body 1 has at least one layer of stress-controlled ultra-thick film cemented carbide coating.

[0057] Further, the upper surface of the base body 1 is provided with a base body surface etching layer 2 formed by etching treatment, and the upper surface of the base body surface etching layer 2 is provided with a first cemented carbide coating 3, and the first cemented carbide coating 3 is deposited, Stress regulation is formed; the upper surface of the first cemented carbide coating 3 is etched to form a first coating surface etching layer 4 . The base body 1 , the etching layer 2 on the surface of the base body, and the first cemented carbide coating 3 form the tool structure 9 of the first thermal cycle.

[0058] Similarly, a second cemented carbide coating 5, a seco...

Embodiment 3

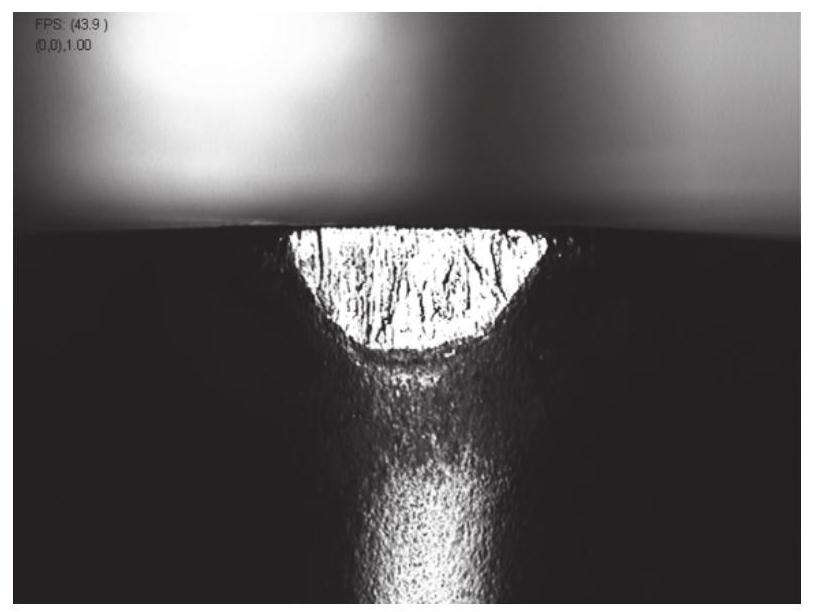

[0064] In this example, WC-Co alloy with 6.0wt% Co is ground and sintered into SCMT09T308 cemented carbide inserts. The metallographic phase of these sintered inserts shows that the grain size is about 1.5 μm, and there is no cobalt at the cutting edge. enrichment phenomenon. The cutting edges of these blades were passivated to 30 μm arcs using the known wet sandblasting (alumina particles) method to obtain uncoated blades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com