Hot bar roadbed and construction method for controlling seasonal frost damage

A construction method and seasonal technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of inconspicuous replacement effect, road surface damage, and delay of a large amount of manpower and material resources, so as to ensure stable and normal operation and improve heat absorption and heat dissipation efficiency, and the effect of eliminating seasonal freezing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

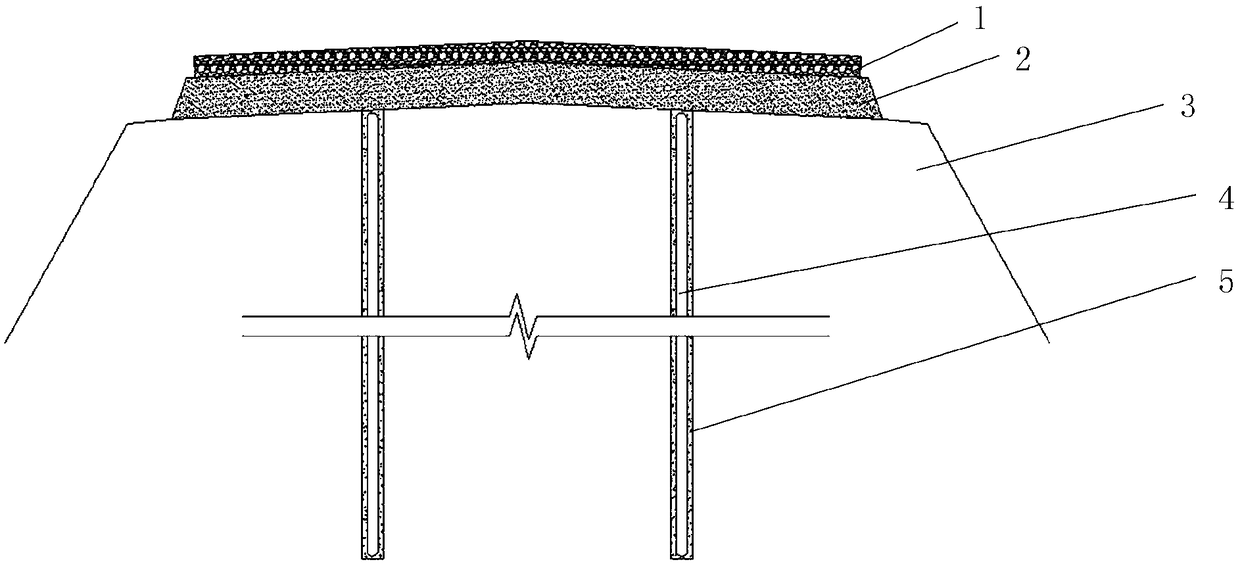

Embodiment 1

[0039] A thermal rod subgrade for controlling seasonal freezing damage, comprising: a permeable layer 1, an impermeable layer 2, a subgrade 3 and a thermal rod 4; the subgrade 3, the impermeable layer 2 and the permeable layer 1 are laid sequentially from bottom to top; the subgrade 3 is provided with a heating rod installation hole; the heating rod 4 is placed in the heating rod installation hole; the heating rod 4 is an airtight hollow structure, and the airtight hollow structure is equipped with liquid ammonia.

[0040] In order to further optimize the above technical solution, the heating rod 4 is a vertical rod; the heating rod 4 is arranged vertically or obliquely.

[0041] In order to further optimize the above-mentioned technical scheme, fine sand is filled between the hot rod 4 and the installation hole of the hot rod.

[0042] In order to further optimize the above technical solution, the hot rod 4 includes an evaporation section and a condensation section; the evapo...

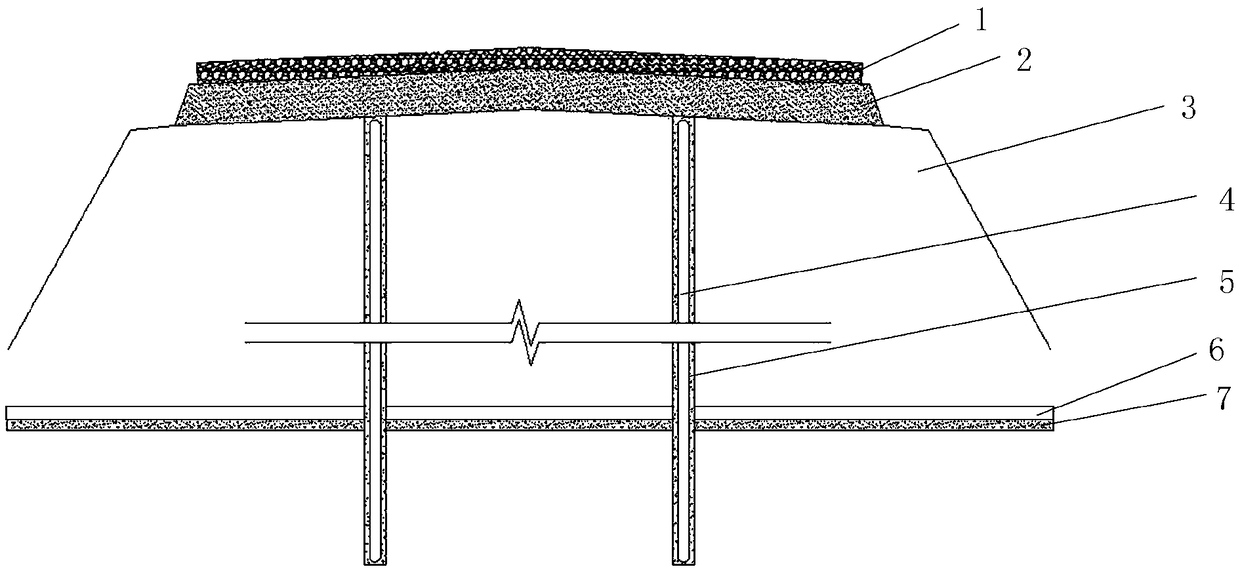

Embodiment 2

[0046] A hot rod subgrade for controlling seasonal freezing damage, comprising: a permeable layer 1, an impermeable layer 2, a subgrade 3, a thermal rod 4, a foam lightweight concrete insulation layer 6, and a heat-accumulating layer 7; the heat-accumulating layer 7, foam Lightweight concrete insulation layer 6, subgrade 3, impermeable layer 2 and permeable layer 1 are laid sequentially from bottom to top; subgrade 3 is provided with a thermal rod installation hole; thermal rod 4 is placed in the thermal rod installation hole; thermal rod 4 is The airtight hollow structure is filled with liquid ammonia; the hot rod runs through the subgrade 3, the foam lightweight concrete insulation layer 6 and the heat accumulation layer 7 in sequence.

[0047] In order to further optimize the above technical solution, the heating rod 4 is a vertical rod; the heating rod 4 is arranged vertically or obliquely.

[0048] In order to further optimize the above-mentioned technical scheme, fine sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com