Diaphragm pump with automatic protection function and automatic protection method of diaphragm pump

An automatic protection and diaphragm pump technology, applied to pumps with flexible working elements, pumps, pump control, etc., can solve the problems affecting the production efficiency of the slurry pipeline transportation system, high maintenance costs, and long maintenance cycles, etc., and can be promoted Strong performance, reduced maintenance rate and maintenance cost, easy to use and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

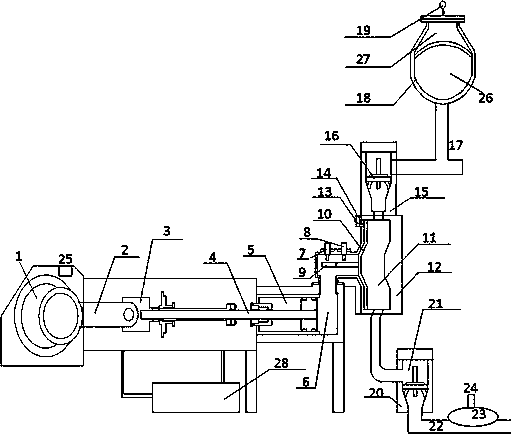

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

[0026] as attached figure 1As shown, the diaphragm pump of the present invention as a whole includes an eccentric wheel 1, a connecting rod 2, a crosshead 3, a piston rod 4, a piston cylinder 5, a diaphragm oil chamber 6, an oil discharge switch 7, an oil replenishment switch 8, and a detection rod 9 , diaphragm 10, diaphragm chamber 11, diaphragm gland 12, pinhole valve 13, first pressure sensor 14, outlet valve chamber 15, discharge check valve 16, pumping outlet pipe 17, first gas stabilizer 18, the first Two pressure sensors 19 , an inlet valve chamber 20 , a feed check valve 21 , a pumping inlet pipe 22 , a second gas stabilizer 23 , a third pressure sensor 24 and a stroke detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com