Constant-pressing-force sweeping system used for ribbon conveyer and having automatic compensation function

A belt conveyor and automatic compensation technology, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems that the cleaning block and belt pressing force cannot be kept constant, so as to achieve ideal cleaning effect, avoid damage, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

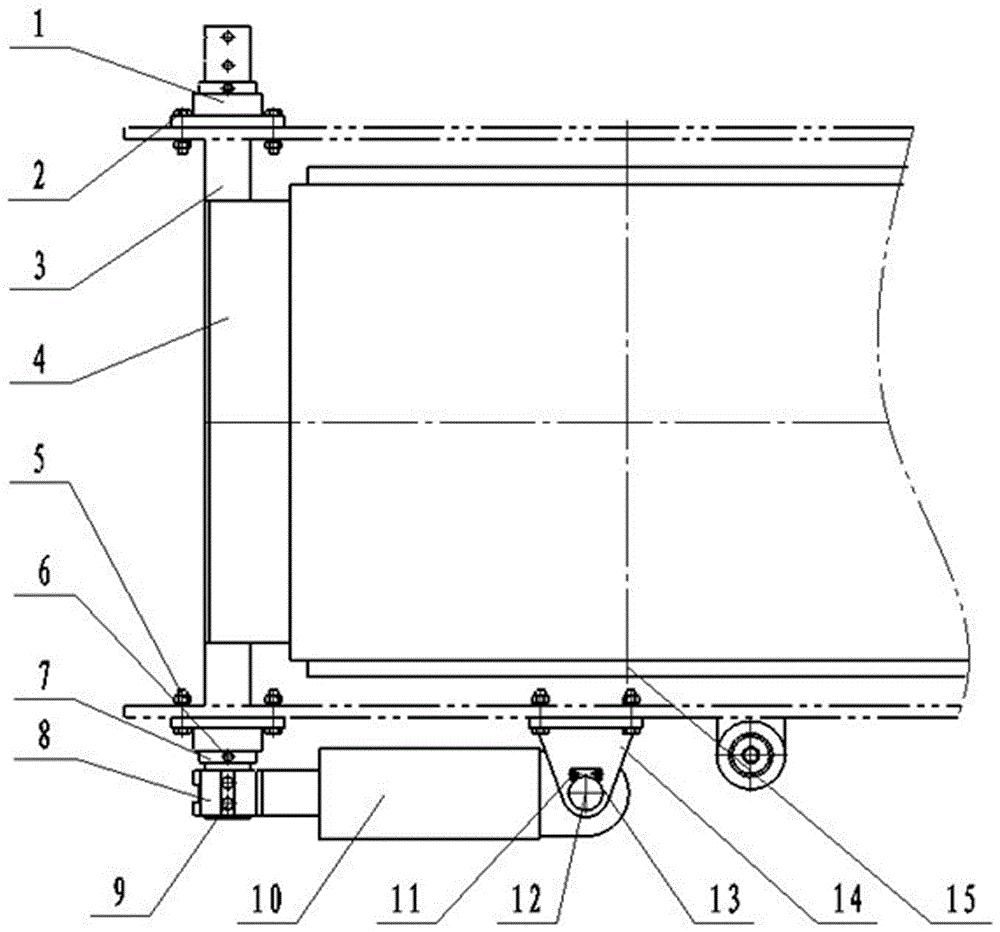

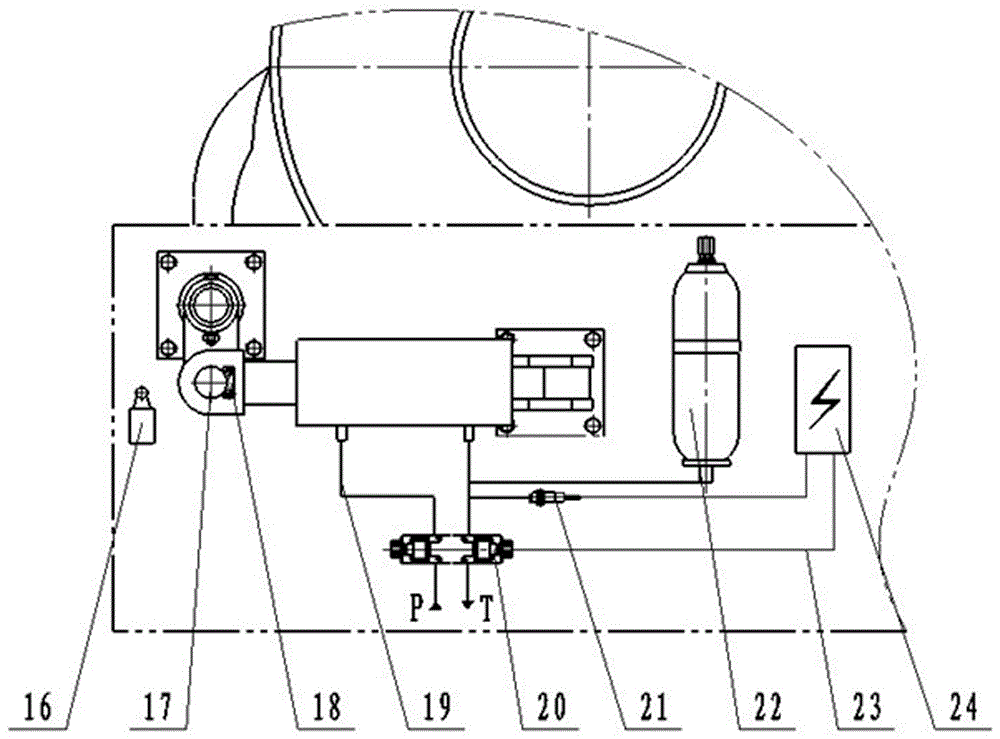

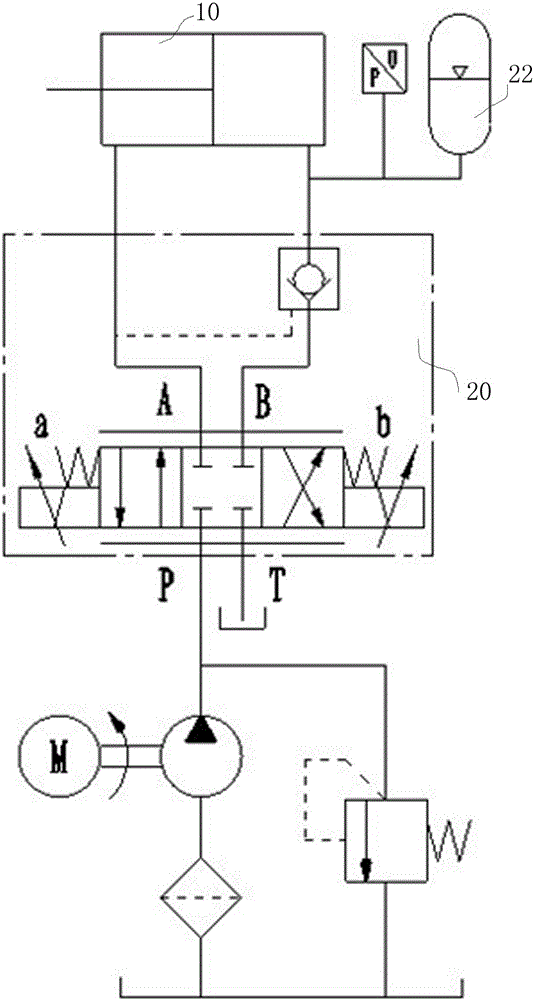

[0042] The conveyor cleaning system of the present invention includes a cleaner assembly, a rotating assembly, a hydraulic system, and an electrical control system. The cleaner assembly is composed of a scraper, a scraper base, a fixing seat and a fixing bolt; , retaining ring and bolts; the hydraulic system is composed of hydraulic cylinders, accumulators, solenoid valves and hoses; the electrical system is composed of controllers, pressure sensors, encoders and travel switches. The cleaner assembly is fixed on the frame; the rotating assembly is respectively connected with the cleaner assembly and the piston rod of the hydraulic cylinder; the oil cylinder, electromagnetic valve group and accumulator are respectively fixed on the frame, and the piston rod chamber of the hydraulic cylinder passes through the rubber tube and the solenoid valve group The outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com