Patents

Literature

32results about How to "Constant pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

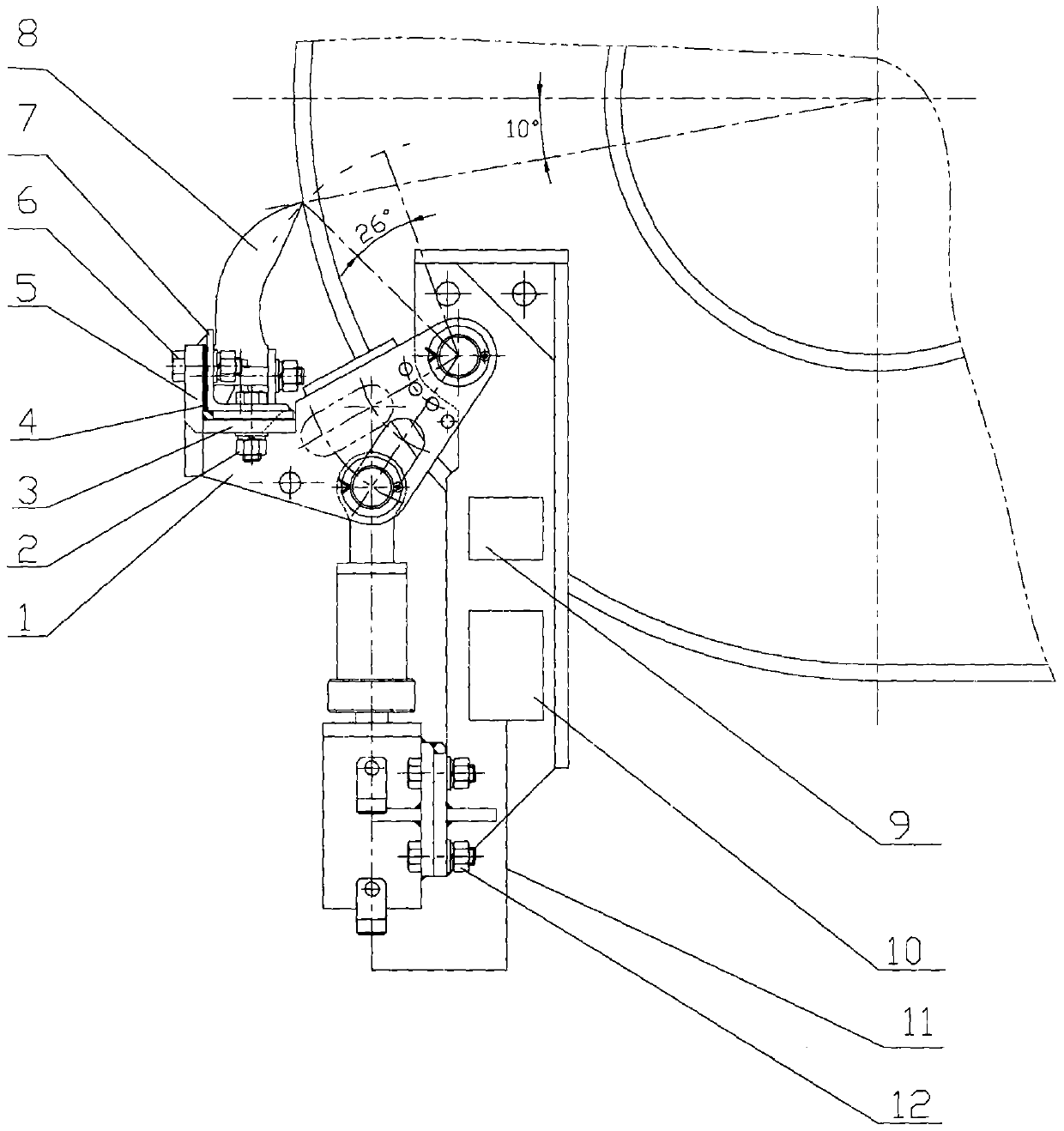

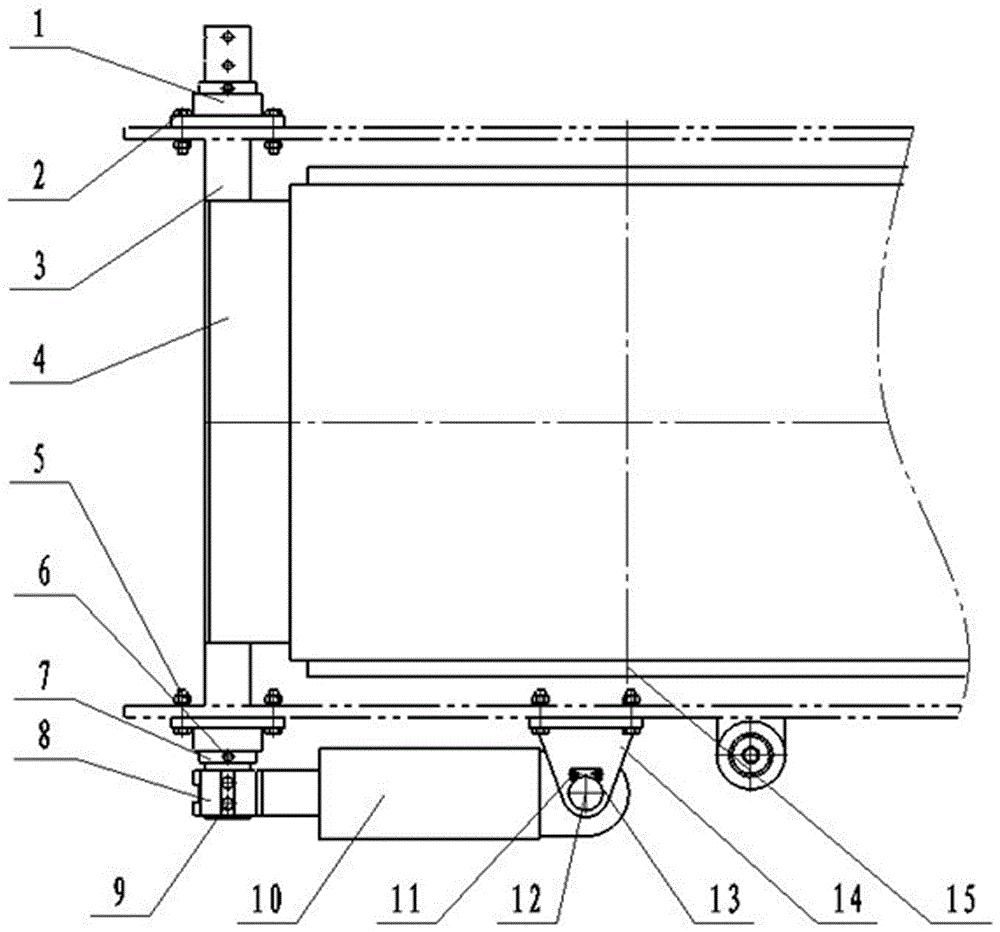

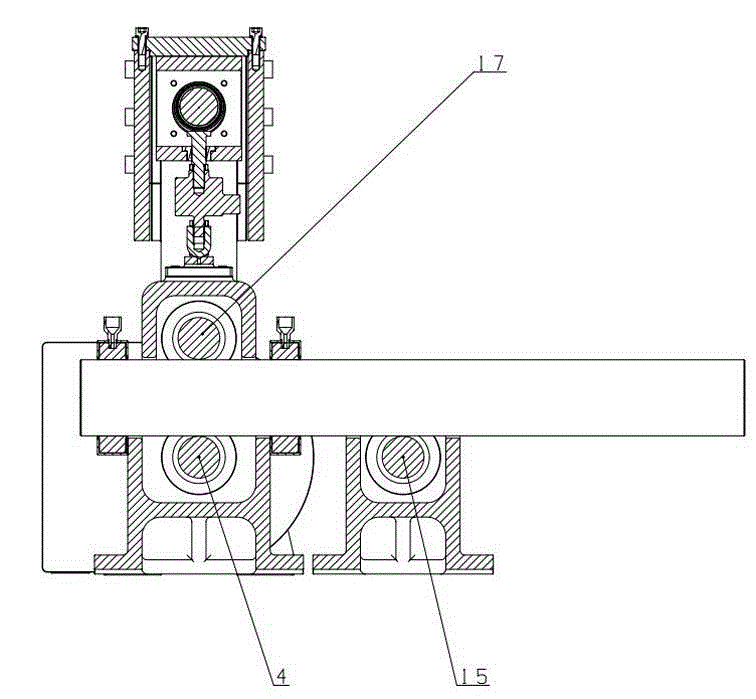

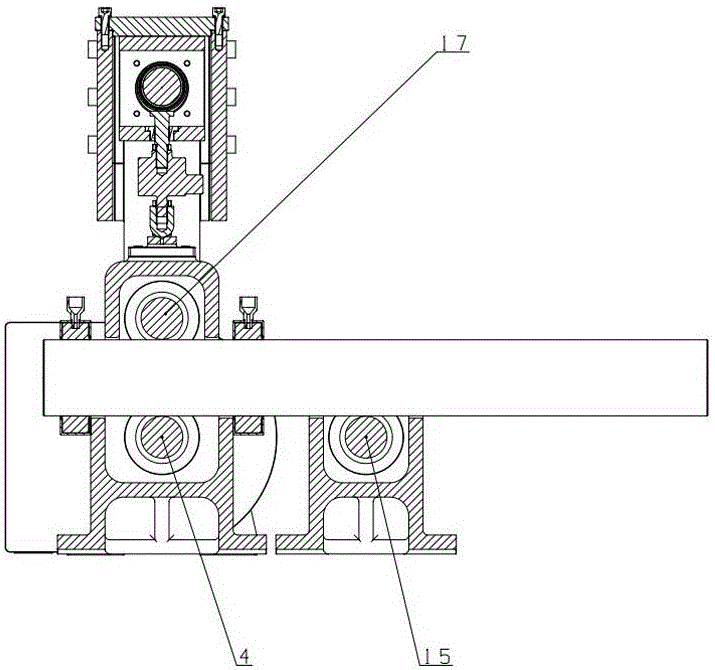

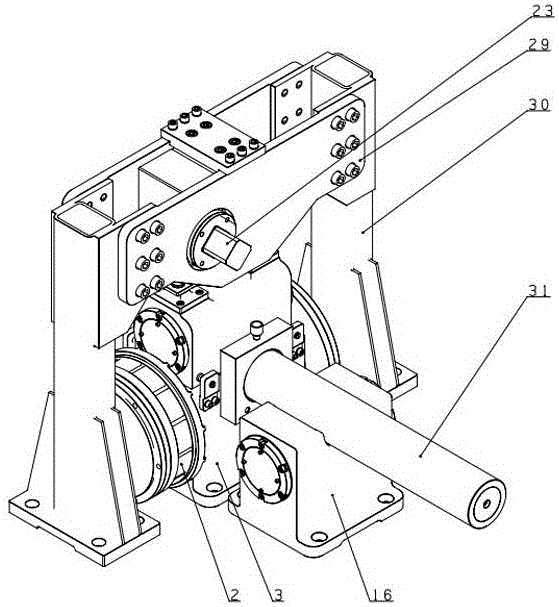

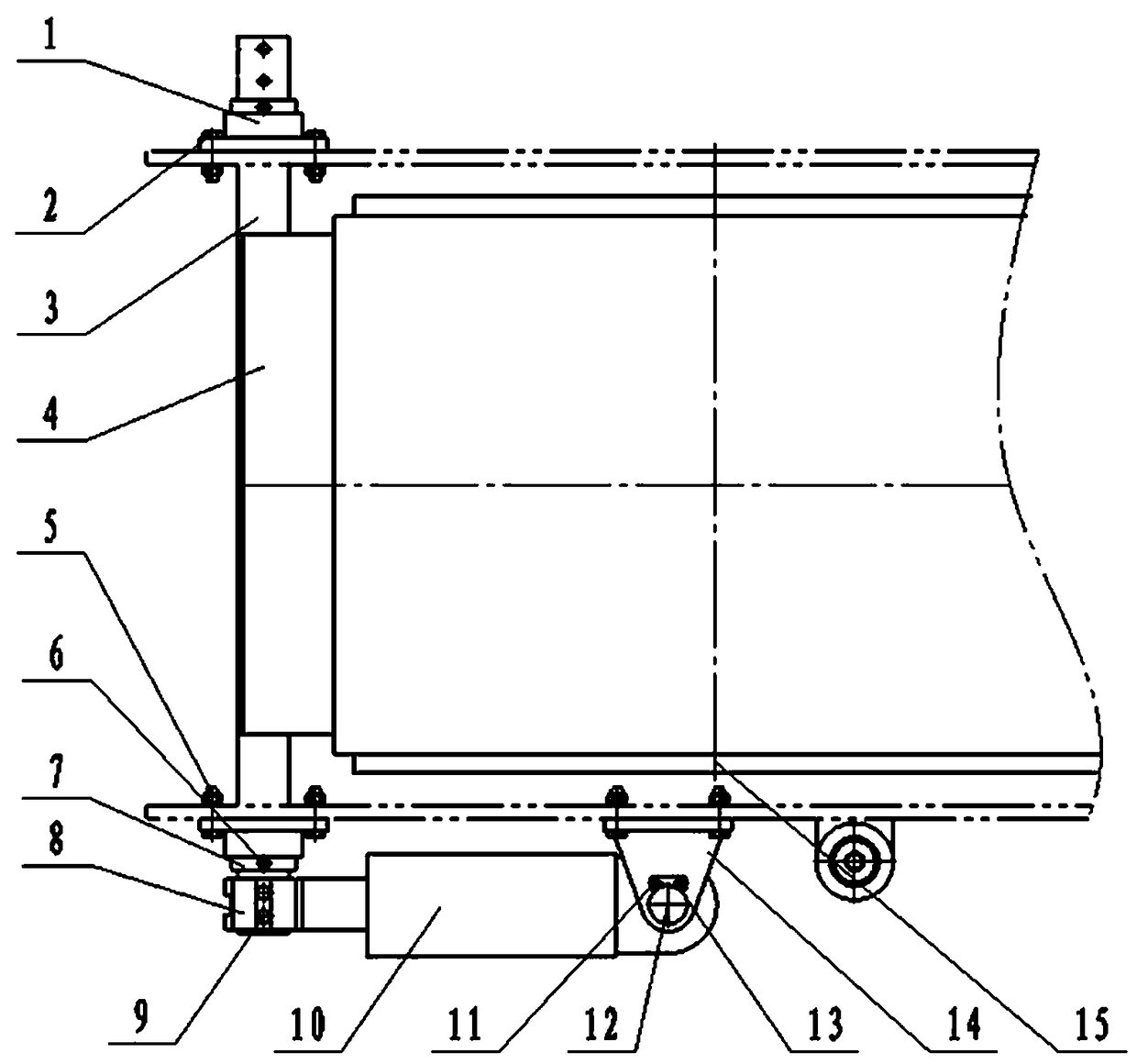

Hydraulic constant-torque heavy-section sweeper for belt conveyor

InactiveCN103787054AGuaranteed automatic compensationConstant pressing forceCleaningControl devices for conveyorsHydraulic cylinderEngineering

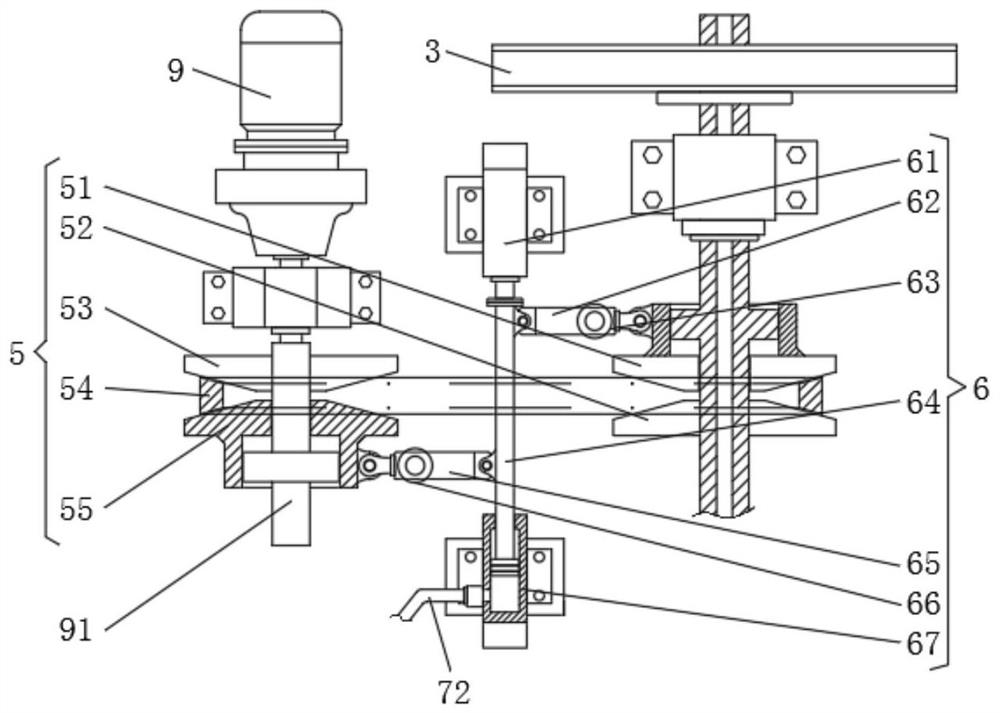

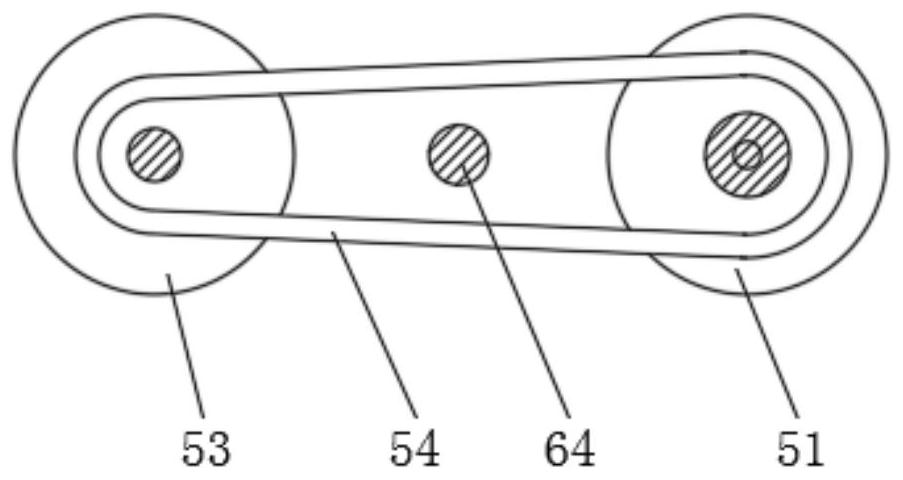

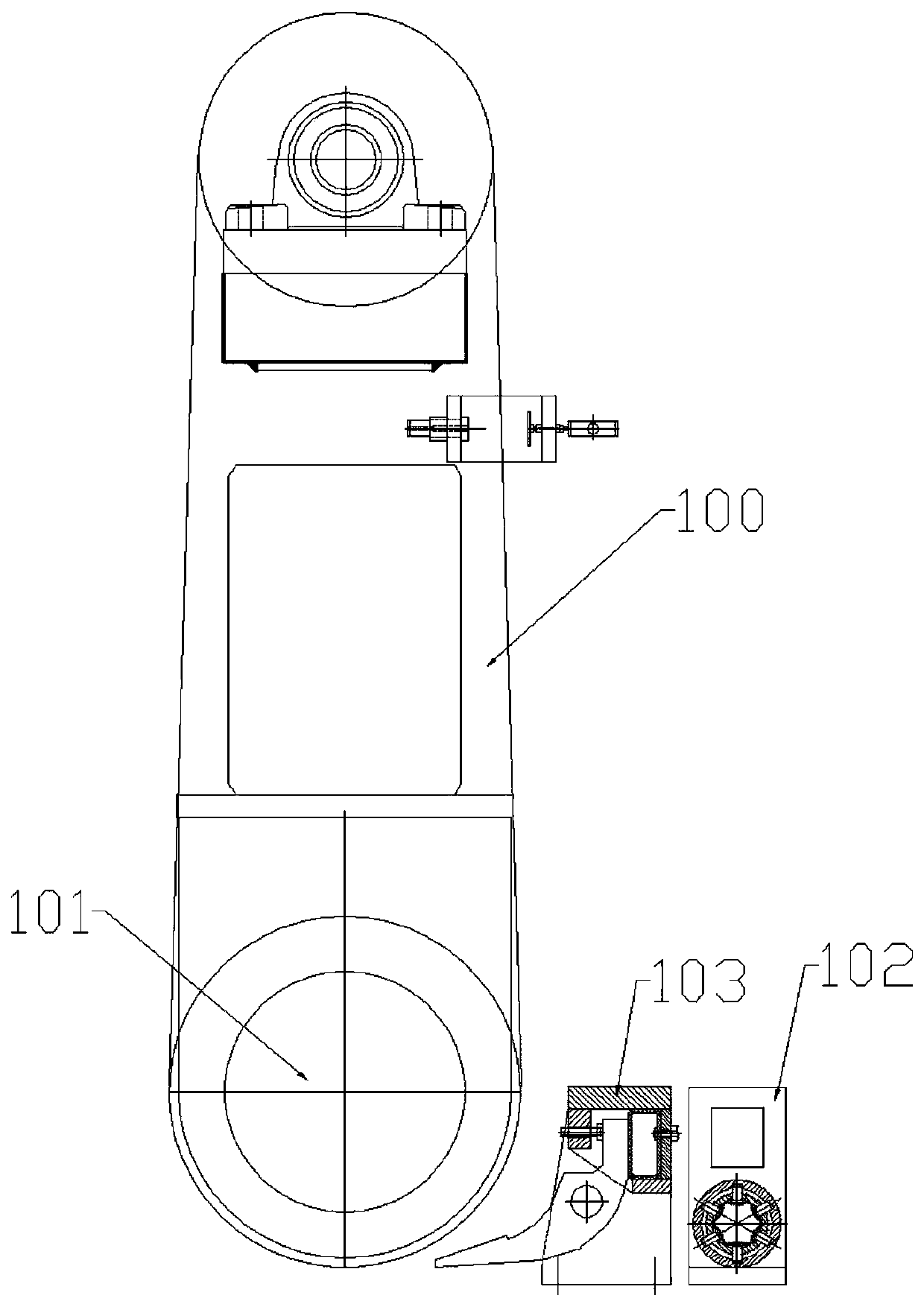

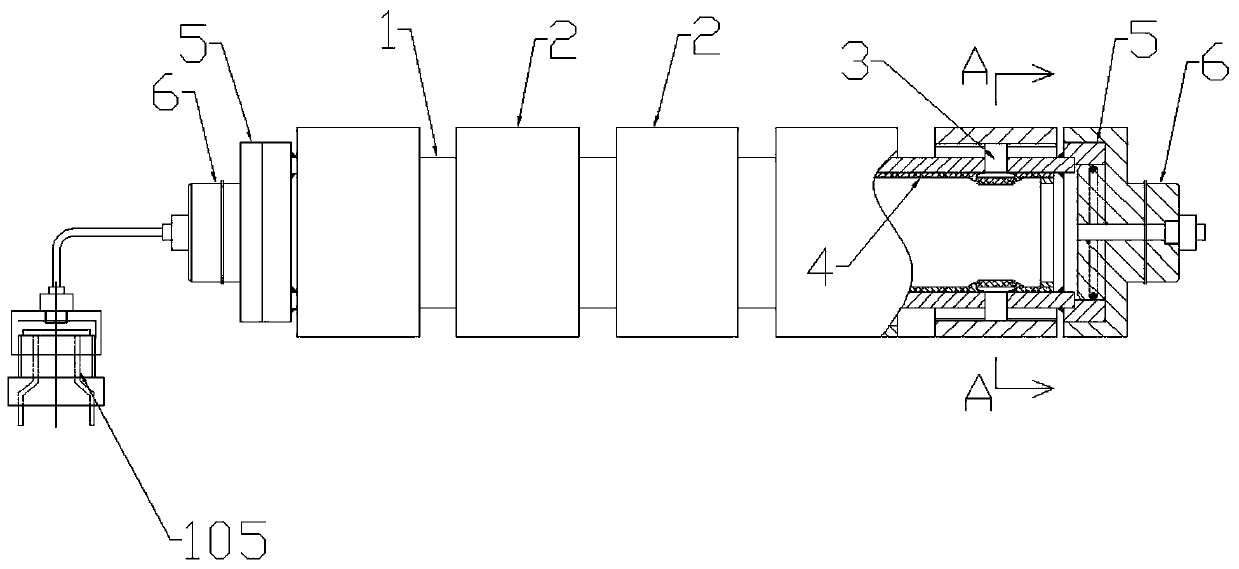

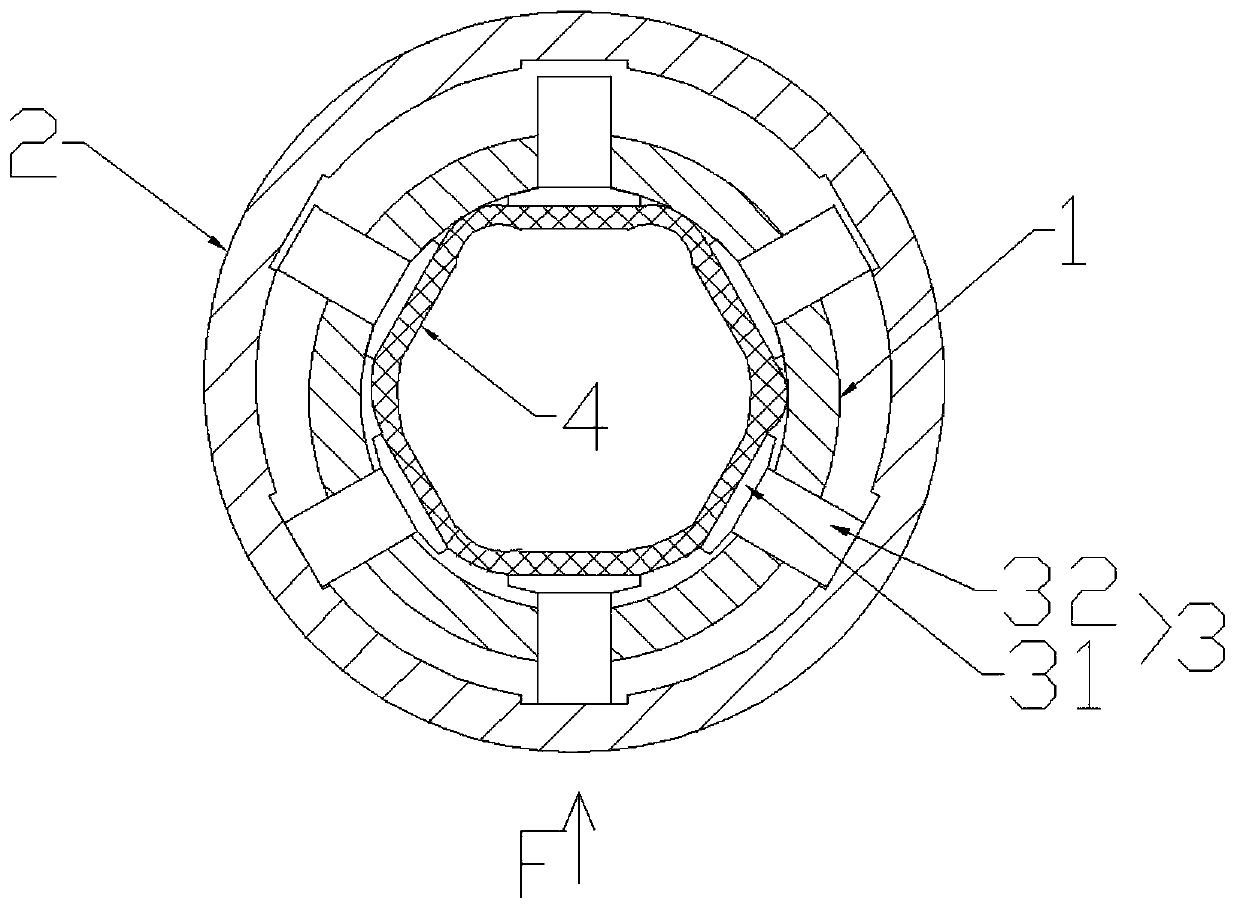

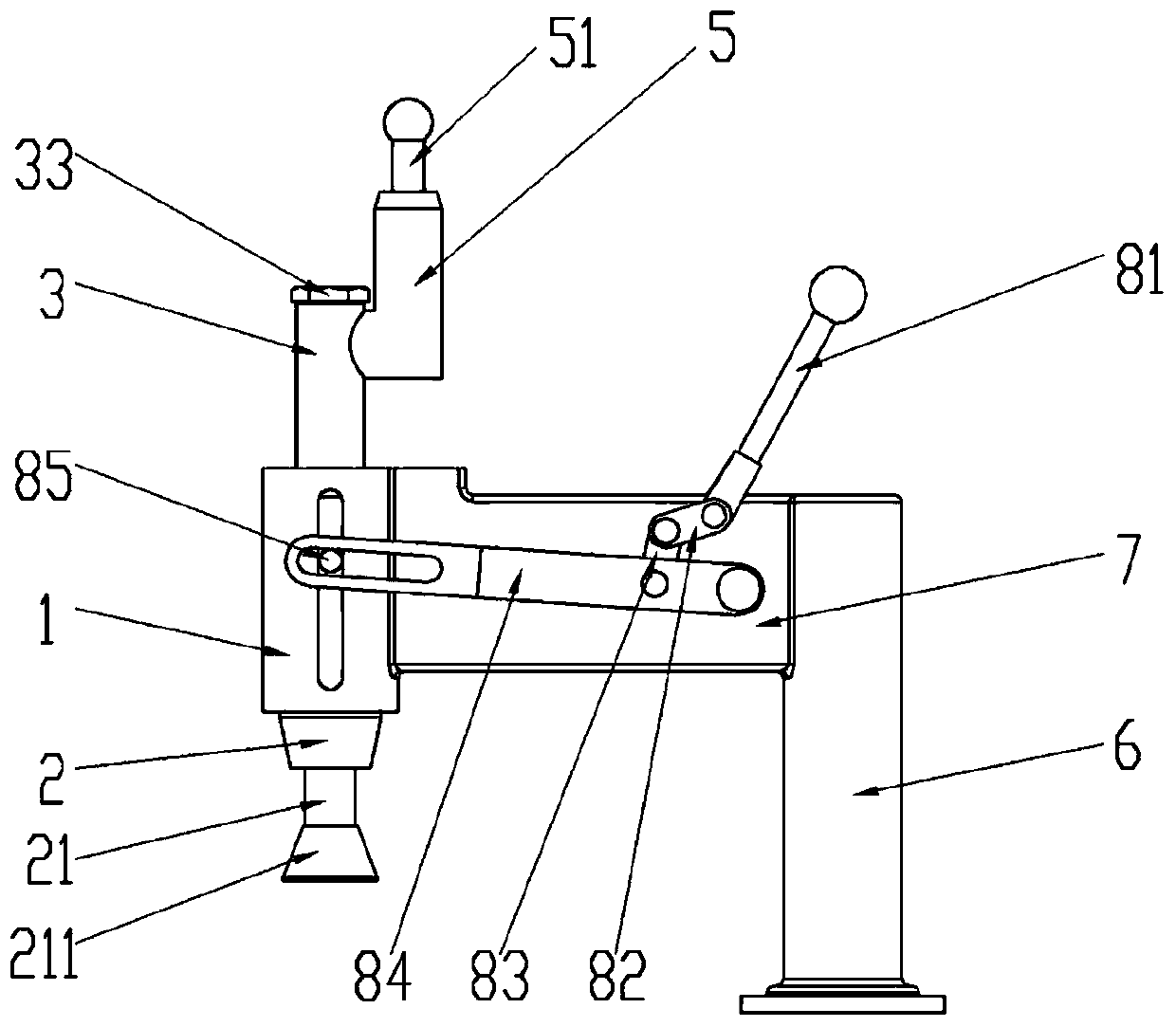

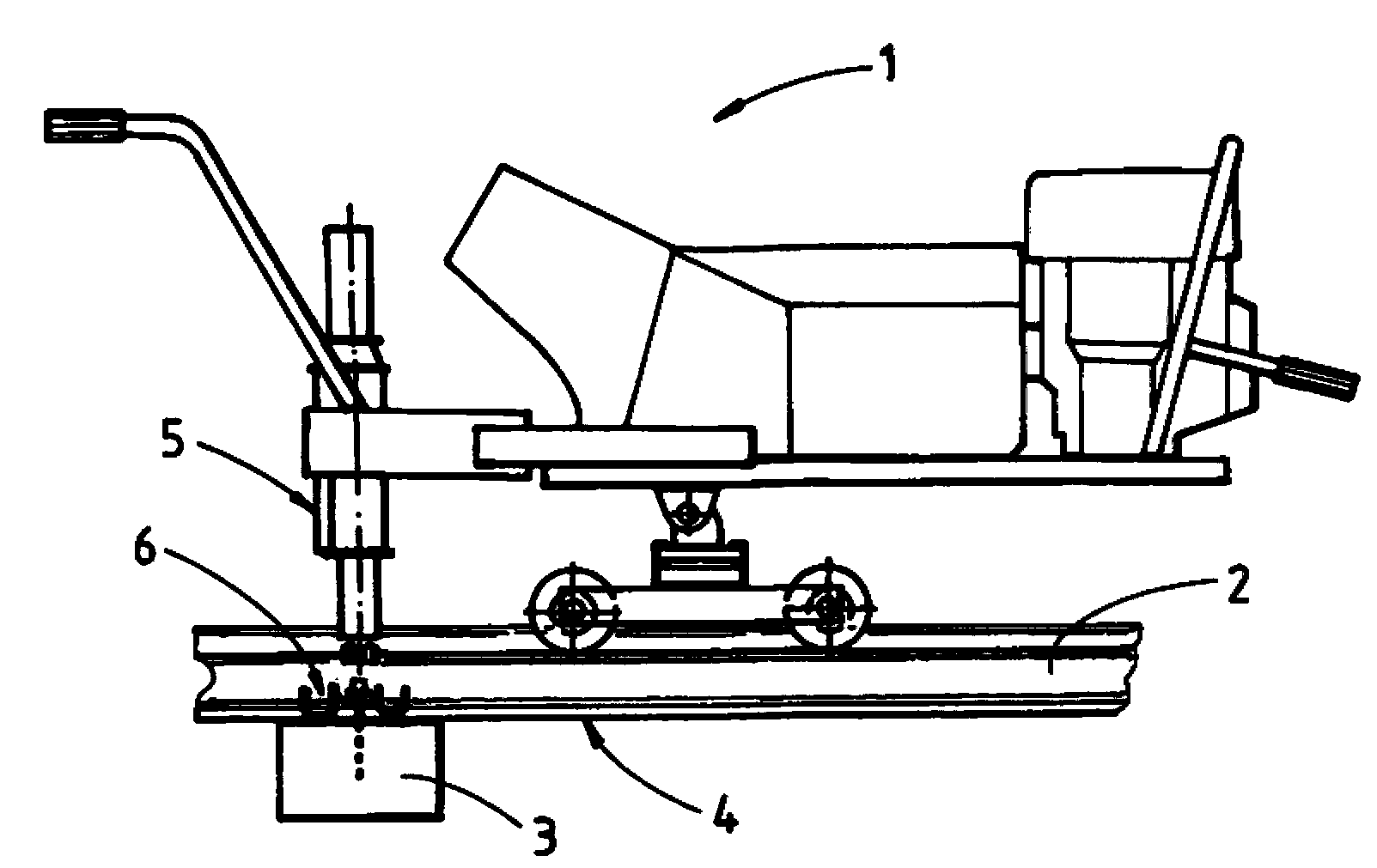

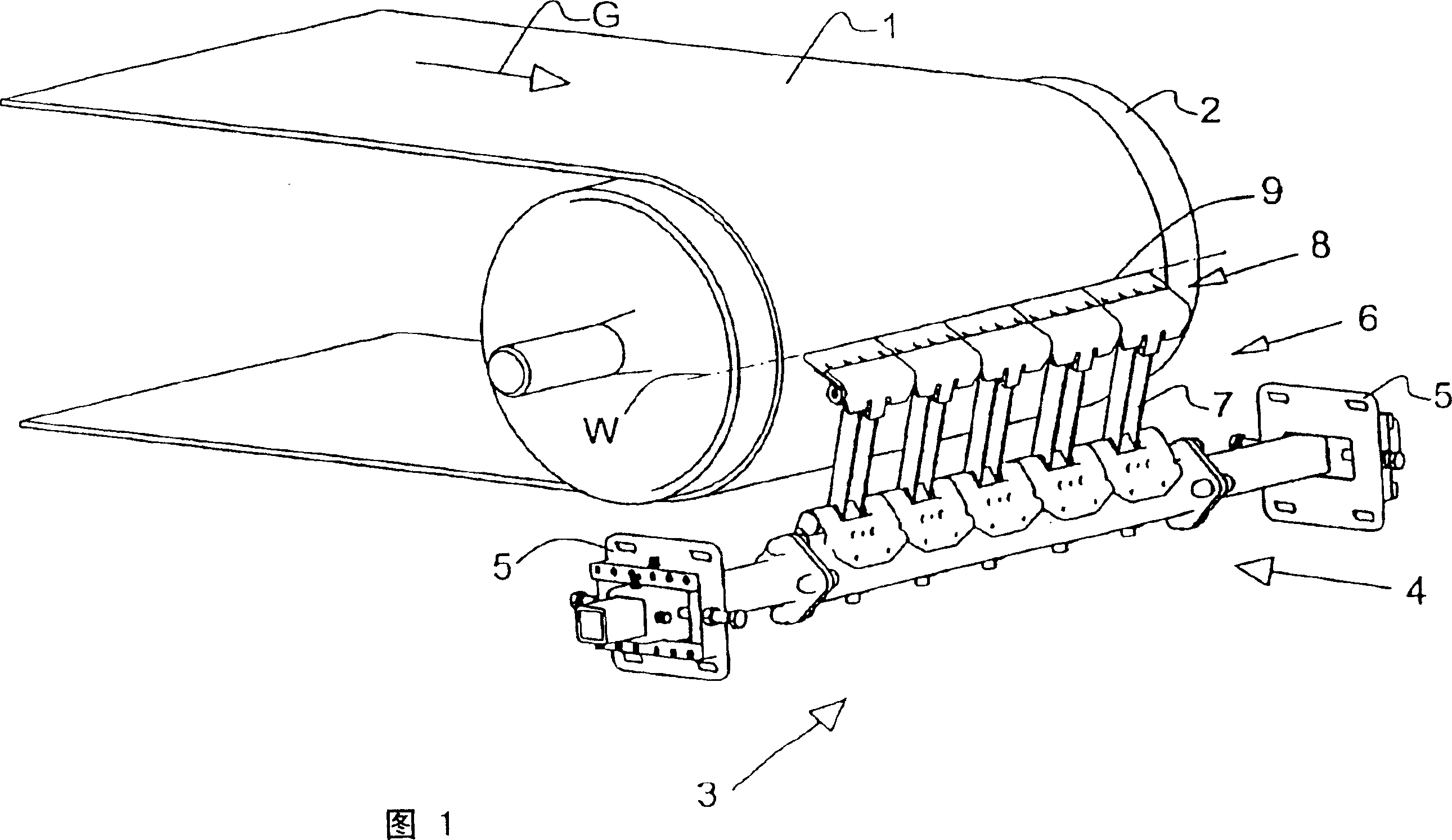

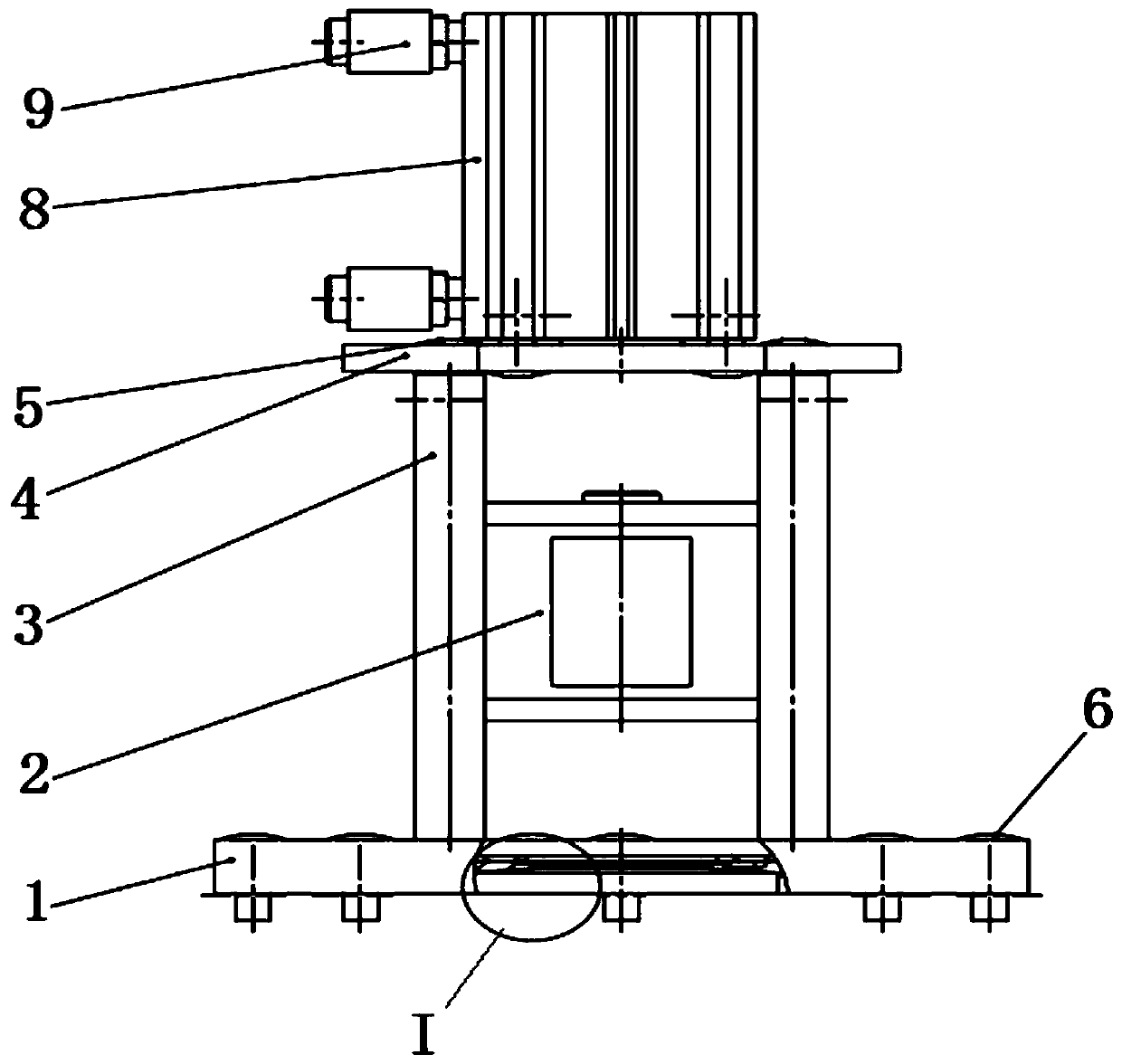

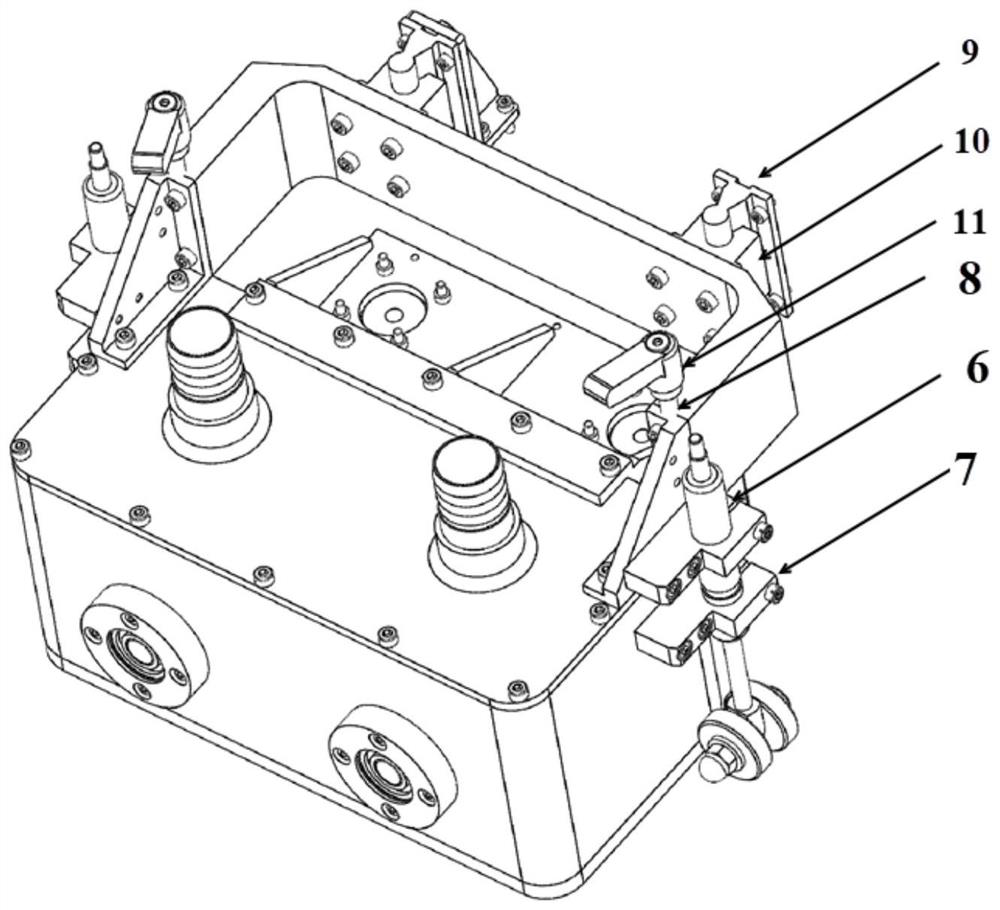

A hydraulic constant-torque heavy-section sweeper for a belt conveyor mainly comprises a sweeping block subassembly, a rotating mechanism, a hydraulic system and the like, wherein the sweeping block subassembly comprises a sweeping block and a slotted-angle shelving; the rotating mechanism comprises a rotating arm, a supporting plate and a reinforcing plate; a guiding device comprises a locking nut, a guiding head, a connecting rod, a disc spring and the like; the hydraulic system comprises a hydraulic cylinder, a hydraulic rubber tube and an energy accumulator; the sweeping block subassembly is connected with the rotating mechanism; the rotating mechanism is connected with the connecting rod through a hinge pin; and the connecting rod is connected with a piston rod in the hydraulic cylinder. When hydraulic force pushes the rotating mechanism to rotate through the connecting rod, the sweeping block subassembly is driven to rotate and compresses a rubber belt, the torque of a rotating arm can be automatically adjusted along with abrasion of the sweeping block, and keeps constant, and a contacting section of the sweeping block and the rubber belt is not changed. In addition, the sweeper has the advantages of simple structure, convenience in installation, high sweeping effect, long service life and the like.

Owner:SHANXI DATONG UNIV

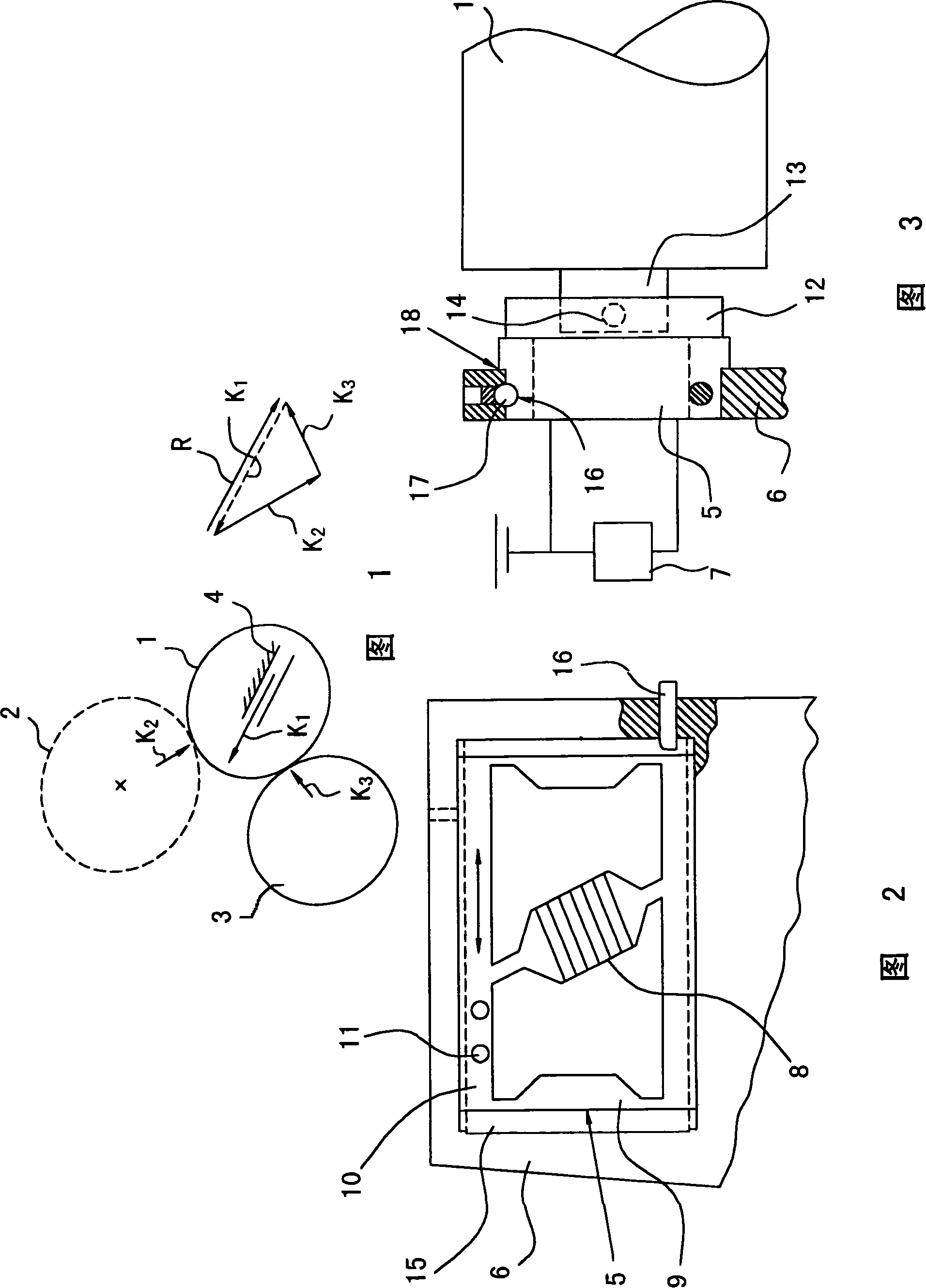

Roller pressing device

InactiveCN101172412AQuality improvementConstant widthRotary lithographic machinesPrinting press partsEngineeringActuator

The invention relates to device for pressing the roller (1)to a paired roller(2,3), capable of implementing constant compression force in the whole operation process by the following method. An actuator (5)for supporting lateral ends of a roller (1) is provided which can generate compression force, and produce the pressing movement of the roller, which runs along the desired compression force. The compression force is kept to a constant value by using a control device (7).

Owner:M A N ROLAND DRUCKMASCHINEN AG

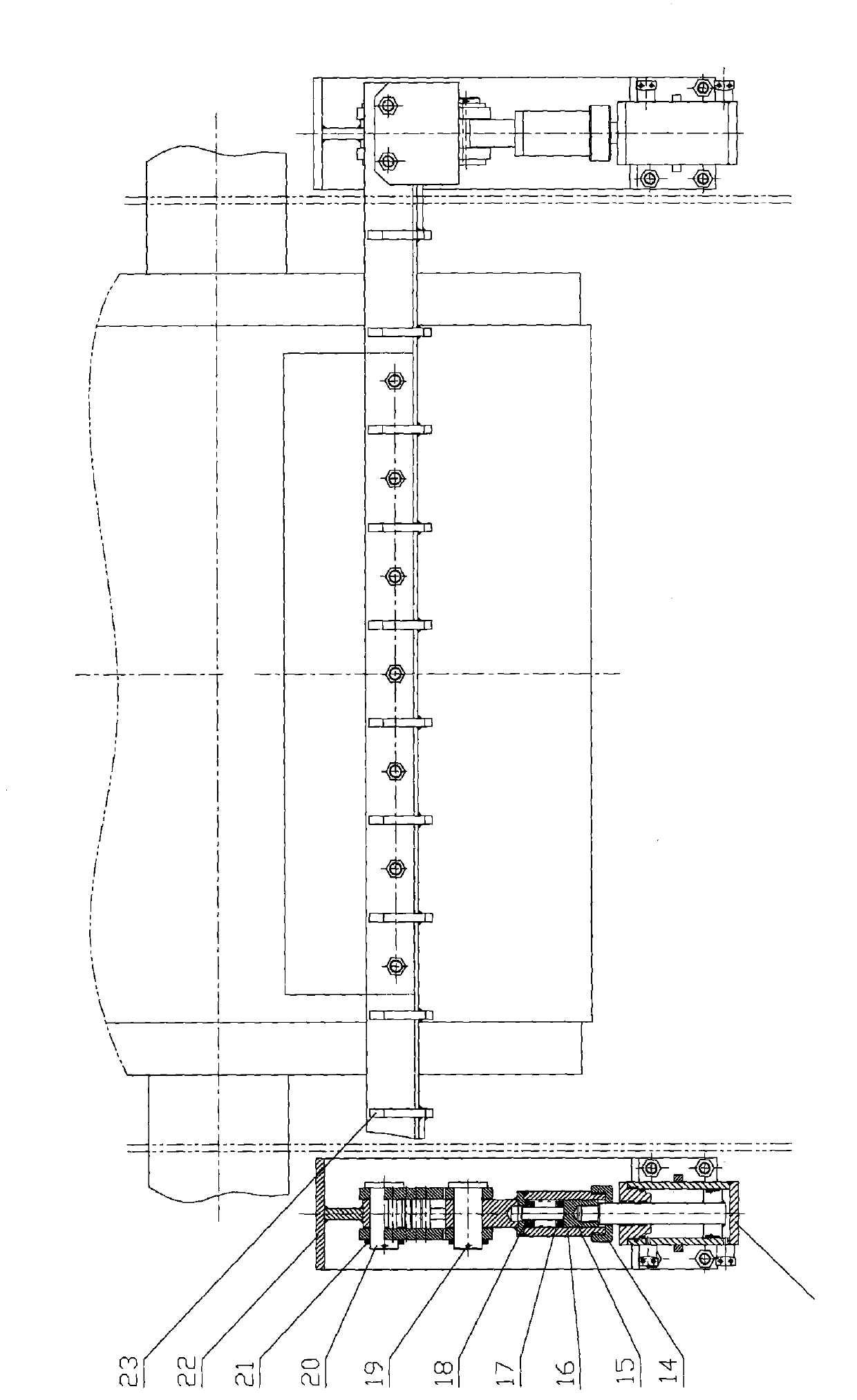

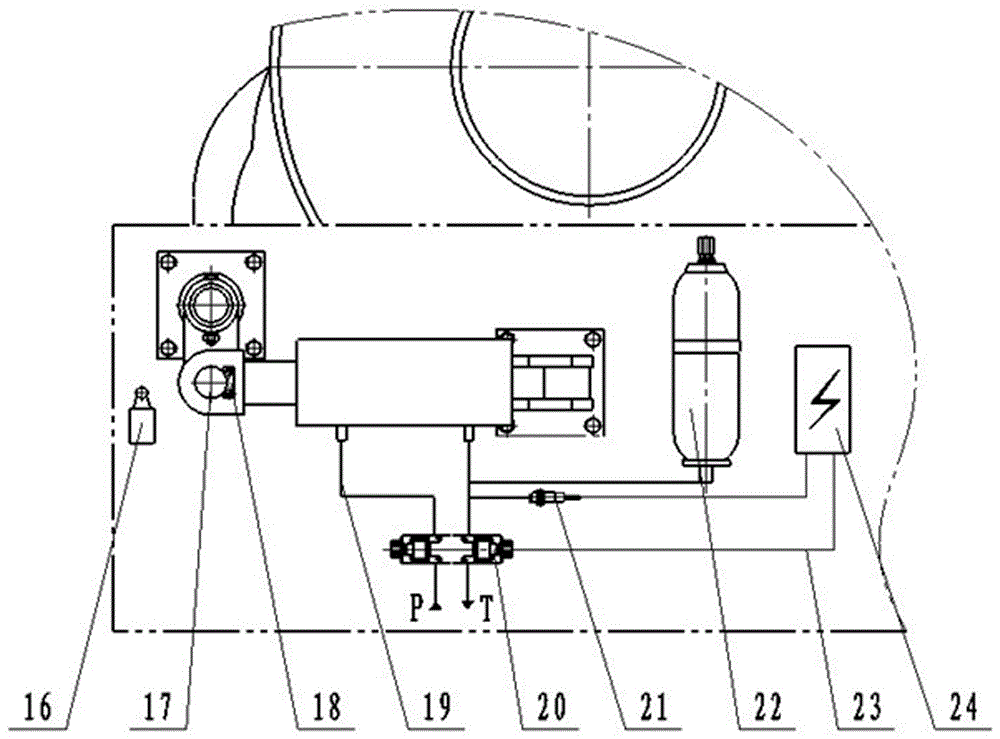

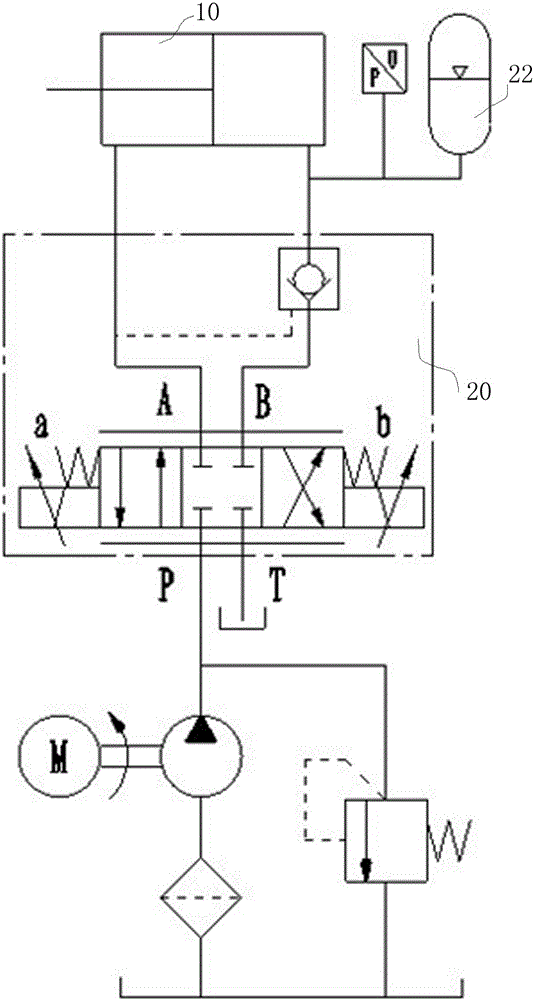

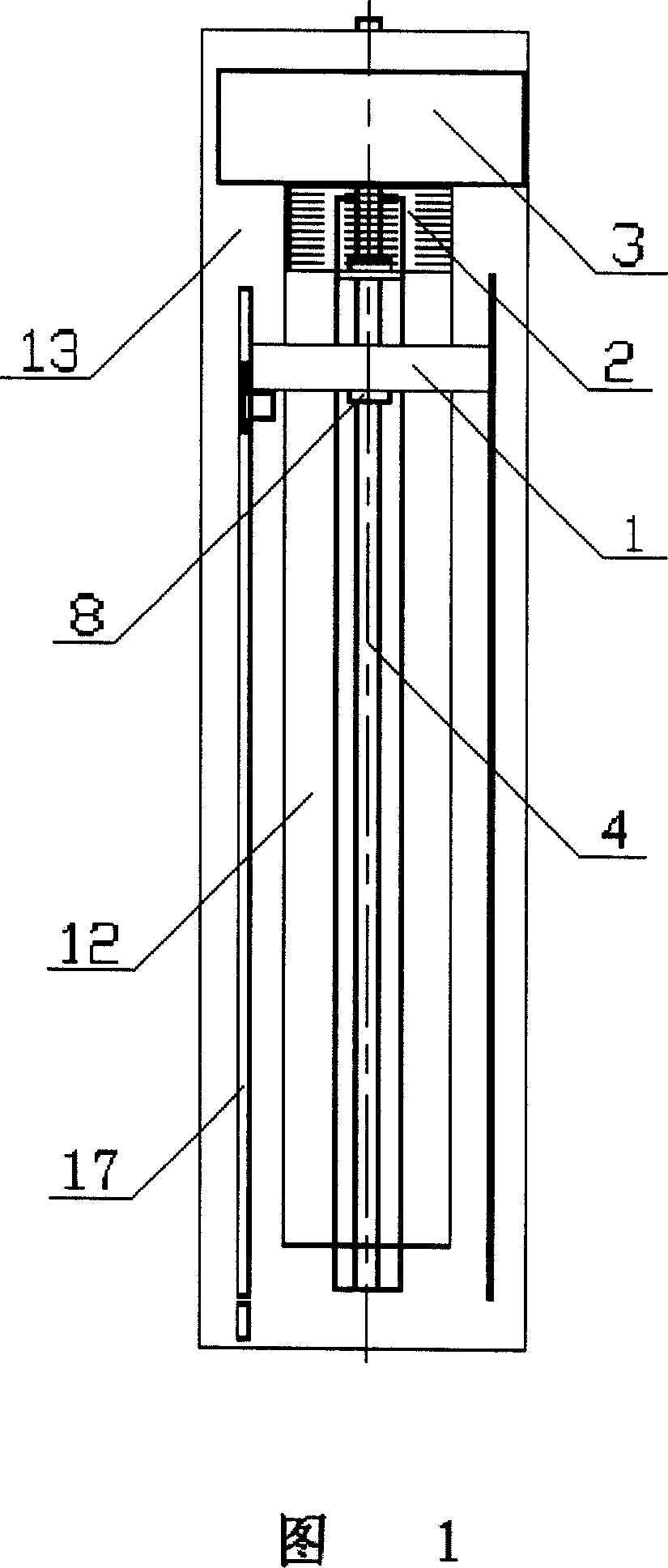

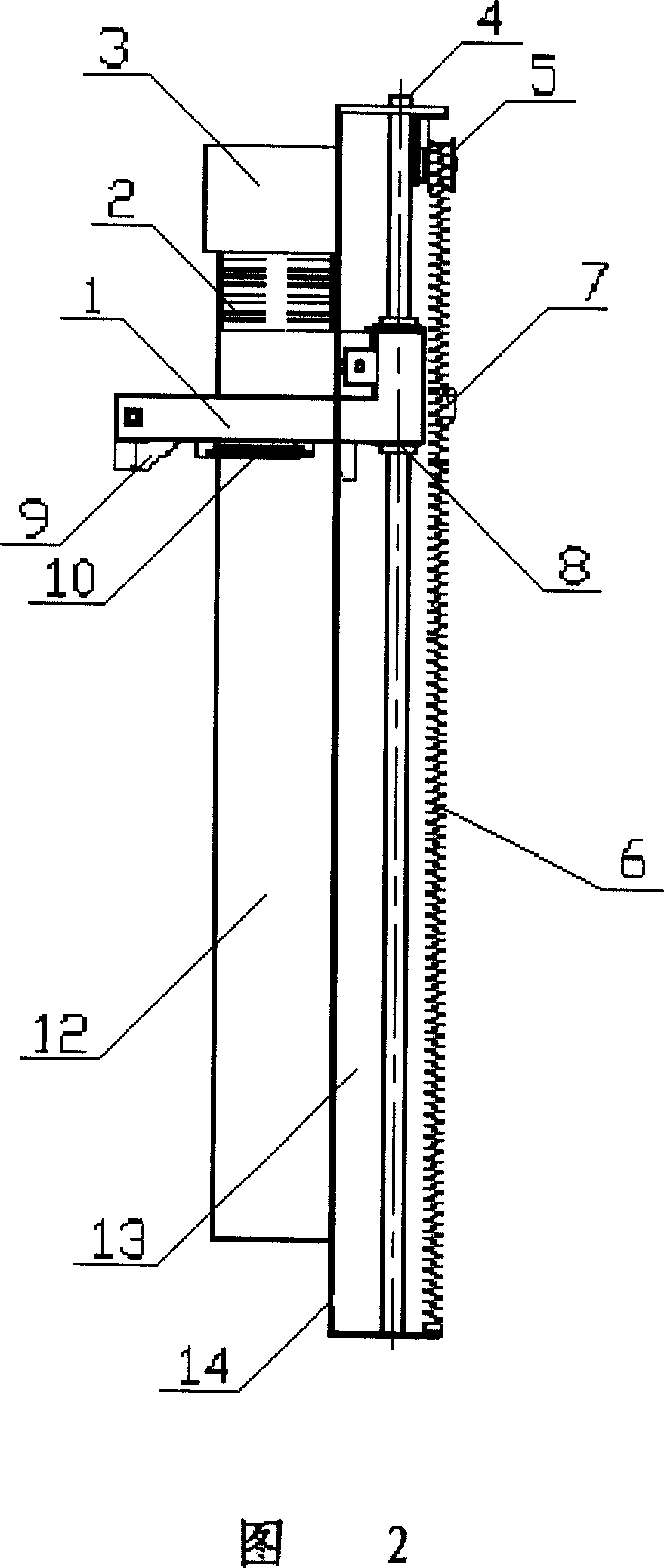

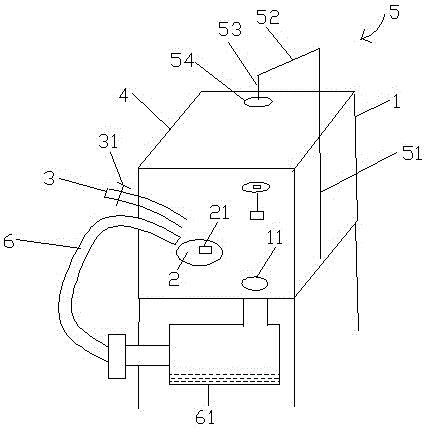

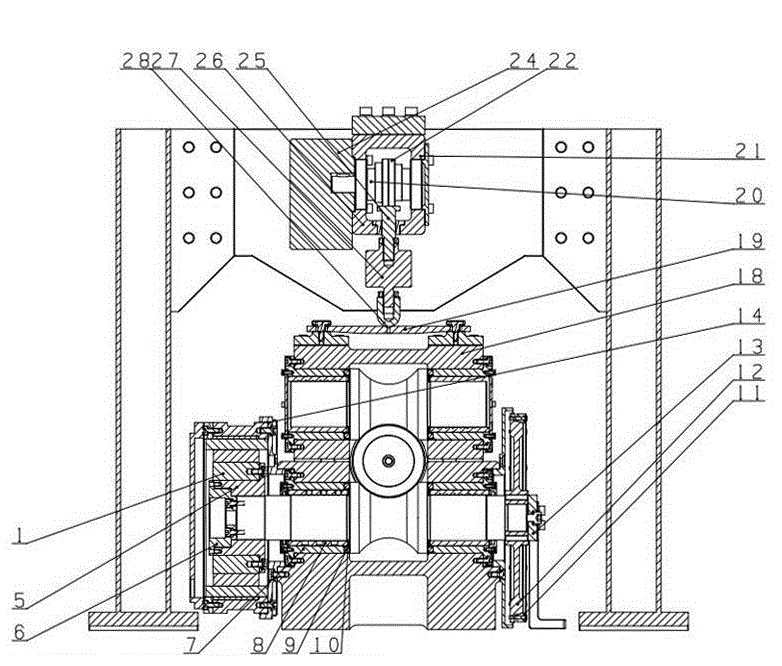

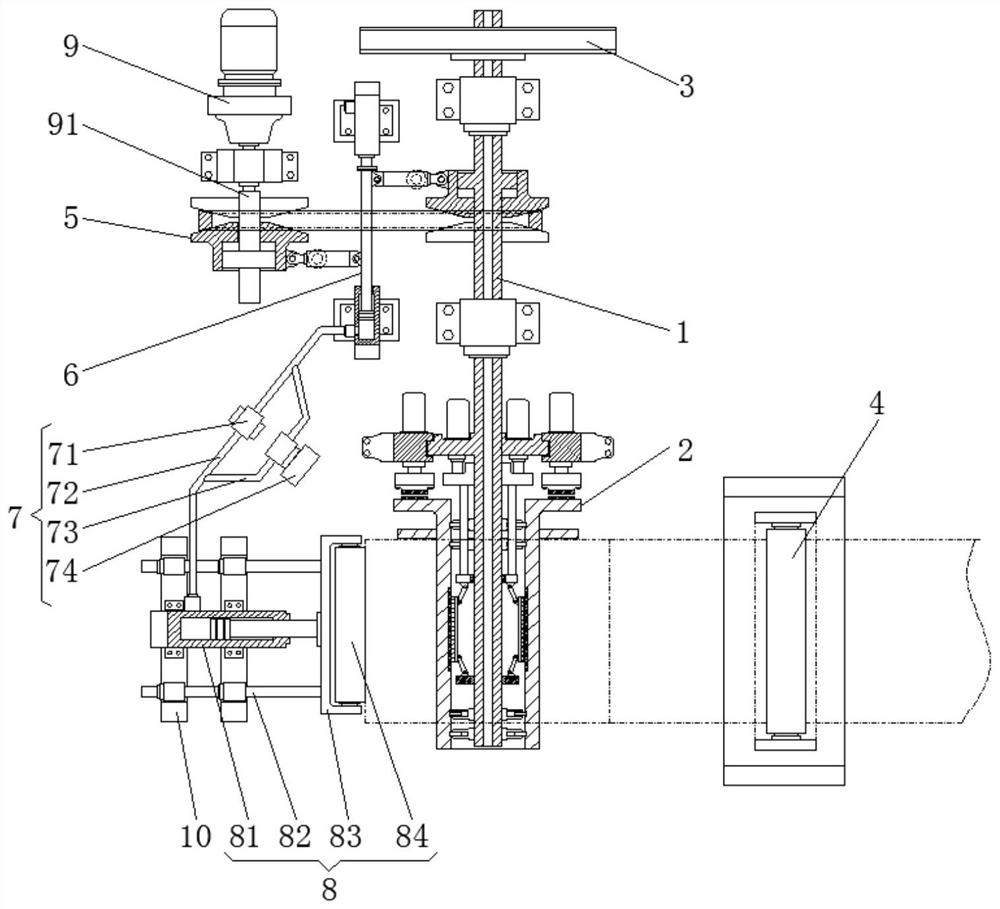

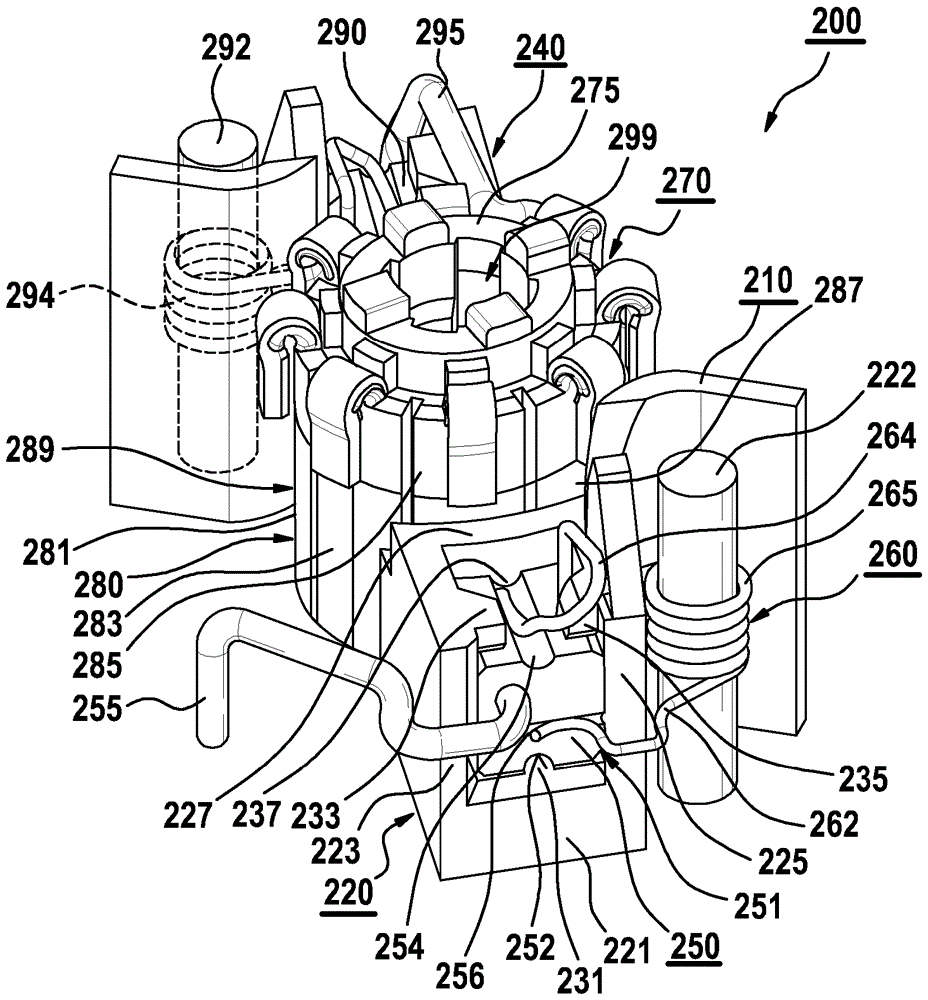

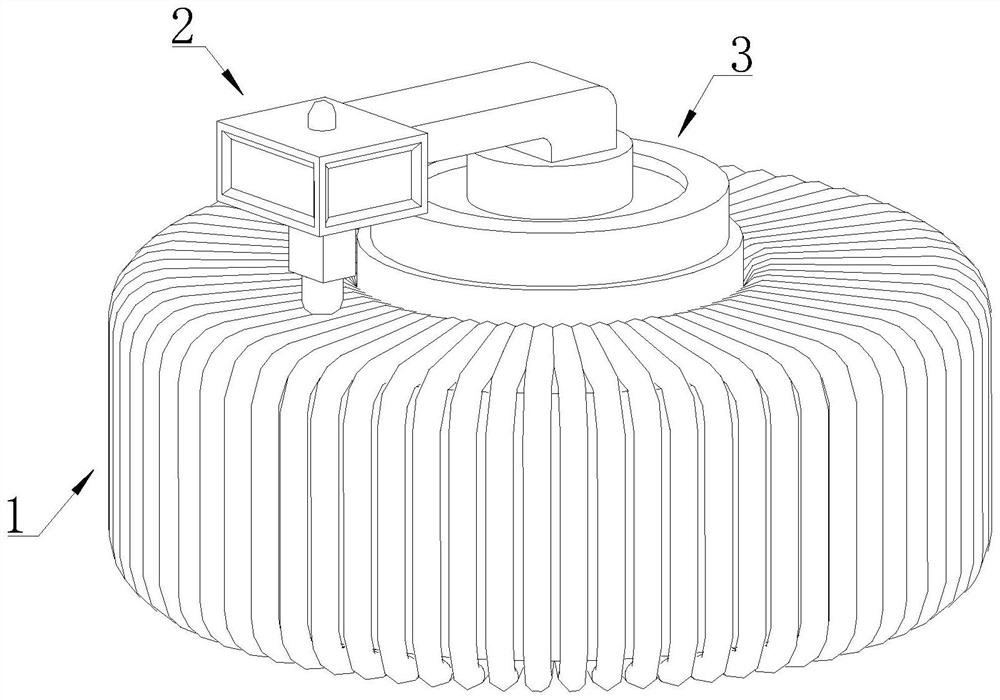

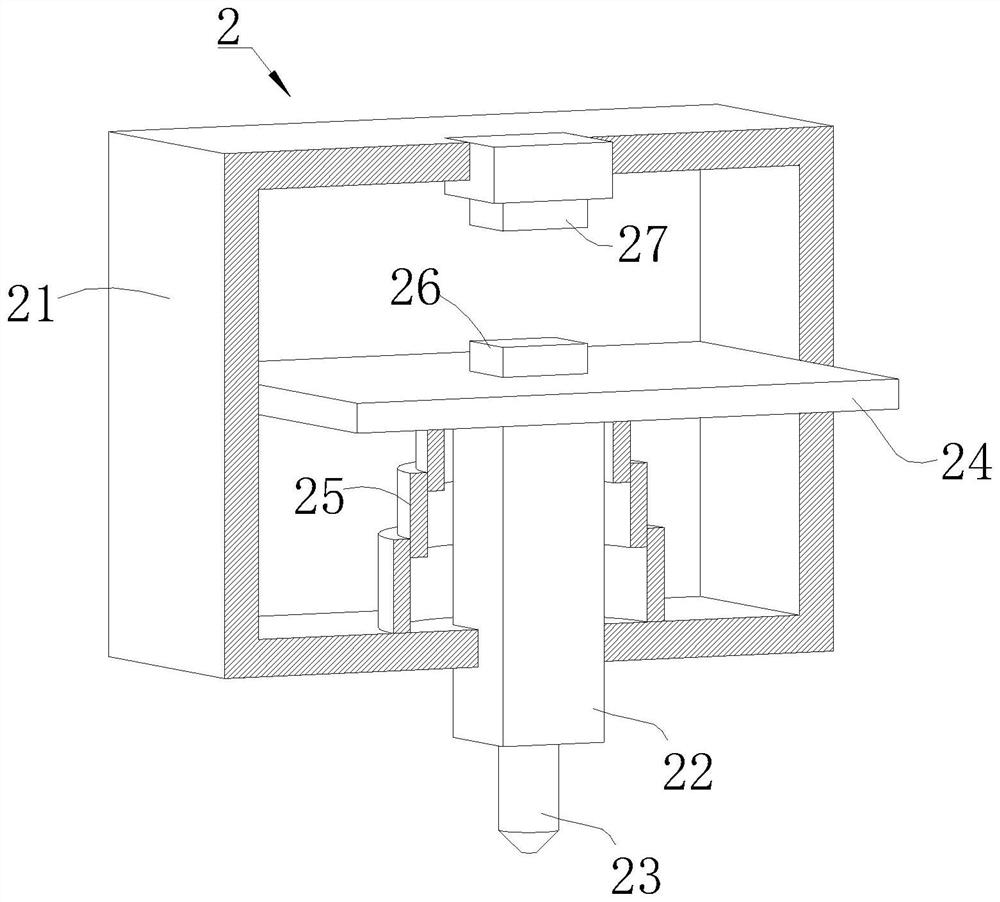

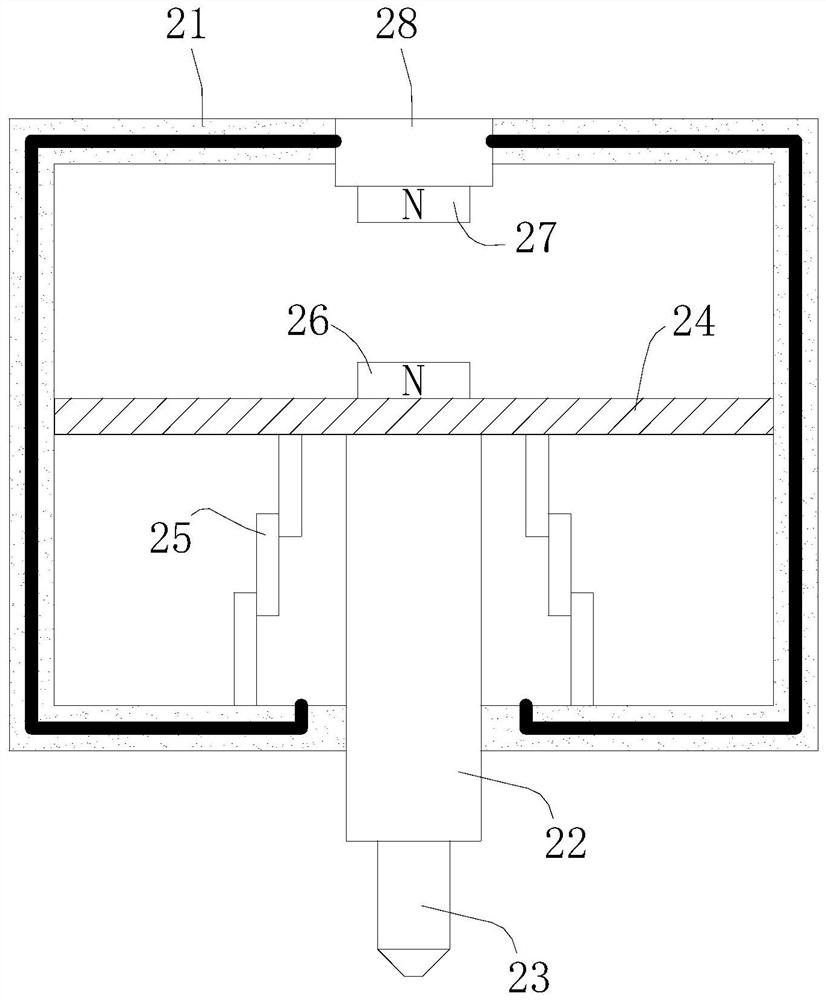

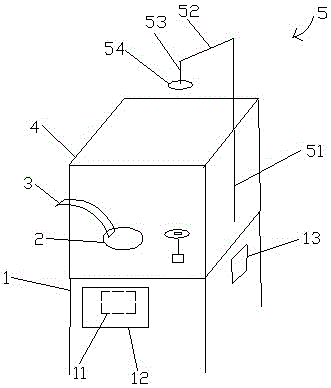

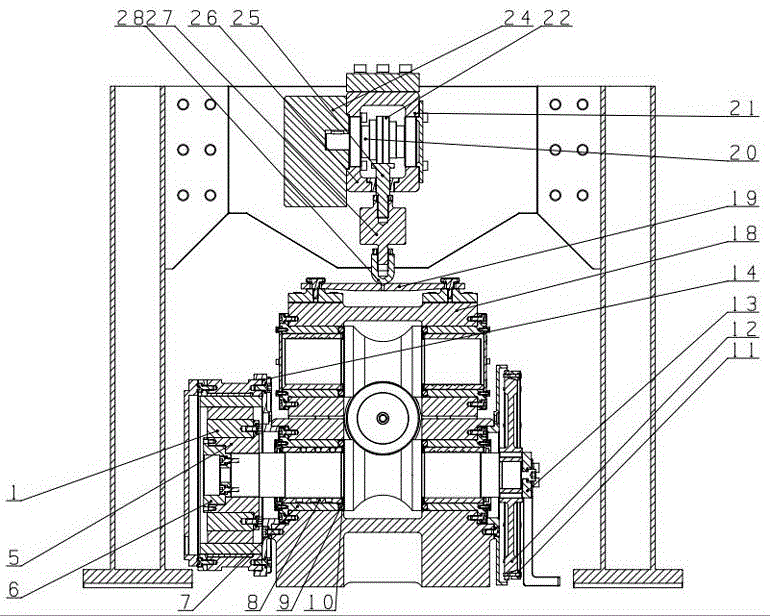

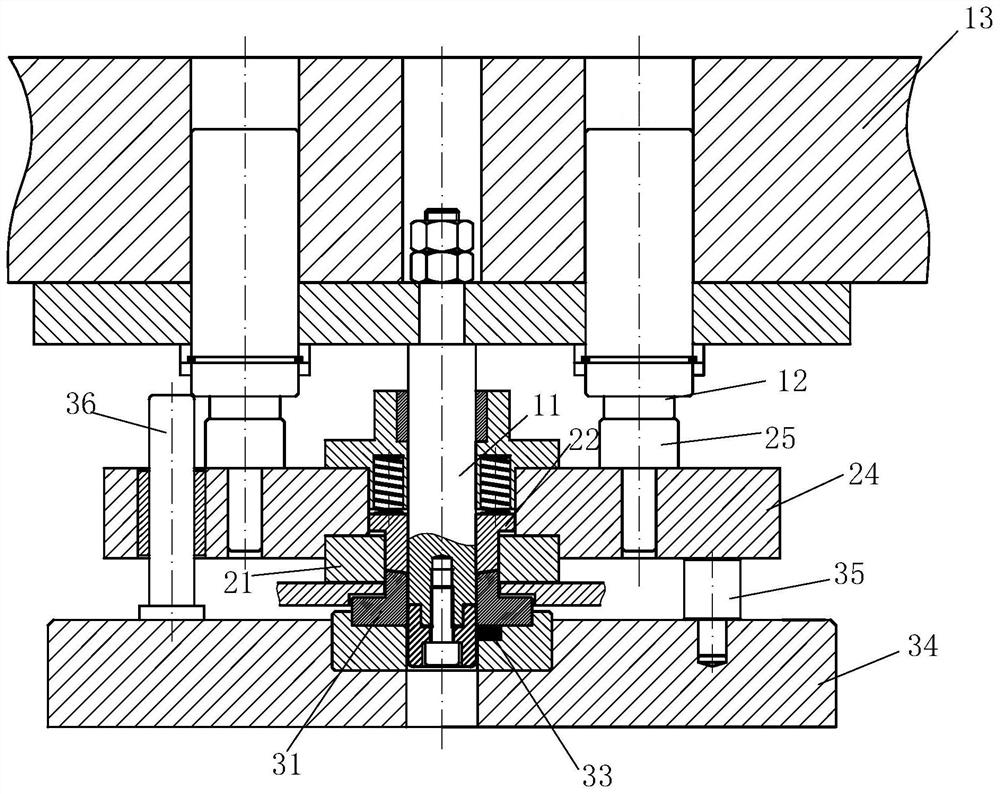

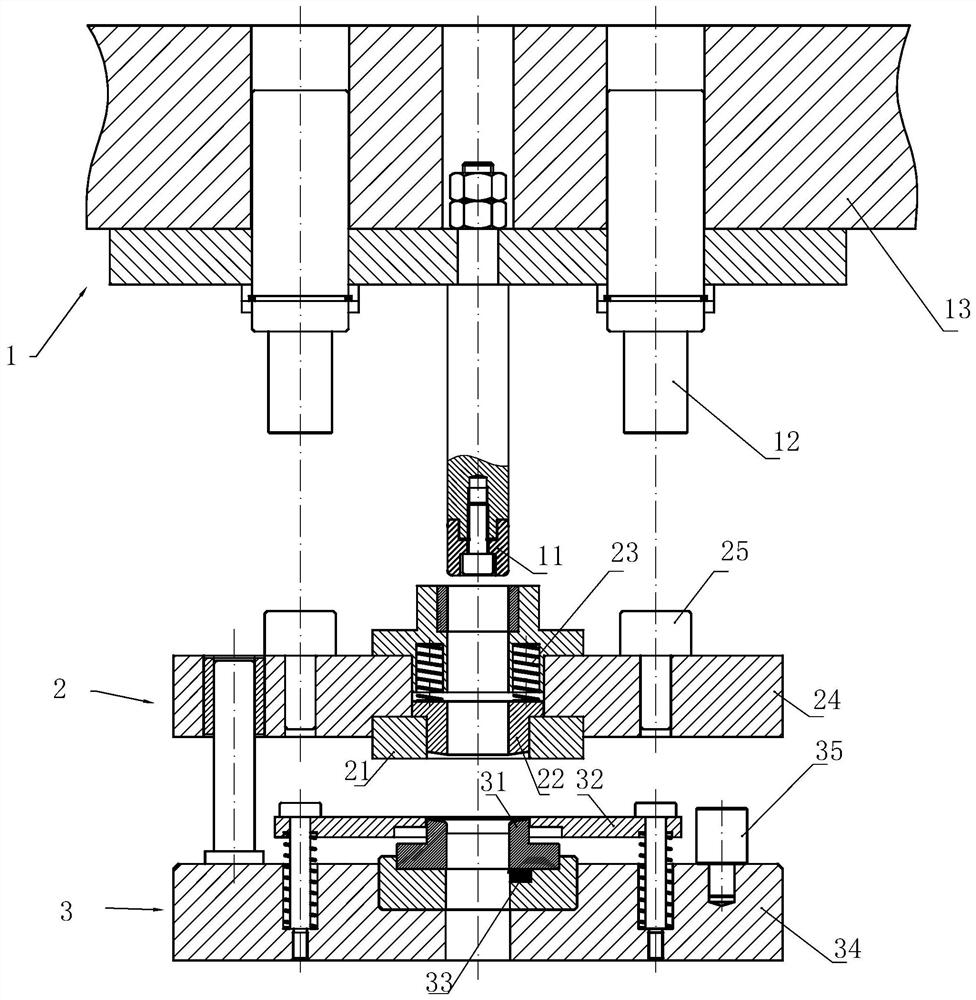

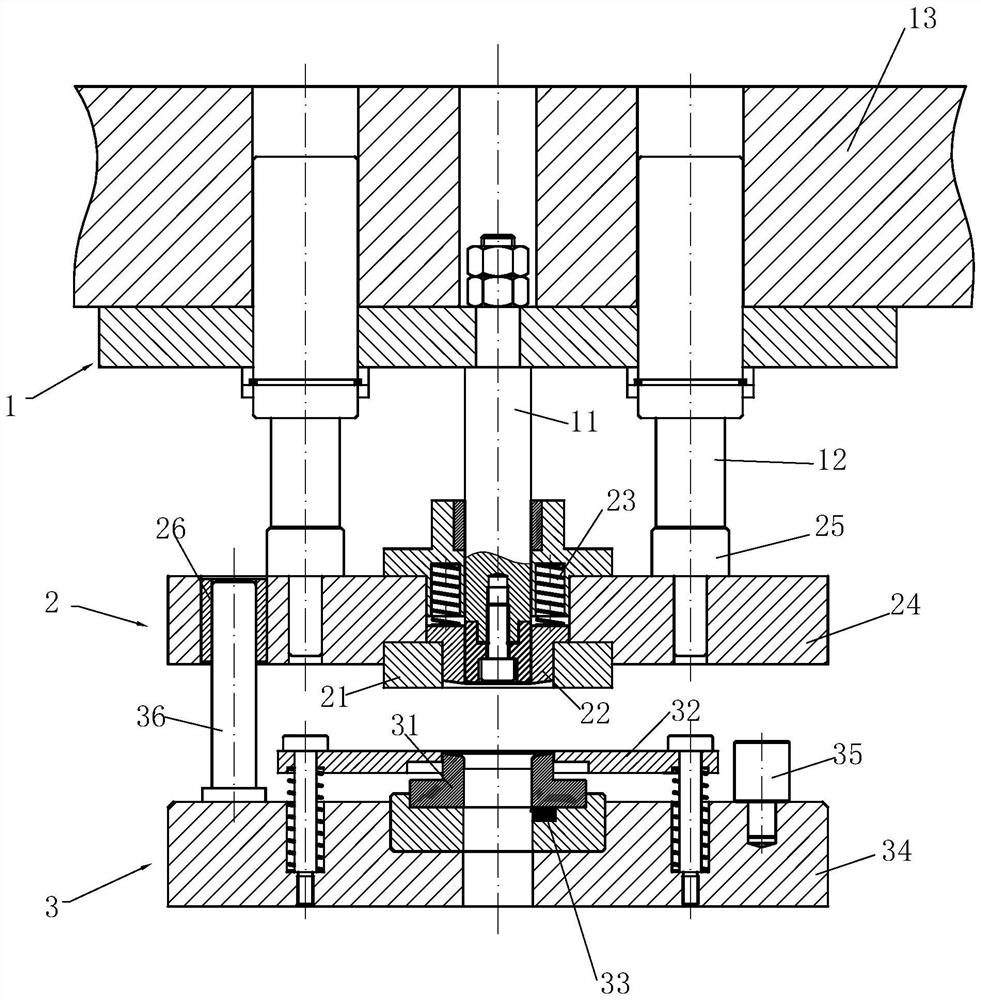

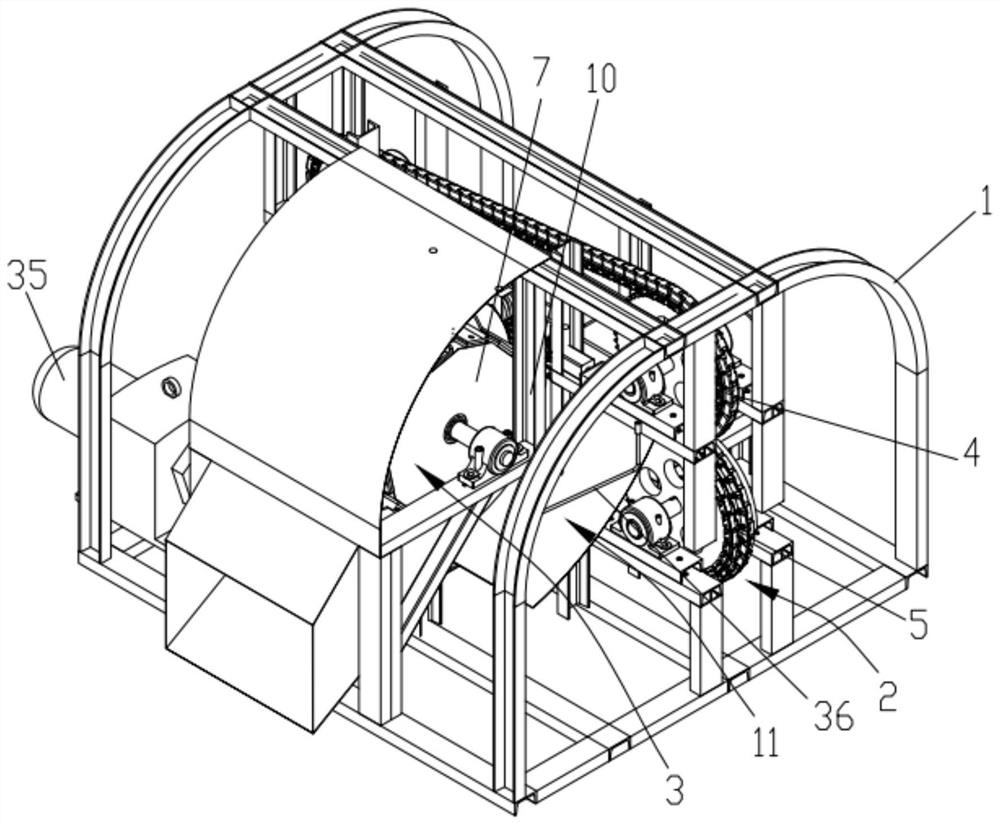

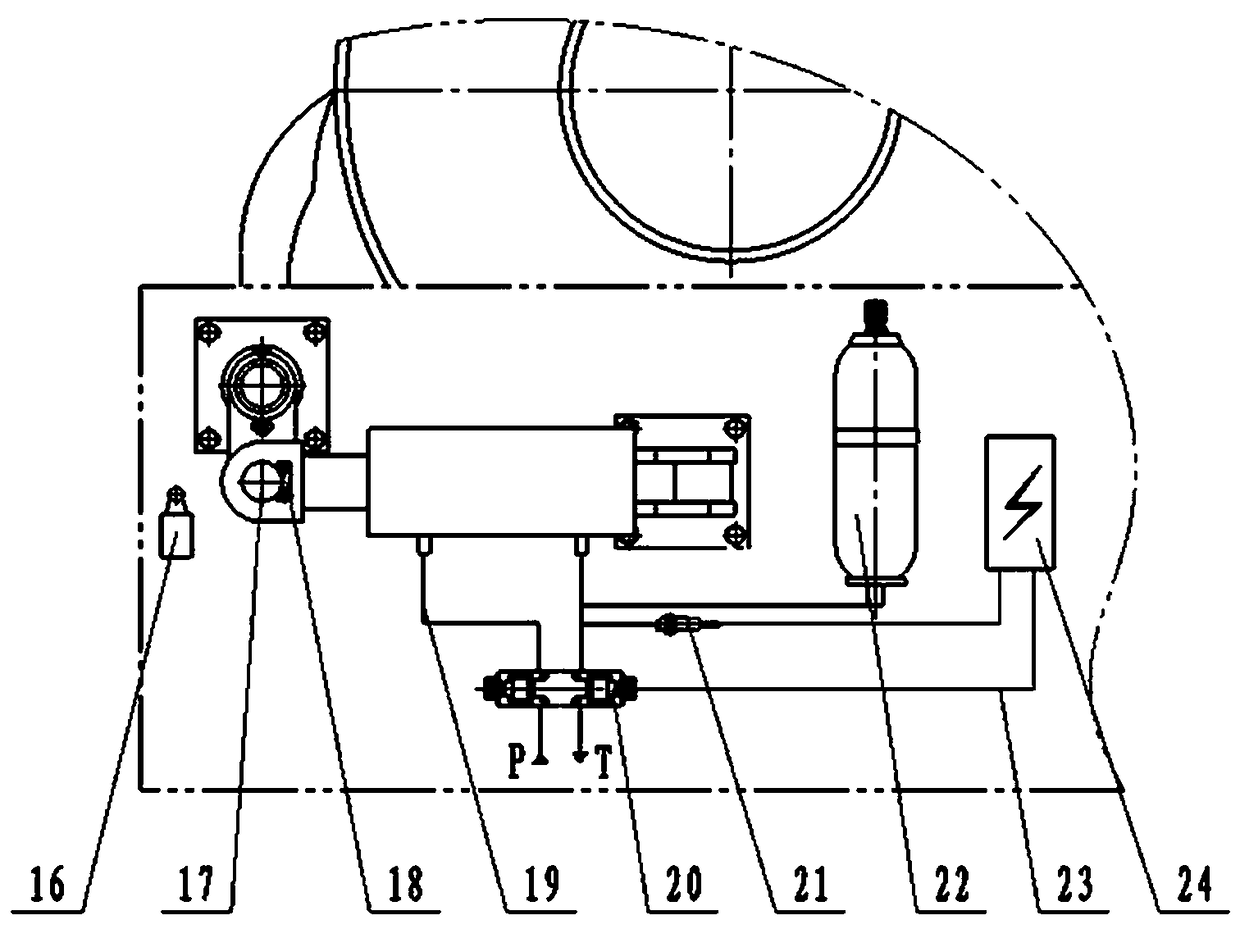

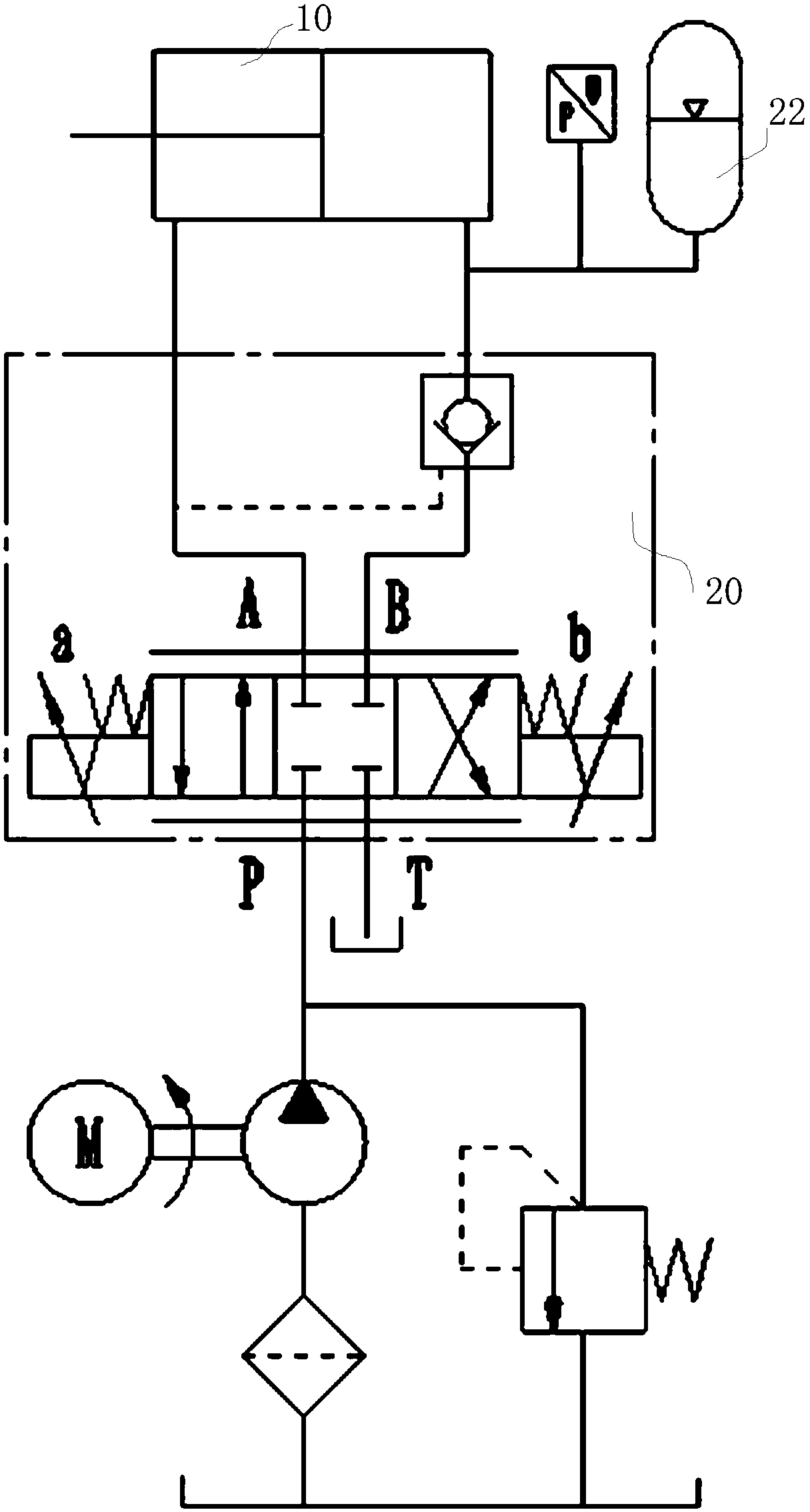

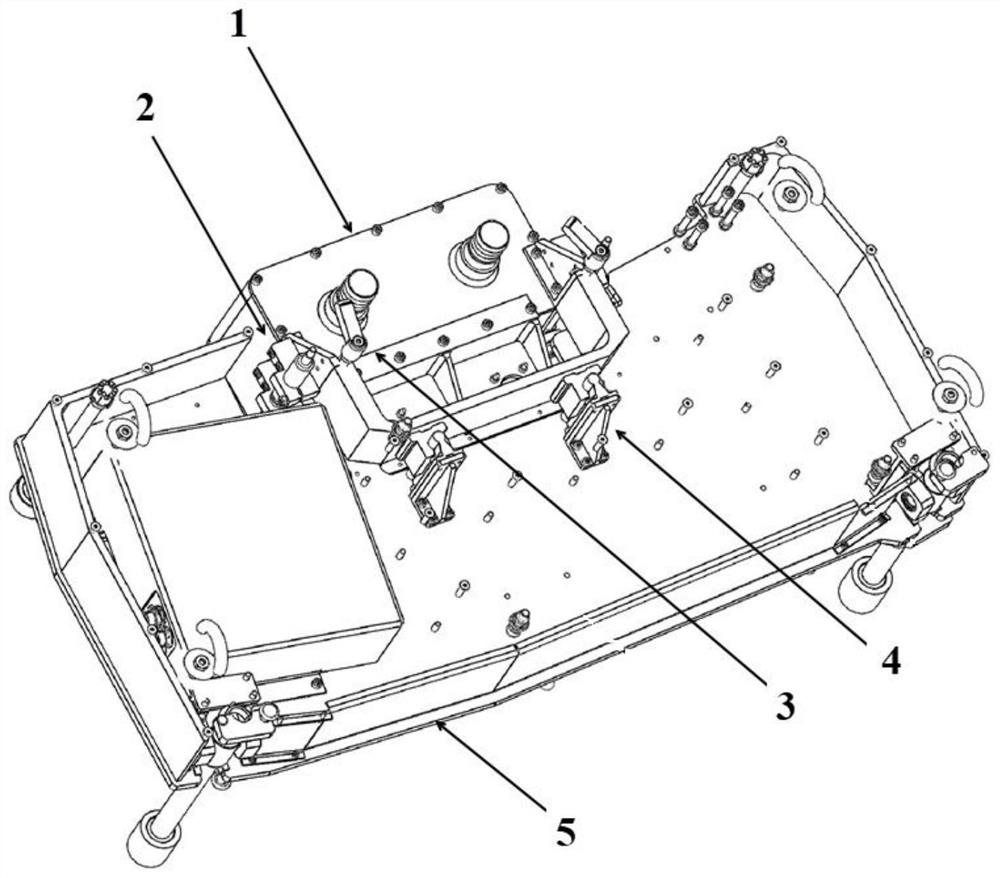

Constant-pressing-force sweeping system used for ribbon conveyer and having automatic compensation function

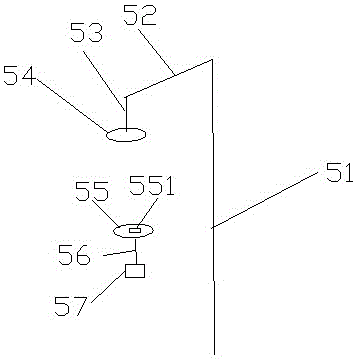

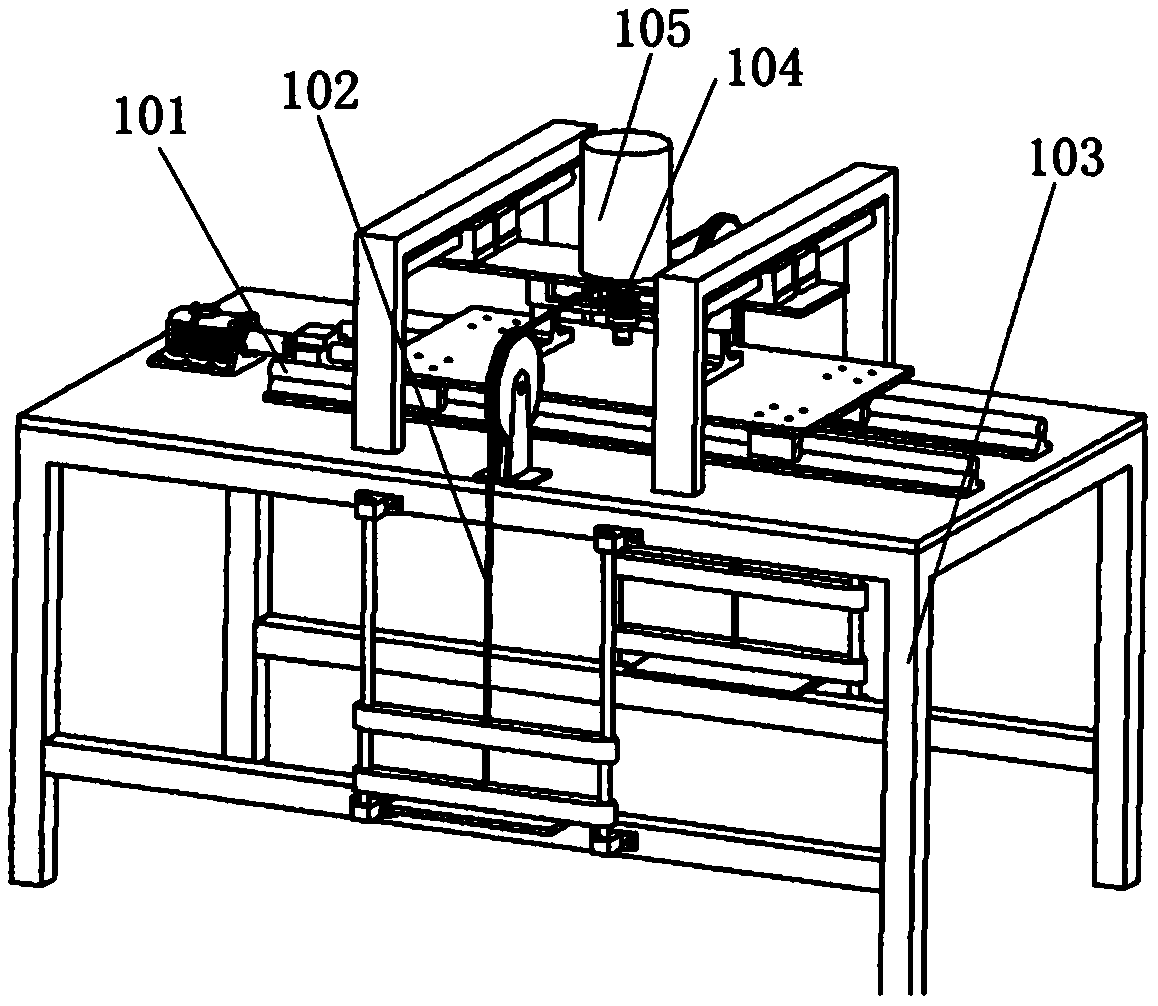

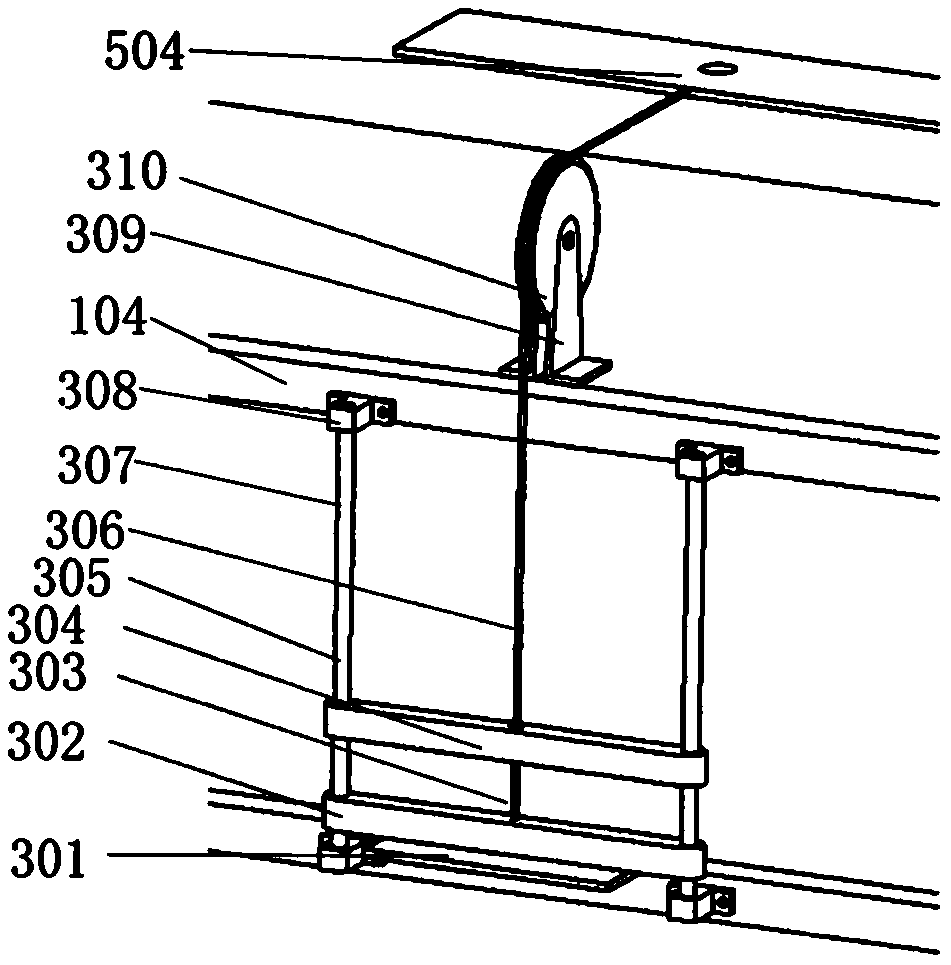

The invention belongs to the technical field of transportation machines and provides a constant-pressing-force sweeping system used for a ribbon conveyer and having an automatic compensation function. By the adoption of the constant-pressing-force sweeping system, the contact force between a scraping plate and a conveying belt is constant, and an ideal cleaning effect is achieved. The constant-pressing-force sweeping system used for the ribbon conveyer and having the automatic compensation function comprises a sweeper assembly, a rotating assembly, a hydraulic system and an electric control system. The rotating assembly is connected with a sweeper and a piston rod of a hydraulic cylinder of the hydraulic system. The electric control system detects and controls pressure information of the hydraulic cylinder. When the conveyer is stopped, the scraping plate is controlled to be separated from the conveying belt, so that the starting resistance when the conveyer is started next time is reduced; after the conveyer is started, the scraping plate is controlled to rapidly make contact with the conveying belt, and the set pressing force is obtained; when the scraping plate is abraded, an oil cylinder is automatically replenished with oil, and the effect that the pressure in the oil cylinder is constant is guaranteed; and when the scraping plate is abraded to the limit, the conveyer is stopped, and an alarm is given. By the adoption of the constant-pressing-force sweeping system, the starting resistance of the conveyer can be reduced, the pressing force between the scraping plate and the conveying belt is automatically controlled to be constant, and the sweeping efficiency and the automation degree are improved.

Owner:YULIN S&G COAL MINE MACHINERY

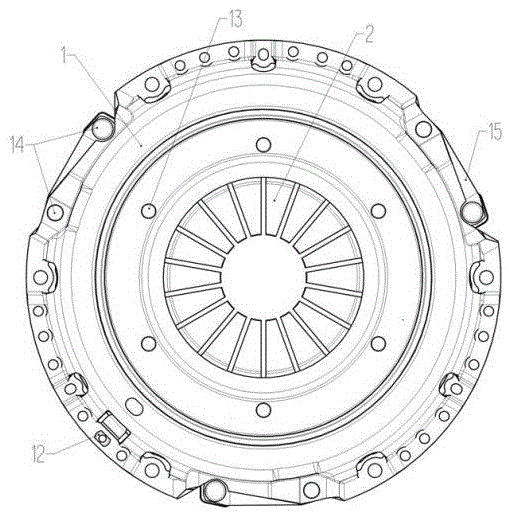

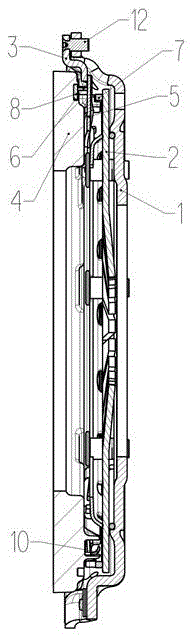

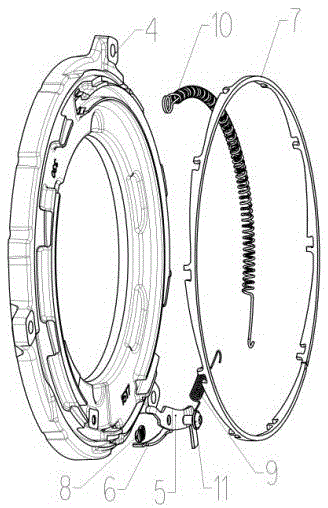

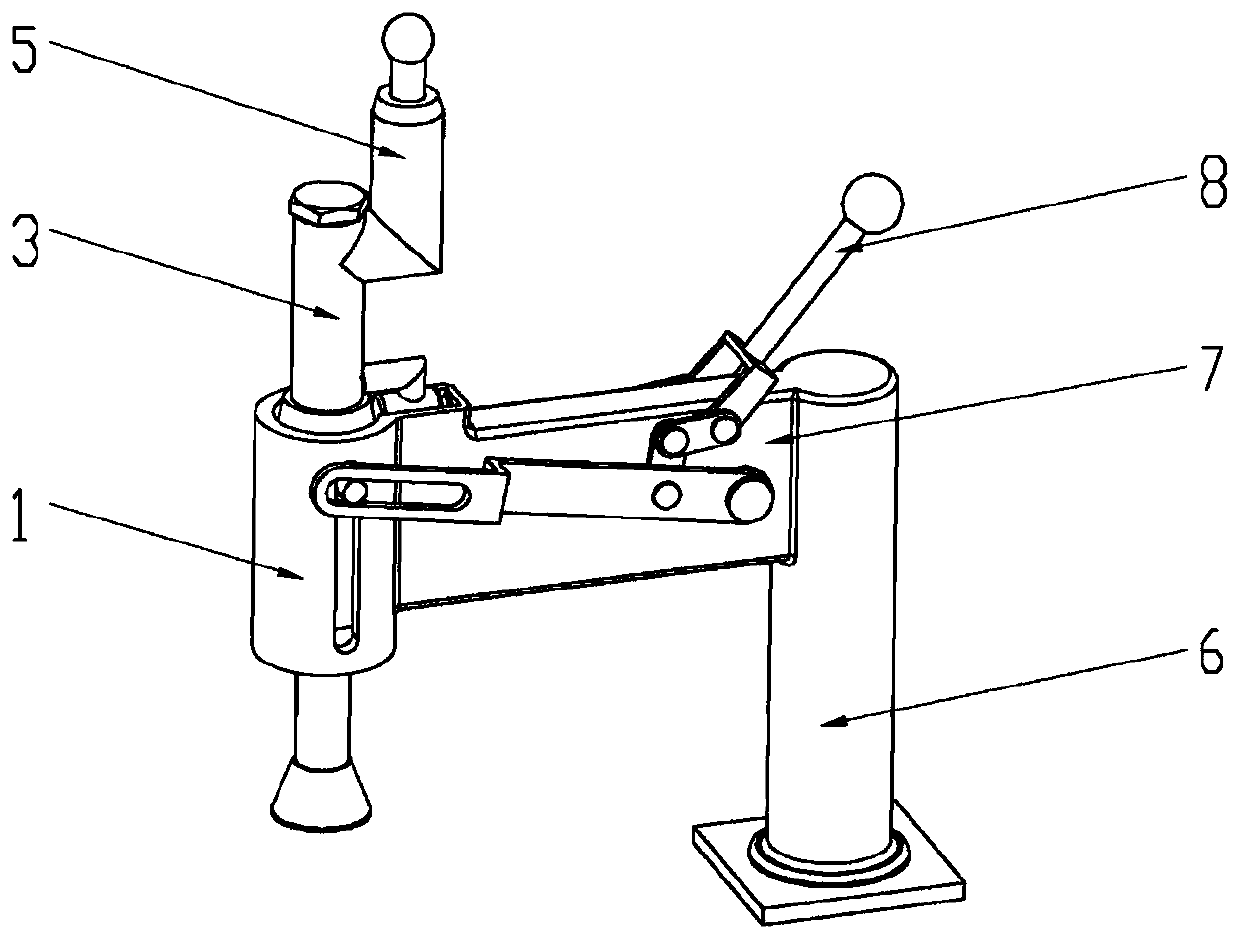

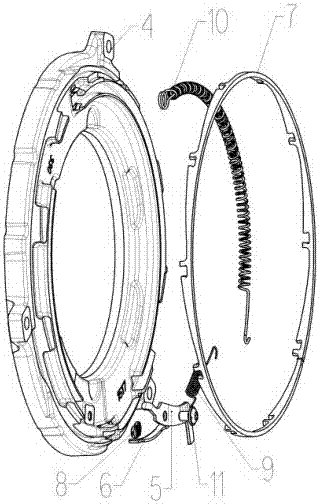

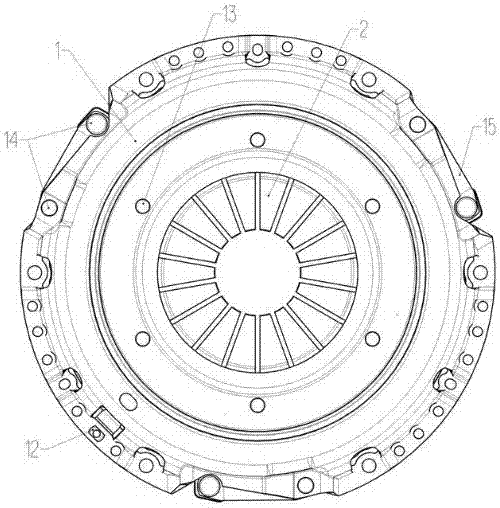

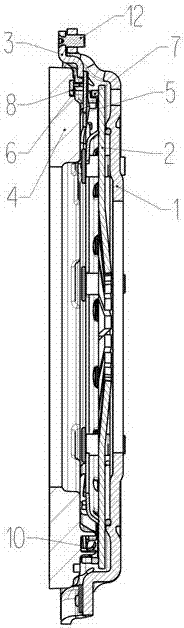

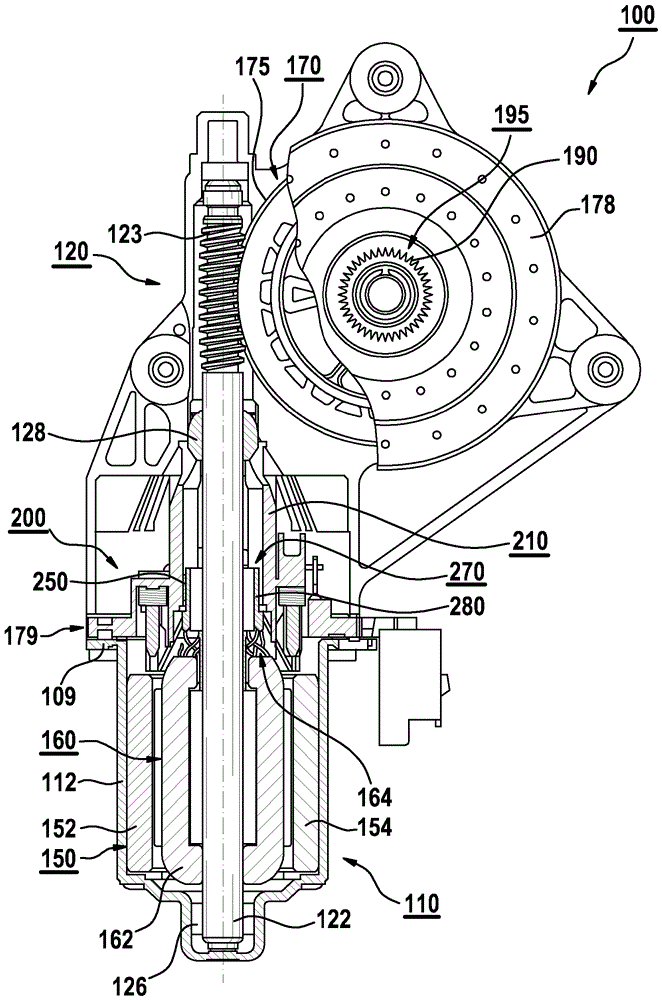

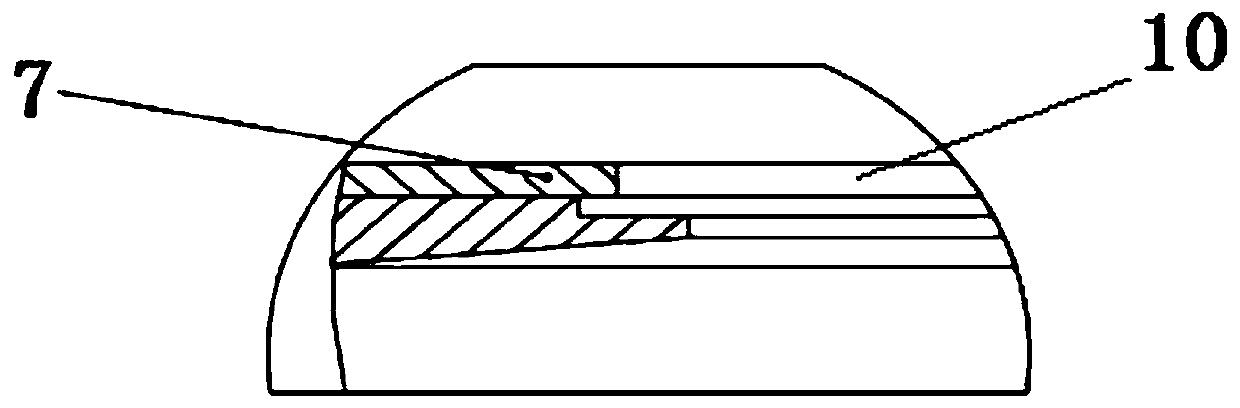

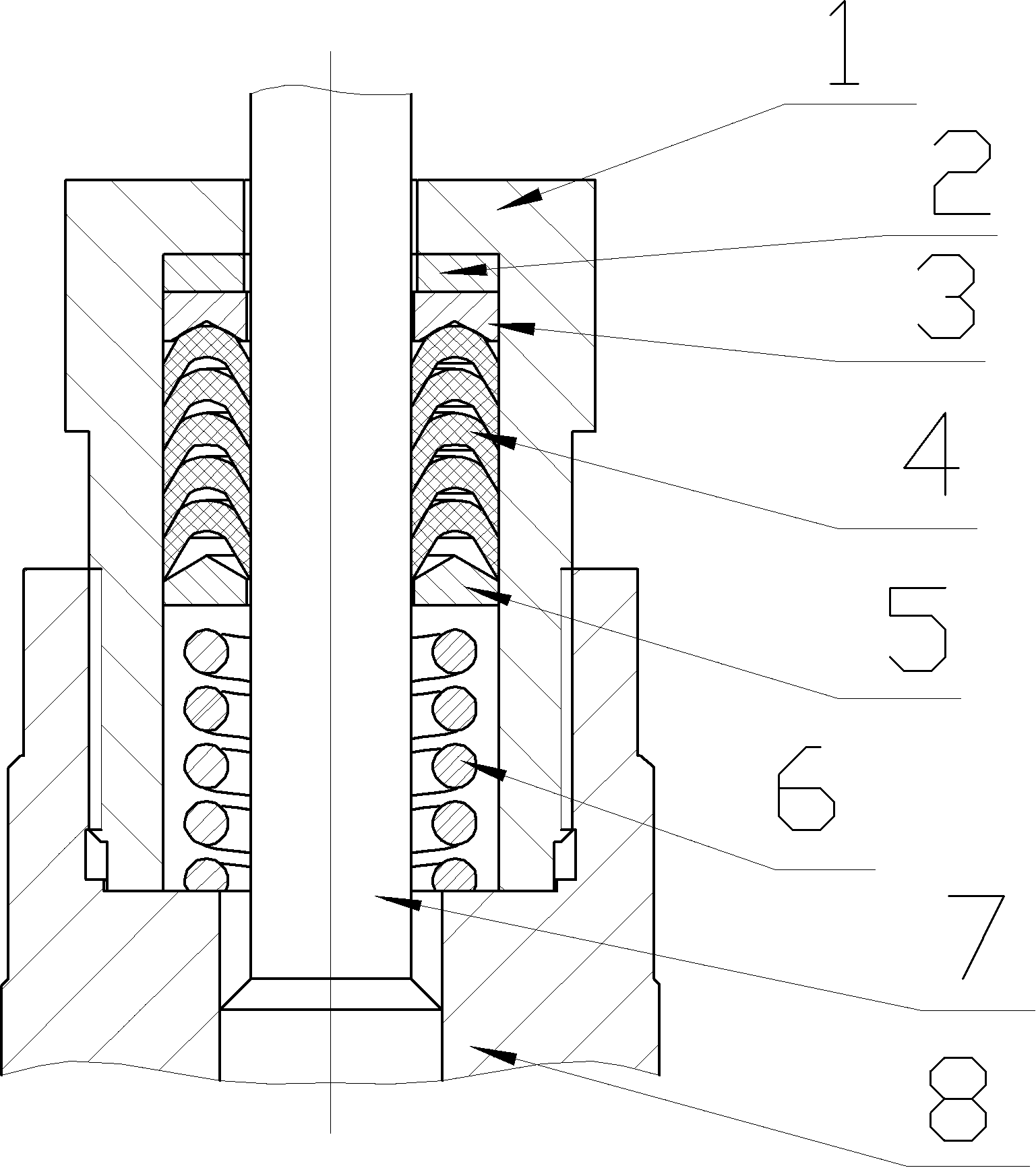

Pressing plate assembly for self-adjusting clutch cover assembly device

InactiveCN105485201AConstant pressing forceCompensation for wearFriction clutchesCoil springEngineering

The invention relates to a pressing plate assembly for a self-adjusting clutch cover assembly device. The pressing plate assembly is characterized by comprising a pressing plate (4), a pressure spring (5), a rack (6), an adjusting ring (7), a tooth-shaped block (8), a small spiral spring (9), a large spiral spring (10) and a bolt (11). The pressing plate assembly is used for assembling the self-adjusting clutch cover assembly device and can automatically compensate for the thickness abrasion of a friction plate of a driven plate of a clutch, the abrasion loss of the thickness of the friction plate can be compensated for by automatically adjusting the supporting height of the pressing plate of the clutch, and therefore the pressing force and the separating force of the clutch can keep constant in the use process.

Owner:JIANGYIN POLYTECHNIC COLLEGE

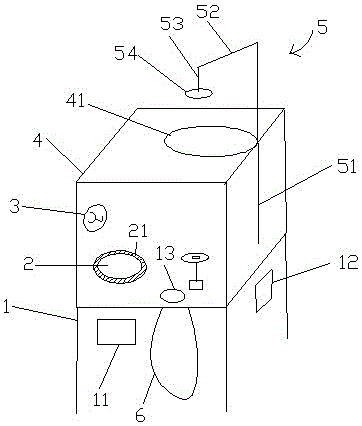

Card holding apparatus for automatic ticket sales

ActiveCN101013510AConstant pressing forceImprove stabilityAuxillary ticket-issuing devicesMachines for issuing preprinted ticketsEngineeringScratching

The invention involves an automatic ticketing system which can be applied in urban rail transport which includes the floor, the card box placed on the floor, the spindle fixed on the floor and a pressure card board sliding on the spindle. The invention will ensure that card's pressure on scratch card device in the scratching is constant, and it increases the scratch cards' stability, thereby improving the success rate of cards sending and reducing the injury of cards and scratch cards, extending the lifetime of card and scratch card.

Owner:GRG BAKING EQUIP CO LTD

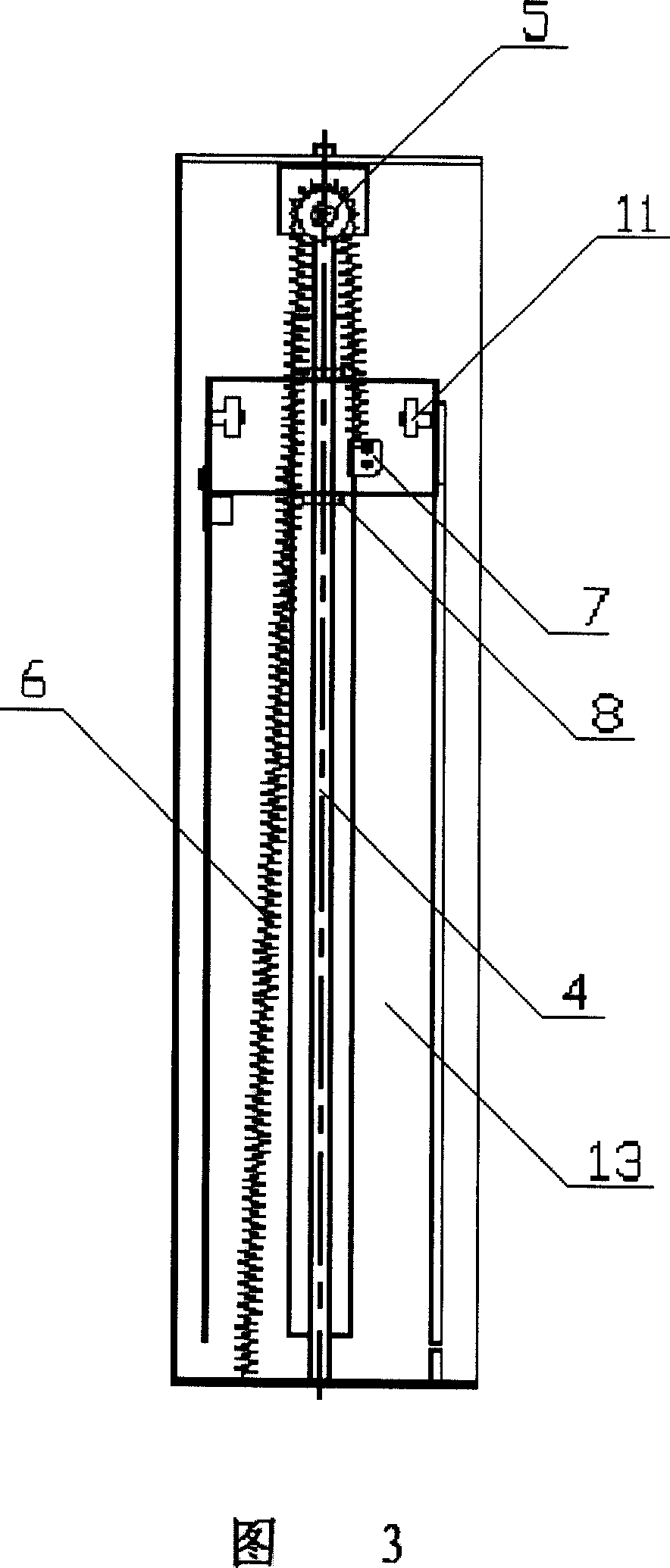

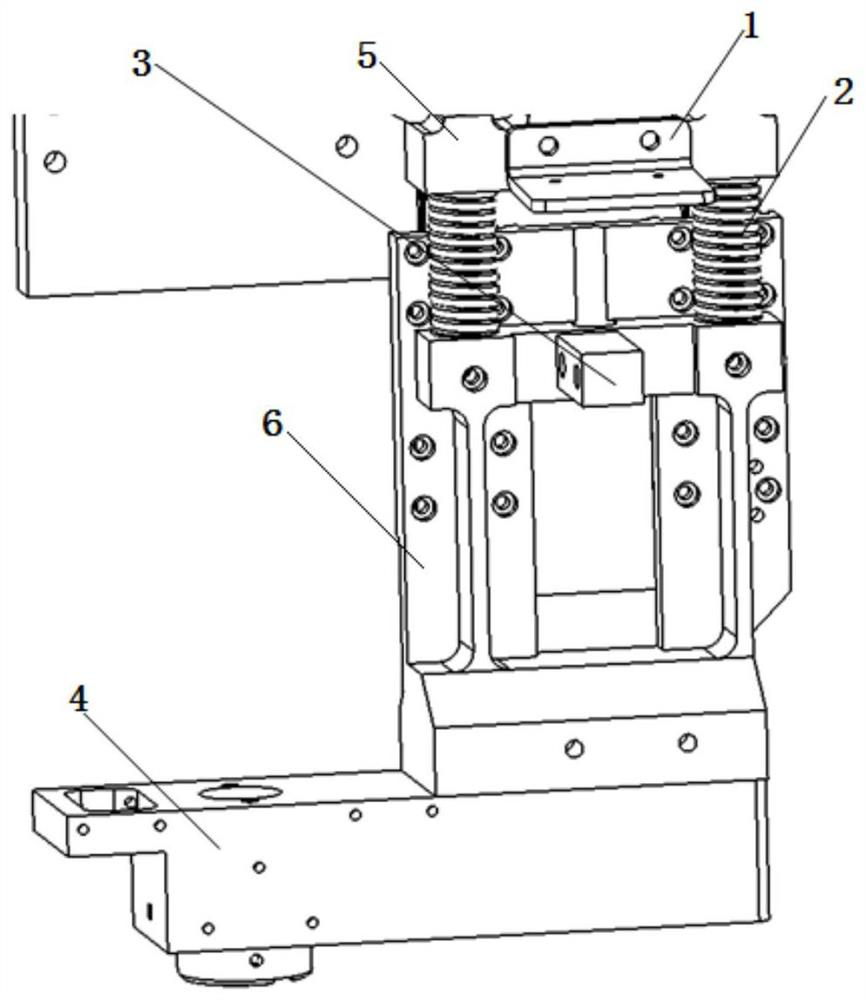

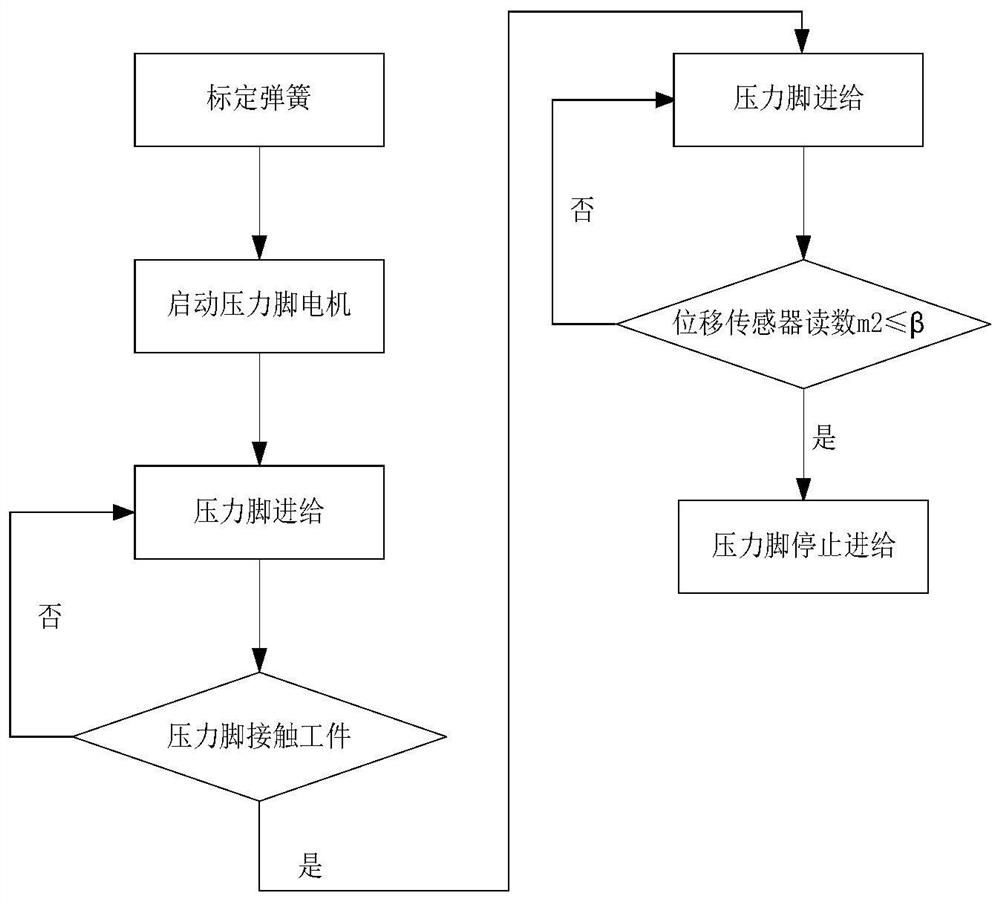

Electric and spring coupling pressure foot pressing force measuring device and control method

PendingCN112525403AGuaranteed small fluctuationsQuality assuranceApparatus for force/torque/work measurementProgramme control in sequence/logic controllersCouplingCoil spring

The invention discloses an electric and spring coupling pressure foot pressing force measuring device and a control method. The method comprises the steps of: utilizing a dynamometer for calibration to obtain the average elastic coefficient of a rectangular spiral spring; calculating the compression deformation amount of the rectangular spiral spring through reading of a small laser displacement sensor, solving the pressing force of a pressure foot, comprehensively considering the pressing force fluctuation allowance caused by workpiece deformation, converting pressing force control into visual rectangular spiral spring displacement control by setting a compression amount threshold value, and indirectly controlling the pressing force of the pressure foot to be constant. The method is simple in measurement and control process and easy to implement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Glass chamfering device capable of preventing cooling water from shortage

InactiveCN106041665AExtended service lifeAvoid bursting and other badEdge grinding machinesGrinding feed controlCooling effectEngineering

The application discloses a glass chamfering device capable of preventing cooling water shortage, which includes a frame, a grinding disc, a water pipe, a circulating water pipe, a protective cover and a glass holding device; the grinding disc is arranged on the top of the frame, and the grinding disc The disc can rotate horizontally, and the grinding disc is equipped with a temperature sensor; the water outlets of the tap water pipe and the circulating water pipe point to the surface of the grinding disc; the tap water pipe is provided with a solenoid valve connected to the temperature sensor; The clamping device includes a rotating lifting rod, a cross bar, a suspension rod, a vacuum suction cup, a fixed disk, a rotating shaft and a third motor; the height of the rotating lifting rod can be lifted and rotated; the outer diameters of the fixed disk and the vacuum suction cup are smaller than The outer diameter of the beveled glass. The application enables the cooling water to be recycled, the cooling effect is good, and the clamped glass to be chamfered can be automatically rotated, so that each circumferential surface of the glass to be chamfered can be evenly chamfered, and the chamfering efficiency is high.

Owner:李平

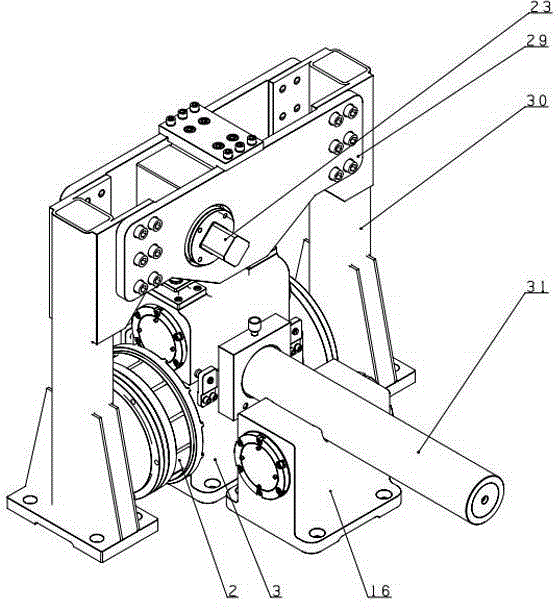

Ultraprecise friction driving mechanism

ActiveCN104405837AReliable preloadAdjustable pressing forceMechanical energy handlingFriction gearingsDrive wheelGrating

The invention discloses an ultraprecise friction driving mechanism. The mechanism mainly comprises a driving part, an auxiliary support part, a pressing part and an eccentric pressing part, wherein stable and precise rotation positioning is provided by the driving part, a torque motor is directly connected with a friction driving shaft, a driving error caused by intermediate transmission links is reduced, a circular grating is connected to the other end of the driving shaft, and the angular precision of a driving wheel is measured; through the auxiliary support part, the deflection deformation of the tail end of a driven rod is reduced, the position precision of the driven rod is guaranteed, so as to achieve the effects of auxiliary support and fine-tuning positioning, wherein the displacement output by an eccentric wheel structure is converted into pressing force by a pressure reed, and a driving wheel system and a friction guide rod are pressed through a prepressing wheel system; through the eccentric pressing part, accurate displacement output can be provided for the pressure reed, the pressing force can be conveniently adjusted, and the change of the pressing force can be monitored in real time by a pressure sensor installed on an eccentric wheel driven component, so as to satisfy the controllable requirement on the pressing force.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

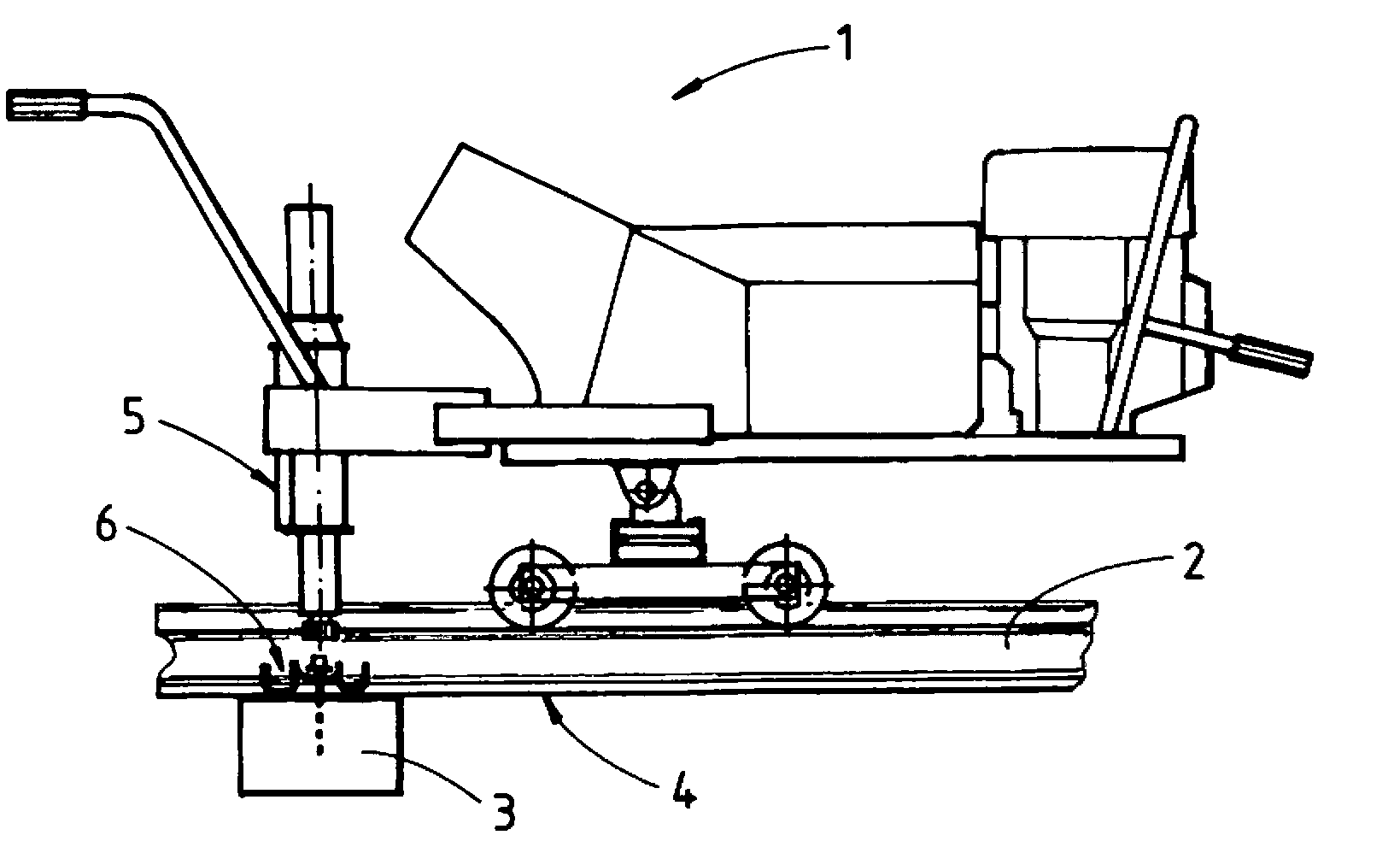

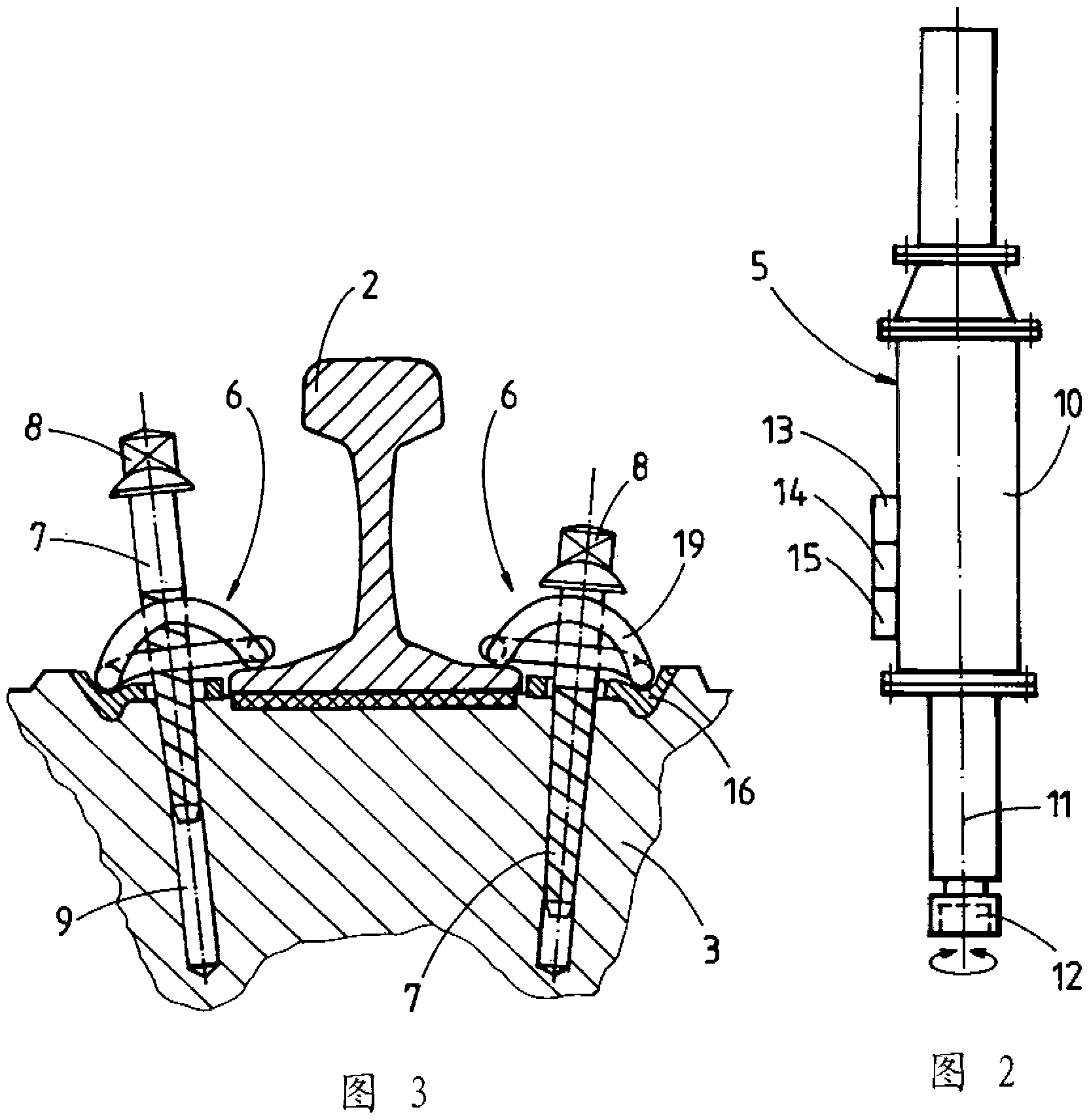

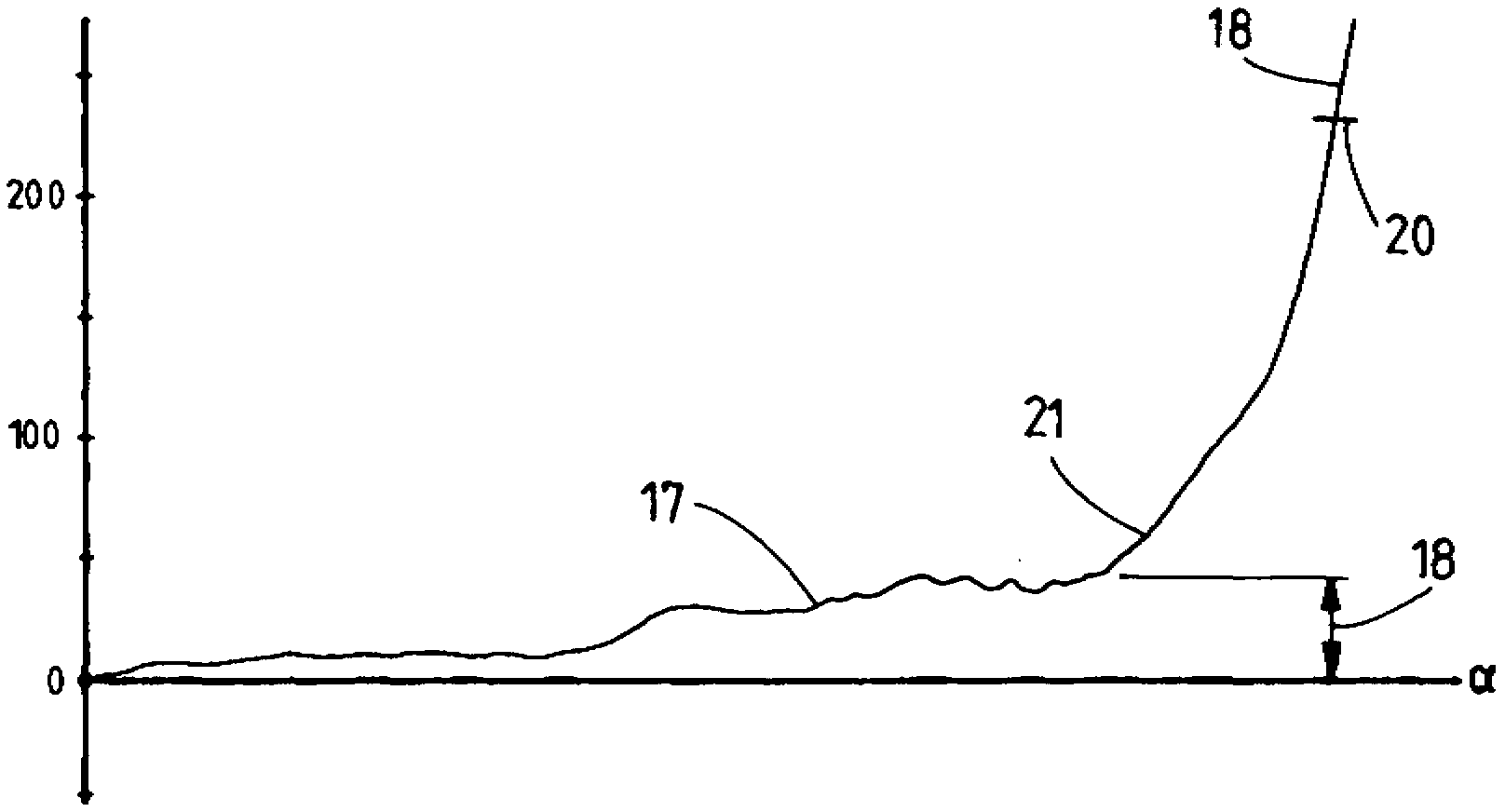

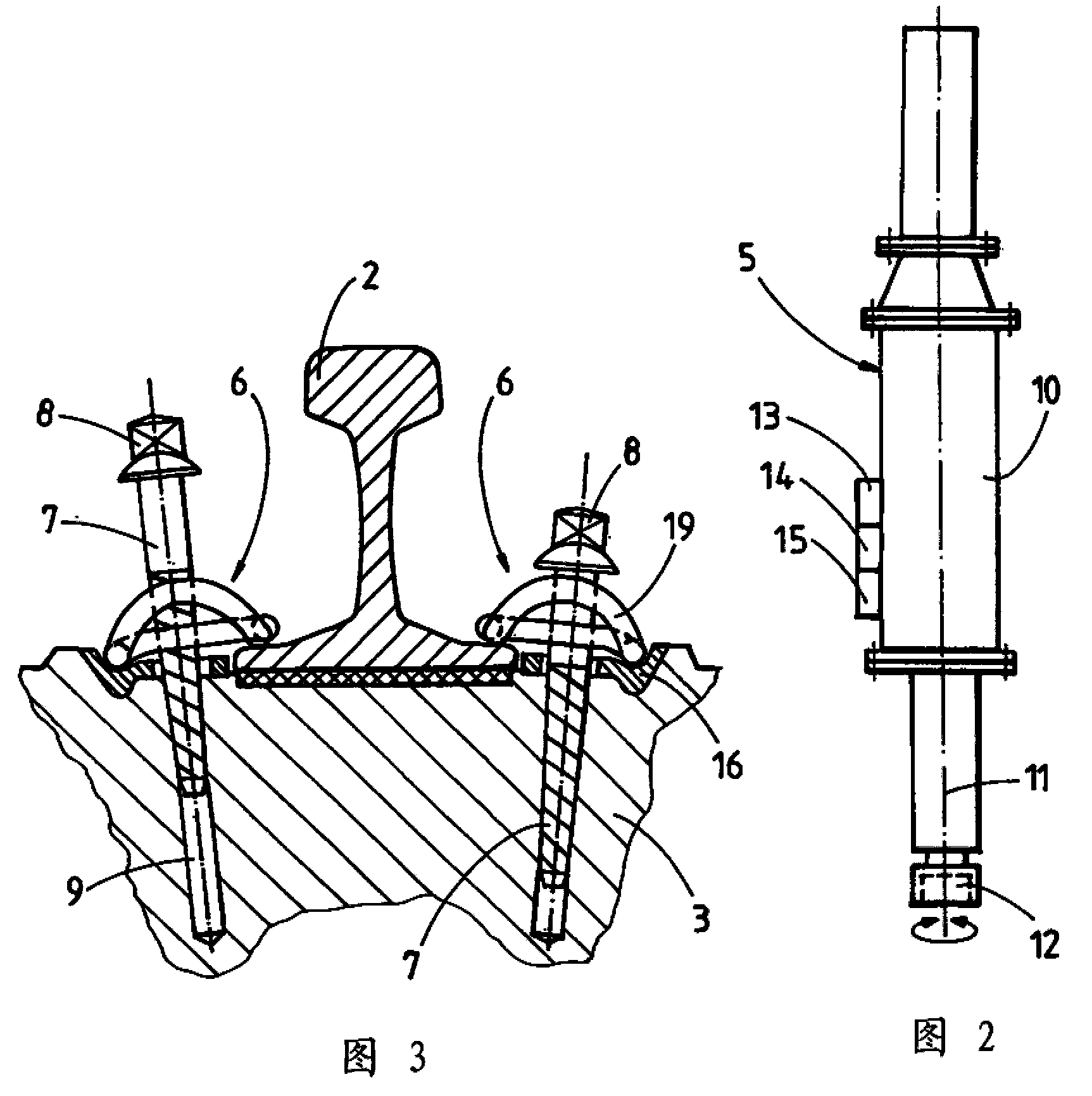

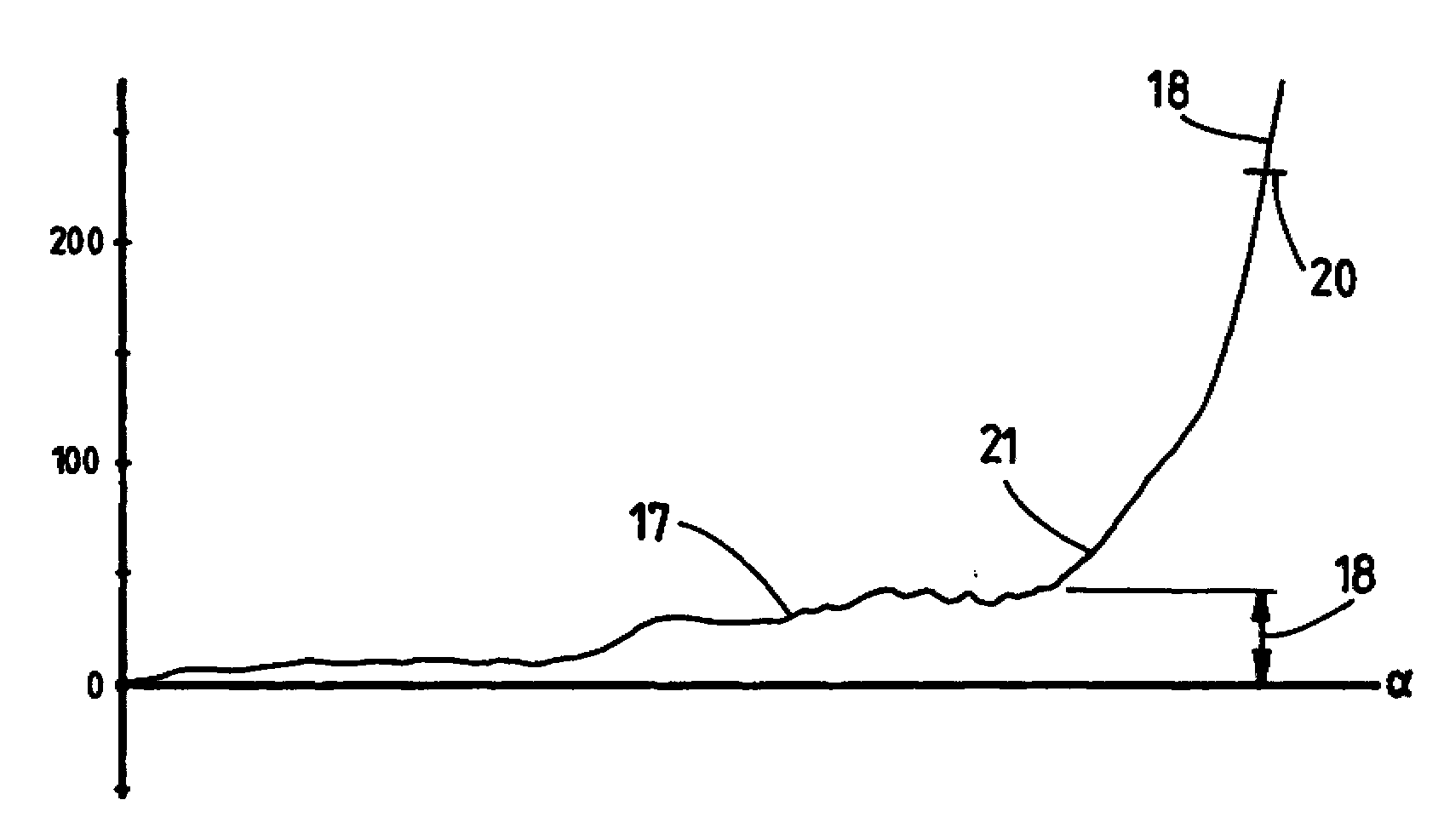

Method for tightening screw connections

In order to tighten screw connections, a screw-in torque (17) which is effective during the screwing in of a screw is sensed and a compensation value (18) which is dependent thereon is determined, and the setpoint torque (20) is increased as a function of the previously determined compensation value (18) for the complete tightening of the screw (7).

Owner:ROBEL BAHNBAUMASCH

Anti-loosening device for rolling hot-rolled stainless rolled plate

ActiveCN114453455AAvoid elasticAvoid looseMetal rolling arrangementsHydraulic cylinderClassical mechanics

The invention relates to the technical field of hot-rolled stainless rolled plate machining, in particular to an anti-loosening device for hot-rolled stainless rolled plate winding, which comprises a winding roller, two pressing assemblies are arranged on the side edge of the winding roller, and each pressing assembly comprises a top pressing roller parallel to the winding roller and a hydraulic telescopic cylinder supported on one side of the top pressing roller; one end of the winding roller is connected with a continuously variable transmission, the continuously variable transmission is connected with a hydraulic adjusting mechanism, and the hydraulic adjusting mechanism is connected with a hydraulic telescopic cylinder in one pressing assembly on the side edge of the winding roller through a first conveying pipe assembly. A plurality of pinch rollers are arranged on one side of the winding roller in parallel, the pinch rollers are arranged on a sliding frame, and one side of the sliding frame is connected with a lifting adjusting hydraulic cylinder. The jacking roller capable of being pressed outside a rolled plate is arranged on one side of the winding position of the hot-rolled stainless rolled plate, and the jacking roller can always keep rolling pressing in the whole winding process of the hot-rolled stainless rolled plate; and the hot-rolled stainless rolled plate which is just rolled is tightly pressed and is prevented from bouncing off and loosening.

Owner:山东世纪正华金属科技有限公司

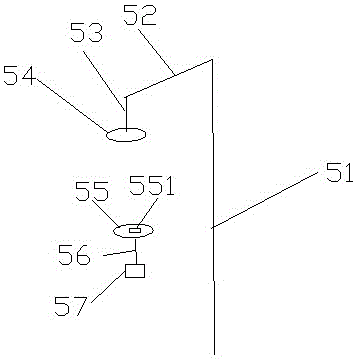

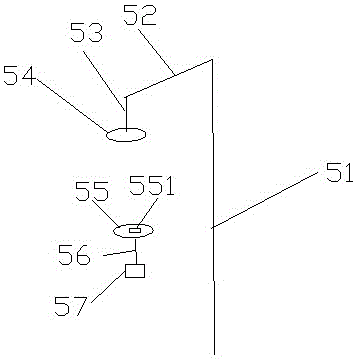

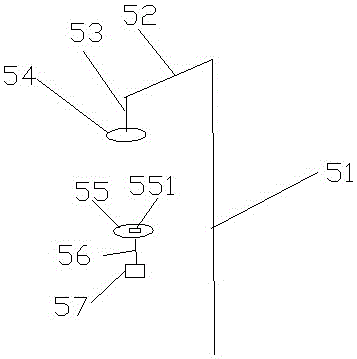

Sectional material pressing mechanism of plate machining equipment

PendingCN110549430AImprove stabilityImprove reliabilityProfiling/shaping machinesWorking accessoriesEngineeringGas pressure transducer

The invention provides a sectional material pressing mechanism of plate machining equipment. The sectional material pressing mechanism of the plate machining equipment comprises two material pressingmechanisms arranged on one side of a machining device, each material pressing mechanism comprises a material pressing support, the material pressing supports are provided with elastic parts and a plurality of material pressing parts; the material pressing parts are movably installed on the material pressing supports, at least one elastic part of the material pressing mechanisms are air bags, and the air bags communicate with air pressure sensors; the material pressing parts are material pressing rings which are arranged on the air bags in a sleeve mode and are propped against the air bags through movable support columns, or the material pressing mechanisms are pressing blocks pivoted to the material pressing supports and propped against the air bags, the air bags are used as the elastic parts, then the air bags communicate with an air pressure sensor and directly measure the pressure of a workpiece applied by the material pressing mechanism in an air pressure monitoring mode, the magnitude threshold value and the sudden change condition of the pressure value can be visually monitored, and the accident conditions such as in-and-out slip, workpiece flying out and the like can be reflected by the air bags, the air bags is combined with the machine table equipment, a material can be pressed by directly stopping the machine, the workpiece is prevented from flying out, and the problem of the safety performance of the plate sanding / milling equipment blank plate material pressing device is poor is solved.

Owner:青岛盛福精磨科技有限公司

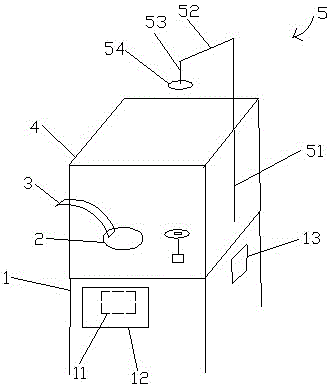

Fixture for chamfering machine

InactiveCN106078409APrevent splashHigh degree of automationEdge grinding machinesGrinding feed controlPulp and paper industry

The invention discloses a fixture for a chamfering machine. The fixture for the chamfering machine comprises a rotary lifting rod, a transverse rod, a hanging rod, a vacuum sucker, a fixing disk, a rotary shaft and a third motor. The rotary lifting rod is liftable in height and capable of rotating. The transverse rod is fixedly arranged at the top of the rotary lifting rod and the hanging rod is nested at the bottom of the transverse rod by a bearing. The vacuum sucker is fixedly arranged at the bottom of the hanging rod. The fixing disk is arranged right below the vacuum sucker in an axial manner and the bottom of the fixing disk is fixedly connected with the rotary shaft. The rotary shaft is driven to rotate by the third motor. The external diameter of the fixing disk and the external diameter of the vacuum sucker are both less than the external diameter of glass to be chamfered. According to the fixture, the clamped glass to be chamfered is capable of rotating automatically, so that all the circumferential surfaces of the glass to be chamfered can be chamfered uniformly and the chamfering efficiency is high.

Owner:李玲

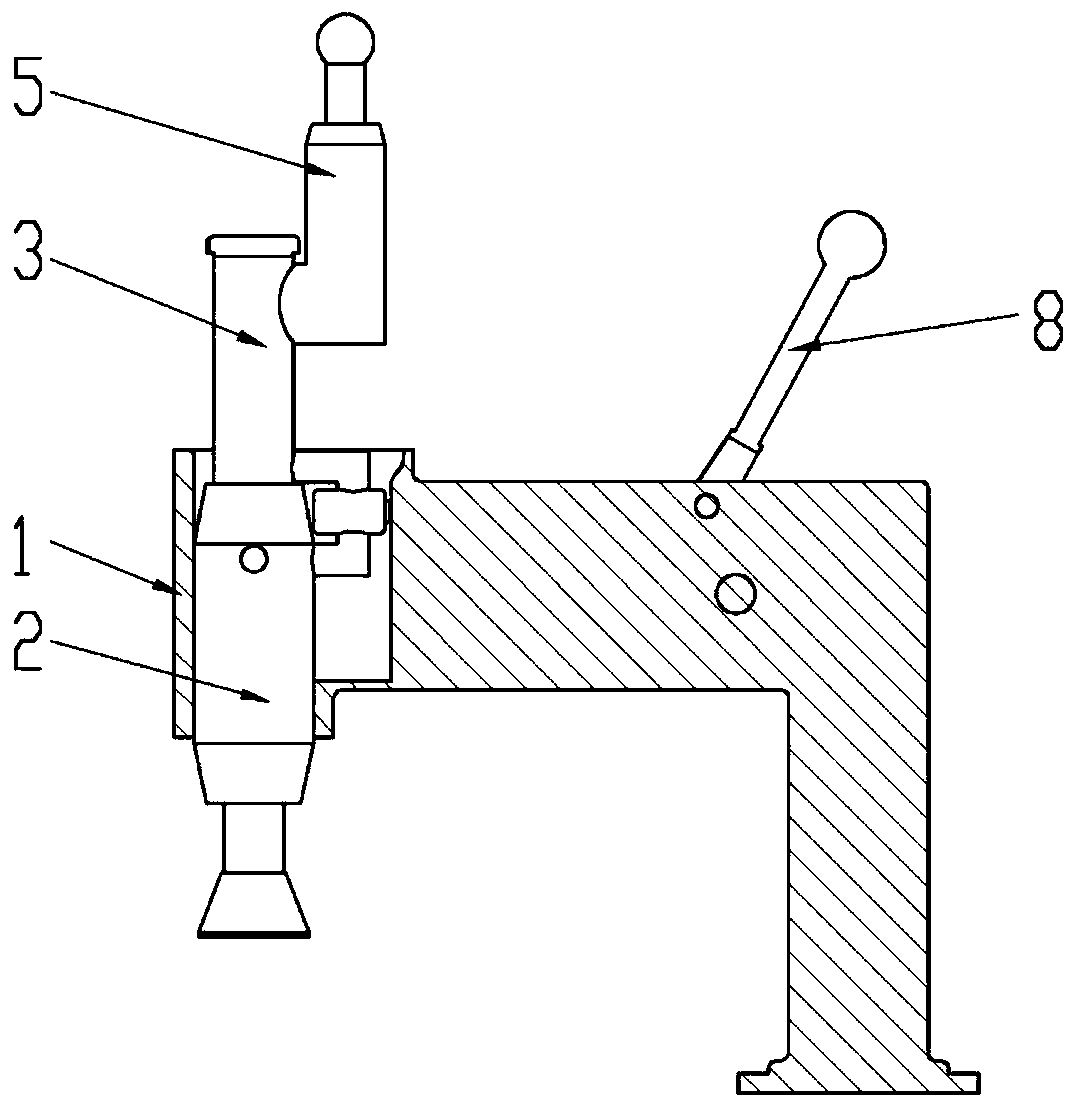

Simple constant-pressure fixture

ActiveCN109968079ASimple structureAchieve compactionPositioning apparatusMetal-working holdersPistonPetroleum engineering

The invention relates to a simple constant-pressure fixture. The simple constant-pressure fixture comprises a guide sleeve, a hold-down oil cylinder and an upper oil cylinder; the hold-down oil cylinder is arranged in the guide sleeve; a hold-down piston is arranged in the hold-down oil cylinder; the bottom end of the upper oil cylinder is fixedly connected with the top end of the hold-down oil cylinder are fixedly connected, and the upper oil cylinder and the hold-down oil cylinder communicate with each other; a pressure limiting barrier part is arranged at the communicating position of the upper oil cylinder and the hold-down oil cylinder; a pressure limiting spring is arranged in the inner cavity of the upper oil cylinder; and a liquid return pipeline which can be selectively opened isfurther connected between the hold-down oil cylinder and the upper oil cylinder. The fixture disclosed by the invention is simple in structure and convenient to operate, is capable of meeting the requirement of having the same hold-down force on workpieces different in thickness, and avoids the defect that a simple hold-down device in the prior art has an excessive hold-down force on a thick workpiece but an insufficient hold-down force on a thin workpiece.

Owner:NORTHEASTERN UNIV

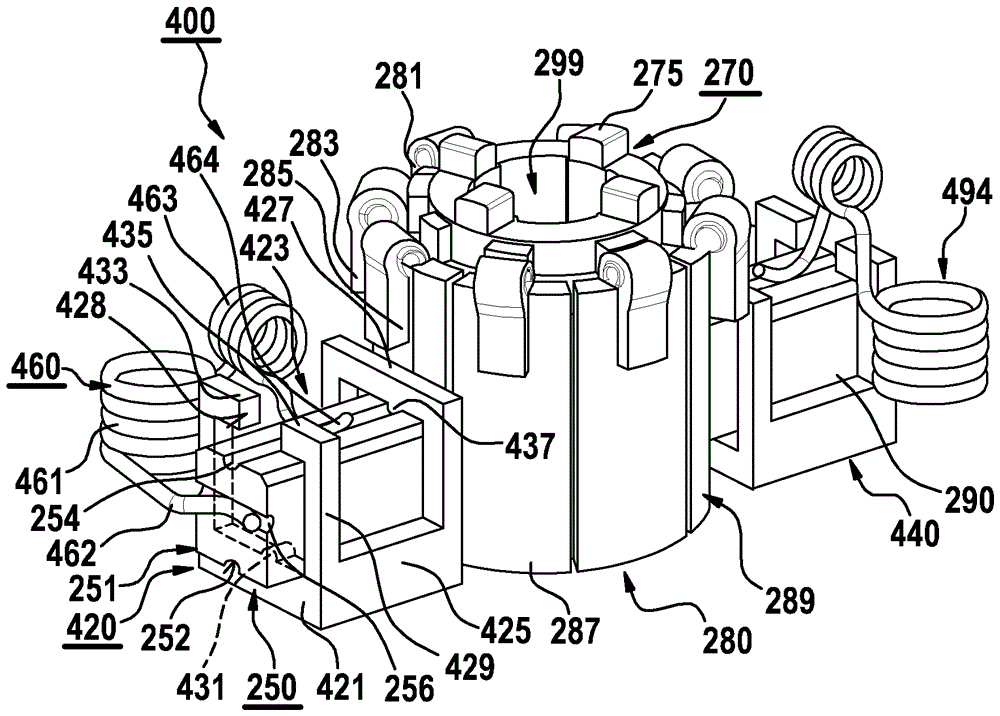

Pressure plate assembly of self-adjusting clutch cover assembly

InactiveCN105485201BConstant pressing forceCompensation for wearFriction clutchesCoil springEngineering

The invention relates to a pressing plate assembly for a self-adjusting clutch cover assembly device. The pressing plate assembly is characterized by comprising a pressing plate (4), a pressure spring (5), a rack (6), an adjusting ring (7), a tooth-shaped block (8), a small spiral spring (9), a large spiral spring (10) and a bolt (11). The pressing plate assembly is used for assembling the self-adjusting clutch cover assembly device and can automatically compensate for the thickness abrasion of a friction plate of a driven plate of a clutch, the abrasion loss of the thickness of the friction plate can be compensated for by automatically adjusting the supporting height of the pressing plate of the clutch, and therefore the pressing force and the separating force of the clutch can keep constant in the use process.

Owner:JIANGYIN POLYTECHNIC COLLEGE

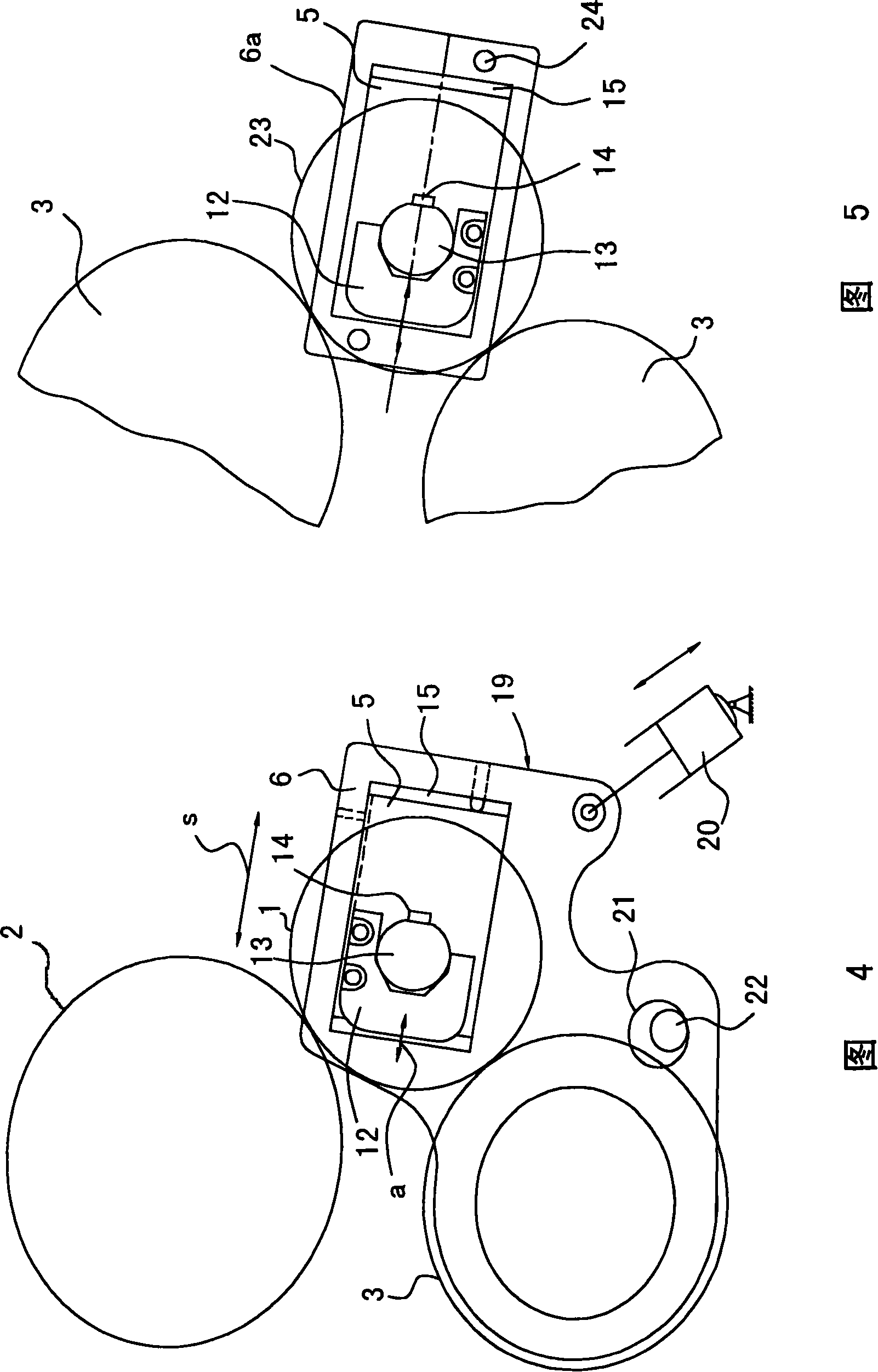

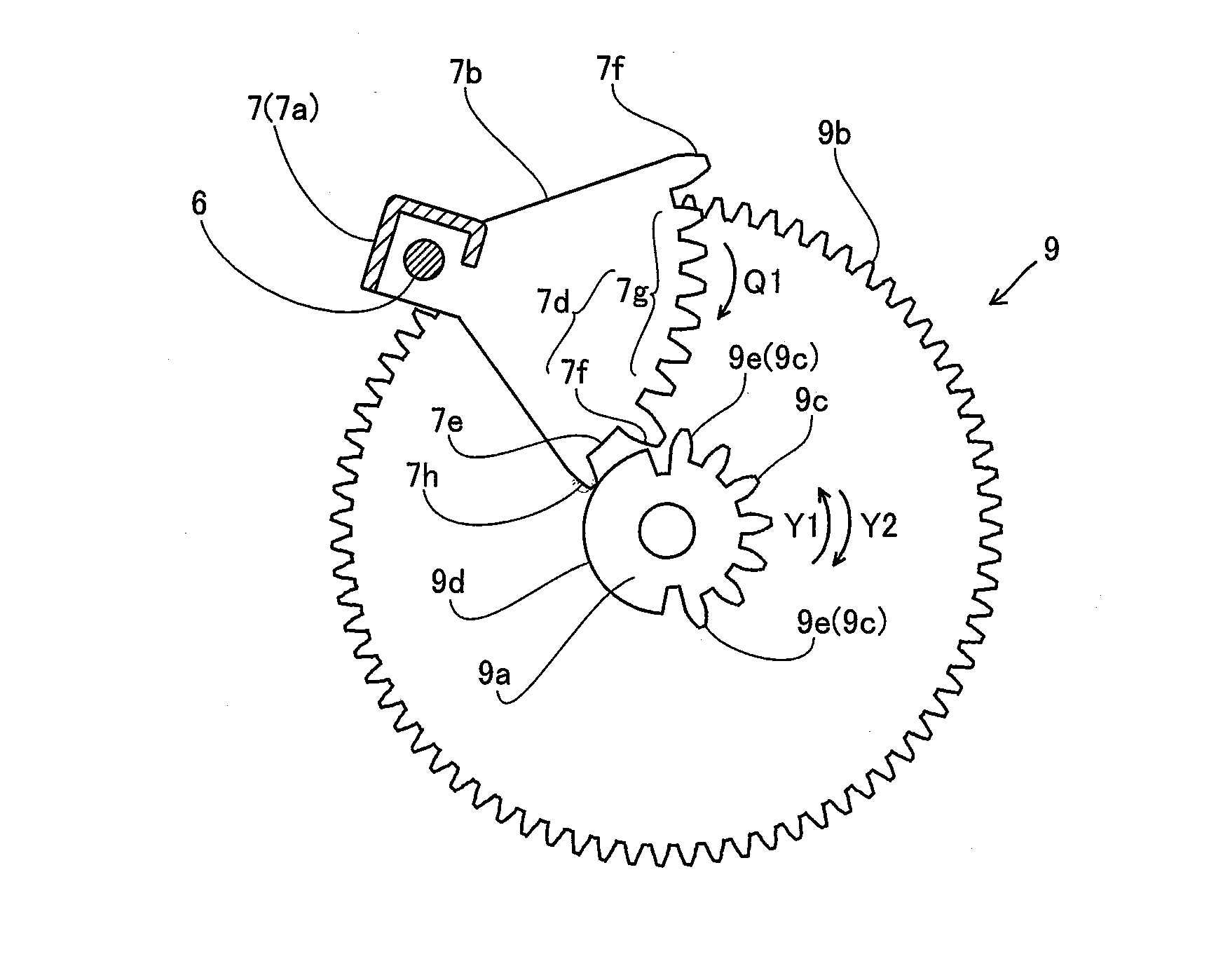

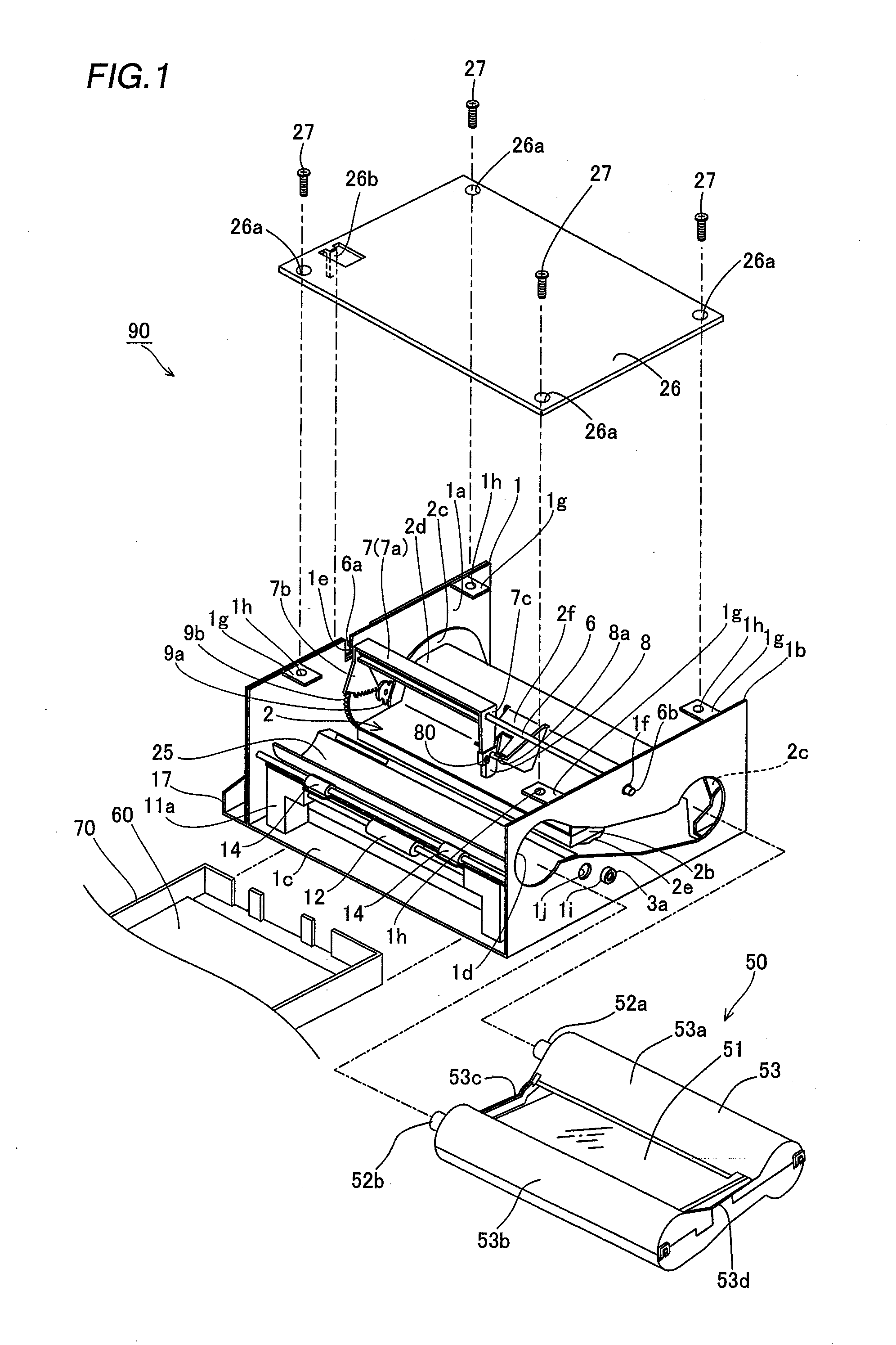

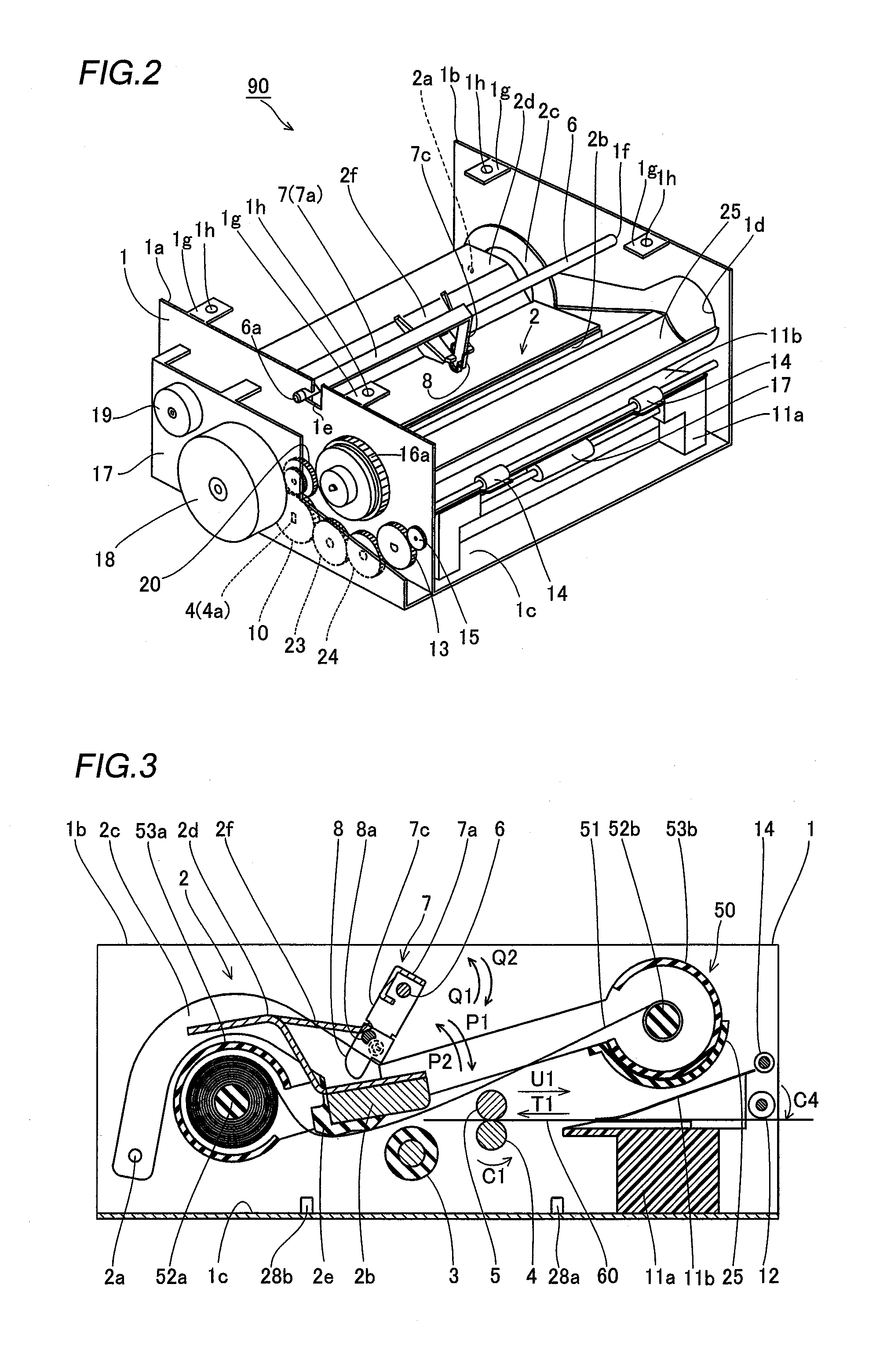

Image Generating Apparatus

InactiveUS20080193185A1Suppressing increase in number of componentConstant pressing forceRecording apparatusPower drive mechanismsEngineeringImage generation

In this image generating apparatus, a driving gear portion is so formed that the diameter of the outer peripheral surface of a first toothless portion is smaller than the tip diameter of a first toothed portion, and so arranged that the first toothless portion thereof slides on a second toothed portion of a driven gear portion of a print head rotating member in the vicinity of a position where a print head presses a platen roller with a pressing portion.

Owner:FUNAI ELECTRIC CO LTD

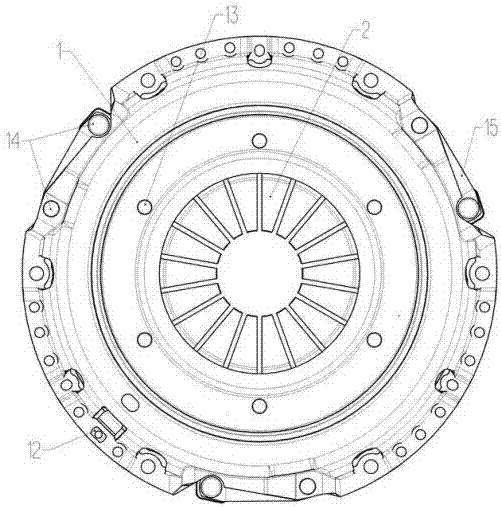

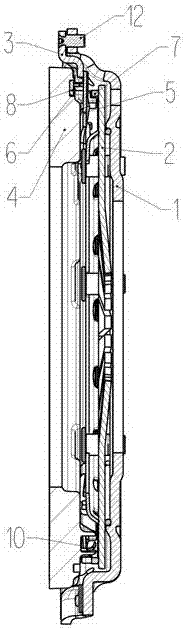

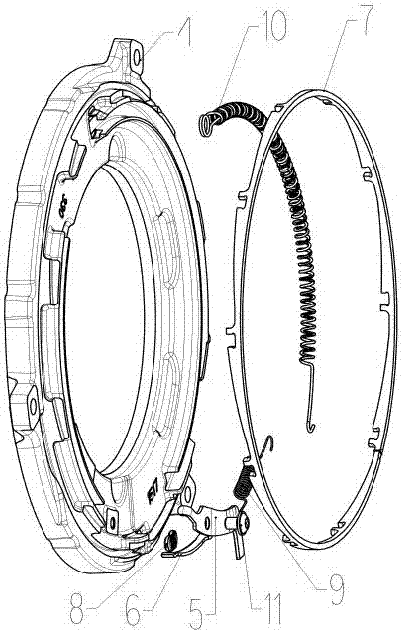

Self-adjusting clutch cover assembly

InactiveCN105485202BConstant pressing forceCompensation for wearFriction clutchesCoil springEngineering

The invention relates to a self-adjusting clutch cover assembly device. The self-adjusting clutch cover assembly device is characterized by comprising a cover (1), a diaphragm spring (2), a stopping block (3), a pressing plate (4), a pressure spring (5), a rack (6), an adjusting ring (7), a tooth-shaped block (8), a small spiral spring (9), a large spiral spring (10), a bolt (11), a limiting rivet (12), supporting rivets (13), fixing rivets (14) and a driving belt (15). The self-adjusting clutch cover assembly device can automatically compensate for the thickness abrasion of a friction plate of a driven plate of a clutch, the abrasion loss of the thickness of the friction plate can be compensated for by automatically adjusting the supporting height of the pressing plate of the clutch, and therefore the pressing force and the separating force of the clutch can keep constant in the use process.

Owner:JIANGYIN POLYTECHNIC COLLEGE

Self-radiating chamfering machine used for glass medicine bottle material analysis

InactiveCN106271961AAvoid phenomena such as burstingPrevent splashEdge grinding machinesGrinding feed controlEngineeringHeat sink

The application discloses a self-radiating chamfering machine used for glass medicine bottle material analysis. The chamfering machine comprises a rack, a grinding disc, a cooling fan, a protective shield, a blowing-type dust collection cloth bag and a glass clamping device, wherein radiator fins are arranged on the lower surface of the grinding disc; the air outlet of the cooling fan faces to the surface of the grinding disc; a dust outlet is arranged on the rack along the air outlet direction of the cooling fan; the blowing-type dust collection cloth bag which is fixedly connected with the dust outlet is arranged on the bottom of the rack; the glass clamping device comprises a rotary lifting rod, a cross rod, a hanging rod, a vacuum sucking disc, a fixed disc and a rotary shaft; the height of the rotary lifting rod can change, and the rotary lifting rod can rotate; the outer diameter of the fixed disc and the outer diameter of the vacuum sucking disc are smaller than the outer diameter of to-be-chamfered glass. According to the self-radiating chamfering machine, the clamped to-be-chamfered glass can rotate automatically, so that each circumferential surface of the to-be-chamfered glass is uniformly chamfered, and the chamfering efficiency is high.

Owner:李平

commutator motor

ActiveCN103999300BDetermine the rotation positionGuaranteed uptimeRotary current collectorDC commutatorEngineeringSliding contact

Owner:ROBERT BOSCH GMBH

A voltage regulator with intelligent protection function

The invention discloses a voltage stabilizer with an intelligent protection function, which belongs to the field of voltage stabilizers. A voltage stabilizer with an intelligent protection function, comprising a coil, a carbon brush and a driving part, characterized in that: the pressure of the carbon brush pressing the coil is constant, and the pressure is regulated by the protection part; the protection part includes a repulsion unit, which is connected with the carbon brush Connect directly or indirectly, and provide the carbon brush with pressure toward the coil direction; and a differential compensation unit, connected with the repulsion unit, and adjust the pressure provided by the repulsion unit; wherein, the pressure value provided by the repulsion unit is the same as the pressure value of the carbon brush toward the coil. The movement value has a linear positive correlation; it can realize that the pressing force of the carbon brush on the upper surface of the coil is always constant, effectively avoiding the problem of excessive wear or poor contact of the carbon brush.

Owner:QUZHOU SANYUAN HUINENG ELECTRONICSAL

Automatic chamfering machine for analyzing materials of glass medicine bottles

InactiveCN106002532APrevent splashHigh degree of automationEdge grinding machinesPreparing sample for investigationEngineeringMechanical engineering

The application discloses an automatic chamfering machine for glass medicine bottle material analysis, which includes a frame, a grinding disc, a cooling water pipe, a protective cover and a glass holding device; the water outlet of the cooling water pipe points to the surface of the grinding disc; the glass holding device includes Rotary lifting rod, cross rod, suspension rod, vacuum suction cup, fixed disc, rotating shaft and the third motor; the height of the rotating lifting rod can be raised and lowered, and can be rotated; the cross rod is fixed on the top of the rotating lifting rod, and the suspension rod passes through the bearing Nested at the bottom of the crossbar, the vacuum suction cup is fixed at the bottom of the suspension rod; the fixed disk is coaxially arranged directly below the vacuum suction cup, and the bottom of the fixed disk is fixedly connected with the rotating shaft, which is driven by the third motor to rotate; fixed The outer diameters of the disc and the vacuum suction cup are all less than three-quarters of the outer diameter of the glass to be chamfered. The application can automatically rotate the clamped glass to be chamfered, so that each circumferential surface of the glass to be chamfered can be evenly chamfered, and the chamfering efficiency is high.

Owner:李玲

Method for tightening screw connections

In order to tighten screw connections, a screw-in torque (17) which is effective during the screwing in of a screw is sensed and a compensation value (18) which is dependent thereon is determined, and the setpoint torque (20) is increased as a function of the previously determined compensation value (18) for the complete tightening of the screw (7).

Owner:ROBEL BAHNBAUMASCH

Cylinder stripper

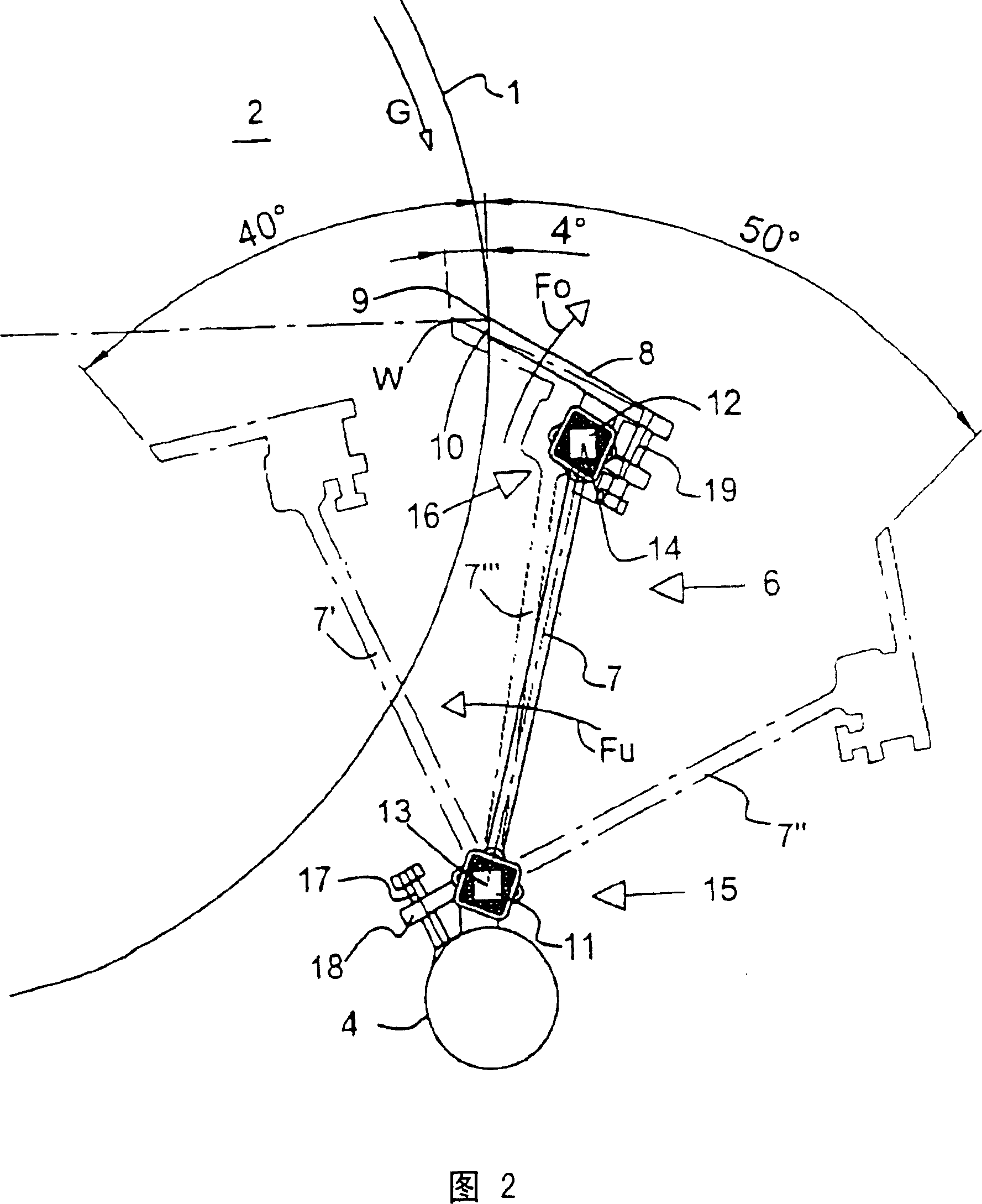

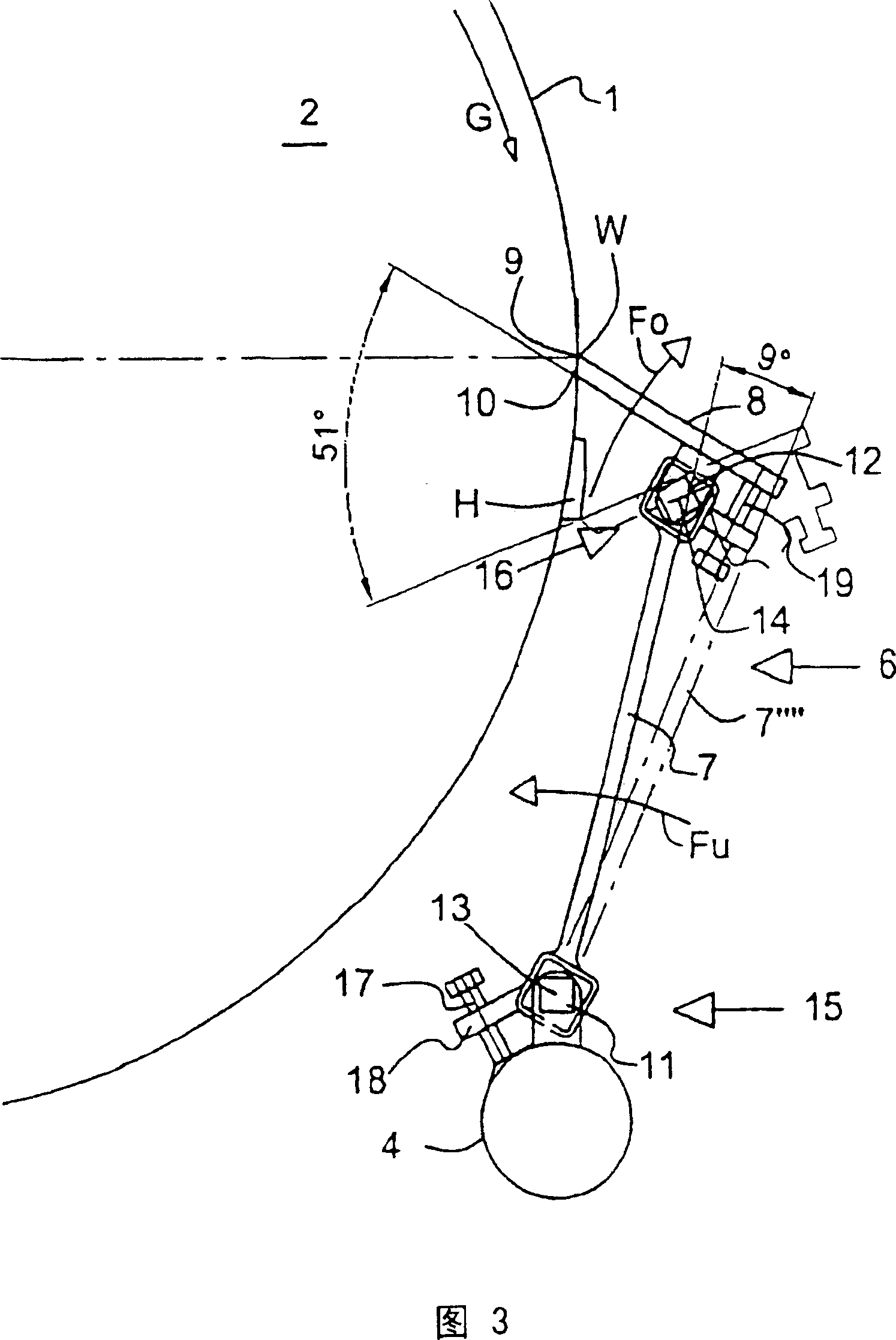

The present invention departs from an apparatus for stripping dirt off belts in conveyor belt assemblies in the area of a drive and / or head pulley of the belt comprising a system carrier to be attached to a belt carrier frame, at which at least one stripping element is arranged, the stripping element having a stripping lamella mounted on a lamella holder, the stripping lamella contacting the belt in a peeling position, and wherein the stripping element has a bottom swivel mount coupled to the lamella holder and having a horizontal swivel axis-indications such as 'horizontal' or the like here and in the following principally refer to the position of use of the stripping element as well as a spring means acting to press the stripping lamella on the lamella holder against the belt in such a form and arrangement that the lamella holder in the stripping position of the stripping lamella is swivelled about the horizontal swivel axis in a spring loaded fashion, and when obstructions fast adhering to the belt impact on the stripping lamella, the lamella holder may be easily deflected and returned back to the working position on the belt. In order for the stripping device to be able to be used in the pulley area of the belt at least as a pre-stripper having uniform stripping performance and long tool lives can be achieved also with high belt velocities associated with correspondingly great material amounts, it is provided that the stripping lamella is swivel mounted at the lamella holder by a top swivel mount having a horizontal swivel axis and is held by a top spring means in a spring biased fashion whose spring action-with respect to the bottom swivel mount and its spring means-is in the counter sense.

Owner:汉斯-奥托·施瓦茨

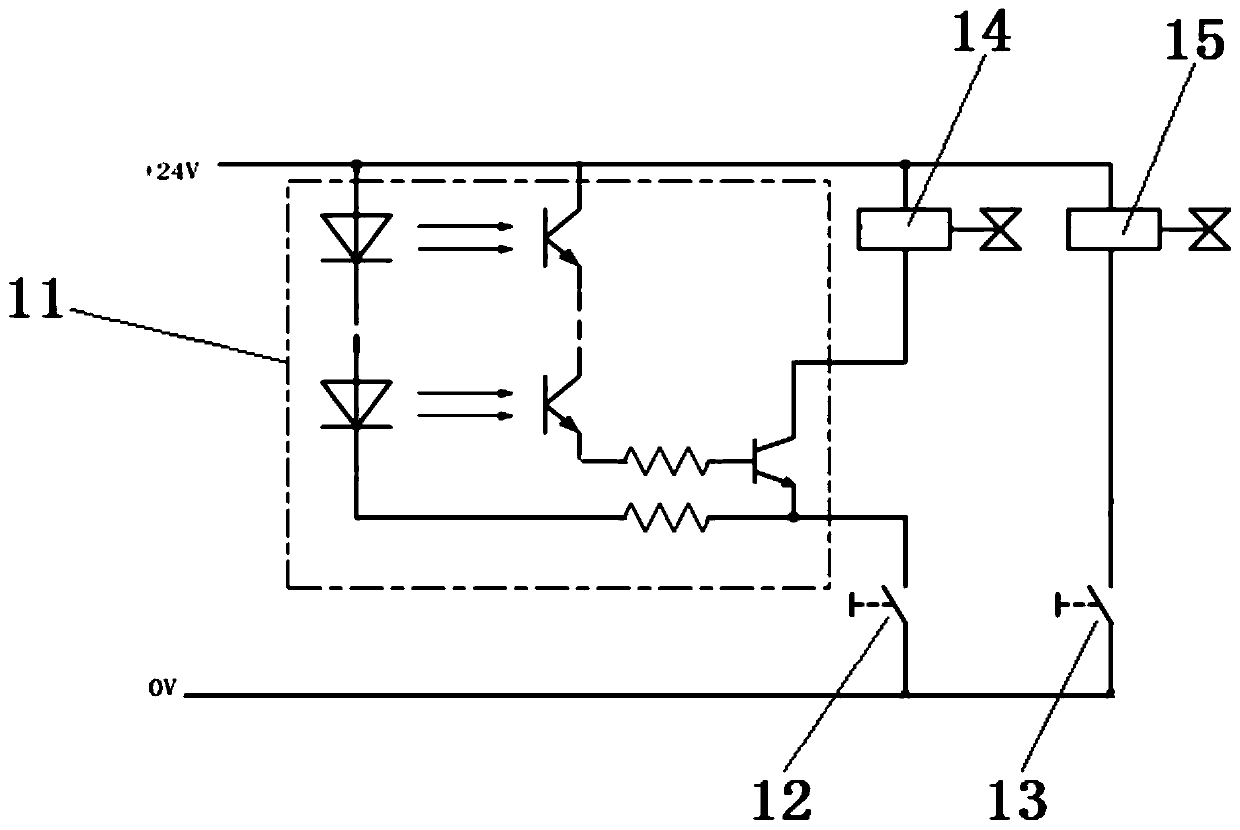

A compression device for vortex air flow test tooling

ActiveCN107782544BPrevent rotational displacementAchieve compactionMachine part testingEngine testingSolenoid valveCompression device

The invention discloses a swirler airflow test tool holddown gear comprising a tool mount body with a disc structure; the middle of the tool mount body is provided with a cavity used for mounting thetest tool; a seal pad is arranged in the cavity; the tool mount body is connected with a cylinder bearer through a plurality of poles; a cylinder is arranged on the cylinder bearer; a compact cavity is arranged between the plurality of poles, and arranged right above tool mount body cavity; a control circuit controlling the cylinder to open / close is provided, and comprises a compact switch controlling the cylinder to move downwards, and a first solenoid valve connected with the compact switch; the control circuit also comprises a loose switch used for controlling the cylinder to move upwards,and a second solenoid valve connected with the loose switch; the first and second solenoid valves are respectively connected with the air inlet of the cylinder through a cylinder current limiter; thedevice is reliable in sealing, can conveniently and fast clamp the test tool, and safe and reliable, thus preventing the experiment data inaccurate problems caused by gas leakage.

Owner:AECC AVIATION POWER CO LTD

An ultra-precise friction drive mechanism

ActiveCN104405837BHigh positioning accuracyBacklash-free movementMechanical energy handlingFriction gearingsGratingDrive wheel

The invention discloses an ultraprecise friction driving mechanism. The mechanism mainly comprises a driving part, an auxiliary support part, a pressing part and an eccentric pressing part, wherein stable and precise rotation positioning is provided by the driving part, a torque motor is directly connected with a friction driving shaft, a driving error caused by intermediate transmission links is reduced, a circular grating is connected to the other end of the driving shaft, and the angular precision of a driving wheel is measured; through the auxiliary support part, the deflection deformation of the tail end of a driven rod is reduced, the position precision of the driven rod is guaranteed, so as to achieve the effects of auxiliary support and fine-tuning positioning, wherein the displacement output by an eccentric wheel structure is converted into pressing force by a pressure reed, and a driving wheel system and a friction guide rod are pressed through a prepressing wheel system; through the eccentric pressing part, accurate displacement output can be provided for the pressure reed, the pressing force can be conveniently adjusted, and the change of the pressing force can be monitored in real time by a pressure sensor installed on an eccentric wheel driven component, so as to satisfy the controllable requirement on the pressing force.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Compound die for cup punching for steel shell

PendingCN113600685AShort tripEliminate lip defectsShaping toolsStripping-off devicesPunch pressStructural engineering

The invention discloses a compound die for cup punching for a steel shell. The compound die for cup punching for the steel shell comprises an upper die part and a lower die part, wherein the upper die part is divided into an upper die for blanking and an upper die for stretching, the upper die for stretching is fixed to the bottom surface of a punch press sliding block, the upper die for blanking is in floating connection with the lower die part, the lower die part comprises a lower die, a discharging plate and a stripping device, and the upper die for blanking comprises an upper knife edge for blanking, a pressing ring and a pressing spring; and the upper die for stretching comprises a stretching punch and a nitrogen spring, when the sliding block moves downwards, the upper die for stretching moves downwards, the nitrogen spring abuts against the upper die for blanking and pushes the upper die for blanking to move downwards, a limiting column is arranged on a lower die fixing plate, when the upper die for blanking moves downwards and abuts against the limiting column, the upper die for blanking and the lower die are matched to complete blanking and pressing, the sliding block continues moving downwards, the stretching punch completes stretching, and when the sliding block moves upwards, the stripping device completes stripping for the cup shell. The compound die for cup punching for the steel shell is reasonable in structure, can stably and reliably realize the four actions of blanking, pressing, stretching and stripping so as to realize a stable, reliable and continuous cup punching process, and can basically eliminate the defects of the rim of the cup shell and increase the production efficiency.

Owner:NINGBO GUANGHUA BATTERY

Separating type stuffing box

The invention discloses a separating type stuffing box comprising a hollow box body with an opening facing toward an upper bonnet, V-shaped fillers in the box body and a filler gland arranged on the box body. The upper bonnet is provided with a chamber accommodating the box body. The bottom face, of the lower end of the opening of the box body, is closely attached to the bottom face of the chamber of the upper bonnet. The box body is detachably connected with the upper bonnet. The separating type stuffing box is simple in structure, handy and practical.

Owner:CHONGQING CHUANWU INSTR

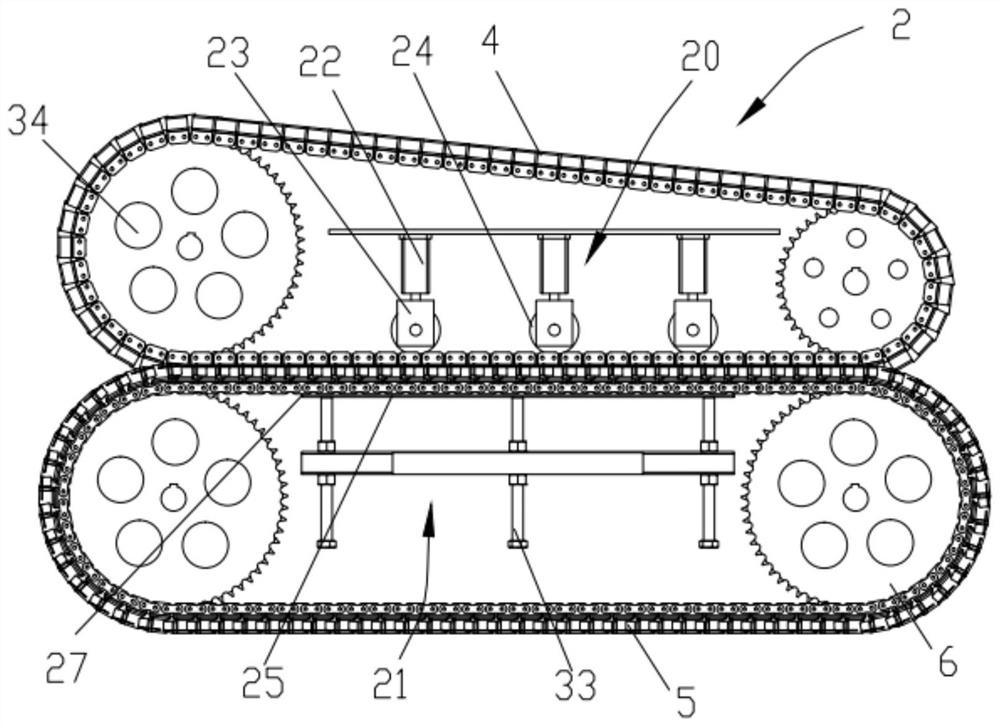

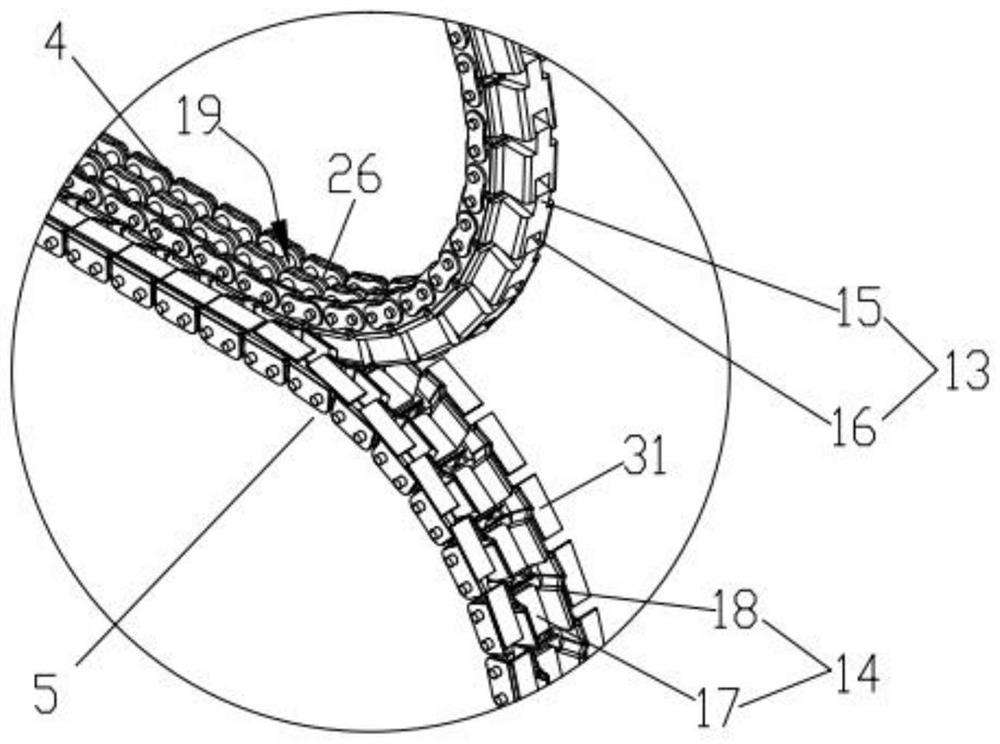

A ramie clamping and conveying device and a ramie stripping device thereof

ActiveCN111254501BAvoid pulling out problemsAvoid loud noiseMechanical fibre separationEngineeringSprocket

The invention discloses a ramie clamping and conveying device and a ramie stripping device thereof, wherein the conveying device comprises a frame and a clamping and conveying chain, and the clamping and conveying chain is relatively installed on the upper and lower sides of the frame, and any one of the clamping and conveying There are sprockets engaged on the chains, and the characteristic is that elastic pressing blocks are installed on the clamping conveying chain on one side of the frame, and concave clamps that can engage with elastic pressing blocks are installed on the clamping conveying chain on the other side of the frame , the head and tail ends of the adjacent elastic pressing blocks and the head and tail ends of the adjacent concave clamps are seamlessly engaged in the conveying direction of the ramie. In the present invention, the head and tail ends of the elastic briquetting blocks and the head and tail ends of the adjacent concave clamps are seamlessly engaged in the conveying direction of ramie, so that in the conveying direction of ramie, ramie stalks or fibers squeeze into the adjacent elastic briquetting blocks Or in the gap between adjacent concave clamping boards, thereby avoiding the problem that the ramie stalks or fibers are directly pulled out by the stripping boards.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

A belt conveyor constant pressure cleaning system with automatic compensation function

The invention belongs to the technical field of transportation machines and provides a constant-pressing-force sweeping system used for a ribbon conveyer and having an automatic compensation function. By the adoption of the constant-pressing-force sweeping system, the contact force between a scraping plate and a conveying belt is constant, and an ideal cleaning effect is achieved. The constant-pressing-force sweeping system used for the ribbon conveyer and having the automatic compensation function comprises a sweeper assembly, a rotating assembly, a hydraulic system and an electric control system. The rotating assembly is connected with a sweeper and a piston rod of a hydraulic cylinder of the hydraulic system. The electric control system detects and controls pressure information of the hydraulic cylinder. When the conveyer is stopped, the scraping plate is controlled to be separated from the conveying belt, so that the starting resistance when the conveyer is started next time is reduced; after the conveyer is started, the scraping plate is controlled to rapidly make contact with the conveying belt, and the set pressing force is obtained; when the scraping plate is abraded, an oil cylinder is automatically replenished with oil, and the effect that the pressure in the oil cylinder is constant is guaranteed; and when the scraping plate is abraded to the limit, the conveyer is stopped, and an alarm is given. By the adoption of the constant-pressing-force sweeping system, the starting resistance of the conveyer can be reduced, the pressing force between the scraping plate and the conveying belt is automatically controlled to be constant, and the sweeping efficiency and the automation degree are improved.

Owner:YULIN S&G COAL MINE MACHINERY

Constant-force pressing adjusting device for sealing surface cleaning operation

PendingCN112643511ASimple structureWith adaptive flexible adjustment functionGrinding drivesGrinding machinesSurface cleaningPolishing

The invention relates to the technical field of grinding and cleaning, and particularly discloses a constant-force pressing adjusting device for sealing surface cleaning operation. The device comprises a cleaning assembly, a spring assembly, a limiting screw assembly and an equipment carrying trolley, and the cleaning assembly is limited and fixed to the equipment carrying trolley through the limiting screw assembly; the distance between a grinding and polishing wheel in the cleaning assembly and the fixed sealing surface to be cleaned and ground where the equipment carrying trolley is located can be adjusted through the limiting screw assembly; and the spring assembly is arranged on the cleaning assembly, and the compression amount of the spring assembly is increased along with reduction of the distance between the cleaning assembly and the sealing surface to be cleaned and ground. The device is simple in structure, and the pressing force and the grinding force before operation can be adjusted without extra tools and operation experience; and meanwhile, the device has a self-adaptive flexible adjusting function, it can be guaranteed that the pressing force and the grinding force are constant in the operation process, and the device can work for a long time in a severe environment.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Automatic dumbbell-shaped sampling machine

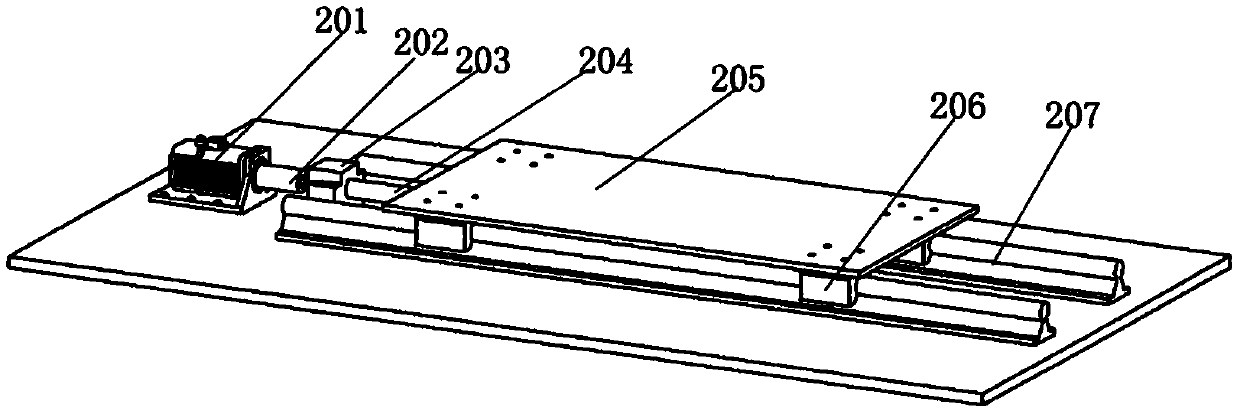

ActiveCN109702250AAvoid precisionAvoid timeMilling equipment detailsMilling cutterMetallic materials

An automatic dumbbell-shaped sampling machine comprises a machine frame; a longitudinal reciprocating moving platform and a transverse moving platform are installed on the machine frame, the longitudinal reciprocating moving platform is provided with a fixture body and an explorator, and the transverse moving platform is provided with a milling cutter; and the front portion and the rear portion ofthe transverse moving platform are provided with counter weight devices correspondingly which are the same, and the milling cutter abuts against the explorator under pressing force action of the counter weight devices. The automatic dumbbell-shaped sampling machine achieves the effects that the automation degree of the manufacturing process is high, the pressing force between the milling cutter and a sample is constant, and milling one-time forming is conducted.

Owner:承德石油高等专科学校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com