Separating type stuffing box

A stuffing box, separate technology, applied in the direction of valve details, engine components, shaft seals, etc., can solve the problems of increasing the difficulty of processing and installation, affecting the sealing performance of stuffing box, and damage to V-shaped packing, so as to achieve simple structure, reduce Effect of small size and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

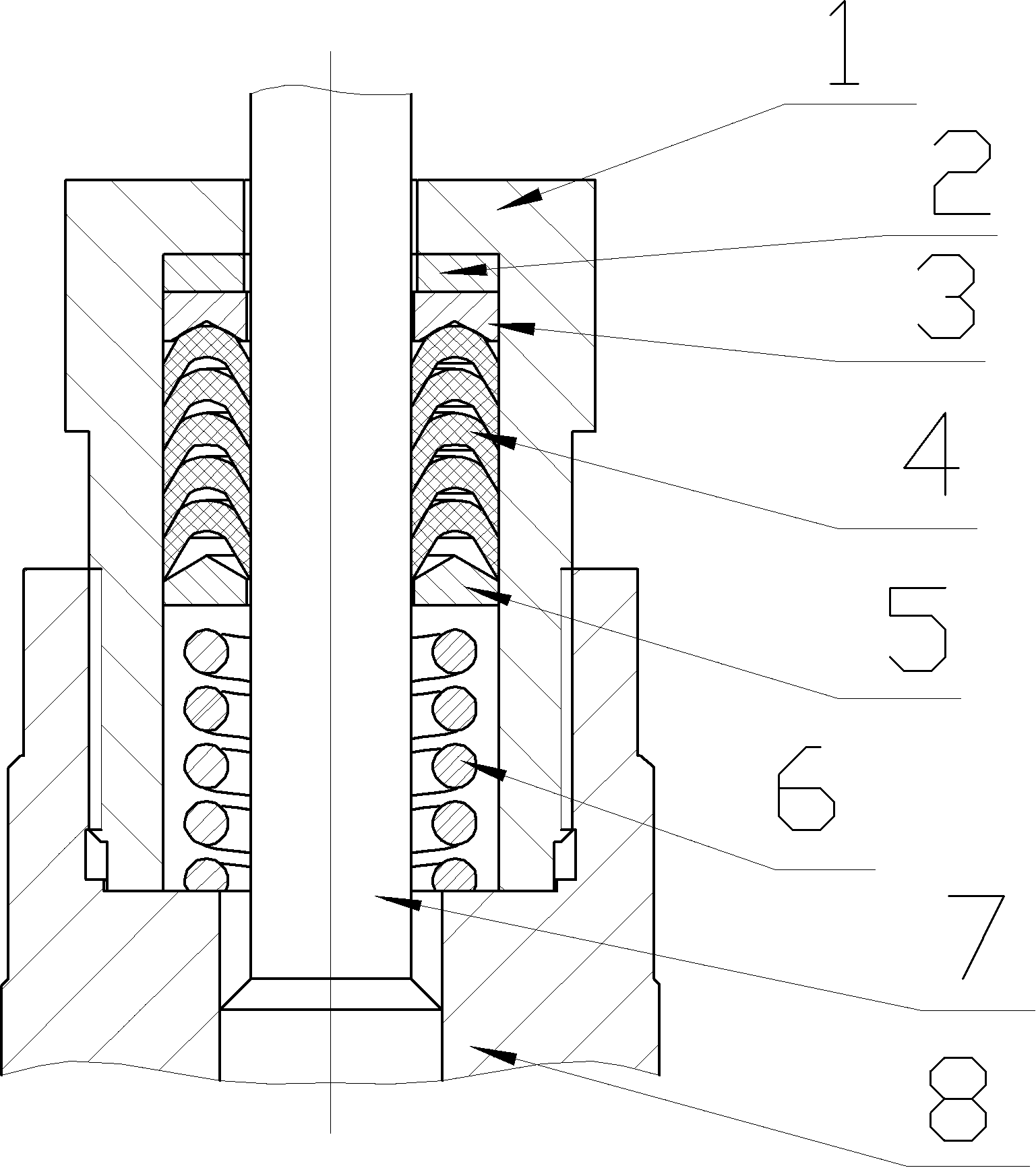

[0017] like figure 1 As shown, the separate stuffing box includes a hollow box body 1 with the opening facing down and a V-shaped packing 4 located in the stuffing chamber of box body 1, and also includes a packing gland on box body 1, and the stuffing gland and box body 1 is integrated, which is convenient for processing. The upper valve cover 8 is provided with a chamber that can accommodate the box body 1. The lower end surface of the box body 1 is closely attached to the bottom surface of the upper valve cover 8 chamber. The gap between the box body 1 and the upper valve cover 8 Threaded connection; the valve stem 7 passes through the packing gland, spacer 2, upper bushing 3, V-shaped packing 4 and lower bushing 5; the upper and lower sides of the V-shaped packing 4 in the box are respectively equipped with an upper bushing 3 and a lower bushing 5 , the lower part of the upper bushing 3 is provided with a V-shaped groove for fixing the V-shaped packing 4, and the lower bus...

Embodiment 2

[0020] The difference from the first embodiment is that the packing gland and the box body are connected by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com