Method for tightening screw connections

A technology for tightening screws and screws, which can be used in screwdrivers, rails, rail maintenance, etc., and can solve different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

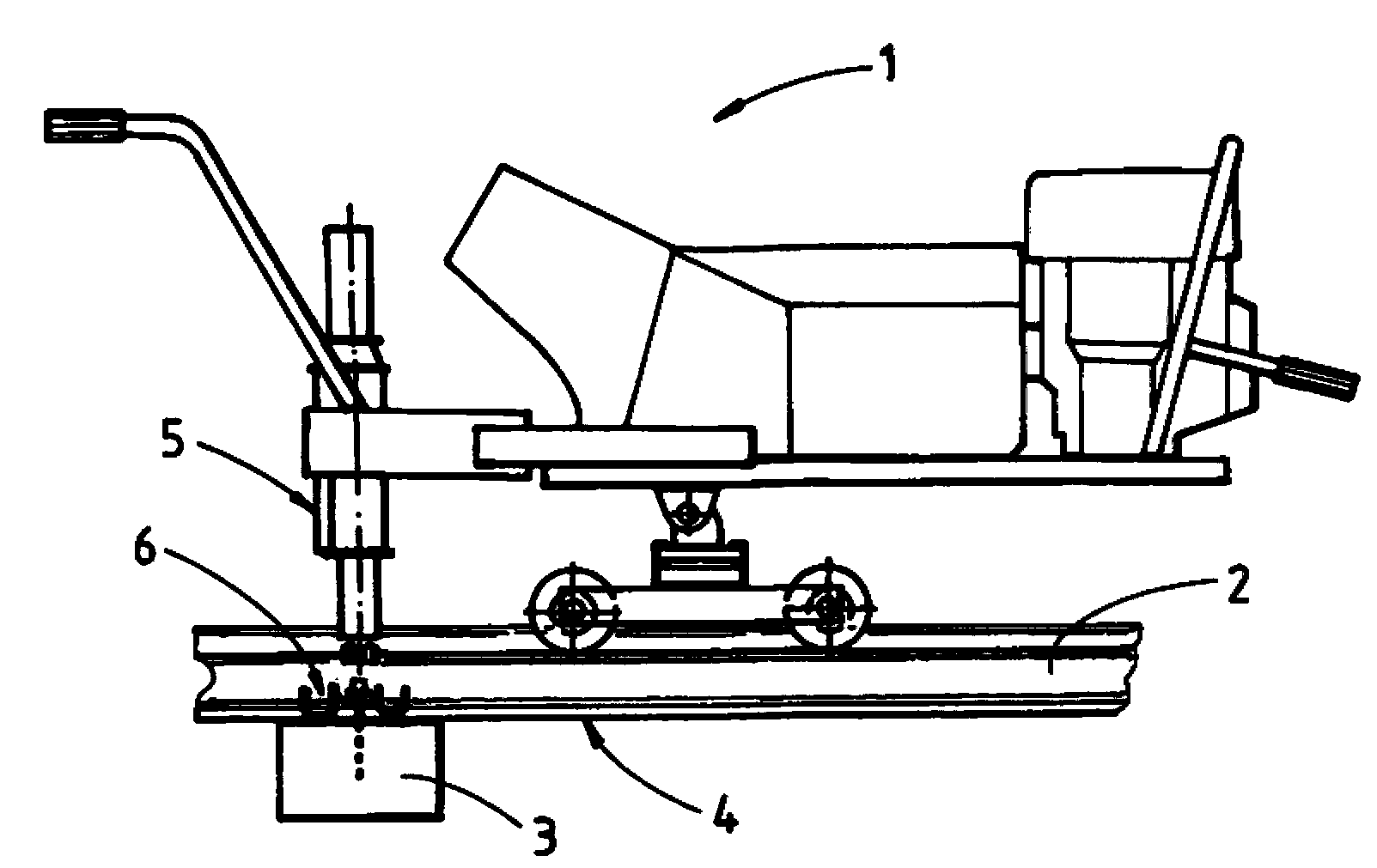

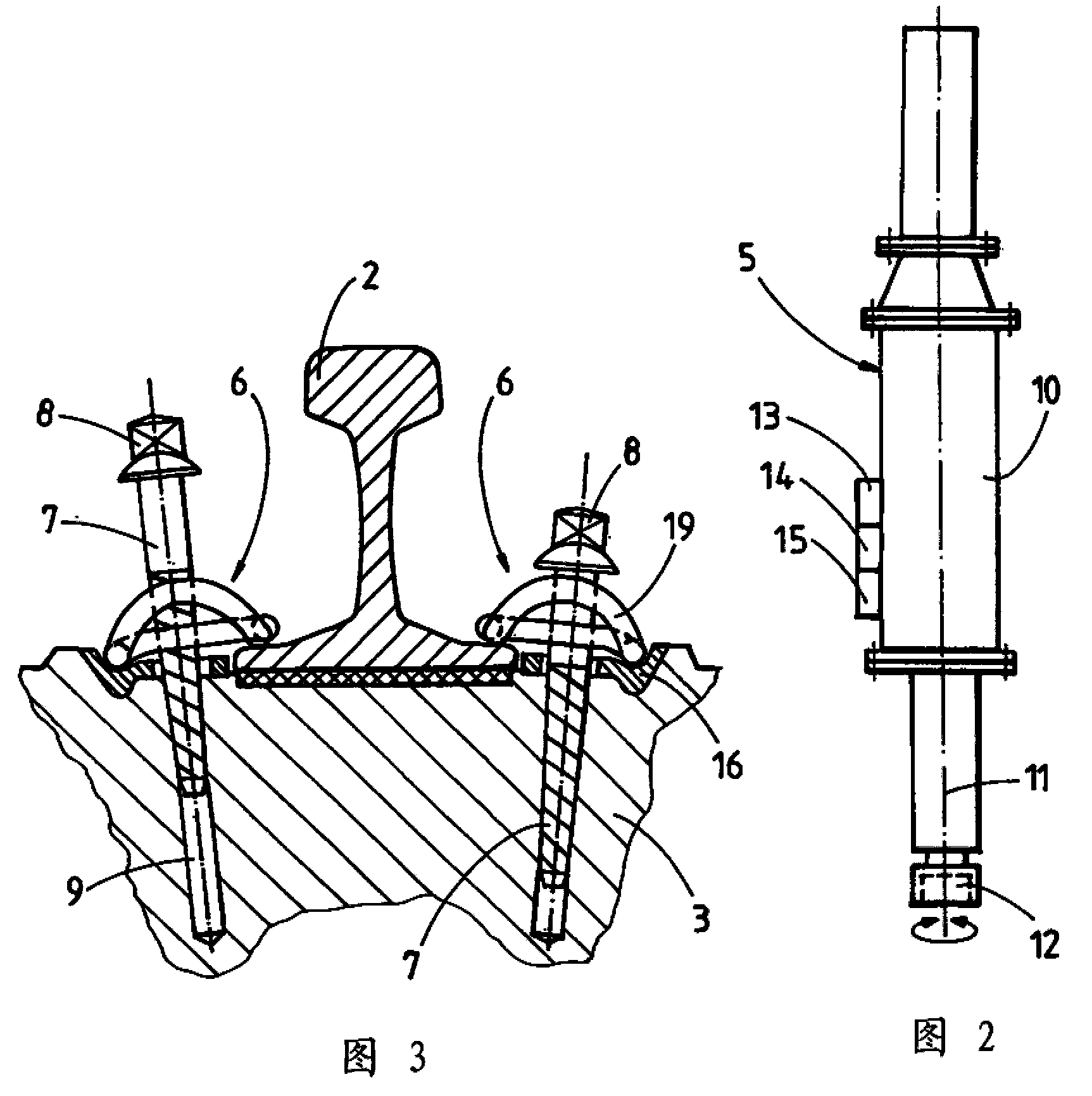

[0009] figure 1 The screw tightening machine 1 seen in is movable on a rail 4 formed by rails 2 and sleepers 3 and is equipped with a vertically adjustable servo screw drive 5 . These parts are used for fastening screw connections 6, according to image 3 In the example shown in more detail, the screw connection comprises a screw 7 with a screw head 8 and a screw hole 9 on the sleeper 3 .

[0010] From figure 2 It can be seen that each servo screw driver 5 has a servo motor 10 and a wrench 12 rotatable about an axis 11 . Furthermore, a processor 13 equipped with a data memory is connected to a rotation angle measurer 14 and a torque sensor 15 .

[0011] Such as image 3 It can be seen that the spring clip-shaped fastening device 19 is arranged between the rail head 8 and the base plate 16 on the sleeper 3 . The spring clips are in contact with the base plate 16 and the rail 2 .

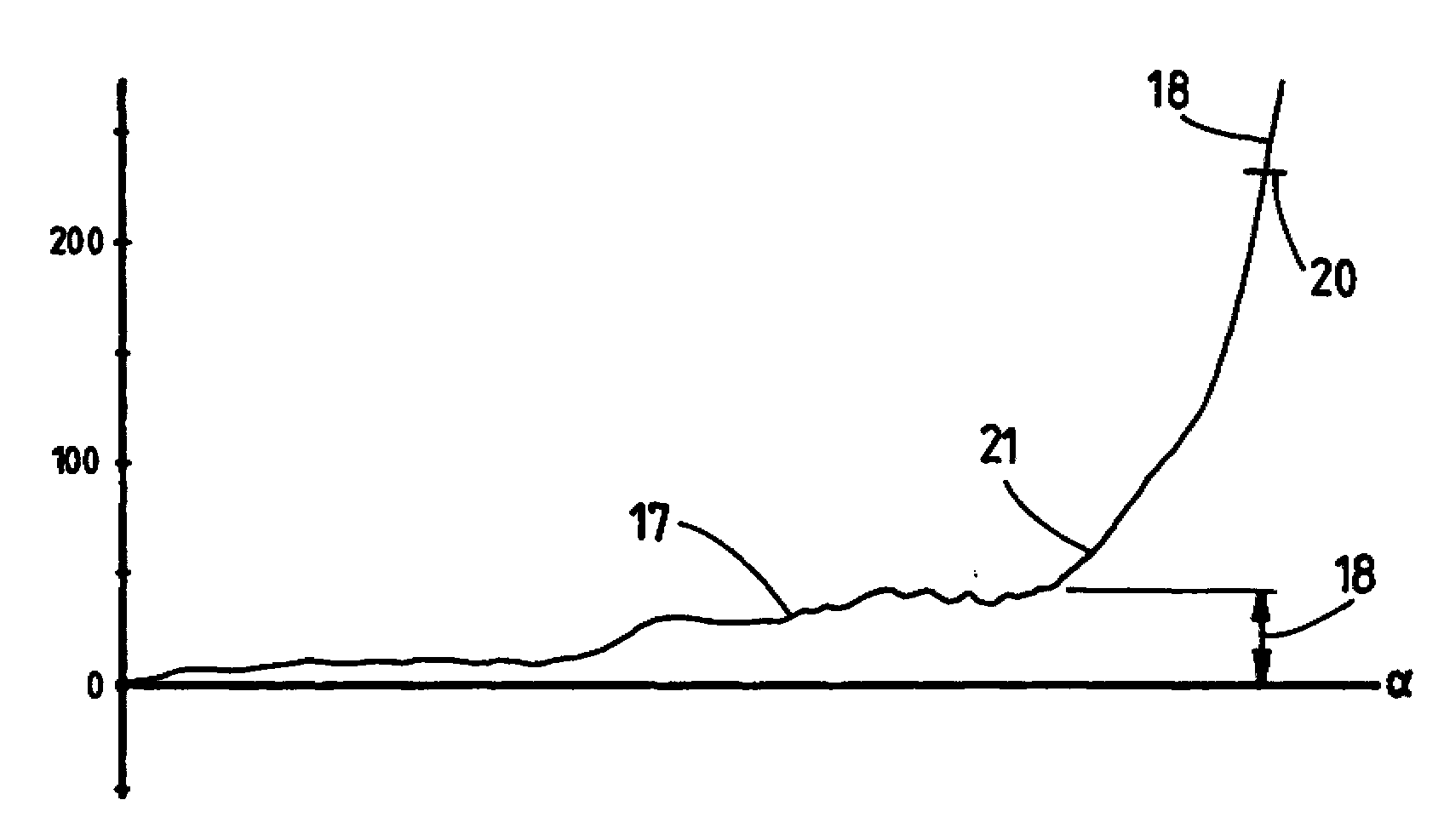

[0012] Starting from the starting position shown in the left half of the figure, the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com