Compound die for cup punching for steel shell

A technology of shell punching cups and composite molds, which is applied in metal processing equipment, stripping devices, forming tools, etc., can solve the problems of unfavorable step-by-step stretching, large difference, and large moving distance of the binder ring 1.4, etc., and achieves easy control, Reliable material removal and the effect of eliminating the defects of the edge of the cup shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

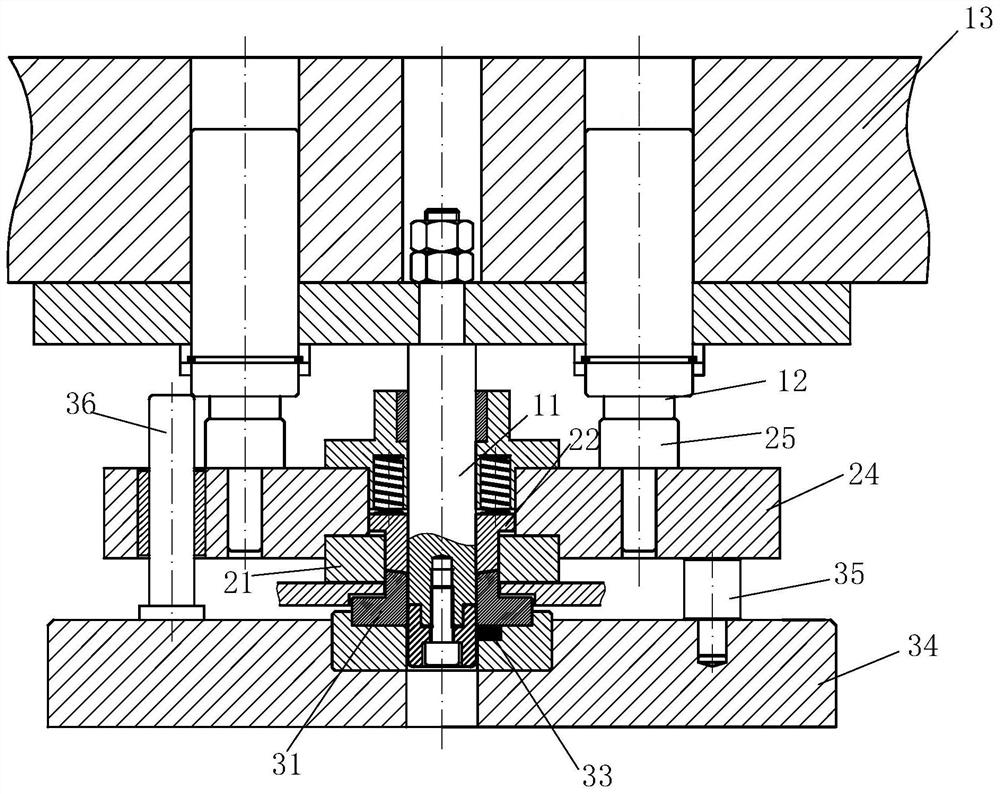

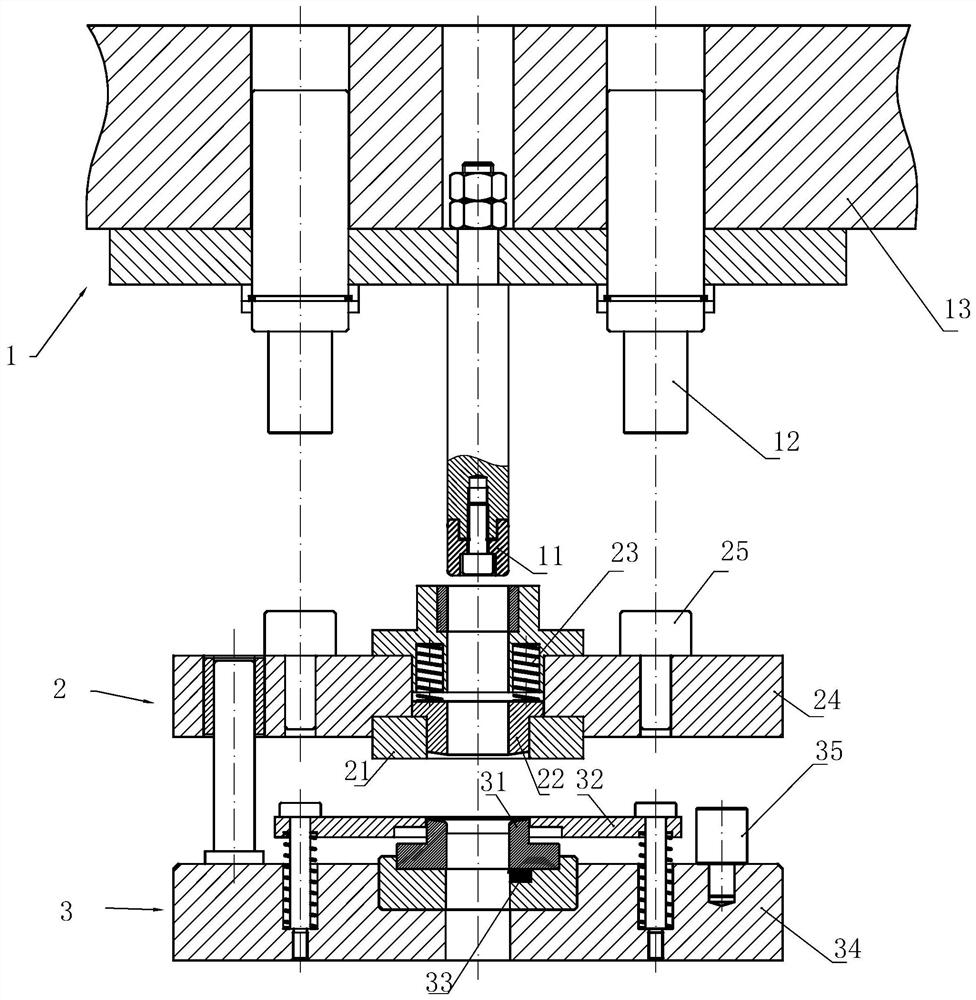

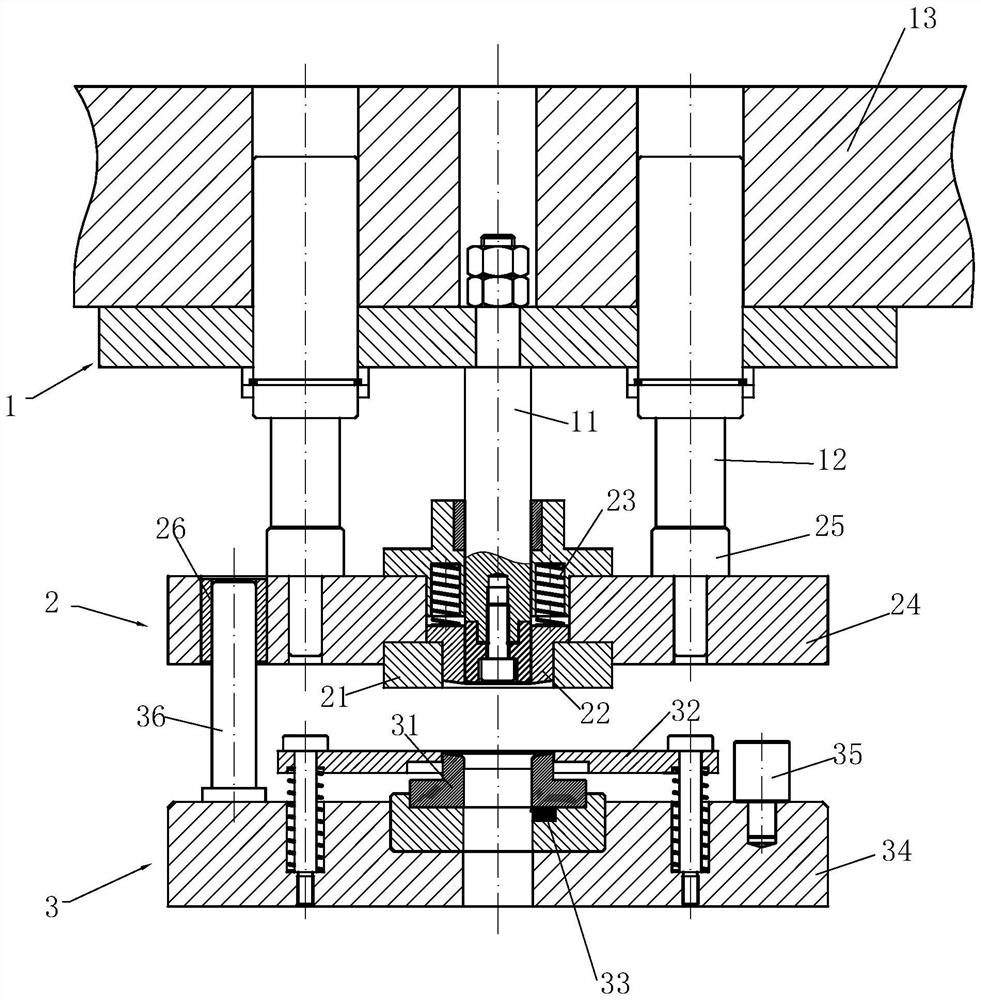

[0024] Such as Figure 1~3 As shown in the figure, a steel shell punching cup composite mold includes an upper mold part and a lower mold part 3, and the upper mold part is divided into two parts: a blanking upper mold 2 and a drawing upper mold 1, wherein the drawing upper mold 1 is fixed on a punching machine The bottom surface of the slider is located above the blanking upper die 2, and the blanking upper die 2 is located above the lower die part 3 and is connected to the lower die part 3 in a floating manner. Lower die part 3 comprises lower die 31, stripper plate 32, stripper 33 and lower die fixed plate 34, lower die 31, stripper plate 32, stripper 33 are installed on the lower die fixed plate 34 and fixed by the lower die Plate 34 is secured to the punch table. Blanking upper die 2 includes a blanking upper knife edge 21 , a pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com