Hydraulic constant-torque heavy-section sweeper for belt conveyor

A technology of constant torque and cleaner, applied in the direction of conveyor objects, conveyor control devices, cleaning devices, etc., can solve the problems of heavy maintenance workload, short service life, high replacement frequency, etc., achieve small maintenance workload and improve use The effect of high life, automation and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

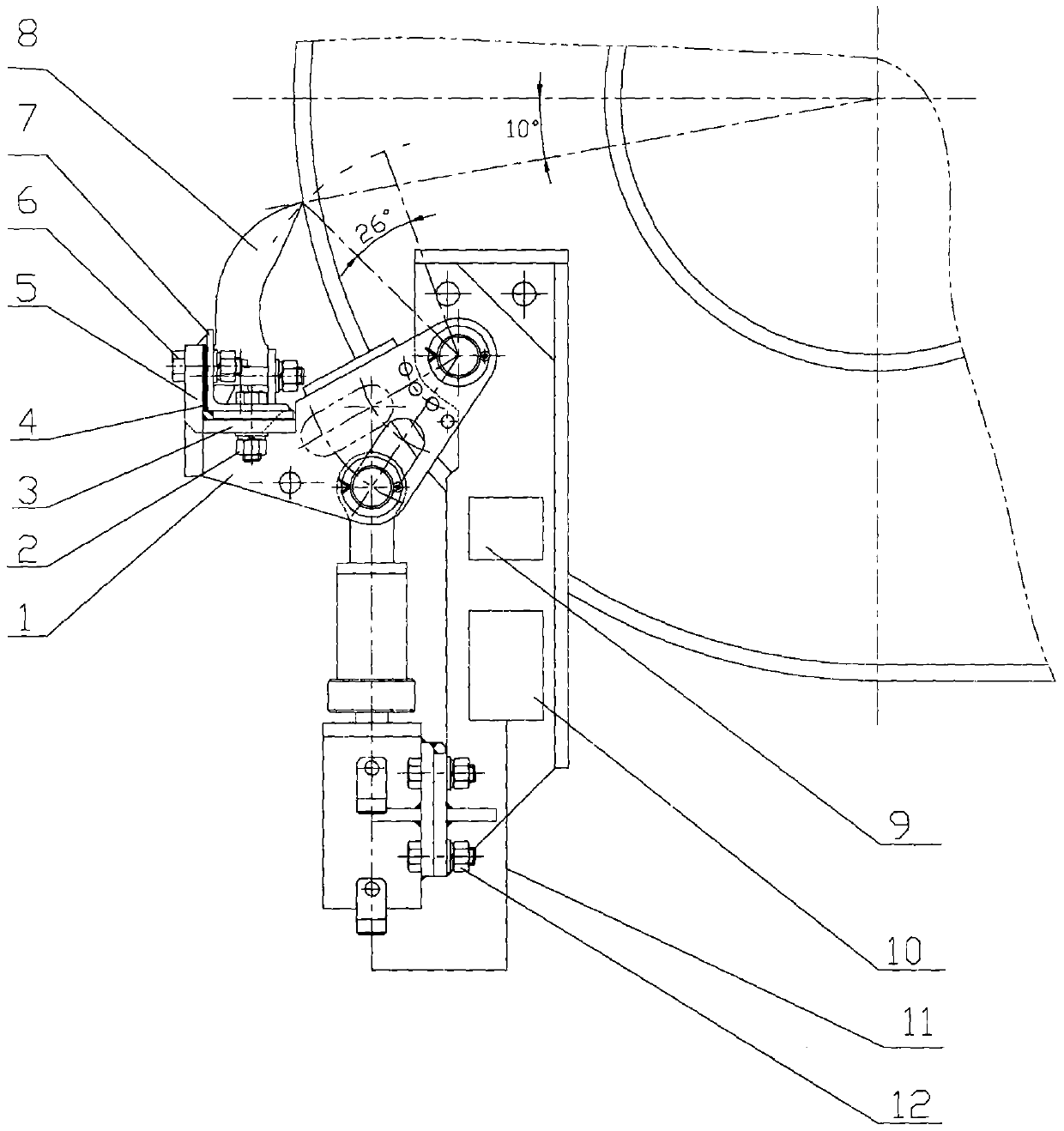

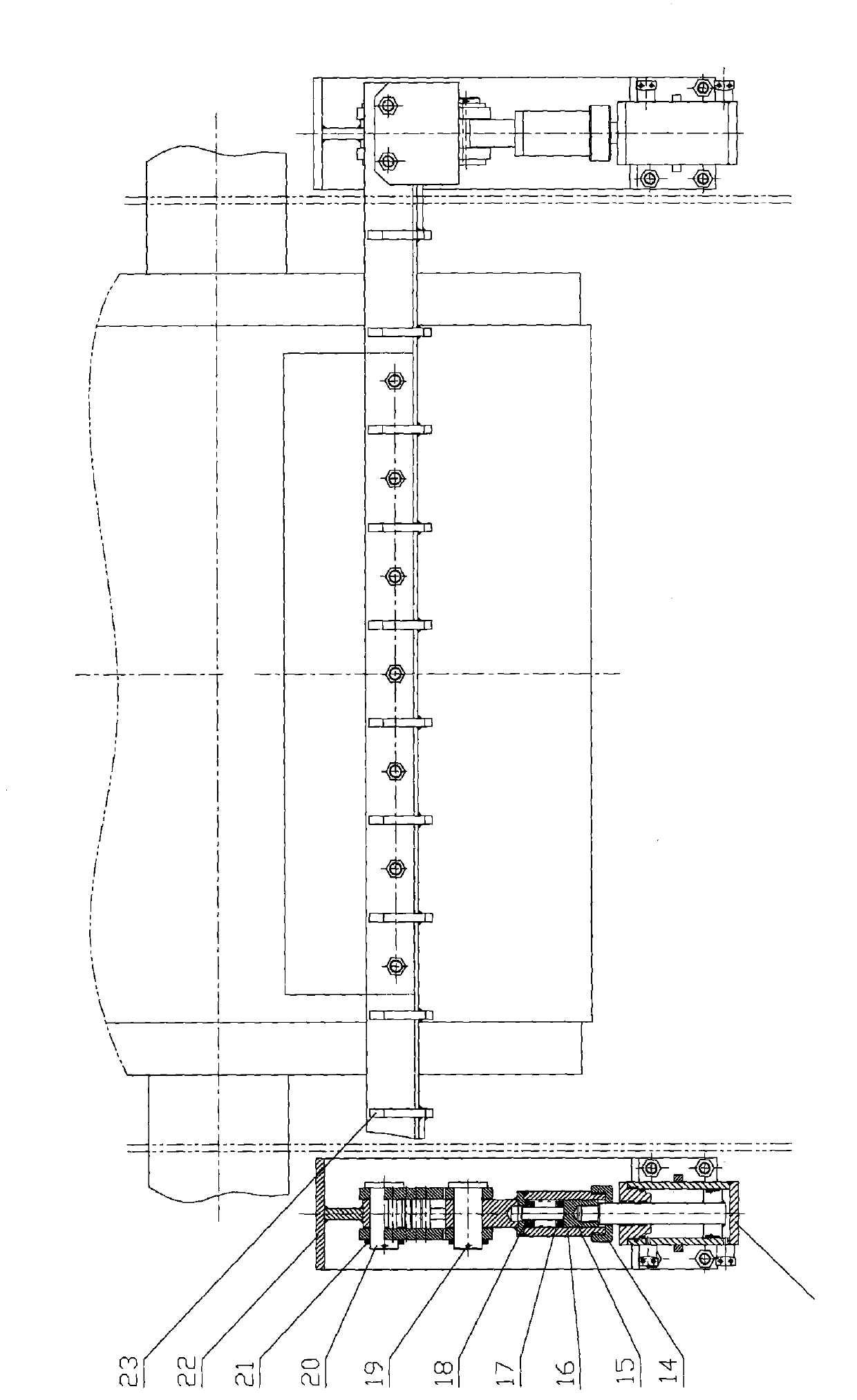

[0013] exist figure 1 , 2 Among them, the angle steel frame (7) and the cleaning block (8) are connected together by bolts to form a cleaning block assembly. In order to ensure the strength of the cleaning block assembly, 10 rib plates (23 ); the support plate (3), the reinforcement plate (5) and the rotating arm (1) are welded together to form a rotating mechanism, and the cleaning block assembly is fixed together with the rotating mechanism through bolts (2), (6), and the cleaning block (8) The contact gap with the adhesive tape can be realized by adding or subtracting the adjusting gasket I (4) on the back of the angle steel frame (7); the rotating mechanism is respectively connected with the fixed frame (22) and the connecting rod ( 16) and lock the pin shaft (20) through the cotter pin (19) and retaining ring (21); the other end of the connecting rod (16) is connected with the piston rod in the hydraulic cylinder (13) to transmit the hydraulic pressure Force, to drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com