Pressing plate assembly for self-adjusting clutch cover assembly device

A clutch cover and self-adjusting technology, applied in the field of auto parts, can solve the problem of automatic compensation for the thickness of the friction plate of the driven disc, etc., and achieve the effect of convenient mass production, reasonable overall structure design, stable and accurate compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

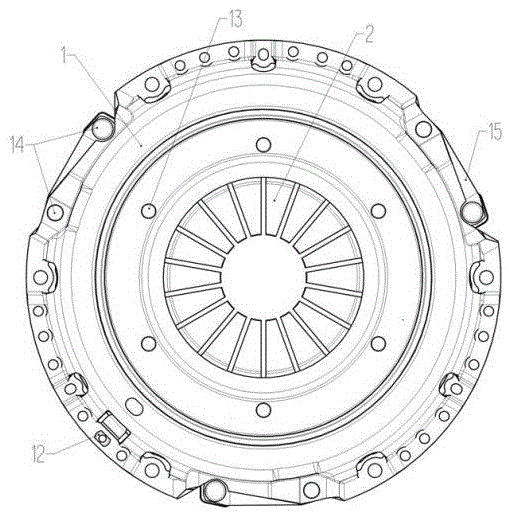

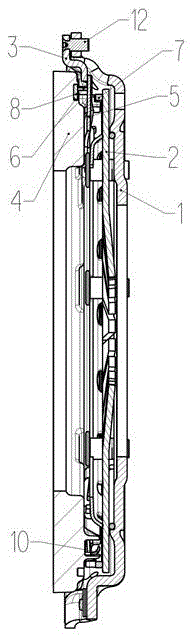

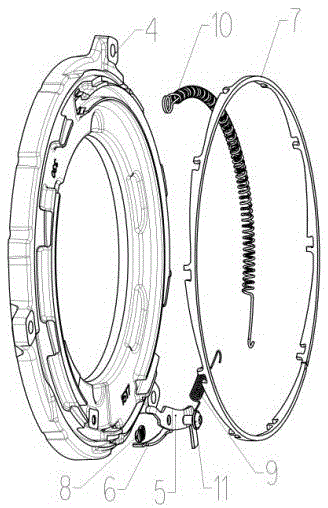

[0033] The present invention relates to a self-adjusting clutch cover assembly, which includes a cover 1, a diaphragm spring 2, a blocking block 3, a pressure plate 4, a compression spring 5, a rack 6, an adjustment ring 7, a toothed block 8, a small Helical spring 9, large helical spring 10, bolt 11, limit rivet 12, support rivet 13, fixed rivet 14, transmission belt 15.

[0034] figure 1 It is the front view of the self-adjusting clutch cover assembly device of the present invention. figure 2 Yes figure 1 cutaway view. Wherein, the support rivet 13 rivets the diaphragm spring 2 and the cover 1 of the clutch together. One end of the transmission belt 15 is fixedly connected to the cover 1 through the fixing rivet 14 , and the other end is fixedly connected to the pressure plate 4 through the fixing rivet 14 , thereby connecting the pressure plate 4 and the cover 1 together.

[0035] image 3 It is a schematic diagram of the component parts of the pressure plate assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com