Glass chamfering device capable of preventing cooling water from shortage

A chamfering device and cooling water technology, which is applied in the direction of adsorption water/sewage treatment, grinding/polishing safety device, flocculation/sedimentation water/sewage treatment, etc. It can solve problems such as unsafe, small glass, and difficult to hold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

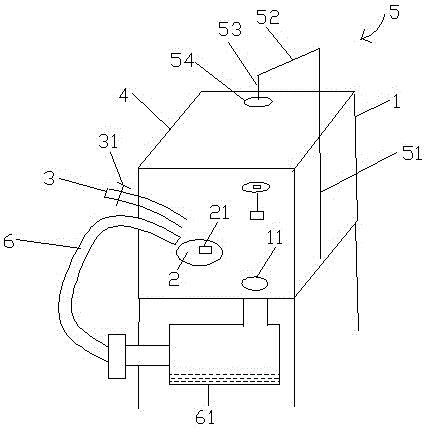

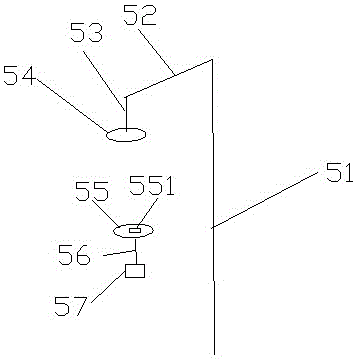

[0023] Such as figure 1 and figure 2 As shown, a glass chamfering device capable of preventing water shortage in cooling water, which includes a frame 1, a water outlet 11, a grinding disc 2, a temperature sensor 21, a water pipe 3, a solenoid valve 31, a protective cover 4, and a glass holder Main technical features such as device 5, rotating lifting rod 51, cross bar 52, suspension rod 53, vacuum suction cup 54, fixed disk 55, pressure sensor 551, rotating shaft 56, third motor 57, circulating water pipe 6, circulating water tank 61.

[0024] A glass chamfering device capable of preventing cooling water shortage, comprising a frame, a grinding disc, a running water pipe, a circulating water pipe, a protective cover and a glass clamping device.

[0025] The grinding disc is arranged on the top of the frame, and the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com