Thermal forming machine

A thermoforming machine and frame technology, applied in the field of thermoforming machines, can solve problems such as the inability to change the height of the closed mold, pollute the internal environment of the workshop, and increase the labor intensity of operators to clean the workshop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

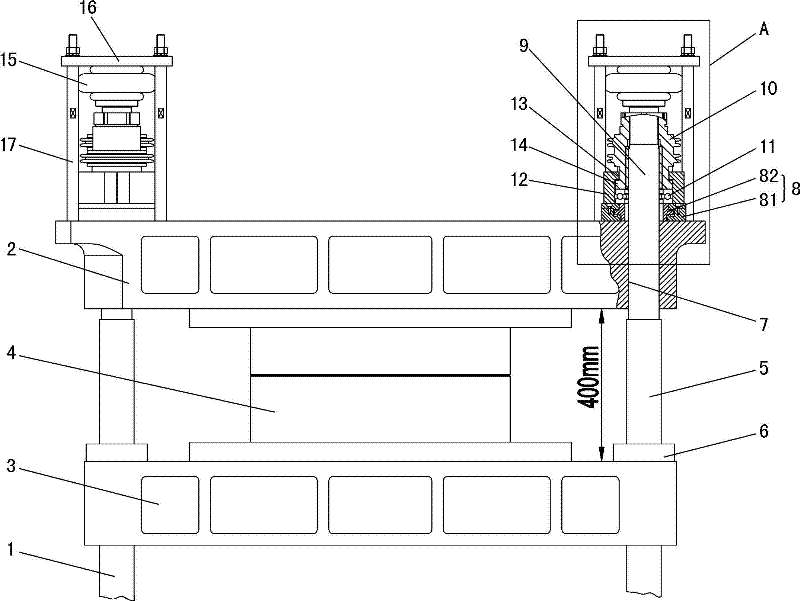

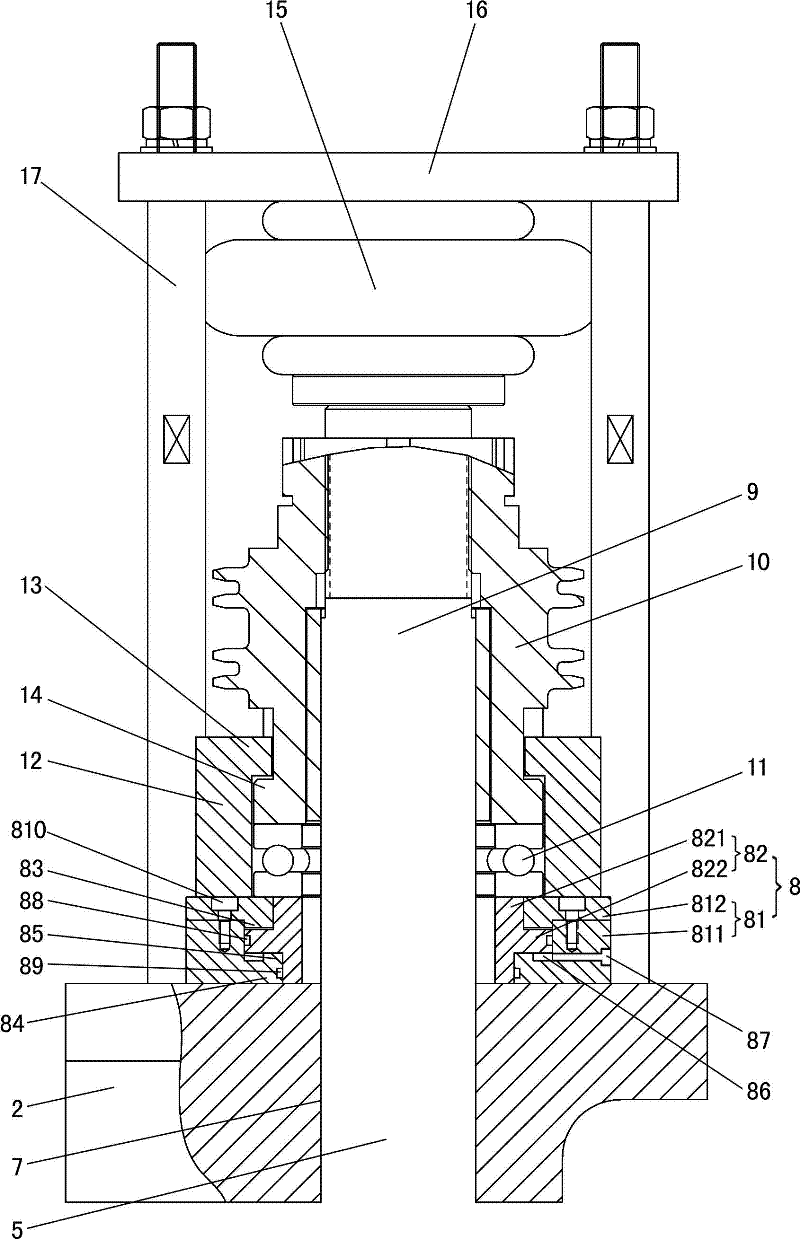

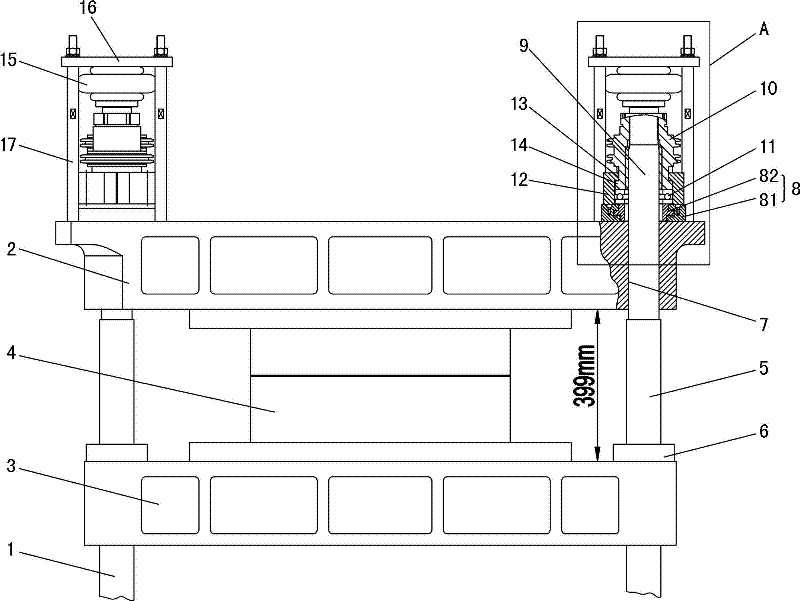

[0026] Such as Figure 1 to Figure 4 As shown, this thermoforming machine includes a frame 1, a fixed mold table 2, a movable mold table 3, a lifting drive mechanism for the movable mold table (the lifting drive mechanism for the movable mold table can use an existing mechanism, and will not be described in detail here) and a fixed mold table. Die table position adjustment mechanism.

[0027] Die 4 is installed on the fixed mold platform 2, the movable mold platform 3, the movable mold platform lifting drive mechanism is a cam mechanism (or connecting rod mechanism), and the movable mold platform 3 is connected with the power output end of the movable mold platform lifting drive mechanism.

[0028] The frame 1 includes four guide posts 5 going up and down; the movable mold table 3 is provided with four first guide sleeves 6, and the first guide sleeves 6 are matched with the guide posts 5 one by one, and the guide posts 5 are in the first guide posts. In the cover 6; the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com