Aluminum-titanium-silicon carbide composite refractory castable for iron-making blast furnace

A technology of aluminum-titanium-silicon carbide and refractory castables, which is applied in the field of aluminum-titanium-silicon carbide composite refractory castables for iron-making blast furnaces, which can solve the problems of inability to obtain service life of the device, loss of cooling equipment protection function, thinning of refractory lining, etc. problems, to achieve the effects of convenient construction, improved chemical erosion, and high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

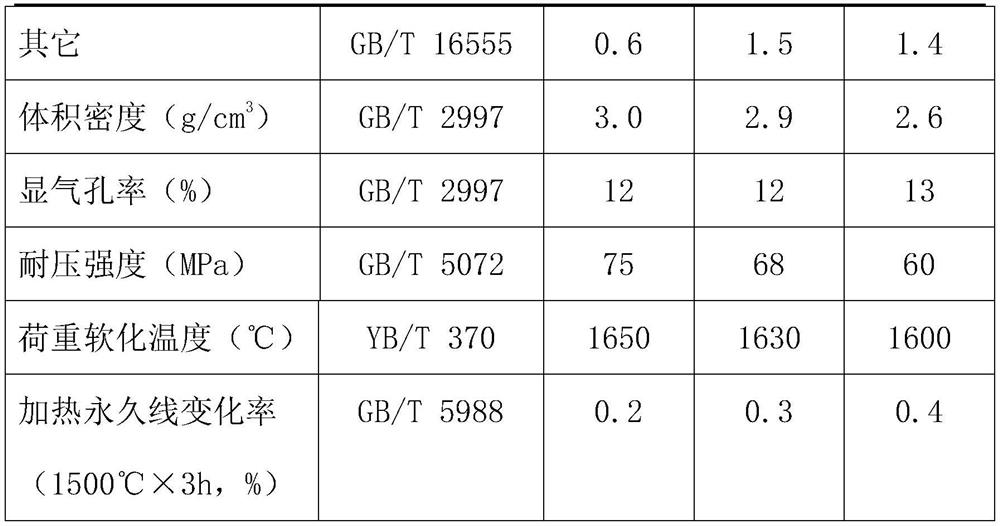

[0020] The specific implementation of the present invention is to combine fused corundum particles, silicon carbide particles and 13% TiO 2 (mass percentage), 82% Al 2 o 3 (Mass percentage) Aluminum-titanium composite raw materials are mixed into a mixture according to the material ratio of the process, and then mixed with silicon carbide fine powder, α-alumina fine powder, silica fine powder, calcium aluminate cement, sodium tripolyphosphate, water reducing agent, according to the process The material ratio is weighed and then mixed to obtain the aluminum-titanium-silicon carbide composite refractory castable for ironmaking blast furnaces of the present invention.

[0021] See Table 1 for the specific composition of the aluminum-titanium-silicon carbide composite refractory castable for ironmaking blast furnaces in this embodiment and the technical performance of sample preparation and testing. The binding agent used in this embodiment is water.

Embodiment 2

[0023] The specific implementation of the present invention is to combine fused corundum particles, silicon carbide particles, mullite particles and 24% TiO 2 (mass percentage), 75% Al 2 o 3 (Mass percentage) Aluminum-titanium composite raw materials are mixed into a mixture according to the process material ratio, and then mixed with silicon carbide fine powder, α-alumina fine powder, silica fine powder, calcium aluminate cement, sodium tripolyphosphate, water reducing agent, etc. according to the process The material ratio is weighed and then mixed to obtain the aluminum-titanium-silicon carbide composite refractory castable for ironmaking blast furnaces of the present invention.

[0024] See Table 1 for the specific composition of the aluminum-titanium-silicon carbide composite refractory castable for ironmaking blast furnaces in this embodiment and the technical performance of sample preparation and testing. The binding agent used in this embodiment is water.

Embodiment 3

[0026] The specific implementation of the present invention is to combine mullite particles, coke sapphire particles, silicon carbide particles and 10% TiO 2 (mass percentage), 86% Al 2 o 3 (Mass percentage) Aluminum-titanium composite raw materials are mixed into a mixture according to the material ratio of the process, and then mixed with silicon carbide fine powder, α-alumina fine powder, silica fine powder, calcium aluminate cement, sodium tripolyphosphate, water reducing agent, etc. according to the process The material ratio is weighed and then mixed to obtain the aluminum-titanium-silicon carbide composite refractory castable for ironmaking blast furnaces of the present invention.

[0027] See Table 1 for the specific composition of the aluminum-titanium-silicon carbide composite refractory castable for ironmaking blast furnaces in this embodiment and the technical performance of sample preparation and testing. The binding agent used in this embodiment is water.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com