Solvent modifying method for polyamide composite film

A technology of polyamide and composite membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of simple process, easy and safe operation, and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

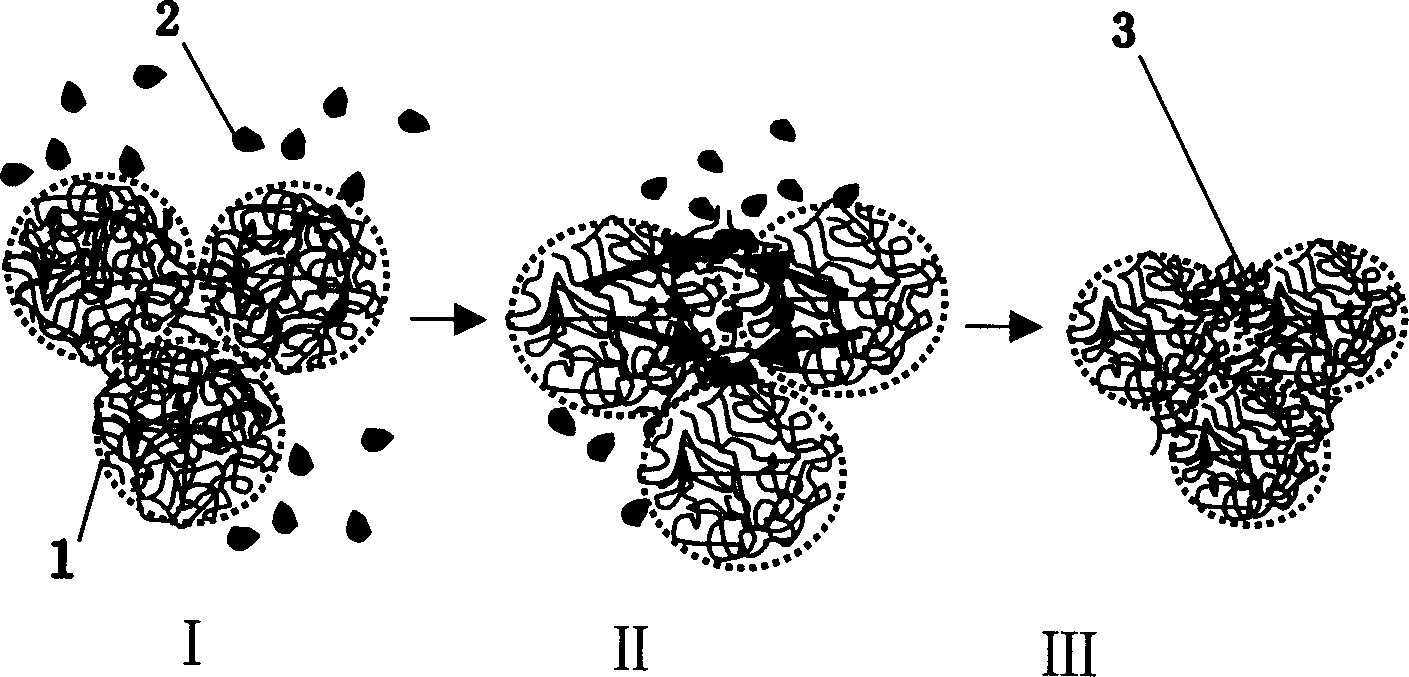

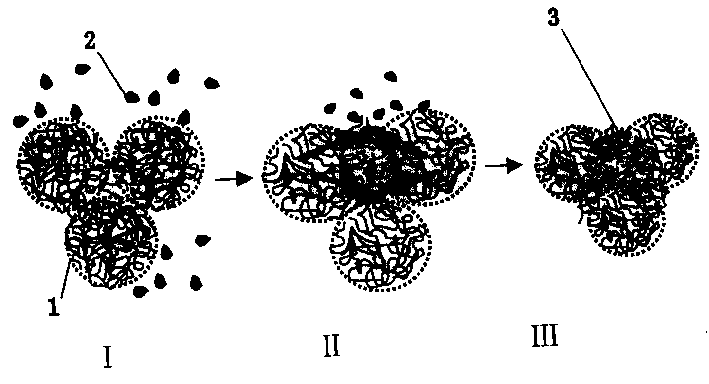

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Get commercial polyamide reverse osmosis composite membrane and immerse in the modifier aqueous solution that acetic acid concentration is 8wt%, temperature 25 ℃, treatment time 1h, the obtained modified polyamide composite membrane pervaporation separates isopropanol water mixture Performance: separation factor 276, water flux 307g / m 2 h.

Embodiment 2

[0036] Embodiment 2: Only change modifier acetic acid concentration 4wt%, all the other conditions are the same as embodiment 1, the performance of the pervaporation separation of isopropanol-water mixture of gained modified polyamide composite membrane: separation factor 210, water flux 332g / m 2 h.

Embodiment 3

[0037] Embodiment 3: only change modifier acetic acid concentration 16wt%, all the other conditions are the same as embodiment 1, the performance of the pervaporation separation of isopropanol-water mixture of gained modified polyamide composite membrane: separation factor 184, water flux 398g / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com