Activated carbon-loaded tetraamino cobalt phthalocyanine and application thereof in preparing dimethyl disulfide as catalyst

A technology of dimethyl disulfide and activated carbon, which is applied in the chemical industry, can solve problems such as limitations, high technical equipment requirements, and low product purity, and achieve the effects of increased effective contact area, high purity of DMDS, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The preparation of embodiment 1 catalyst AC-CoTAPc

[0078] 1. Preparation of 1,5-dibromopentane modified activated carbon (AC-Br)

[0079] Weigh the dried 10g activated carbon powder (AC) with concentrated nitric acid aqueous solution V (HNO 3 ):V(H 2 (0)=1:2 was immersed in a 250mL beaker at 60°C for 24h, then washed with deionized water until neutral, dried in a 60°C oven, and then placed in a vacuum oven and dried under vacuum at 105°C to obtain nitric acid-treated Activated carbon (AC-T), spare.

[0080] Accurately weigh 2.0 g of activated carbon after nitrification and drying into a 100 mL round bottom flask, add 50 mL of DMF after redistillation, K 2 CO 3 2.0g, add 2g NaH to react in ice bath for 8h, add 2.0g 1,5-dibromopentane to react at room temperature for 1h, then react at 80°C for 24 hours. After cooling, suction filtration, washing and drying, 2.03 g of activated carbon modified by 1,5-dibromopentane was obtained.

[0081] 2. Preparation of activate...

Embodiment 2

[0083] Example 2 AC-CoTAPc as a catalyst for the preparation of dimethyl disulfide device and method

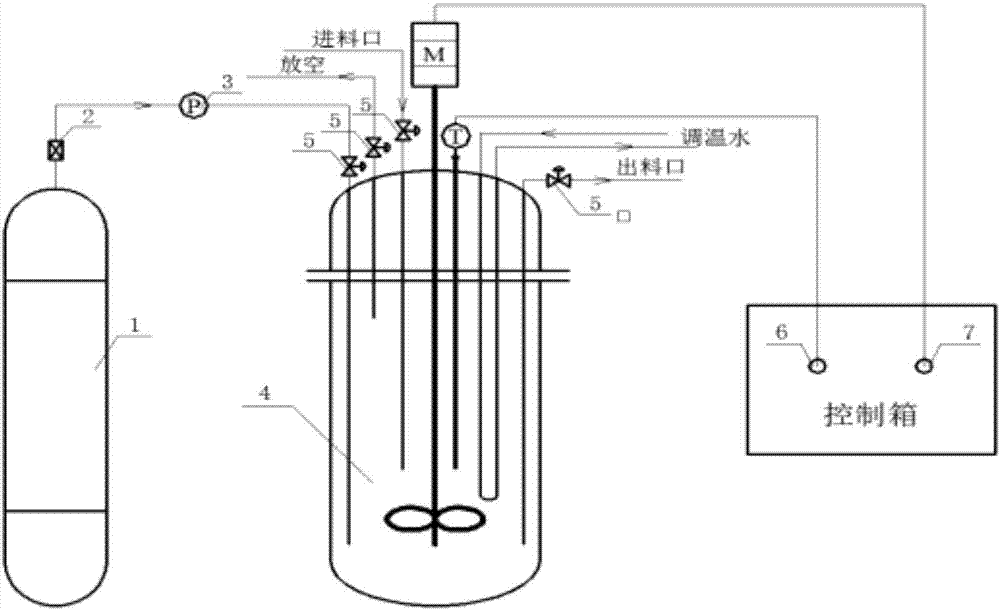

[0084] The production device for preparing dimethyl disulfide includes a reactor 4, a high-purity oxygen device 1, a temperature controller 6 and a speed controller 7; the high-purity oxygen device 1 is connected to the top of the reactor 4 through a pipeline, and the The pipeline is also provided with an oxygen pressure reducing valve 2 and an oxygen pressure gauge 3; the reactor 4 is provided with a stirring and heating device, and the temperature controller 6 and the speed controller 7 are used to control the speed and temperature in the reactor; The top of the kettle 4 is also provided with a feed inlet, a feed outlet, an exhaust outlet and cooling water circulation pipes. The cooling water circulation pipeline adjusts the temperature in the reactor by circulating cooling water. The schematic flow chart of the production device is as figure 1 shown.

[0085] The method...

Embodiment 3

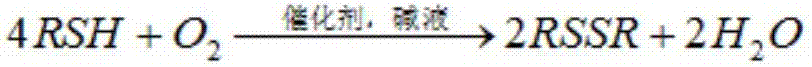

[0086] Embodiment 3 prepares the method for dimethyl disulfide

[0087] Take 400mL sodium methyl mercaptide solution (mass fraction of sodium methyl mercaptide is 18%) and 0.1g AC-CoTAPc in a reaction device where the oxygen pressure is 0.6MPa and the temperature is 55°C for 80min to produce dimethyl disulfide ether. The one-way conversion rate of sodium methyl mercaptide reaches 89.7%, the one-way yield of dimethyl disulfide reaches 38.7%, and the product purity is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com