Novel glucosyl group ionic liquid stationary phase and application thereof

An ionic liquid, glucose-based technology, applied in the liquid separation of solid adsorbents, sugar derivatives, sugar derivatives, etc., can solve the problems of limited stability and single target analyte, and achieve the effect of excellent separation and analysis performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

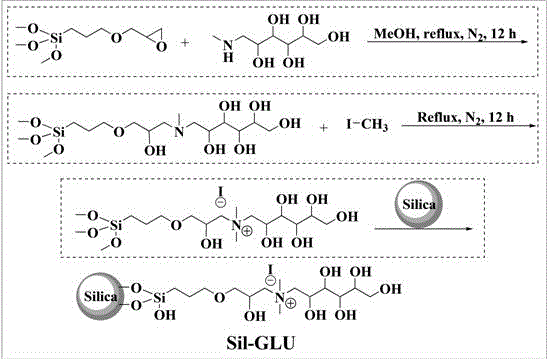

[0031] Preparation of Sil-GLU Glucose-based Ionic Liquid Stationary Phase

[0032] Steps:

[0033] The three steps of the preparative synthesis were carried out in the same vessel.

[0034] ①Weigh 8 mM meglumine and GPTMS of the same mole, dissolve both in 80 mL of methanol at the same time, heat to 70 °C, and reflux for 12 h.

[0035] ② After the reflux for 12 h in step ① is completed, continue to add 10 mM methyl iodide in the same reaction vessel, then continue to heat to 70 ° C, and further reflux for 12 h.

[0036] ③ Add magnets for mechanical stirring, and add methanol homogenate (20 mL) of silica gel (3 g), stir evenly, suspend for 24 h, heat to 70 °C, and reflux for 12 h.

[0037] ④ Filter the milky white suspension obtained in step ③, wash it with methanol / water solution (volume ratio 1 / 1) after filtering, and finally the filtered product is the new glucose-based ionic liquid stationary phase Sil-GLU. Sil-GLU was placed in a vacuum oven, dried for 8 h at 80 °C, and...

Embodiment 2

[0039] Preparation of Sil-GLU Glucose-based Ionic Liquid Stationary Phase

[0040] Steps:

[0041] The three steps of the preparative synthesis were carried out in the same vessel.

[0042] ① Weigh 7.5 mM meglumine and GPTMS of the same mole, dissolve both in 75 mL of methanol at the same time, heat to 70 °C, and reflux for 13 h.

[0043] ②After the reflux for 12 h in step ①, continue to add 9 mM methyl iodide in the same reaction vessel, then continue heating to 70°C, and further reflux for 13 h.

[0044] ③ Add magnets for mechanical stirring, and add methanol homogenate (20 mL) of silica gel (3.2 g), stir evenly, suspend for 24 h, heat to 70 °C, and reflux for 13 h.

[0045] ④ Filter the milky white suspension obtained in step ③, wash it with methanol / water solution (volume ratio 1 / 1) after filtering, and finally the filtered product is the new glucose-based ionic liquid stationary phase Sil-GLU. Sil-GLU was placed in a vacuum oven, dried for 10 h at 80 °C, and stored in ...

Embodiment 3

[0047] Preparation of Sil-GLU Glucose-based Ionic Liquid Stationary Phase

[0048] Steps:

[0049] The three steps of the preparative synthesis were carried out in the same vessel.

[0050] ①Weigh 8 mM meglumine and GPTMS of the same mole, dissolve both in 80 mL of methanol at the same time, heat to 75 °C, and reflux for 12 h.

[0051] ②After the 12 h reflux in step ①, continue to add 10 mM methyl iodide in the same reaction vessel, then continue to heat to 75°C, and further reflux for 12 h.

[0052] ③ Add magnets for mechanical stirring, and add methanol homogenate (20 mL) of silica gel (3 g), stir evenly, suspend for 24 h, heat to 75 °C, and reflux for 12 h.

[0053] ④ Filter the milky white suspension obtained in step ③, wash it with methanol / water solution (volume ratio 1 / 1) after filtering, and finally the filtered product is the new glucose-based ionic liquid stationary phase Sil-GLU. Sil-GLU was placed in a vacuum oven, dried for 8 h at 80 °C, and stored in amber via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com