Irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and preparation method of irradiation crosslinking halogen-free flame retardant polyolefin material

A polyolefin, inorganic flame retardant technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of poor resistance to environmental stress cracking, reduced comprehensive performance, loss of mechanical properties, etc., to achieve superior flame retardant performance , the effect of excellent processing performance, excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

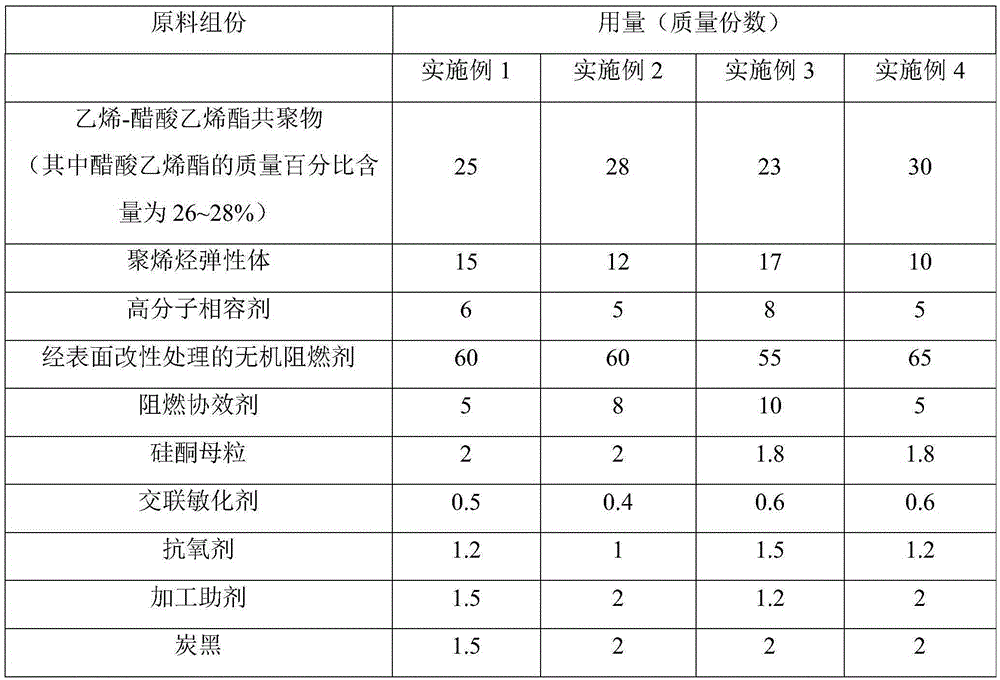

Embodiment 1

[0036] Embodiment 1: polyolefin elastomer adopts ethylene-octene copolymer, macromolecular compatibilizer adopts maleic anhydride grafted polyolefin elastomer; Inorganic flame retardant adopts 40 parts of aluminum hydroxide and 20 parts of magnesium hydroxide and use ( mass fraction), the surface treatment agent is a silane coupling agent, the flame retardant synergist is bentonite, the antioxidant uses 4,4'-thiobis(6-tert-butyl m-cresol), and the cross-linking sensitizer uses Triallyl isocyanurate, high molecular wax is used as processing aid.

Embodiment 2

[0037] Embodiment 2: The polyolefin elastomer adopts ethylene-octene copolymer, the polymer compatibilizer adopts maleic anhydride grafted ethylene-vinyl acetate copolymer; the inorganic flame retardant adopts aluminum hydroxide, and the surface treatment agent is silane coupling agent and titanate coupling agent, the ratio is 1:1, the flame retardant synergist is melamine cyanurate, and the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester, the cross-linking sensitizer adopts triallyl isocyanurate, and the processing aid adopts stearic acid.

Embodiment 3

[0038] Embodiment 3: Polyolefin elastomer adopts ethylene-butylene copolymer, and polymer compatibilizer adopts maleic anhydride grafted low-density polyethylene; Inorganic flame retardant adopts 40 parts of aluminum hydroxide and 15 parts of hydrotalcites and uses (mass fraction), the surface treatment agent is stearic acid, the flame retardant synergist is 5 parts of melamine cyanurate and 5 parts of white carbon black (mass fraction), and the antioxidant uses four [β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, the cross-linking sensitizer adopts triallyl isocyanurate, and the processing aid adopts ethylene bis-stearamide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com