Patents

Literature

45results about How to "Achieve scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano composite top facing paint with hydrophobic foul resisting sticking-proof and preparation process thereof

InactiveCN1861714AAchieving aging resistanceAchieve scrub resistanceAntifouling/underwater paintsPaints with biocidesMaterials scienceWetting

The invention relates to a nanometer compound cover paint which has the hydrophobicity and is resistance to the pollution and the sticking. The paint contains the film forming material, the antifouling component, the filler and the diluting agent, necessary the wetting agent, dispersant and the thickener. So it can be used for the antifouling of the high-end building and the protection for the outlook of the public utility.

Owner:江西中江纳米科技有限公司

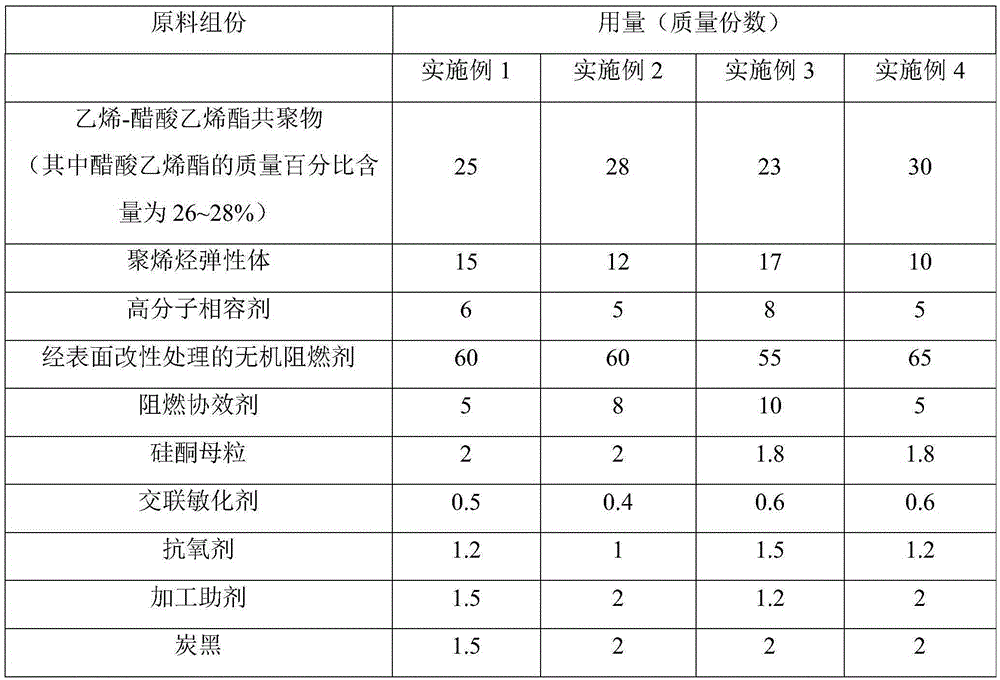

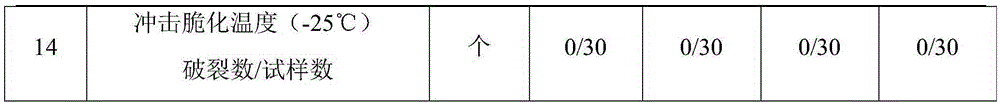

Irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and preparation method of irradiation crosslinking halogen-free flame retardant polyolefin material

InactiveCN105315541AAchieve oil resistanceAchieve high temperature resistancePlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the field of low-smoke halogen-free flame retardant materials, and particularly relates to an irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and a preparation method of the irradiation crosslinking halogen-free flame retardant polyolefin material. The polyolefin material comprises the following components in parts by mass: 20-30 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polyolefin elastomer, 5-10 parts of a macromolecular compatilizer, 45-65 parts of an inorganic flame retardant subjected to surface modification treatment, 5-10 parts of a flame retardant synergist, 0.8-1.5 parts of an antioxidant, 1.5-2.5 parts of silicone masterbatches, 0.3-0.6 part of a crosslinking sensitizer, 1.5-2 parts of carbon black and 1-2 parts of a processing aid. The preparation method comprises the technological steps of surface treatment of the inorganic flame retardant, proportioning, mixing, melting, extrusion for pelletization, and the like. Compared with the prior art, the polyolefin material has the characteristics of excellent flame retardation (capable of passing the D type group burning test), oil resistance (mineral oil and fuel oil resistant), high temperature resistance (the grade is 150 DEG C), ultraviolet resistance, scratch resistance, low corrosion, low toxicity, environment friendliness, excellent processing performance, extrusion speed capable of reaching 100-150 m / min, and bright surface.

Owner:SHANDONG UNIV OF TECH +1

In-mold decoration injection process

InactiveCN103240842AIncrease freedomColorfulOrnamental structuresSpecial ornamental structuresInjection molding processPrinting ink

The invention provides an in-mold decoration injection process which comprises a step of preparing a mold and a film, a step of drying a net making plate in the sun and preheating a sheet, a step of printing a pattern, a step of curing printing ink, a step of punching for positioning, a step of punching, a step of hotly pressing for forming, a step of injecting for forming, a step of packaging a semi-finished product, a step of checking and a step of warehousing a finished product. The finished product is scratch-resistant, strong in corrosiveness, long in service life, good in body sensation, attractive, light, firm and safe, can provide more choices for final users, and is widely applied to various products such as household appliance products, computers and peripherals, mobile communication terminal products, and in the technical field of car industry and the like.

Owner:重庆斯伯莱德塑料制品有限公司

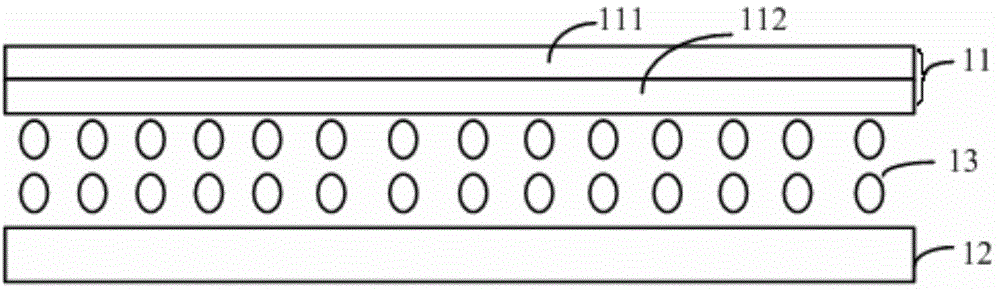

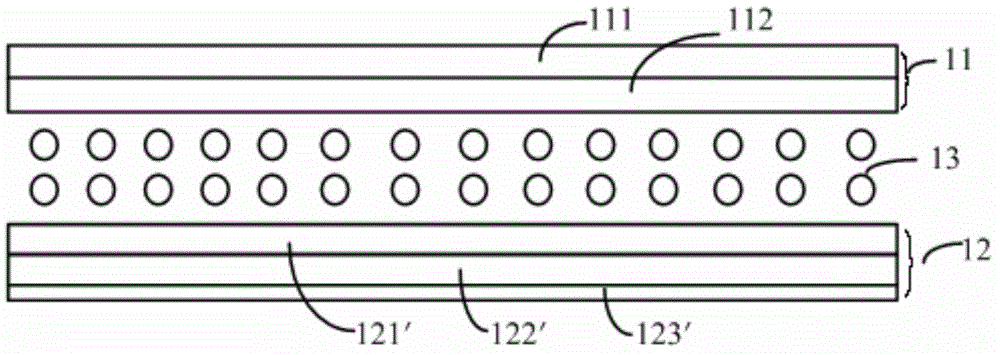

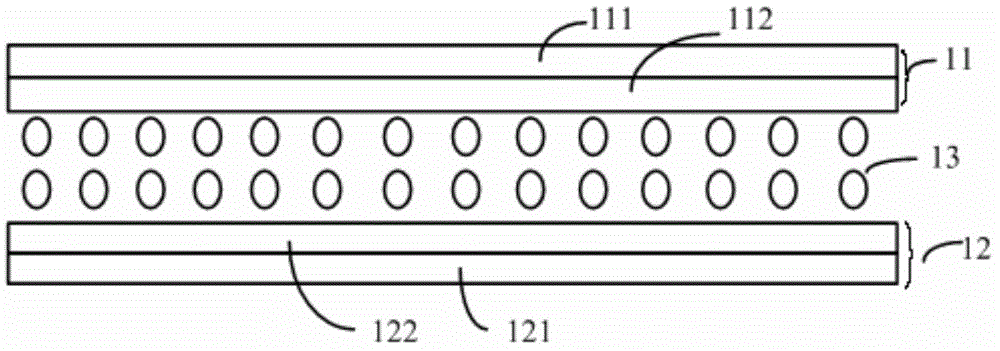

Display panel, manufacturing method of display panel, and display device

InactiveCN104965340APrevent phase shiftCurved mirror surface display effect is goodNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display panel, a manufacturing method of the display panel, and a display device. The main content comprises: one side surface, close to a liquid crystal layer, located in a first substrate on a light-emitting side is provided with a semi-transparent and semi-reflecting layer such that a mirror surface can perform a display function well without adding any polaroid and protection layer, thereby realizing fine anti-scratch and low-weight performance; furthermore, due to the fact that the semi-transparent and semi-reflecting layer is located on one side surface, close to the liquid crystal layer, of the first substrate, phase deviation of polarized light caused by bending of a base is avoided in the display technique of a curved mirror surface; and therefore, unnecessary light leakage and other phenomena are avoided so that a display effect of the curved mirror surface is well achieved.

Owner:BOE TECH GRP CO LTD

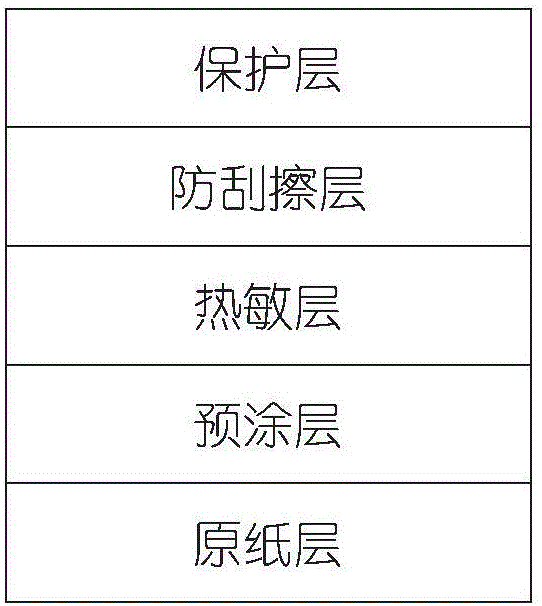

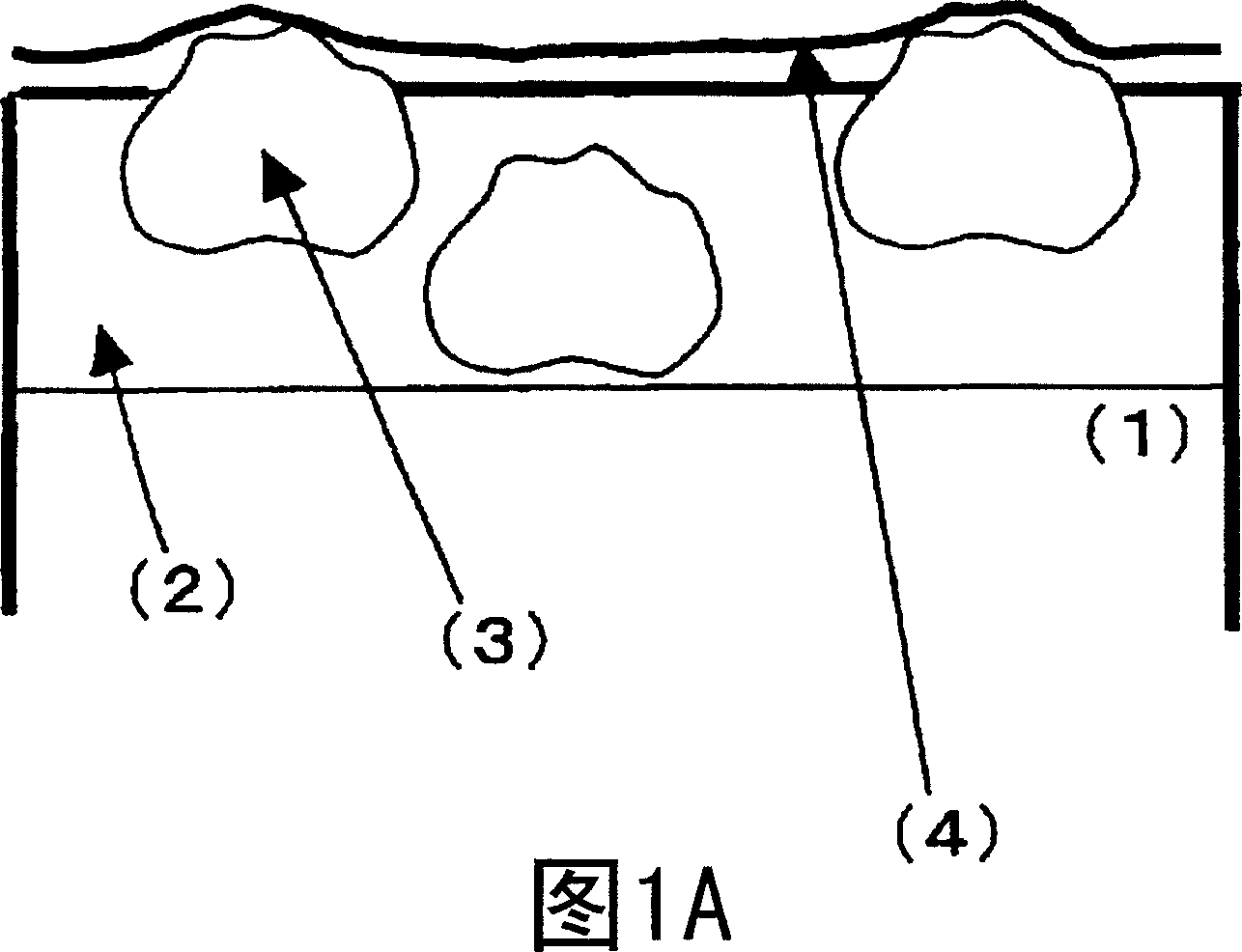

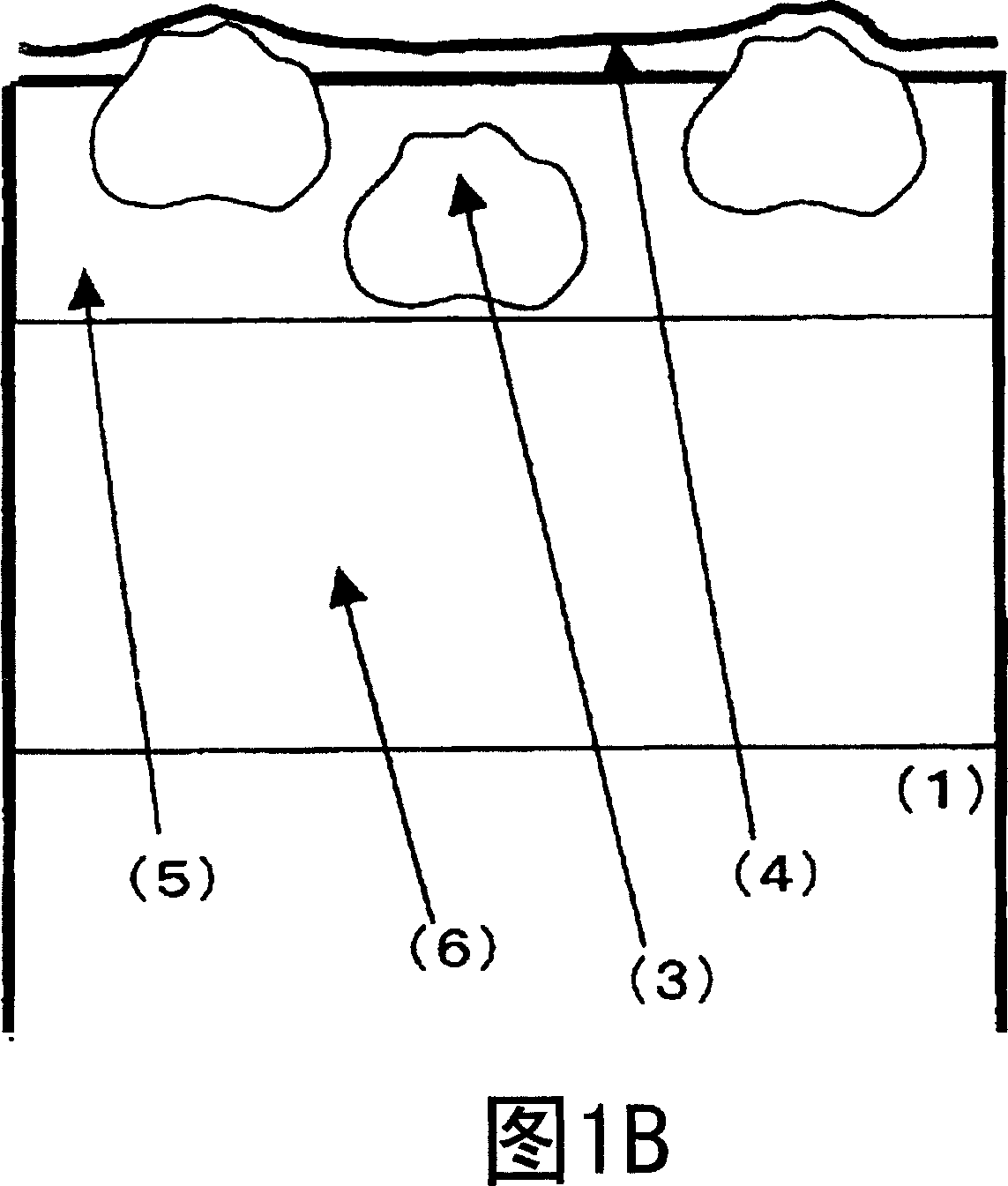

Anti-scraping thermo-sensitive paper and manufacturing method thereof

InactiveCN106149465AImprove face feelingImprove efficacyNon-fibrous pulp additionCoatings with pigmentsPulp and paper industryThermal paper

The invention discloses an anti-scraping thermo-sensitive paper which comprises a raw paper layer, a pre-coating layer, a coloring layer, an anti-scraping layer and a protecting layer, wherein the raw paper layer, the raw paper layer is coated with the pre-coating layer, the coloring layer, the anti-scraping layer and the protecting layer. The invention provides a manufacturing method for the anti-scraping thermo-sensitive paper. The thermo-sensitive paper provided by the invention has the anti-scraping layer, so that the thermo-sensitive paper is not colored under the condition of repeated scraping with external force and the interference on normal word identification caused by unnecessary image-text shown due to the scraping with external force is avoided.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Benzene-free spray paint and preparation method thereof

The invention relates to a benzene-free spray paint. The spray paint is characterized by comprising the following components by weight percent: 21-25% of acrylic resin, 4-10% of pigment, 0.5-1% of dispersing agent, 0.3-0.8% of flatting agent, 0.5-1% of bentonite, 5-10% of ethylene glycol monobutyl ether, 4-8% of n-butyl acetate, 8-18% of acetic ether, 10-15% of acetone, and 38-42% of dimethyl ether. The spray paint is prepared from raw materials which are completely free of harmful substances like benzene and heavy metals through a certain production method, thus avoiding harm of benzene and heavy metals to human health, and effectively protecting environment and safety of people.

Owner:ZHONGSHAN DATIAN CAR CARE IND

Polyurethane coating material for shoe coating and preparation method of polyurethane coating material

ActiveCN109762456AReduce coefficient of frictionGel fastAntifouling/underwater paintsPaints with biocidesALUMINUM POTASSIUM SULFATEIsocyanate

The invention provides a polyurethane coating material for shoe coating and a preparation method of the polyurethane coating material. The preparation method comprises the following steps that step (1) isocyanate, polyester polyol, a moisture scavenger and a diluent are added into a reaction kettle in proportion and mixed evenly, reaction is carried out for 6-8 hours under the condition of 80-120DEG C, vacuum bubble removal is carried out, and cooling is performed to obtain a component A; step (2) polyester polyol, a chain extender, a catalytic agent and a glycerin solution of dehydrated aluminum potassium sulfate dodecahydrate are added into the reaction kettle in proportion and mixed evenly and vacuumized for 2-3 hours to remove bubbles, and a component B is obtained; and step (3) the component A and the component B are evenly mixed in proportion, vacuum bubble removal is carried out for 30s, and the polyurethane coating material is obtained. The prepared polyurethane coating material is used for coating the surface of a shoe, once-forming can be achieved, and the problem that bubbles generated in the coating due to the fact that a known spraying polyurethane elastomer reacts with moisture is further solved.

Owner:FOSHAN NANHAI QIHONG SHOES MATERIAL CO LTD

Optical film, polarizing plate and image display device

ActiveCN1975466AImprove clarityAchieve scratch resistanceStatic indicating devicesOptical filtersDisplay deviceMetal

An optical film comprises: a transparent support; and at least one hard coat layer containing a translucent resin and a coagulating metal oxide particle, and having a surface haze value of from 0 to 12%, an internal haze value of from 0 to 35% and an Sm value of from 50 to 200 mum.

Owner:FUJIFILM CORP

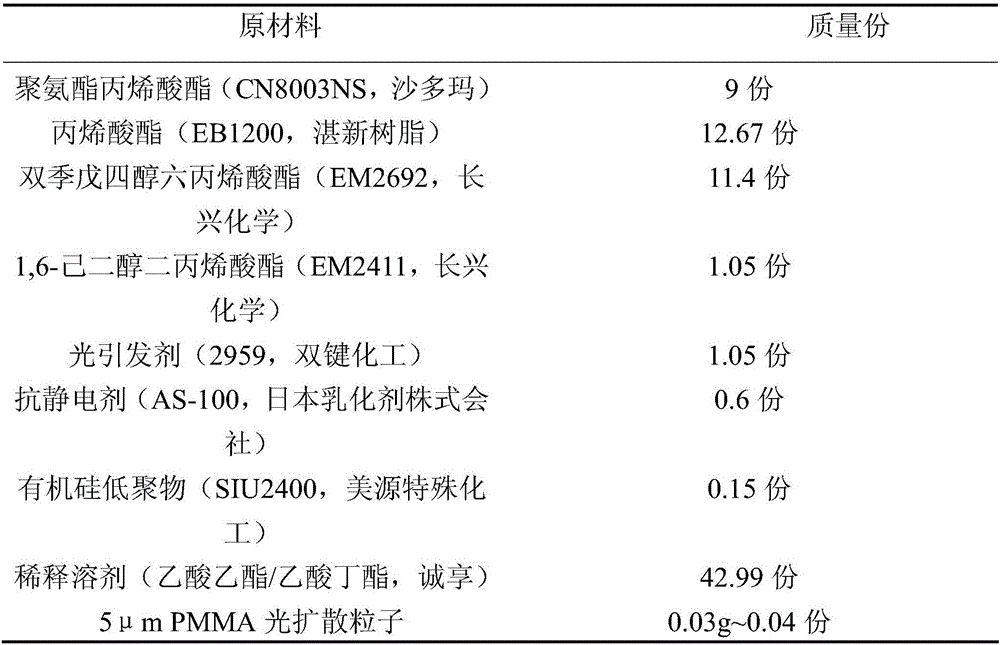

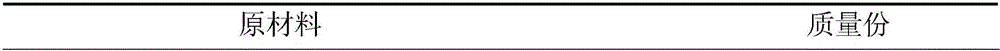

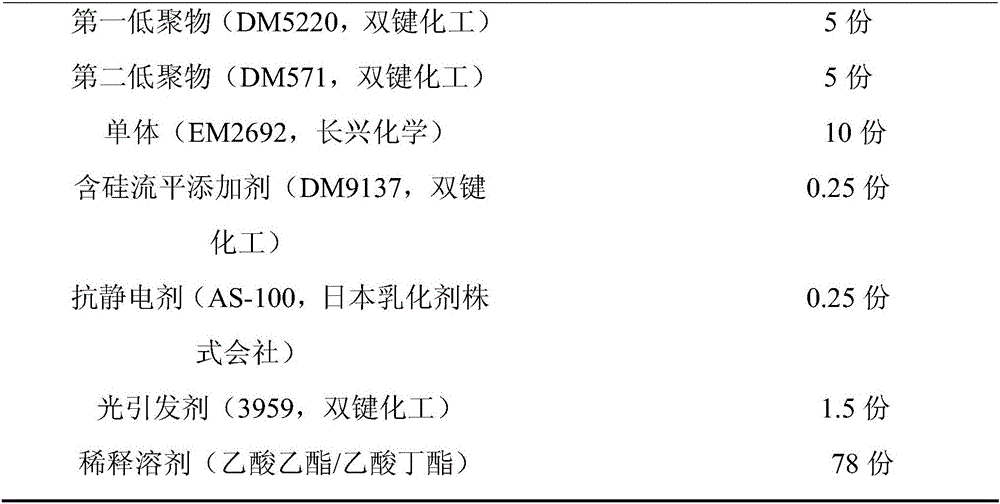

Resin paint for optical film and application of resin paint

ActiveCN106118442AAchieve anti-adhesionAchieve atomizationPolyurea/polyurethane coatingsChemistryPhotoinitiator

The invention provides resin paint for an optical film. The resin paint for the optical film comprises a first component, a second component, a flatting agent, an antistatic agent, a photoinitiator and a diluent, wherein the mass ratio range of the first component and the second component is 1:3 to 1:1; the first component is selected from any two of a first low polymer, a second low polymer and a monomer; the second component comprises the rest component except for the two components selected by the first component. The resin paint for the optical film provided by the invention utilizes the compatibility difference between resins with different polarities or the resins and the monomer to form a non-planar micro-structure with similar particle action on the surface of an object being painted after being solidified, so that the effects of bonding resistance, atomization, scratch resistance and delustering are achieved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Car garment cloth containing poly ethylene (PE) and oxford fabric (polyester taffeta)

InactiveCN102535185AStrong fastnessNot easy to tearSynthetic resin layered productsRemovable external protective coveringsPolyesterSurface layer

The invention relates to a car garment cloth containing poly ethylene (PE) and oxford fabric (polyester taffeta); the surface layer of the car garment cloth is made of the PE; a layer arranged under the PE is made of the oxford fabric or polyester taffeta; and the PE is stuck with the oxford fabric or polyester taffeta in a compounding way without a medium. A car garment made from the car garment cloth has the functions of the common car garment, is strong in firmness so as to be not easily torn, and also has a waterproof function.

Owner:杭州汇龙汽车用品有限公司

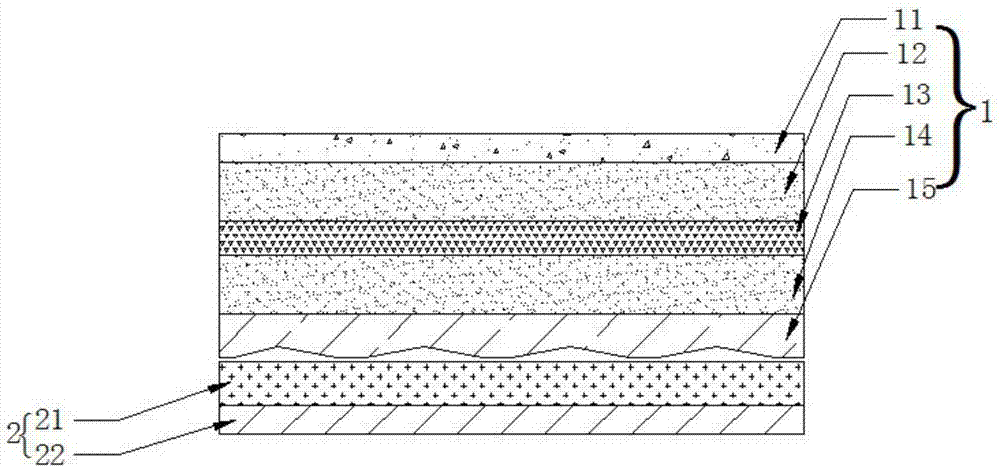

Production method of 3D multidimensional cambered multilayer laminated glass substrate

ActiveCN106746558AAchieve scratch resistanceAchieve shock resistanceEdge grinding machinesSynthetic resin layered productsFlat glassNumerical control

The invention discloses a preparation method of a 3D multidimensional cambered multilayer laminated glass substrate, which is a multilayer laminated glass substrate with the characteristics of multidimension and multiple curved surfaces and is prepared based on plate glass through cutting, edging, hot bending, steeling, heating and laminating. The preparation method comprises the steps: adoption of vertical pull plate glass (divided into slotted / slotless two types), flat pull plate glass and float glass sheets which are 0.1mm-12mm in thickness; numerically-controlled precise cutting according to a prescribed or specified dimension by a full automatic computer; precise edging and polishing according to specified parameters by a numerical control double edge grinding machine; multidimensional cambered modeling, hot bending and wind cooling steeling by a reciprocating bending and steeling furnace; and multilayer glass laminating and deburring by a numerical control heating and laminating machine. The 3D multidimensional cambered multilayer laminated glass has the shaped characteristics of multidimension, cambered surfaces and curved surfaces, and simultaneously, the substrate double-sided glass is abrasion resistant, shock resistant, easy to clean, and suitable to be matched in use for various products and processes requiring curved surface modeling.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

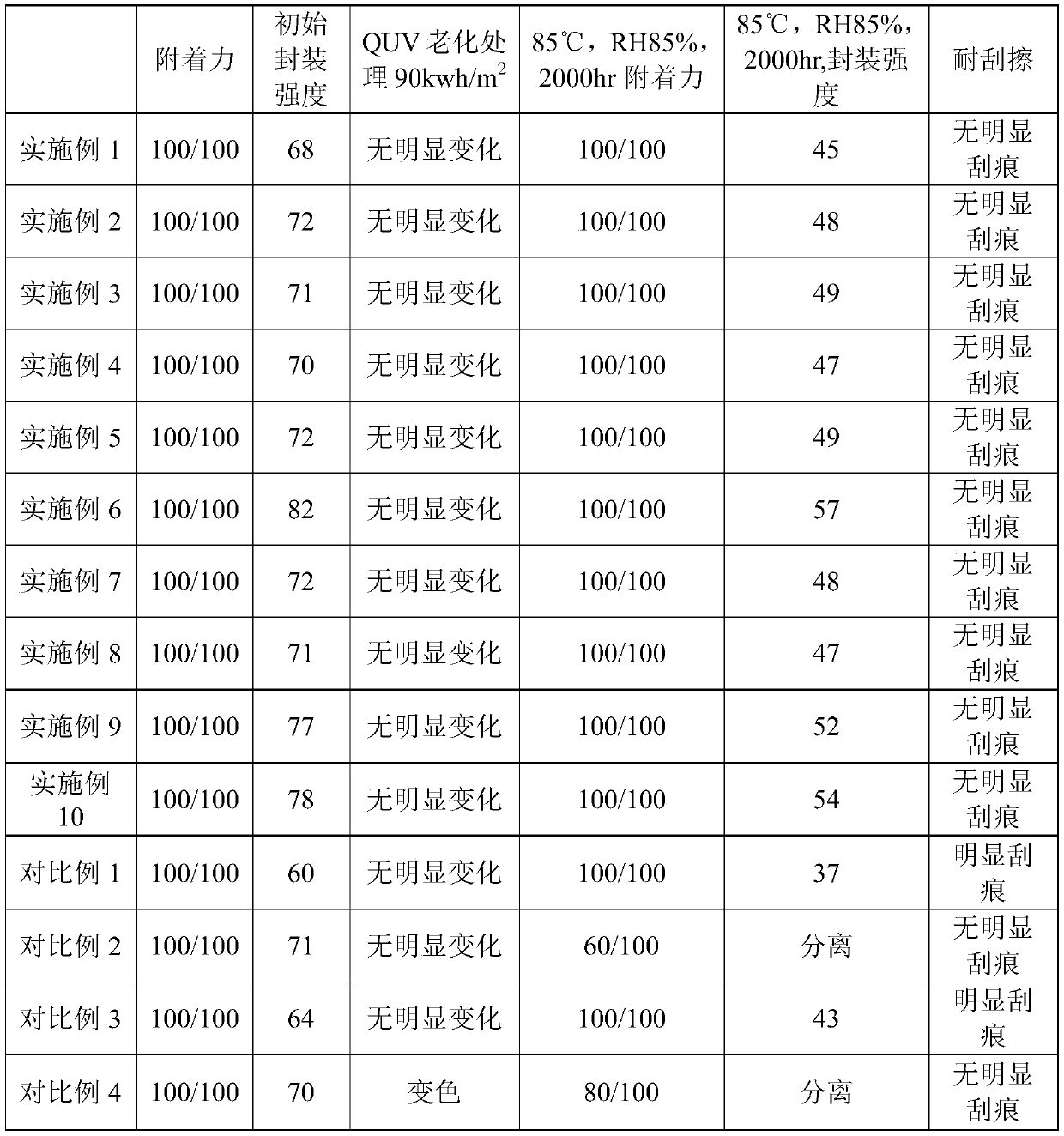

Scratch-resistant fluorocarbon layer coating liquid and solar back sheet using coating liquid

ActiveCN110358375AGood weather resistanceGood scratch resistance on the inner surfacePolyurea/polyurethane coatingsPhotovoltaic energy generationWeather resistanceThermoplastic polyurethane

The present invention relates to the technical field of solar back sheets, particularly to a fluorocarbon layer coating liquid and a solar back sheet using the coating liquid. In order to solve the problem that the existing fluorocarbon layer is easily scratched, the present invention provides a scratch-resistant fluorocarbon layer coating liquid and a solar back sheet using the coating liquid, wherein the fluorocarbon layer coating liquid comprises, by weight, 40-60% of a fluorocarbon resin, 20-30% of titanium dioxide, 1-5% of matting powder, 10-20% of a modified thermoplastic polyurethane resin, 0.2-0.8% of polyacrylate, and 5-10% of isocyanate. According to the present invention, the surface of the fluorocarbon layer formed by the fluorocarbon layer coating liquid has characteristics ofscratch resistance and good weather resistance; and the inner surface of the solar back sheet using the coating liquid is excellent in scratch resistance, and the weather resistance of the solar backsheet is good.

Owner:宁波激阳新材料有限公司

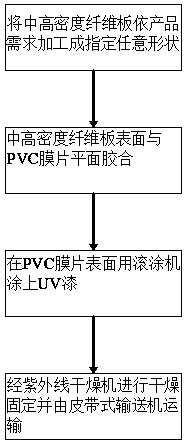

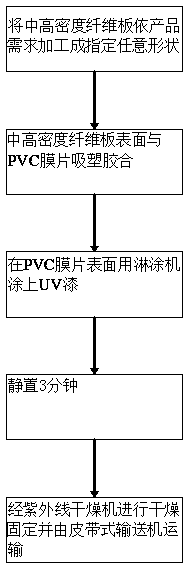

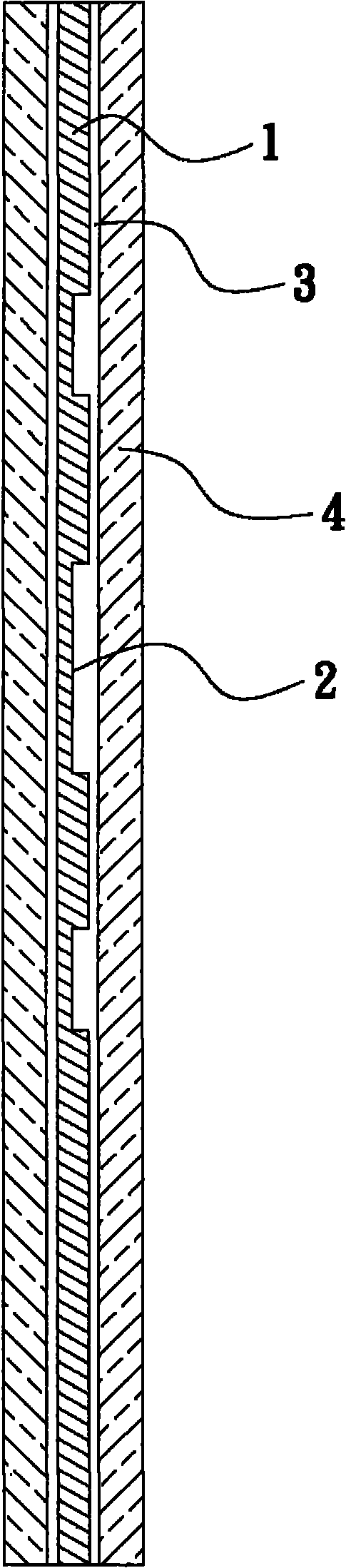

PVC overlaid plywood and manufacturing method thereof

InactiveCN108501133AHigh hardnessImprove wear resistanceOther plywood/veneer working apparatusPretreated surfacesFiberHigh density

The invention discloses PVC overlaid plywood and a manufacturing method thereof and belongs to the technical field of plywood. The PVC overlaid plywood comprises a medium-high density fiber board, a PVC membrane and UV paint, wherein the PVC membrane is arranged on the surface of the medium-high density fiber board; and the UV paint is arranged on the surface of the PVC membrane. The UV paint is sprayed to the PVC membrane and is subjected to UV curing to form a layer of film which is high in hardness, good in abrasion resistance and high in transparency, and the effects of scraping resistance, scraping prevention, heat resistance and durability are achieved. Meanwhile, the curved UV paint is stable in color and luster, the mirror flat effect is better, the paint film is full and free of orange peel phenomenon, and the color and luster uniformity of the surface of the film is effectively increased. The surface of the plywood is wrapped with the PVC membrane easily, conveniently and rapidly, the UV paint coating efficiency is high, the coating cost is low, and coating is environmentally friendly. The problems that wrapping of the plywood wastes time and labor, the poor phenomena like bubbles and delaminating are easily generated, the features of high hardness, scraping prevention, scraping resistance and heat resistance are not achieved, and durability in transportation and useis poor are effectively solved.

Owner:张梦琪

Wear-resistant floor polish wax

Wear-resistant floor polish wax is prepared from the following raw materials in parts by weight: 20-35 parts of liquid paraffin, 3-6 parts of triethanolamine, 5-8 parts of xylene, 7-11 parts of butyl acetate, 2.5-4.3 parts of vaseline, 2-3.5 parts of borax, 6-14 parts of white wax, 3-7 parts of sweet orange oil, 2-5 parts of beewax, 2-4 parts of tri-butoxyethyl phosphate, 1-5 parts of surfactant, 3-4 parts of methyl benzimidazolecarbamate, 6-8 parts of rosin modified resin, 12-24 parts of coconut oil, 6-10 parts of mandarin oil and 0.4-0.7 part of a light stabilizer. The wear-resistant floor polish wax has the beneficial effects that the wear-resistant floor polish wax has quite high glossiness and relatively high wear resistance, and can have the effect of protecting floors, and scratch-proof, corrosion-resistant and moth-proof effects can be achieved.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

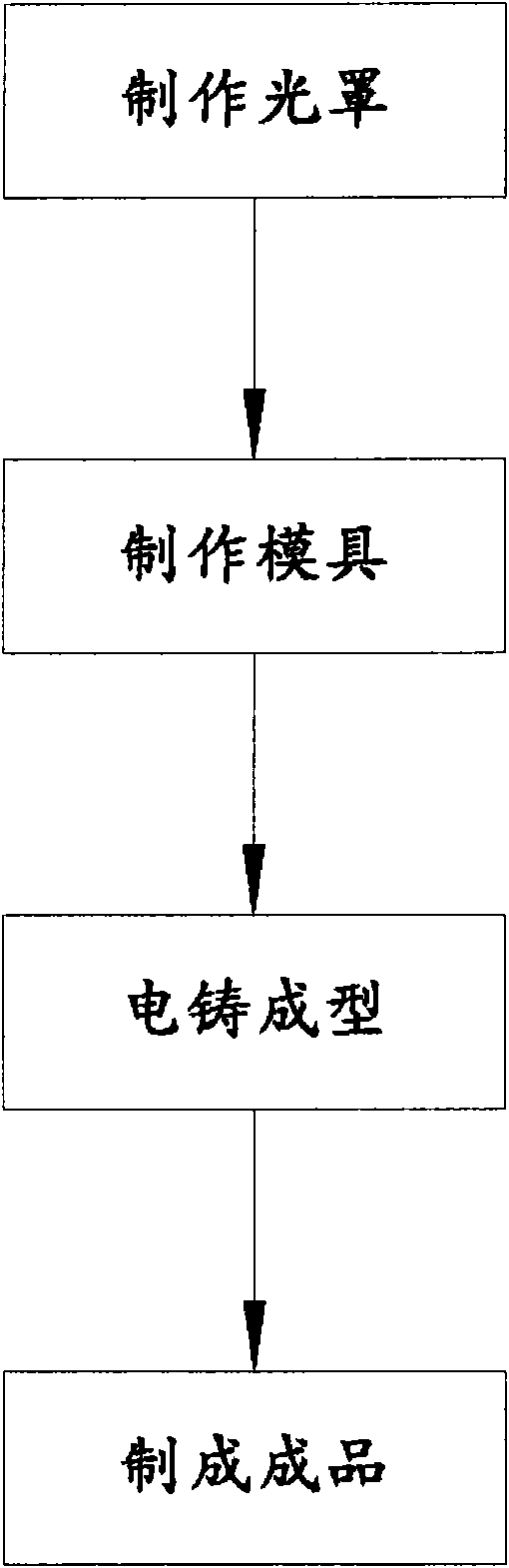

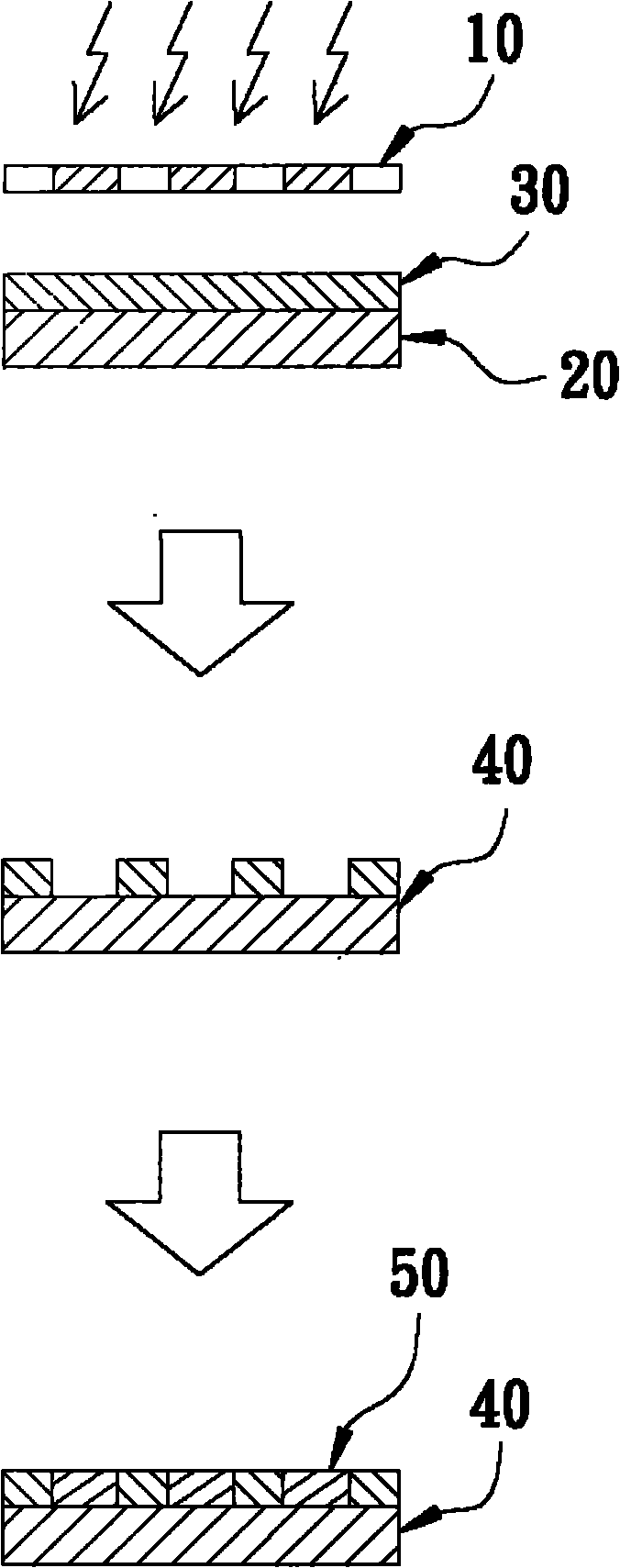

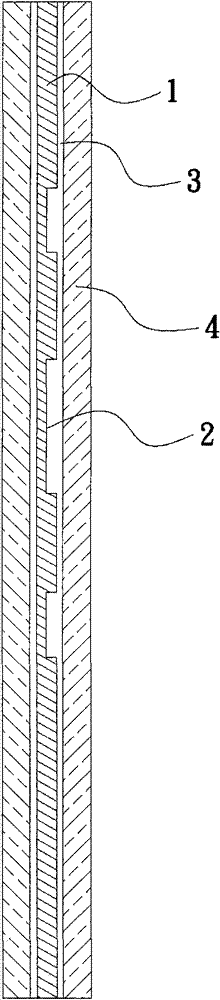

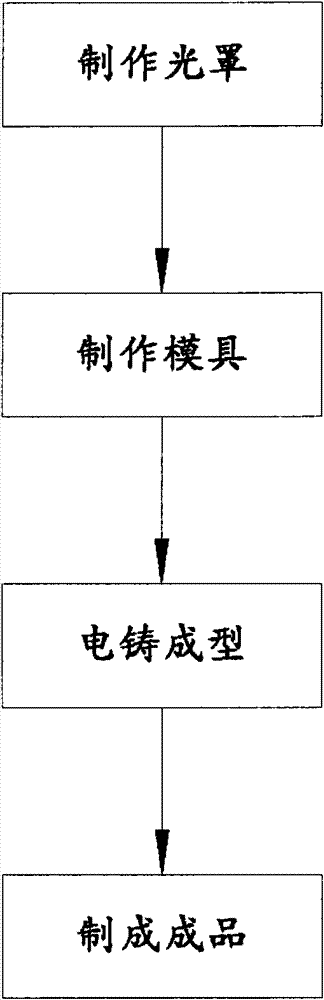

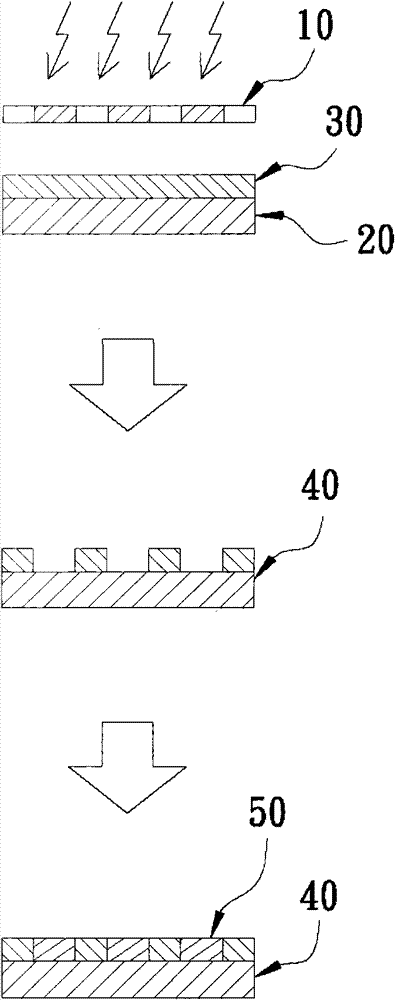

Method for manufacturing metal sandwich glass

InactiveCN102120401AThe overall thickness is thinReduce weightPoint-like light sourceLighting elementsPhotomaskMetal

The invention discloses a method for manufacturing metal sandwich glass. The method comprises the steps of photomask manufacturing, mould manufacturing, electrotyping forming, finished product manufacturing, and the like. The method is characterized in that a hollow metal film can be formed between a bottom layer and a transparent glass layer, and the hollow metal film is formed into a hollow pattern, therefore, a particular hollow pattern can be presented on the metal sandwich glass, and compared with known techniques, the metal sandwich glass is thinner in thickness and lighter in weight, meanwhile, because the hollow metal film is arranged between the bottom layer and the glass layer, the hollow metal film can be protected by the bottom layer and the glass layer, thereby achieving the effects of resisting scratch and small possibility of wearing.

Owner:LIGA PRECISION TECH

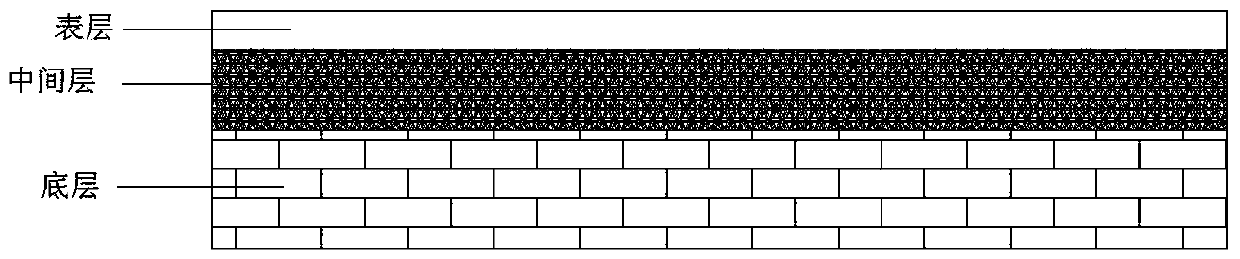

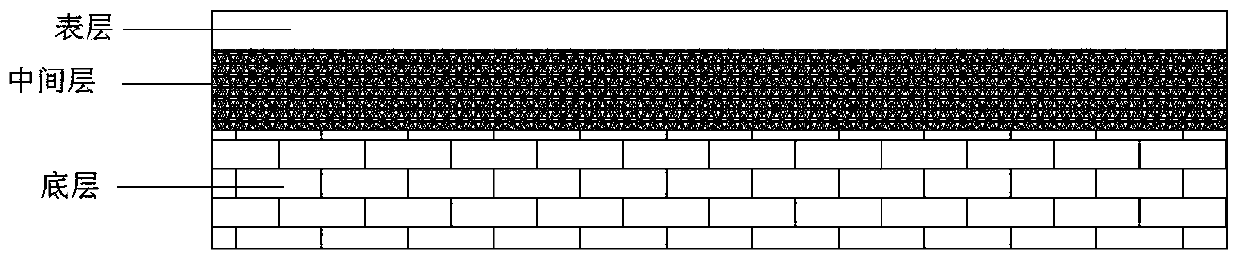

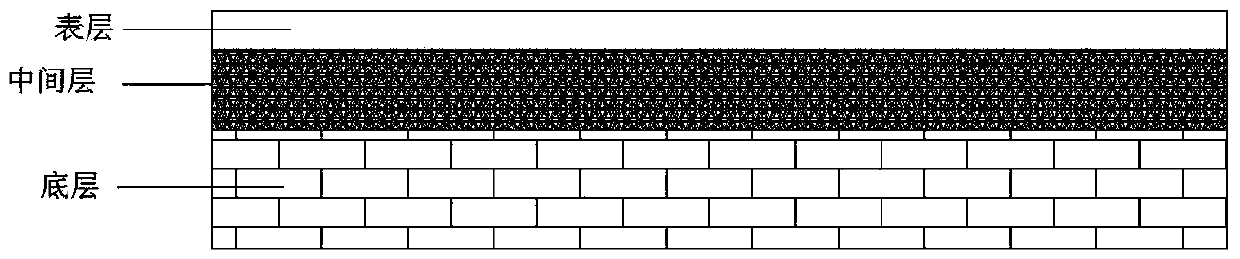

Manufacturing method of high-strength scratch-resistant veneer

The invention discloses a manufacturing method of a high high-strength scratch-resistant veneer. In order to solve the problems that the existing veneer is easily cracked, easily rolled and afraid of being scratched, the invention provides a manufacturing method of a high high-strength scratch-resistant veneer as follows: selecting a special-grade solid wood veneer or a high-density plate as a bottom layer, selecting impregnated paper as a middle layer and selecting aluminum oxide as a surface layer; and hot-pressing and forming by a cold-hot-cold hot-pressing process through a hot press. The manufacturing method achieves the effects of resisting cracking, rolling, deforming and scratching.

Owner:HEILONGJIANG HUAXIN FURNITURE

High-temperature-resistant release paper and preparation method thereof

ActiveCN111455725AIncrease surface tensionIncrease free energyMechanical working/deformationPaper coatingPolymer scienceBonding strength

The invention relates to the field of release paper, in particular to high-temperature-resistant release paper. The high-temperature-resistant release paper comprises a coating layer consisting of PP,PE, TPX resin and an organosilicon high-temperature-resistant aid, wherein the coating layer coats base paper in a laminating manner; in terms of weight percentage, the PP accounts for 60-80%, the PEaccounts for 5-10%, the TPX resin accounts for 10-20%, and the organic silicon high-temperature-resistant aid accounts for 5-10%; all the components are mixed and melted through a screw extruder to obtain a coating material; the coating material is subjected to laminating and embossing on the surface of the base paper through a laminating machine so as to obtain the high-temperature-resistant release paper; and the base paper is subjected to corona treatment before lamination. The release paper prepared in the invention can meet the use requirements of a high-temperature environment, is improved in scratch resistance, and has good paper film bonding strength, and therefore, various different performance requirements on the PU leather embossed release paper are met.

Owner:浙江望泰特种纸业有限公司

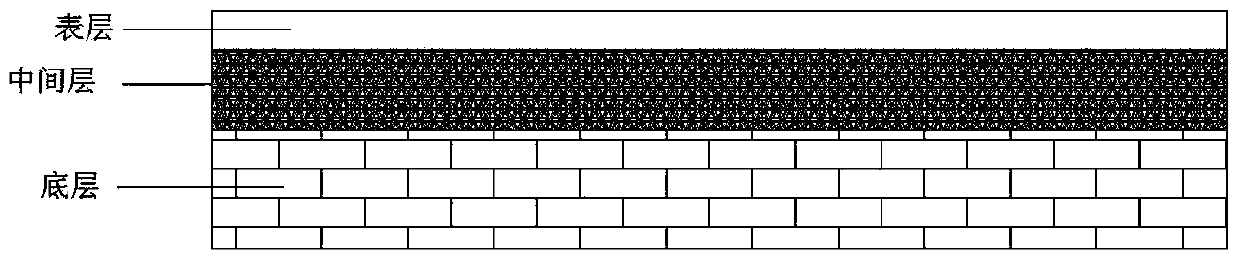

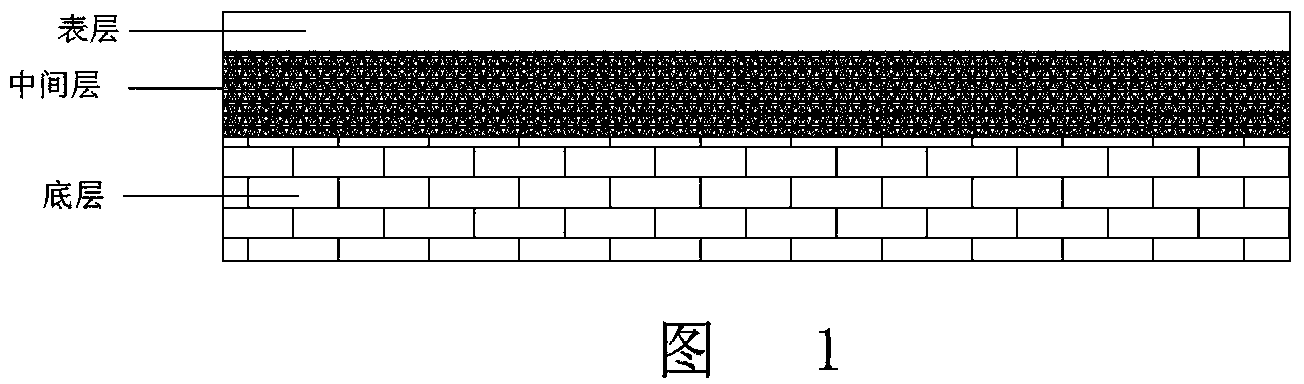

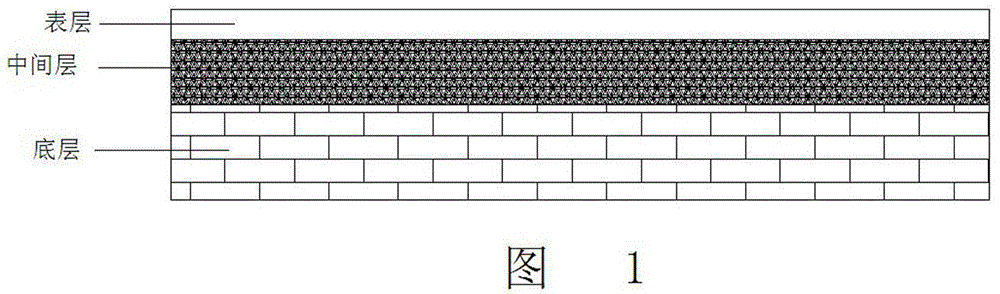

High-strength scratch-resisting fireproof veneer

InactiveCN103526896AAnti-crackingAnti-curlingCovering/liningsSpecial ornamental structuresSolid woodSingle plate

The invention discloses a high-strength scratch-resisting fireproof veneer. The high-strength scratch-resisting fireproof veneer aims to solve the problems that in the prior art, a great number of veneers used in building materials are easy to crack, crimp and scratch, and the like. The high-strength scratch-resisting fireproof veneer comprises a bottom layer, a middle layer and a surface layer, wherein the bottom layer is made of special-grade solid-wood fireproof single boards or E1-grade fireproof high-density boards, the middle layer is made of melamine impregnated paper, and the surface layer is made of aluminum oxide; the high-strength scratch-resisting fireproof veneer is manufactured in the cold-hot-cold hot-pressing process, the temperature of a hot press ranges from 50 DEG C to 135 DEG C, the time range from 2 minutes to 5 minutes, and the pressure ranges from 13mpa to 15mpa. The high-strength scratch-resisting fireproof veneer has the advantages of preventing cracking and crimping, resisting to deformation and scratch, and preventing fire.

Owner:HEILONGJIANG HUAXIN FURNITURE

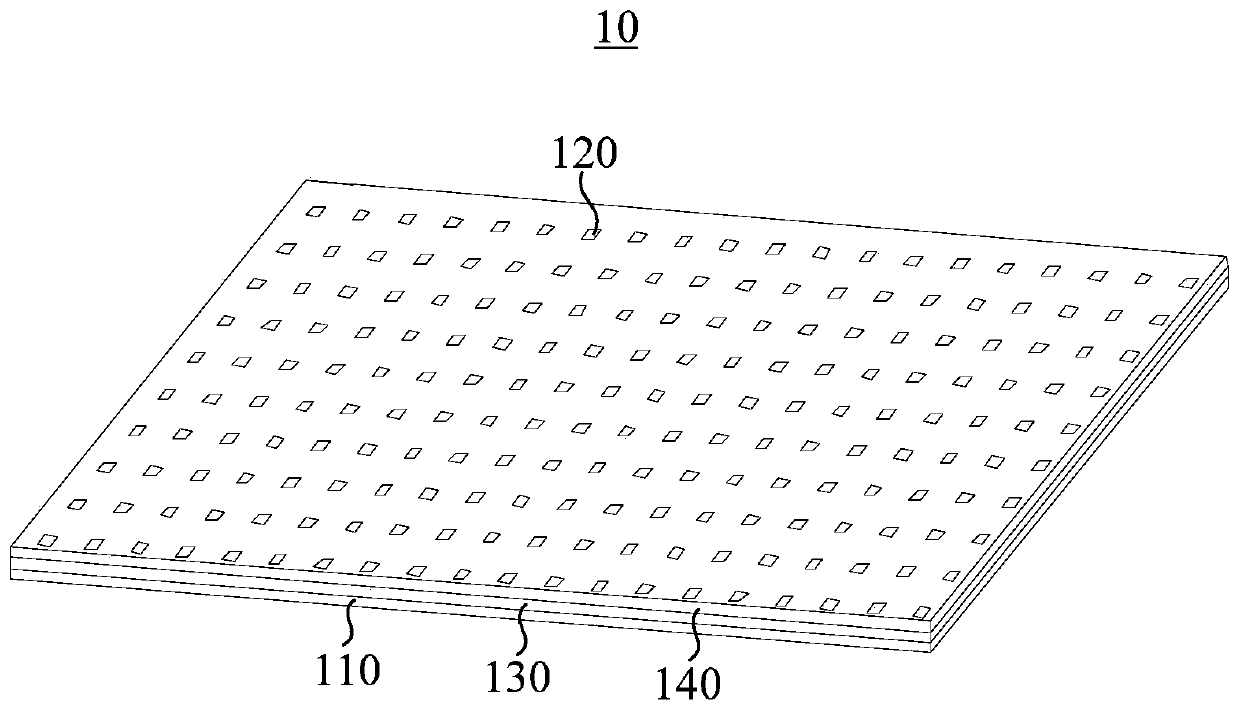

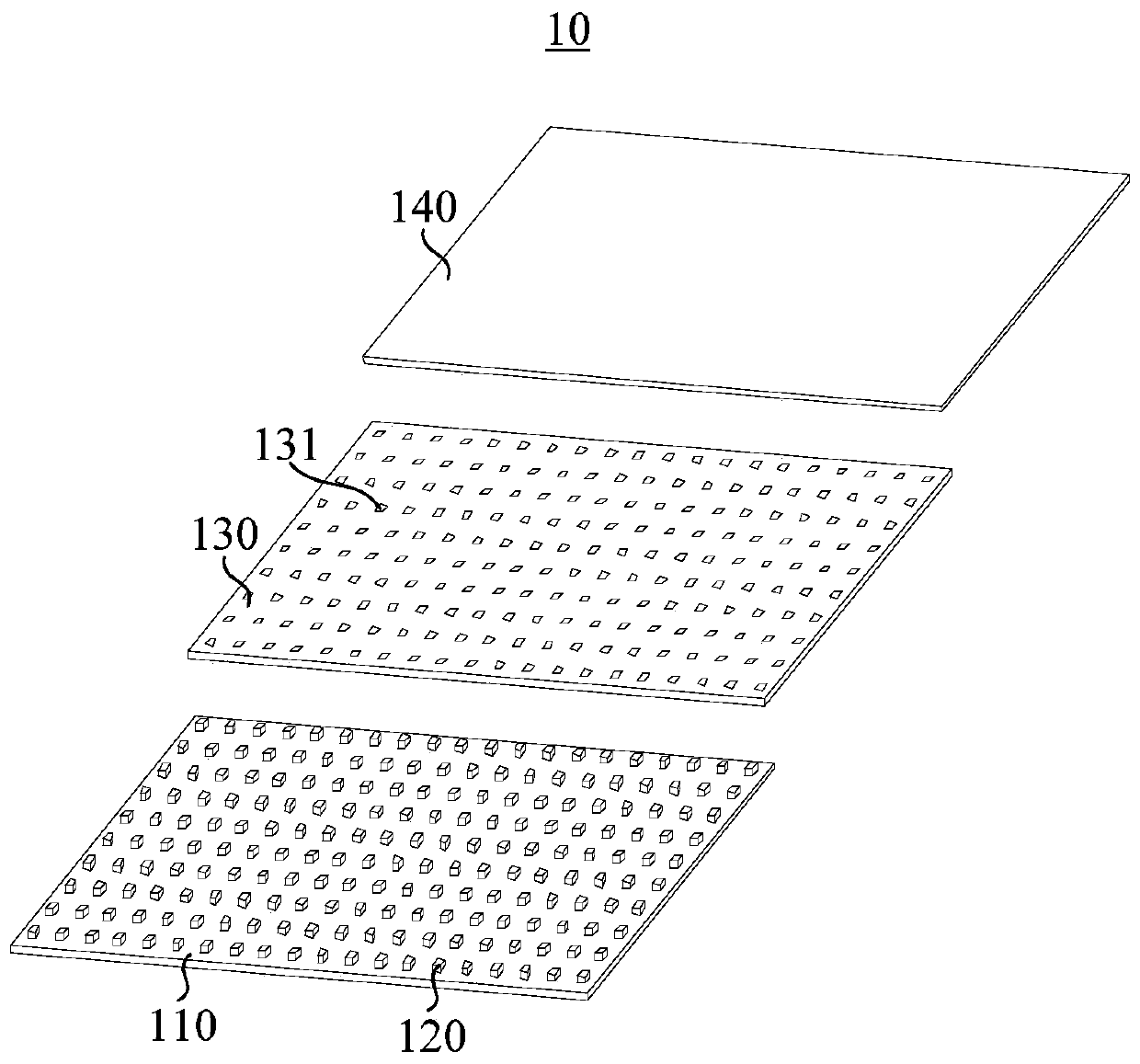

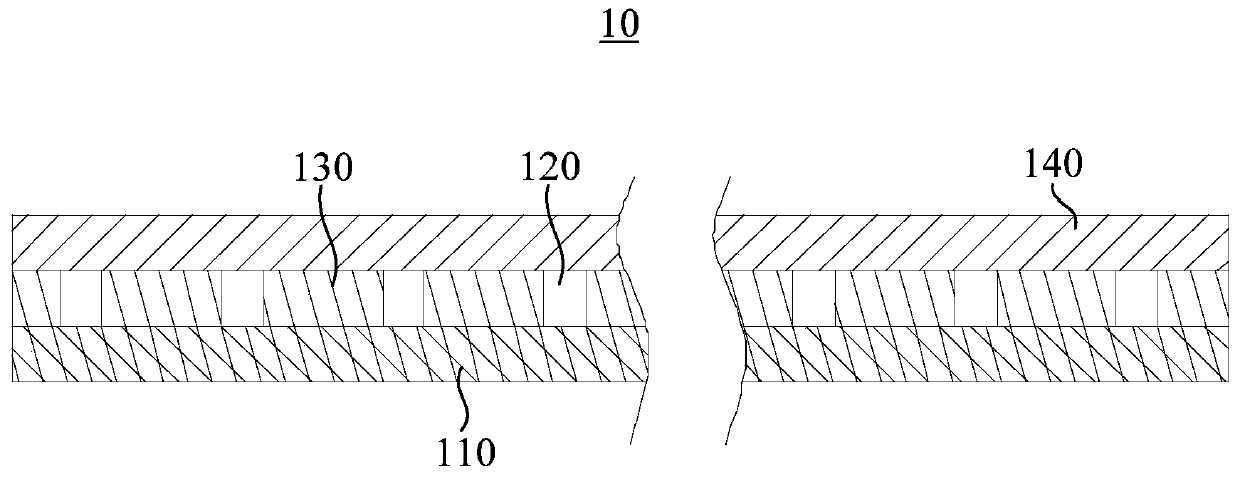

Multifunctional protective film

InactiveCN107418468AAchieve scratch resistanceAchieve antistaticFilm/foil adhesivesElectrically-conductive paintsPolyethylene terephthalateBlue light

The invention discloses a multifunctional protective film which comprises a use layer and a peeling layer. The use layer sequentially comprises a scratch-resistant layer, a first PET (polyethylene terephthalate) base film layer, a blue light preventive coating, a second PET base film layer and an antistatic pressure-sensitive adhesive layer; the peeling layer comprises a release film layer and an antistatic coating, and the release film layer clings to the antistatic pressure-sensitive adhesive layer and is arranged on the lower side of the antistatic pressure-sensitive adhesive layer. The multifunctional protective film has the advantages that scratch-resistant, antistatic and blue light preventive effects can be realized by means of composite modification; the multifunctional protective film with the netted pressure-sensitive adhesive layer is easy to stick and tear and free of adhesive residues.

Owner:FOSHAN NANHAI HAOSEN MACHINERY EQUIP CO LTD

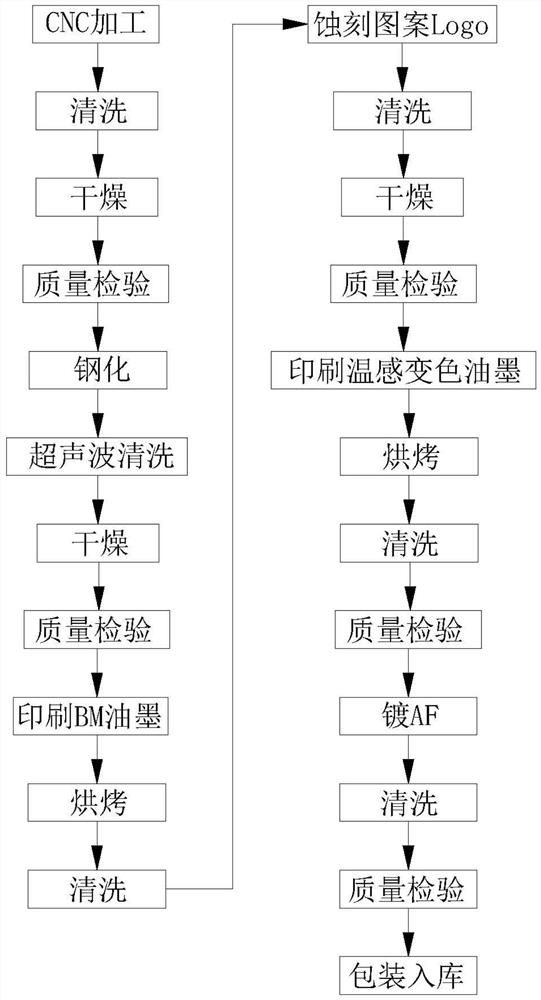

Manufacturing method of temperature sensing computer keyboard touchpad glass

The invention discloses a manufacturing method of temperature sensing computer keyboard touchpad glass. The method comprises the following steps: step 1, putting a touch panel glass raw material on a numerical control machine tool for CNC (Computer Numerical Control) processing; step 2, putting the glass substrate into a toughening furnace for toughening treatment; step 3, sequentially immersing the glass substrate into a chemical washing tank I and a chemical washing tank II for ultrasonic cleaning, rinsing the glass substrate subjected to ultrasonic cleaning by a countercurrent method, washing off the cleaning agent attached to the glass substrate, and then drying and inspecting the quality of the glass substrate which is rinsed to be clean; step 4, screen printing of BM ink and etching of a pattern Logo are carried out; step 5, silk-screen printing of temperature-sensitive color-changing ink; step 6, coating the surface of the glass substrate by using AF liquid medicine to form a touch panel glass finished product; and step 7, performing final quality inspection on the touch panel glass finished product, and packaging and warehousing the touch panel glass finished product. The touch panel glass has the beneficial effect that the surface color of the touch panel glass can be changed along with the change of temperature.

Owner:杭州万程科技有限公司

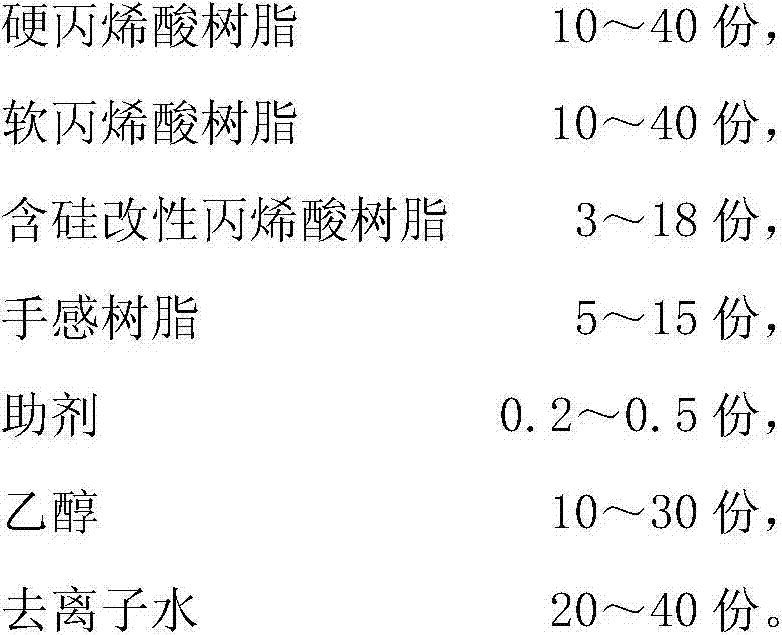

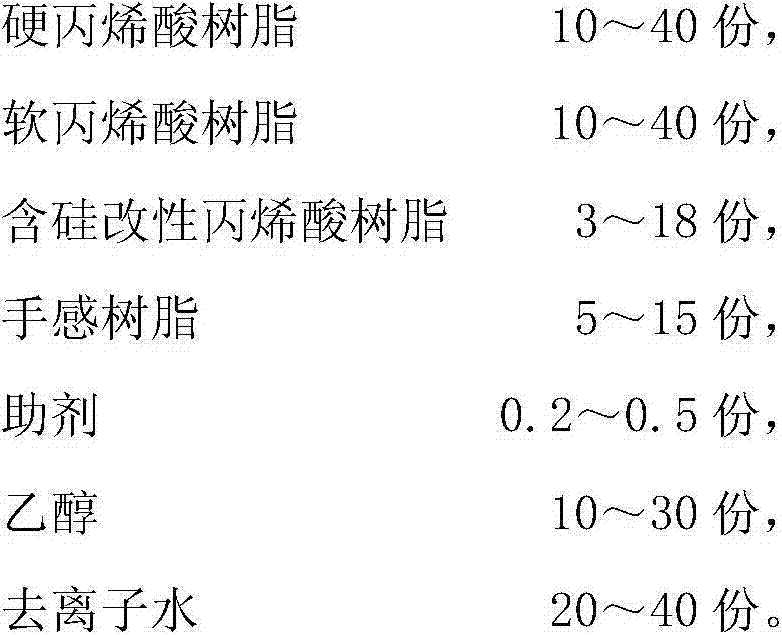

Coating composition capable of regulating surface friction coefficient of inner liner for cigarettes

ActiveCN103541271AImprove scratch resistanceAvoid slipperyNon-fibrous pulp additionCoatingsIonSurface friction

The invention relates to a coating composition capable of regulating the surface friction coefficient of an inner liner for cigarettes. The coating composition is composed of the following components in parts by weight: 10-40 parts of hard acrylic resin, 10-40 parts of soft acrylic resin, 3-18 parts of silicon-containing modified acrylic resin, 5-15 parts of hand feel resin, 0.2-0.5 part of auxiliaries, 10-30 parts of ethanol and 20-40 parts of deionized water. Compared with the prior art, the composition provided by the invention is capable of realizing the regulation of the surface friction coefficient of the coating layer because the soft acrylic resin and the hard acrylic resin are taken as a major part in combination with the silicon-containing modified acrylic resin and the hand feel resin; as a result, the composition is capable of meeting the requirements of different cigarette packing processes for the surface friction coefficient of the inner liner and satisfying the own scratch resistance of the inner liner.

Owner:SHANGHAI WEIKAI CHEM

Microcrystalline surface LED display screen

PendingCN111554203AImprove surface protection performanceImprove flame retardant performanceCooling/ventilation/heating modificationsIdentification meansLED displayLED lamp

The invention relates to a microcrystalline surface LED display screen, which comprises a PCB, LED lamp beads, a mask and a microcrystalline layer, and is characterized in that the LED lamp beads arearranged on the PCB in an array manner; lamp holes corresponding to the LED lamp beads are formed in the mask, and each LED lamp bead corresponds to one lamp hole and penetrates out of the lamp hole.The mask and the LED lamp beads are packaged on the PCB through the microcrystal layer, and glass beads are arranged in the microcrystal layer. The mask and the LED lamp beads are packaged on the PCBthrough the microcrystal layer, so that the waterproof and dustproof effects are realized, the wear resistance and scratch resistance can be realized, and the surface protection capability of the microcrystal surface LED display screen is greatly enhanced.

Owner:筑觉绘(上海)科技有限公司

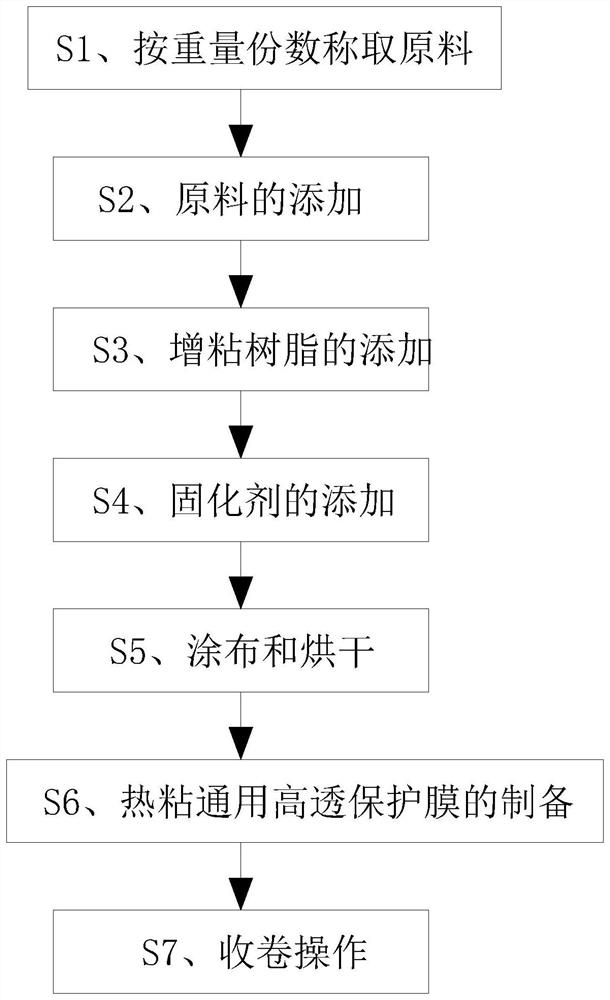

Preparation method of adhesive-feeling-free heat-shrinkable heat-sticking universal high-transmittance protective film

InactiveCN112760065AImprove fitHigh transparencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive glue

The invention discloses a preparation method of an adhesive-feeling-free heat-shrinkable heat-sticking universal high-transmittance protective film, and relates to the technical field of protective films. The preparation method comprises the following steps: S1, weighing the raw materials in parts by weight: 15-20 parts of tackifying resin, 25-35 parts of an acrylate pressure-sensitive adhesive, 3-5 parts of an auxiliary agent, 12-15 parts of an inorganic filler, 1-3 parts of a coupling agent, 20-25 parts of a curing agent and 10-15 parts of a solvent. According to the preparation method of the adhesive-feeling-free heat-shrinkable heat-sticking universal high-transmittance protective film, the prepared protective film adopts a heat shrinkage technology, the protective film can shrink and deform at the temperature of 80 DEG C or above, the surface of a protected product is covered with the film firstly, the film is heated to be shrunk, then the film can be well attached to the protected product after being tightened, universal protection is achieved, and no adhesive feeling exists; the glue is hot viscose water, does not have viscidity at normal temperature, and only has viscidity after being heated to 90 DEG C; and the protective film does not need to be coated with backing paper in the storage and transportation processes.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

High-strength scratch-resistant veneer

InactiveCN105464314AAnti-crackingAnti-curlingCovering/liningsWood layered productsWood veneerSolid wood

The invention discloses a high-strength scratch-resistant veneer. By aiming at the problems that the existing veneer is easy to crack and curl and does not have scratch-resistant performance and the like, the invention provides the high-strength scratch-resistant veneer. The high-strength scratch-resistant veneer comprises a bottom layer, a middle layer and a surface layer, wherein the bottom layer uses a superfine solid wood veneer or a high-density plate; the middle layer uses impregnated paper; the surface layer uses aluminum oxide; and the high-strength scratch-resistant veneer is formed through hot pressing by a hot press via a cold-hot-cold hot pressing process. The effects of cracking resistance, curling resistance, deformation resistance and scratch resistance are achieved.

Owner:HARBIN SHENGSHI HUALIN TECH

Polyester ink for ultra-thin colored film and method for making ultra-thin colored film

ActiveCN104263067BIncrease the variety of functionsMeet needsSynthetic resin layered productsInksPolyethylene terephthalateColor film

The invention discloses a polyester ink for an ultrathin colored film, which is prepared from the following raw materials in parts by mass: polyester resin, pigment, matting powder, dispersing agent, diluter and curing agent. The invention also discloses a manufacturing method of the ultrathin colored film, which comprises the following steps: 1) coating a release agent on a PET (polyethylene terephthalate) substrate, drying and curing to obtain a release layer; 2) coating the polyester ink on the release layer, drying and curing; and peeling the base film. Otherwise, the manufacturing method of the ultrathin colored film comprises the following steps: 1) coating a release agent on a PET substrate, drying and curing to obtain a release layer; 2) coating protective gloss oil on the release layer to form an ink protective layer; 3) coating the polyester ink on the ink protective layer, drying and curing to form an ink layer; and peeling the base film. The manufacturing method can be used for flexibly producing the film of any thickness or color, and can be used for preparing the polyester films with different tensile strengths and percentages of elongation; and the added ink protective layer can promote the diversification of the product functions.

Owner:DONGGUAN WEISHI ELECTRONICS MATERIALS TECH

High-strength scratch-resistant fireproof veneer

The invention discloses a high-strength scratch-resistant fireproof veneer. By aiming at the problems that the existing veneers heavily used in building materials in the prior art are easy to crack and curl and do not have scratch-resistant performance and the like, the invention provides the high-strength scratch-resistant veneer. The high-strength scratch-resistant fireproof veneer comprises a bottom layer, a middle layer and a surface layer, wherein the bottom layer uses a superfine solid wood veneer or an E1-grade fireproof high-density plate; the middle layer uses melamine impregnated paper; and the surface layer uses aluminum oxide. During the manufacturing, a cold-hot-cold hot pressing process is used; and the temperature of a hot press is 50 to 135 DEG C, the time is 2 to 5 minutes, and the pressure is 13 to 15mpa. The effects of cracking resistance, curling resistance, deformation resistance, scratch resistance and fireproof functions are achieved.

Owner:HARBIN SHENGSHI HUALIN TECH

Manufacturing method of high-strength scratch-resisting fireproof veneer

InactiveCN103526895AAnti-crackingAnti-curlingCovering/liningsSynthetic resin layered productsSolid woodSingle plate

The invention discloses a manufacturing method of a high-strength scratch-resisting fireproof veneer. The manufacturing method of the high-strength scratch-resisting fireproof veneer aims to solve the problems that in the prior art, a great number of veneers used in building materials are easy to crack, crimp and scratch, and the like. The manufacturing method of the high-strength scratch-resisting fireproof veneer comprises the steps that special-grade solid-wood fireproof single boards or E1-grade fireproof high-density boards are used as a bottom layer, melamine impregnated paper is used as a middle layer, aluminum oxide is used as a surface layer, and the high-strength scratch-resisting fireproof veneer is formed in the cold-hot-cold hot-pressing process through a hot press. The manufacturing method of the high-strength scratch-resisting fireproof veneer has the advantages of achieving cracking prevention, crimping prevention, deforming resistance, scratch resistance and fire prevention.

Owner:HEILONGJIANG HUAXIN FURNITURE

Method for manufacturing metal sandwich glass

InactiveCN102120401BThe overall thickness is thinReduce weightPoint-like light sourceLighting elementsPhotomaskMetal

Owner:LIGA PRECISION TECH

High-strength anti-scratch veneer

The invention discloses a high-strength anti-scratch veneer. According to the high-strength anti-scratch veneer, the problems that an existing veneer is easily cracked, curled and scratched are solved. The high-strength anti-scratch veneer comprises a bottom layer, a middle layer and a surface layer, wherein the bottom layer is a special-grade solid wood singe board or a high-density board; the middle layer is dipped paper; the surface layer is prepared from aluminum oxide. The high-strength anti-scratch veneer is thermally formed by a hot pres through a cold-hot-cold thermal pressing process, and effects of preventing cracking and curling and resisting deformation and scratching are achieved.

Owner:HEILONGJIANG HUAXIN FURNITURE

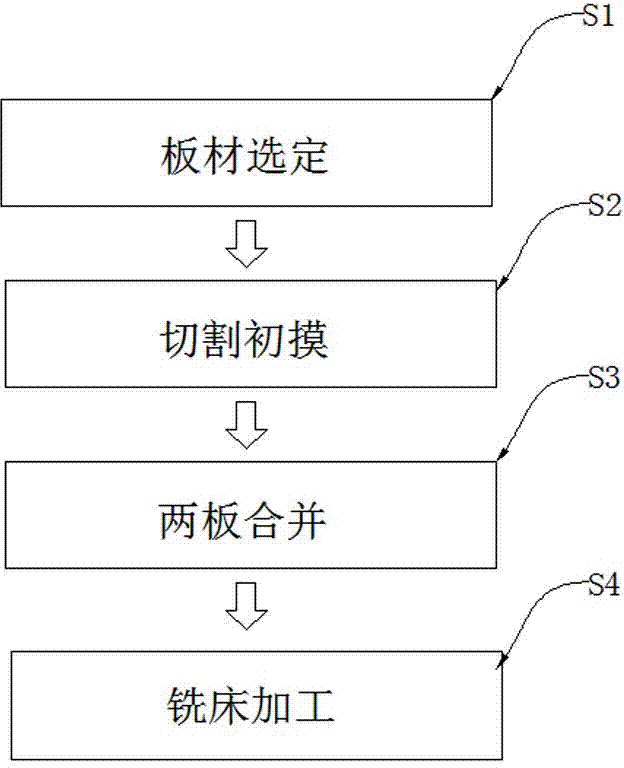

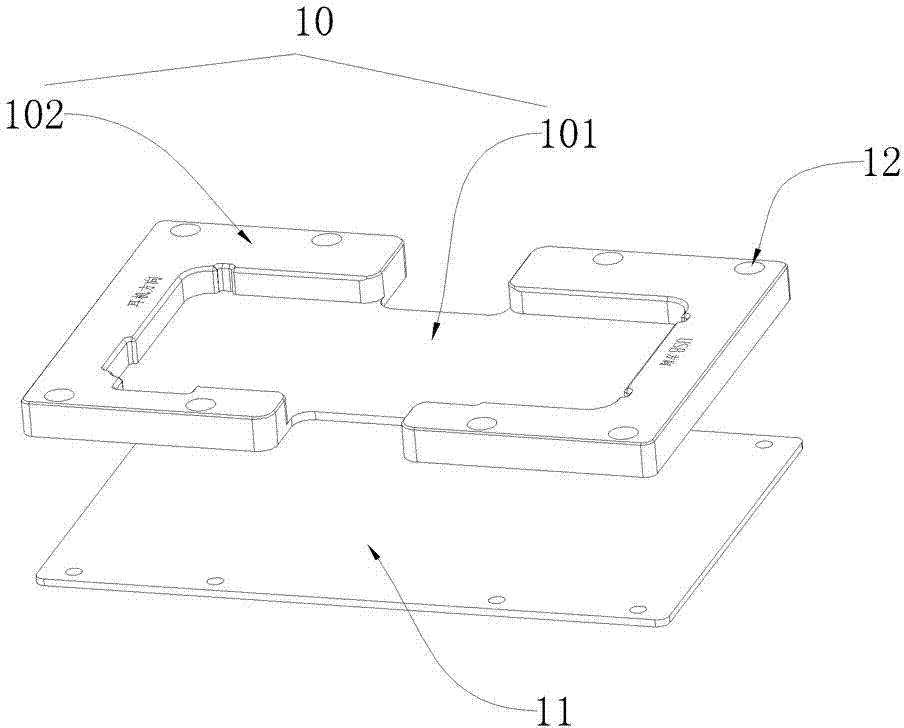

Silica gel positioning die and manufacturing process thereof

ActiveCN104723590ASolve the lack of hardnessLow processing costDomestic articlesNumerical controlFiber

The invention discloses a silica gel positioning die and a manufacturing process thereof. The process comprises the following steps: selecting plates, selecting and purchasing a silica gel plate with standard hardness; cutting an initial die, cutting the silica gel plate to be with the size of the positioning die according to the specific specification of the silica gel positioning die to form an initial positioning die; combining the two plates, bonding an ultrathin fiber plate with the silica gel plate of the initial positioning die; carrying out miller processing, namely, processing the bound positioning die to be of a positioning die shape by using a CNC numerical control miller. Through the adoption of the silica gel positioning die manufacturing process disclosed by the invention, the silica gel plate is bound with the ultrathin fiber plate, so that the silica gel plate has enough hardness and can be processed to form the positioning die shape by directly using the CNC numerical control miller to process. According to the improvement process disclosed by the invention, liquid-state silica gel can be injected without using a silica gel model, so that the processing technic cost is lowered, the period is shortened, and the precision control consistency is high.

Owner:SHENZHEN QIANGRUI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com