Silica gel positioning die and manufacturing process thereof

A production process and positioning die technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of poor consistency of batch production precision control, a lot of manpower and material resources, and long production cycle, and achieve high precision control consistency, Reduced cycle time, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

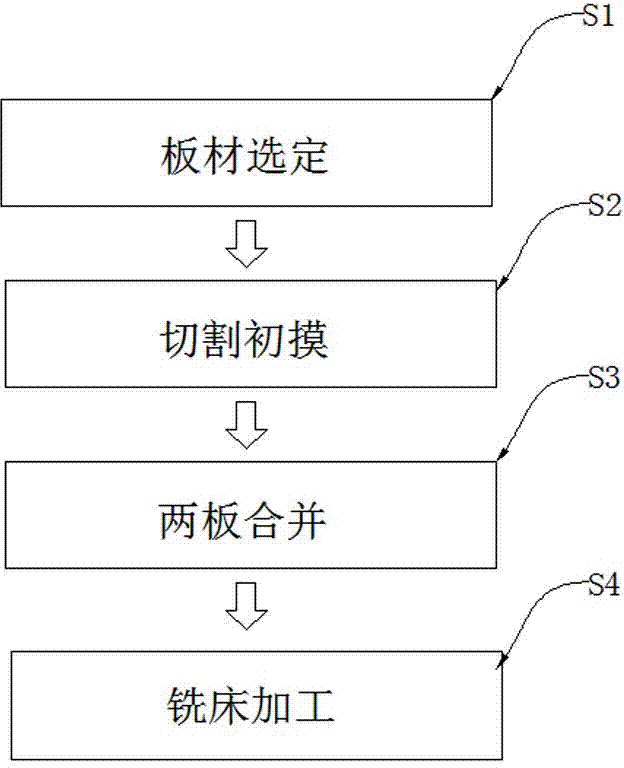

[0030] refer to figure 1 , the manufacture technology of a kind of silica gel positioning mold of the present invention, comprises the following steps:

[0031] S1: The plate is selected, and the silicone plate with standard hardness is selected and purchased;

[0032] S2: Cut the initial mold, according to the specifications of the specific silicone positioning mold, cut the silicone plate into the size of the positioning mold to form a preliminary positioning mold;

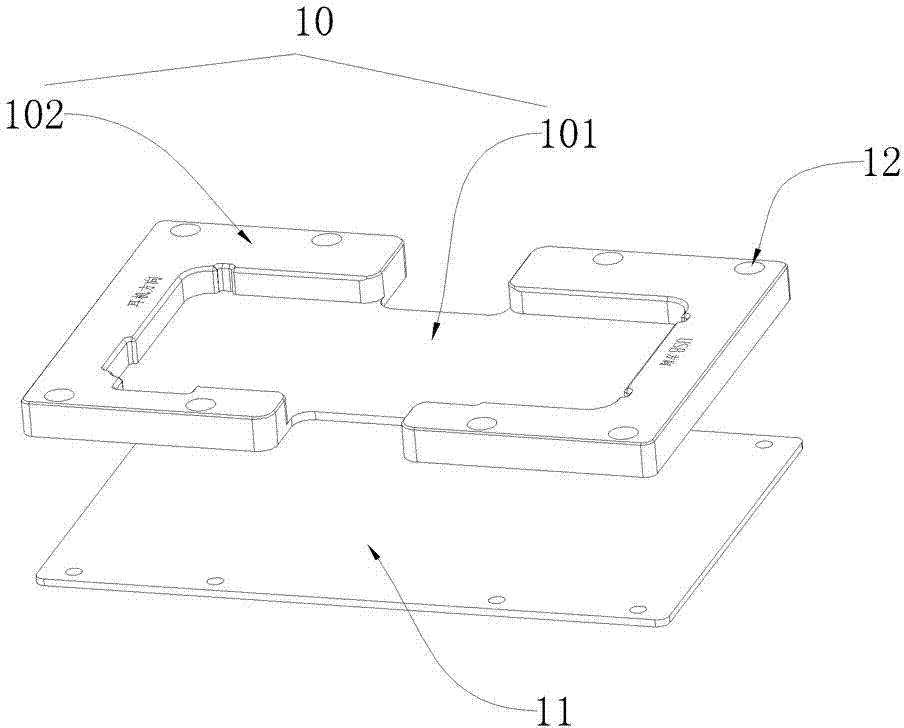

[0033] S3: the two plates are merged, and the ultra-thin fiberboard 11 is bonded to the silica gel plate 10 of the preliminary positioning mold;

[0034] S4: Milling machine processing, using CNC numerical control milling machine to further process the bonded positioning mold into the shape of the positioning mold.

[0035] Compared with the prio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com