Production method of 3D multidimensional cambered multilayer laminated glass substrate

A technology of laminated glass and arc surface is applied in the field of 3D multi-dimensional arc surface multilayer laminated glass substrate production, which can solve the problems of easy deformation, wear resistance, and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

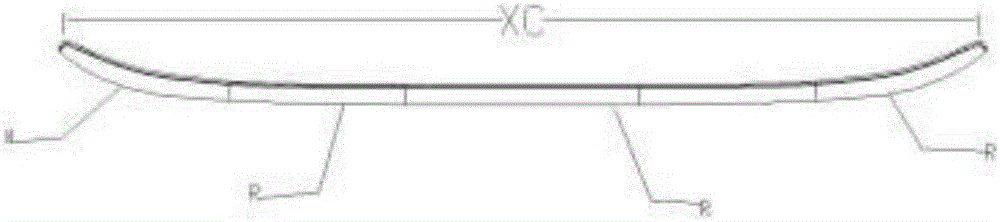

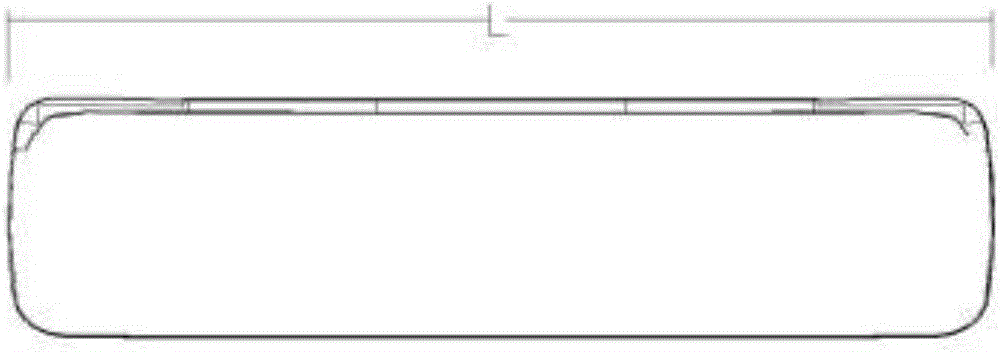

[0021] The present invention is a 3D multi-dimensional arc-surface multi-layer laminated glass substrate. The final glass substrate produced is a 3D multi-dimensional arc-surface multi-layer laminated structural glass or a 3D multi-dimensional arc-surface special-shaped multi-layer laminated structural glass. The glass substrate is The reverse side can be fabricated and matched with a layered coating process. The matching processes include: spraying, color sputtering coating, heat transfer printing, water transfer printing, film sticking, screen printing, laser engraving, high temperature sintering, UV transfer printing, roller coating, etc. After the matching process, the 3D The shape of multi-dimensional curved multi-layer laminated glass will not change, and the surface or inside of the glass substrate will present metal texture, frosting, bumps, bubbles, refraction, reflection, colorful discoloration, stone texture, wood, cloth texture and other effects according to differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com