Manufacturing method of high-strength scratch-resisting fireproof veneer

A production method and anti-scratch technology, applied in chemical instruments and methods, wood layered products, lamination, etc., can solve the problems of general price, single color, and easy deformation of fireproof boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for manufacturing a high-strength anti-scratch fireproof decorative panel, characterized in that it includes the following steps:

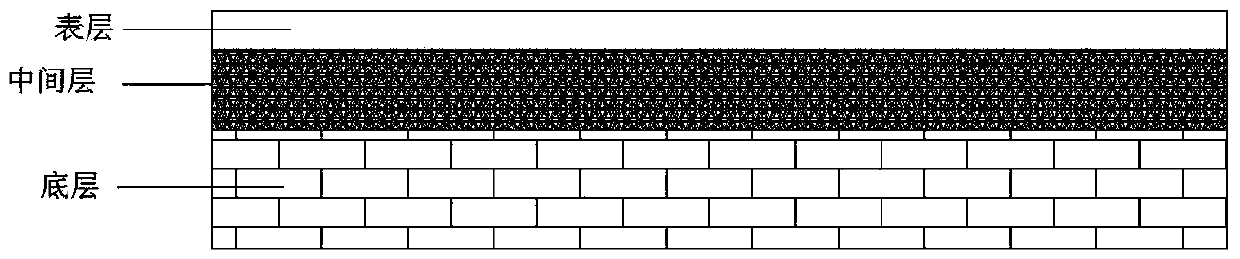

[0016] ①. Select suitable materials for the bottom layer, middle layer and surface layer;

[0017] ②. Put the selected material into the hot press for hot pressing.

Embodiment 2

[0019] In the step ①, the bottom layer is made of super-grade solid wood fireproof veneer or E1 fireproof high-density board; the middle layer is made of melamine impregnated paper; the surface layer is made of aluminum oxide.

Embodiment 3

[0021] In the step ②, the temperature of the hot press is 50-135° C., a cold-hot-cold hot-pressing process is adopted, the time is 2-5 minutes, and the pressure is 13-15 mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com