Method for manufacturing metal sandwich glass

A technology of metal interlayer and manufacturing method, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, decorative arts, etc., can solve the problems of heavy weight, thick glass products, and damage to decorative effects, etc., and achieve light weight and thickness thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

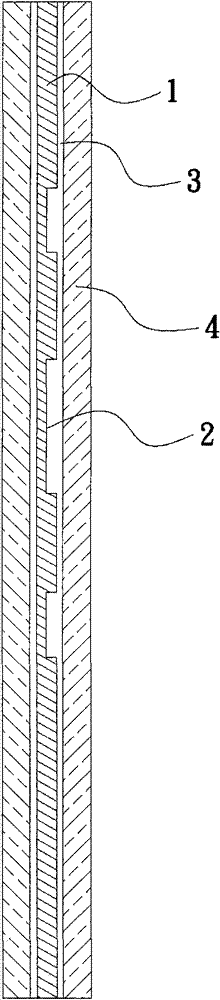

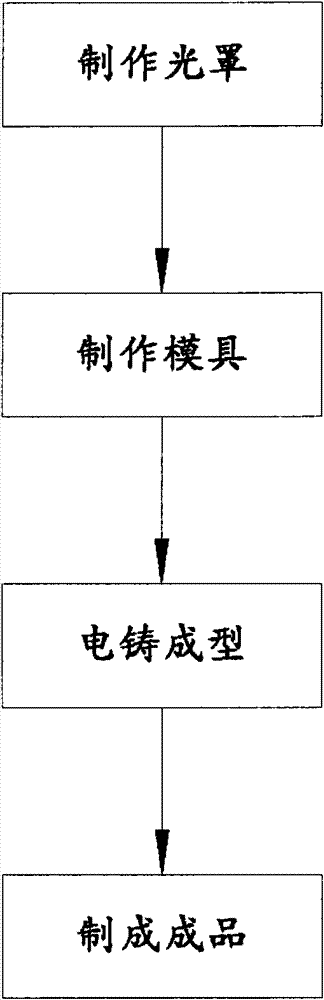

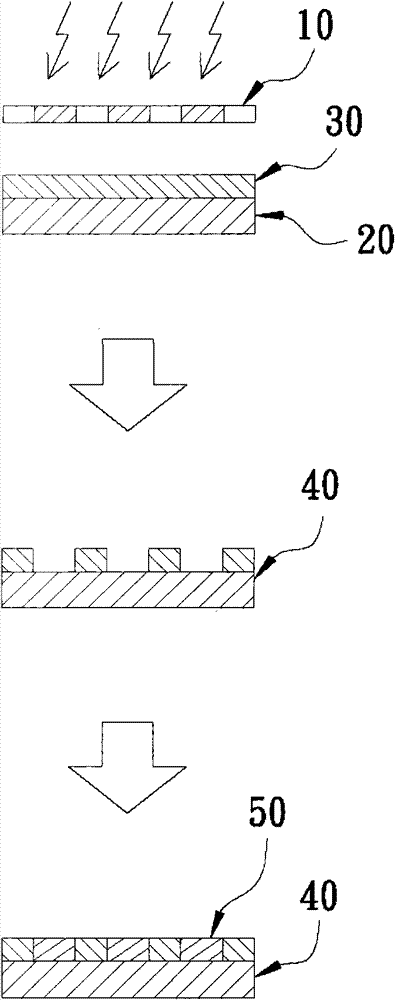

[0031] The manufacturing method of the present invention includes manufacturing steps such as making a photomask, making a mold, electroforming, and making a finished product. First, a pattern to be formed is made into a photomask, and then a photoresist is coated on a substrate. layer, and place the photomask on the top of the photoresist layer for exposure, so that the light-receiving part on the photoresist layer is cured, and then remove the uncured part of the photoresist layer to obtain a hollow pattern mold, and then, electroforming is performed through the mold to obtain a hollow metal film, and the hollow metal film will form a hollow pattern identical to the pattern, and finally, a glued film is pasted on at least one side of the hollow metal film , and attach a bottom layer and a glass layer to both sides of the hollowed-out metal film, and then pressurize and evacuate the hollowed-out metal film into the glued film, and pass the glued film between the bottom layer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com