Manufacturing method of temperature sensing computer keyboard touchpad glass

A technology for a computer keyboard and a manufacturing method, which are applied in the directions of glass tempering, glass manufacturing equipment, and cleaning methods using liquids, etc., can solve the problem that the touch panel glass does not have the function of discoloration, and achieve the improvement of aesthetics, strength, printing and so on. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

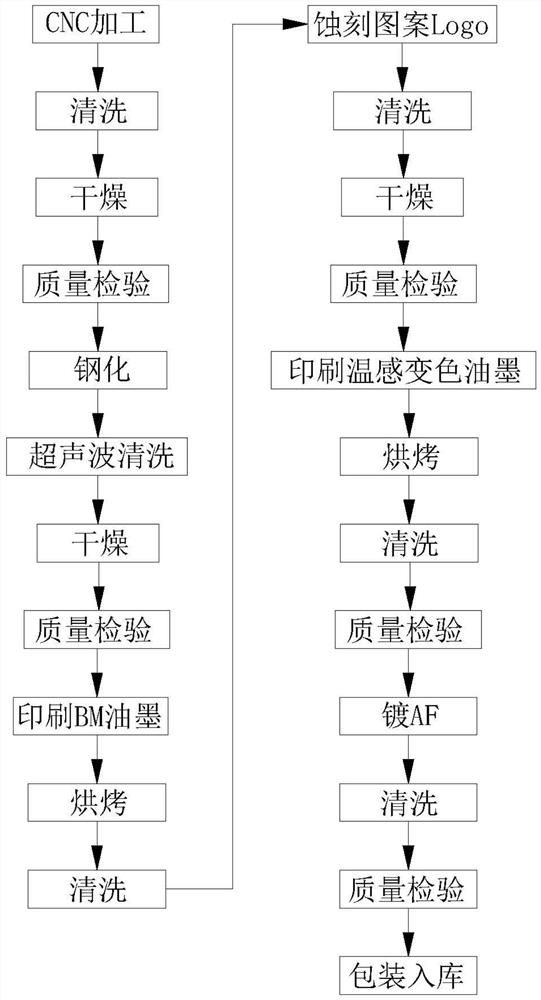

[0036] A method for manufacturing temperature-sensing computer keyboard touch panel glass, comprising the following steps:

[0037] Step 1: Put the glass raw material of the touch panel on the CNC machine tool for CNC processing, and clean, dry and inspect the glass substrate after CNC processing;

[0038] Step 2, putting the glass substrate into a tempering furnace for tempering treatment, and cooling the tempered glass substrate;

[0039] Step 3, immerse the glass substrate in the chemical washing tank 1 and the chemical washing tank 2 in turn for ultrasonic cleaning, and then rinse the glass substrate after ultrasonic cleaning by countercurrent method, wash off the cleaning agent attached to the glass substrate, and then rinse Drying and quality inspection of clean glass substrates;

[0040] Step 4: Perform the first screen printing on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com