Resin paint for optical film and application of resin paint

A technology of resin coatings and optical films, applied in polyurea/polyurethane coatings, coatings, etc.

Active Publication Date: 2016-11-16

ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, for the backlight device, when the light diffusion film, prism sheet, and light guide plate are stacked, between the light diffusion layer of the light diffusion film and the back or front of the prism sheet, the anti-adhesion layer of the light diffusion film and the surface of the light guide plate, prism sheet The contact between the front surface or the light diffusion layer will cause friction. In addition, friction will occur due to contact during the superimposed use and production and transportation of the light diffusion film, whether it is the diffusion layer of the diffusion film or the anti-adhesion layer, prism sheet There are still scratches on the front and back of the light guide plate. In the high-definition liquid crystal display in recent years, the slight scratch will become the bad cause of the liquid crystal display.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

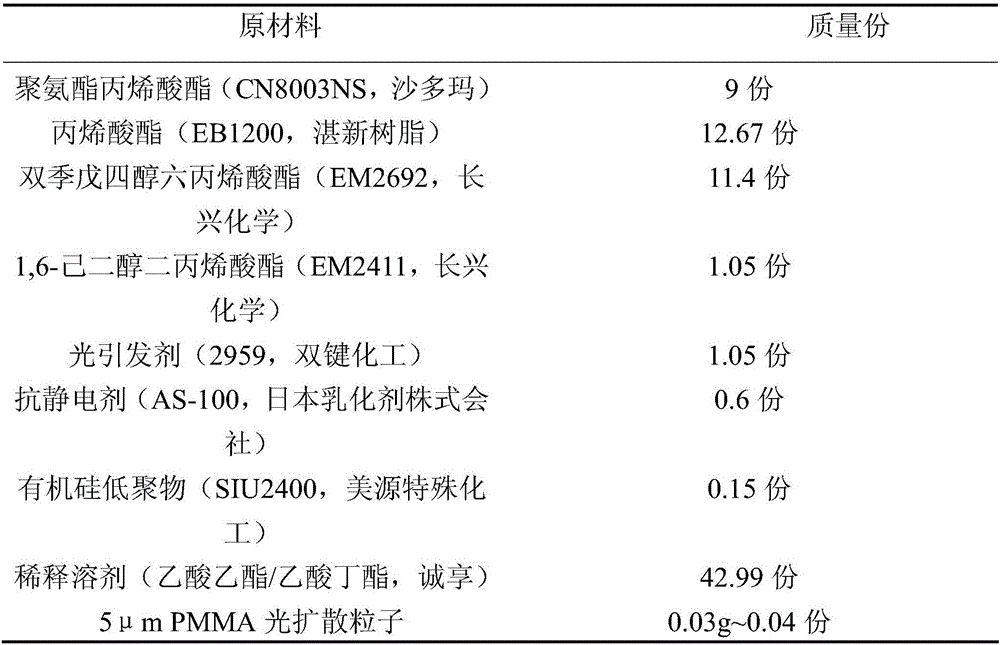

specific Embodiment example 1

[0038]

[0039]

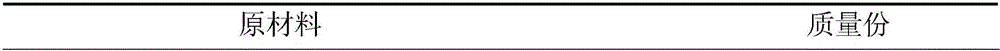

specific Embodiment example 2

[0042]

specific Embodiment example 3

[0045]

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides resin paint for an optical film. The resin paint for the optical film comprises a first component, a second component, a flatting agent, an antistatic agent, a photoinitiator and a diluent, wherein the mass ratio range of the first component and the second component is 1:3 to 1:1; the first component is selected from any two of a first low polymer, a second low polymer and a monomer; the second component comprises the rest component except for the two components selected by the first component. The resin paint for the optical film provided by the invention utilizes the compatibility difference between resins with different polarities or the resins and the monomer to form a non-planar micro-structure with similar particle action on the surface of an object being painted after being solidified, so that the effects of bonding resistance, atomization, scratch resistance and delustering are achieved.

Description

Technical field: [0001] The invention relates to a resin coating for an optical film, in particular to components and applications of the resin coating for an optical film. Background technique: [0002] Currently, the self-dulling resins on the market are usually chemically synthesized, that is, structures or groups that can absorb light are introduced during the coating synthesis process to play a matting effect. Chinese patent CN103163571A discloses an optical film and its manufacturing method. First, a mold with a wavy pattern is manufactured, and then the mold is transferred to the base film so that the optical film has a certain haze; Chinese patent CN103740250A discloses a A preparation method of a self-dulling type leather water-based polyurethane finishing agent, which firstly synthesizes two components A and B respectively, and then mixes and prepares them; Chinese patent CN104530328A discloses a preparation method of a self-dulling resin. Sol, and then use the si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/14

CPCC09D175/14

Inventor 袁龙飞张冬菊丁清华夏春苗

Owner ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com