High-temperature-resistant mirror ink and preparation method thereof

A technology of mirror ink and high temperature resistance, which is applied in ink, household utensils, applications, etc., and can solve problems such as low product yield, poor surface effect, and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

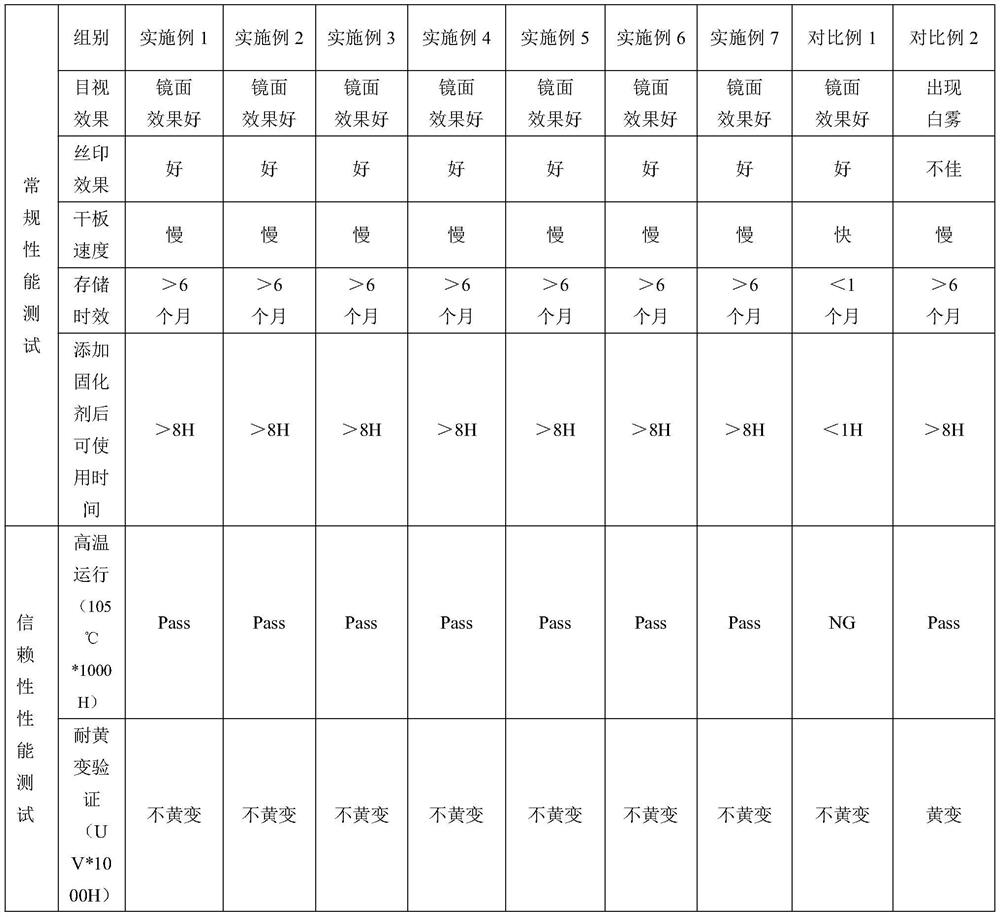

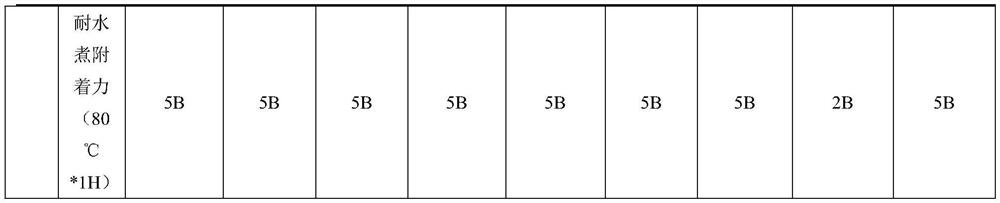

Examples

Embodiment 1

[0071] A high temperature resistant mirror ink, comprising the following components by weight: 20g of rubber modified epoxy resin, 2g of saturated polyester resin, 20g of nano nickel powder, 45.5ml of diethylene glycol butyl ether, 0.1ml of silicone leveling agent , Silicone defoamer 3ml, epoxy silane coupling agent 1.5ml, silicone wetting agent 0.5ml, polyether modified anti-settling agent 0.2ml, oleic acid dispersant 5ml, cationic thermal initiator 2ml, salicylate Phenyl ester 0.2ml.

[0072] The preparation method of the high temperature resistant mirror ink of the present embodiment is:

[0073] S1. Mix the above-mentioned rubber-modified epoxy resin, saturated polyester resin, and diethylene glycol butyl ether, and use a high-speed disperser to disperse and stir at a speed of 1500 rpm to make the rubber-modified epoxy resin and saturated polyester resin Completely dissolve in the solvent to obtain the mixed solution A;

[0074] S2. Mix the above silicone leveling agent,...

Embodiment 2

[0078] A high temperature resistant mirror ink, comprising the following components by weight: 20g of bisphenol A epoxy resin, 2g of thermoplastic acrylic resin, 20g of nanometer copper powder, 45.5ml of propylene glycol phenyl ether, 0.1ml of silicone leveling agent, polyether Modified defoamer 3ml, mercaptosilane coupling agent 1.5ml, fluorocarbon modified wetting agent 0.5ml, fumed silica anti-sedimentation agent 0.2ml, oleylamine dispersant 5ml, dicyandiamide 2ml, 2,4- Dihydroxybenzophenone 0.2ml.

[0079] The preparation method of the high temperature resistant mirror ink of the present embodiment is:

[0080] S1. Mix bisphenol A epoxy resin, thermoplastic acrylic resin, and propylene glycol phenyl ether, and use a high-speed disperser to disperse and stir at a speed of 2000rpm to completely dissolve bisphenol A epoxy resin and thermoplastic acrylic resin in propylene glycol In phenyl ether, mixed solution A was obtained;

[0081] S2. Silicone leveling agent, polyether ...

Embodiment 3

[0085] A high temperature resistant mirror ink, comprising the following components in parts by weight: 20g of cycloaliphatic epoxy resin, 2g of thermoplastic acrylic resin, 20g of nano-aluminum powder, 45.5ml of glycerin, 0.1ml of silicone leveling agent, and silicone defoamer 3ml, epoxy silane coupling agent 1.5ml, silicone wetting agent 0.5ml, polyether modified anti-sedimentation agent 0.2ml, oleylamine dispersant 5ml, cationic thermal initiator 2ml, salicylate phenyl ester 0.2ml.

[0086] The preparation method of the high temperature resistant mirror ink of the present embodiment is:

[0087] S1. Mix alicyclic epoxy resin, thermoplastic acrylic resin, and glycerin, and use a high-speed disperser to disperse and stir at a speed of 2000 rpm, so that the alicyclic epoxy resin and thermoplastic acrylic resin are completely dissolved in glycerin, and the mixture is obtained. Liquid A;

[0088] S2. Silicone leveling agent, silicone defoamer, epoxy silane coupling agent, silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com