High temperature resistant common mode inductor having shielding layers and magnetic core embedded in PCB

A technology of common-mode inductors and shielding layers, which is applied in the field of high-temperature-resistant common-mode inductors, can solve problems such as poor high-frequency filtering characteristics, achieve the effects of reducing production processes, realizing high-temperature resistance characteristics, and meeting the needs of harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

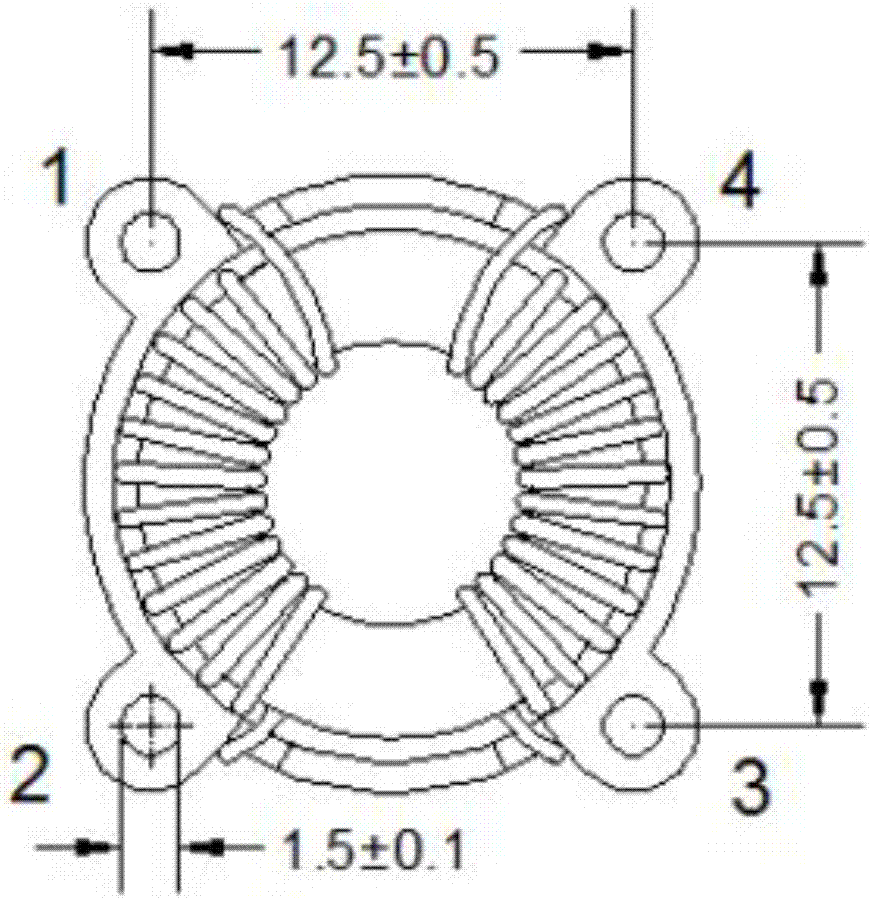

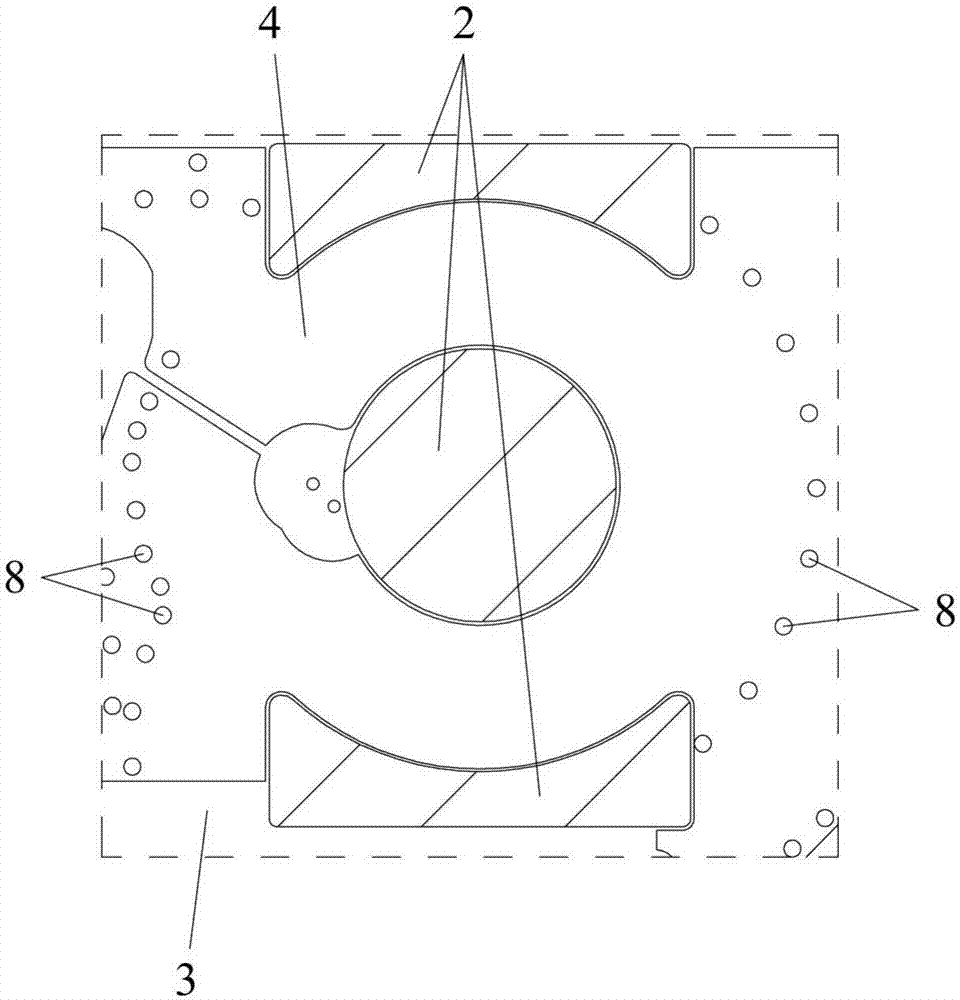

[0035] Embodiment one: as attached image 3 to attach Figure 7 As shown, a high temperature resistant common mode inductor with a shielding layer 4 embedded in a PCB with a magnetic core 2 includes a PCB 1 and a magnetic core 2 vertically embedded in the PCB 1 .

[0036] The magnetic core 2 can be a magnetic core in the shape of ECW, ETD, EP, FED, PQ, DQ or EIW, which is selected according to the required inductance and current. The magnetic core 2 as a whole includes a central column, two side columns which are arranged on both sides of the central column and whose axes are parallel to the axis of the central column, and two connecting parts for connecting the end of the central column and the end of the side column, Therefore, the longitudinal cross-sectional structure of the magnetic core 2 is in the shape of a horizontal Japanese font. Wherein, the central column of the magnetic core 2 is cylindrical, and its cross-section is circular, and the cross-section of the centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com