Smokeless smellless inorganic nano high-temperature-resistant corrosion-resistant wear-resistant paint and preparation method thereof

An inorganic nano, anti-corrosion and wear-resistant technology, applied in the field of materials, can solve problems such as pungent odor, inconvenient use for customers, easy yellowing, etc., achieve good high-temperature heat insulation, save material consumption, and enhance the effect of cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 50kg of 10 nanometer to 20 nanometer silica dispersion, 20kg of 30 nanometer to 50 nanometer silica dispersion, and 30kg of 60 nanometer to 90 nanometer silica dispersion into a jacketed water-cooled pull cylinder, start stirring, and then put in 8kg Acetic acid, adjust the PH value to 4, then increase the temperature to 50 degrees, start dripping a mixture of 45kg methyltrimethoxysilane, 4.5kg dimethyldimethoxysilane, 0.5kg glycidyl ether trimethoxysilane, Finish the drop within 30 minutes, keep the reaction temperature at 60 degrees, react at a constant temperature for 3 hours, then add 1.5 kg of accelerator HMT, keep the reaction for 30 minutes, stop heating, cool down, and obtain an inorganic nanometer with the appearance of a semi-opaque transparent viscous liquid Resin. The solid content of inorganic nano-resin is 35.6%, the pencil hardness is 9H, the gloss is 58°, and the temperature resistance is 1000°.

[0036] The prepared 50kg inorganic nano resin, 15kg env...

Embodiment 2 Embodiment 17

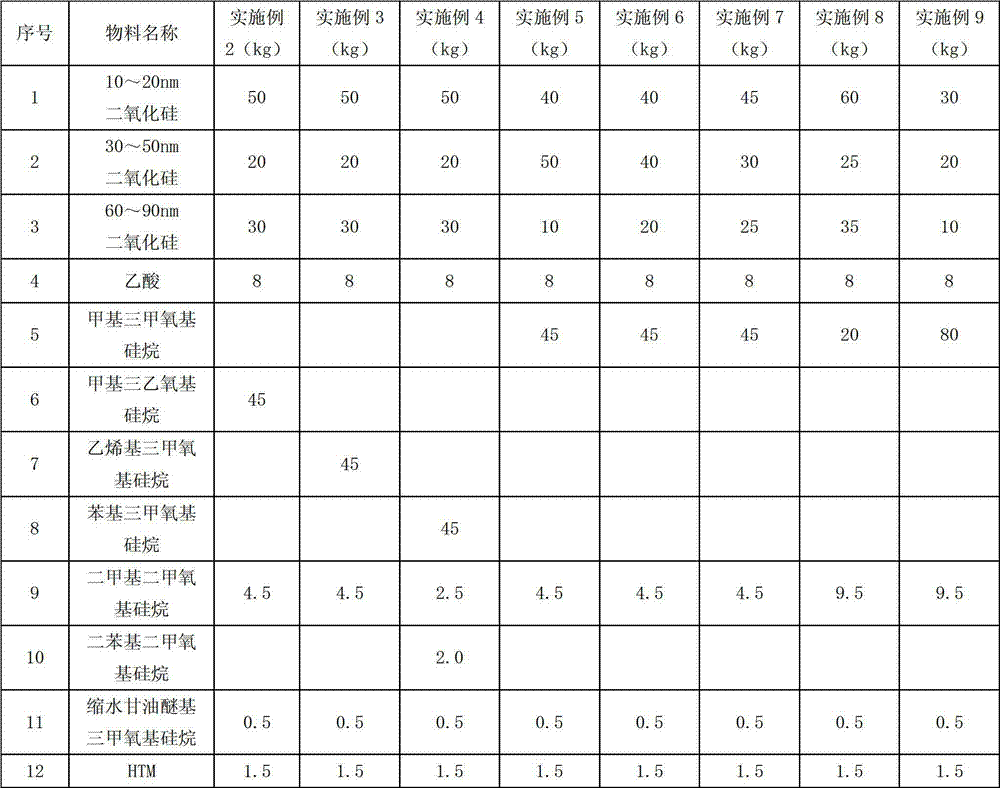

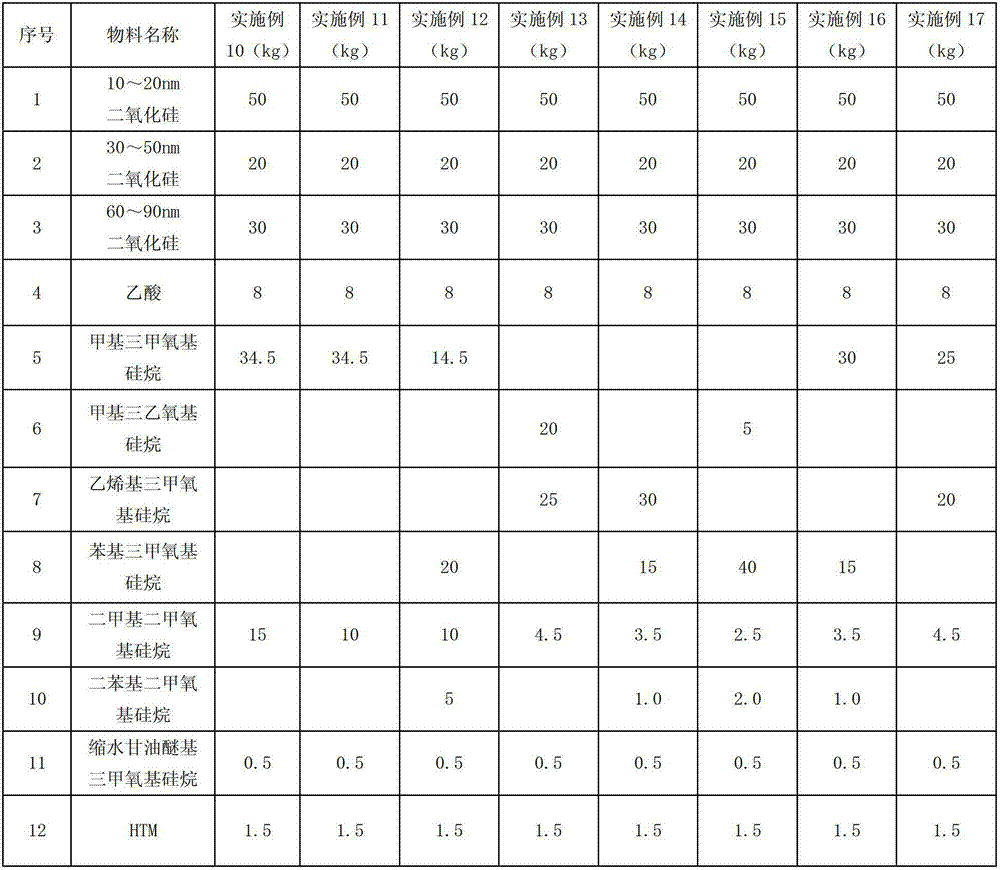

[0038] The preparation methods of Examples 2 to 17 are the same as those of the Examples, and for the formula, please refer to Table 1 and Table 2:

[0039] Table 1: Formulations of Example 2 to Example 9

[0040]

[0041] Table 2: Formulations of Example 10 to Example 17

[0042]

[0043] For its main performance indicators, please refer to Table 3 and Table 4:

[0044] Table 3: Main performance indexes of Example 2 to Example 9

[0045] Serial number

Indicator name

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

Example 9

1

Solid content

35

42

48

35.5

35

35

34

34

2

Pencil hardness

9H

9H

7H

9H

9H

9H

9H

9H

3

Luster

55°

68°

75°

65°

61°

60°

40°

67°

4

1000°

800°

600°

1000°

1000°

1000°

1000。

600°

[0046] Table 4: Main performance indexes of Example 10 to Example 17

[0047] Serial number

Indicator name

Example 10

Example 11

Example 12

Example 13

Example 14

Example 15

Example 16

Example 17

1

Soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com