Preparation method of embedded porous Fe-Nx@Pd-NC nanorod, nanorod prepared by preparation method, and application of nanorod

An embedded and nanorod technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of not having high temperature resistance, difficult to construct Pd active centers synchronously, and Pd surface active sites Issues such as point count reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

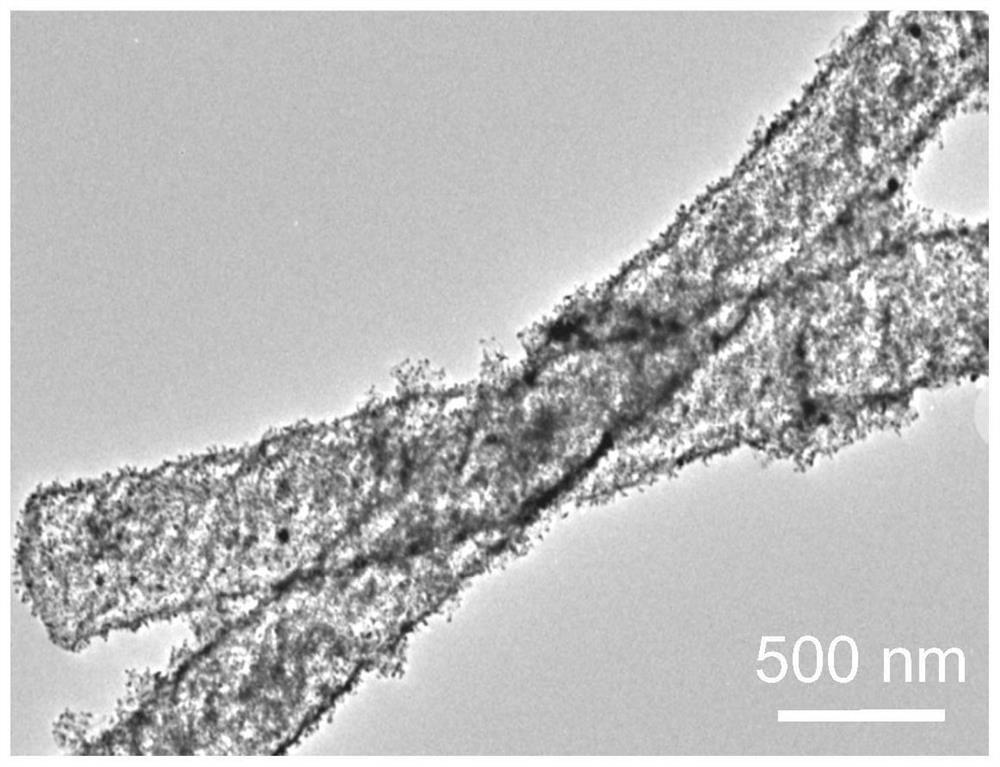

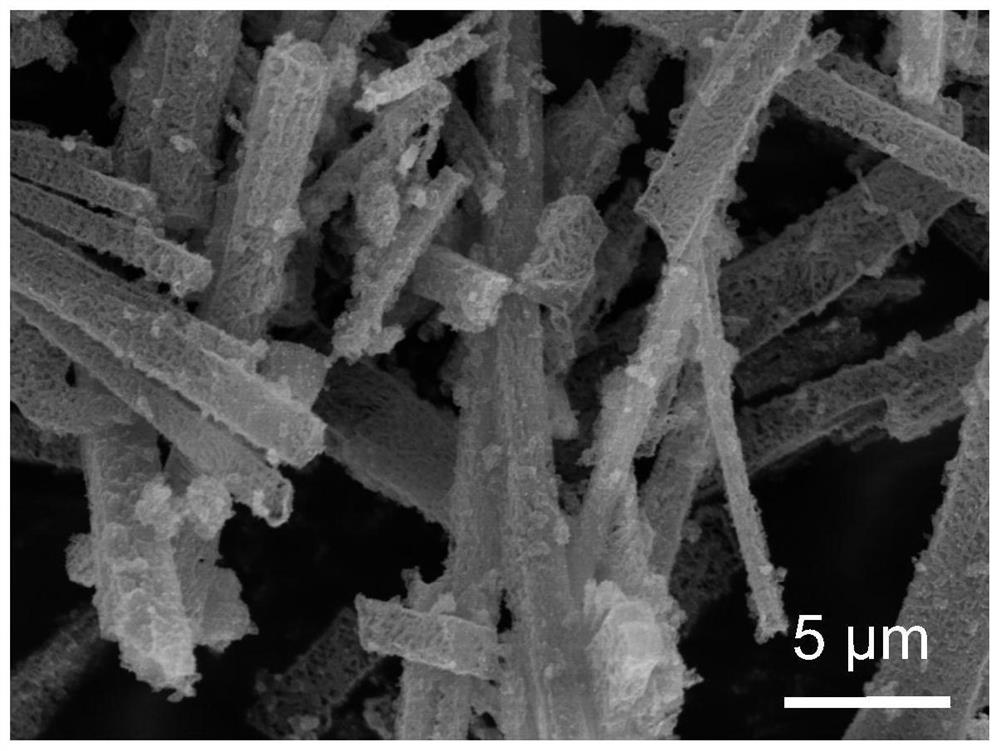

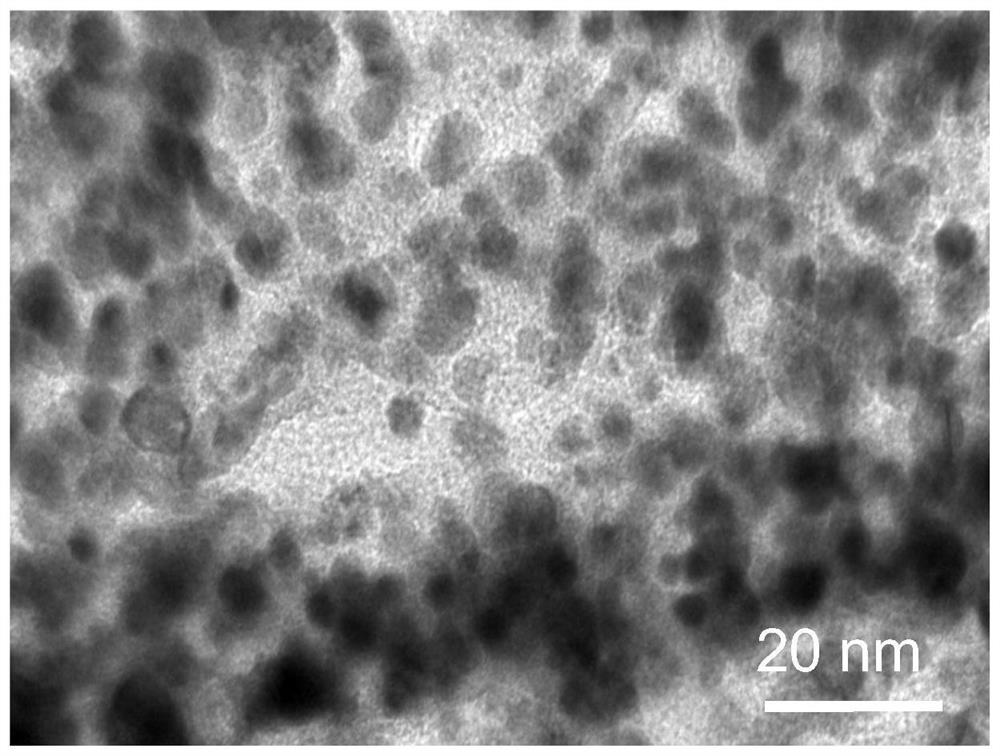

[0039] An embedded porous Fe-N X The preparation method of @Pd-NC nanorod, comprises the following steps:

[0040] 1) Preparation of metal precursor complex: weigh 0.15g naphthylamine (C 10 h 9 N), added to 30mL of water and ethanol mixed solvent (the ratio of water and ethanol is 10:1), fully ultrasonic to dissolve; then add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, mix evenly, after standing still, centrifuge to remove the liquid and dry to get yellow flaky Pd(II)-naphthylamine complex powder (observed under a 200nm scale electron microscope, the product is flaky, and the product is yellow), and the product is tested by icp The mass fraction of Pd in the medium is 10.1%;

[0041] 2) Preparation of the green rod-shaped intermediate product FePc@Pd-NC: Weigh 20 mg of the yellow powder prepared in step 1), and at the same time weigh 10 mg of FePc and disperse them in 40 mL of THF, stir for 24 hours, evaporate the solvent, and centrifuge to remove the liquid and dry it, th...

Embodiment 2

[0044] An embedded porous Fe-N X The preparation method of @Pd-NC nanorod, comprises the following steps:

[0045] 1) Preparation of metal precursor complex: weigh 0.15g naphthylamine (C 10 h 9 N), added to 30mL of water and ethanol mixed solvent (the ratio of water and ethanol is 10:1), fully ultrasonic to dissolve; then add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, mixed evenly, centrifuged to remove liquid after standing and dried to obtain yellow flake Pd(II)-naphthylamine complex;

[0046] 2) Preparation of the green rod-shaped intermediate product FePc@Pd-NC: Weigh 20 mg of the yellow powder prepared in step 1), and at the same time weigh 20 mg of FePc and disperse them in 40 ml THF, stir for 24 hours, evaporate the solvent, and centrifuge to remove the liquid and dry it, that is Green rod-shaped intermediate product FePc@Pd-NC powder can be obtained;

[0047] 3) Embedded porous Fe-N X Preparation of @Pd-NC nanorods: the green powder prepared in step 1) was heated ...

Embodiment 3

[0049] An embedded porous Fe-N X The preparation method of @Pd-NC nanorod, comprises the following steps:

[0050] 1) Preparation of metal precursor complex: weigh 0.15g naphthylamine (C 10 h 9 N), added to 30mL of water and ethanol mixed solvent (the ratio of water and ethanol is 10:1), fully ultrasonic to dissolve; then add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, mixed evenly, centrifuged to remove liquid after standing and dried to obtain yellow flake Pd(II)-naphthylamine complex;

[0051] 2) Preparation of the green rod-shaped intermediate product FePc@Pd-NC: Weigh 20 mg of the yellow powder obtained in step 1), and at the same time weigh 30 mg of FePc and disperse them in 40 ml of THF, stir for 24 hours, evaporate the solvent, and centrifuge to remove the liquid and dry it, that is Green rod-shaped intermediate product FePc@Pd-NC powder can be obtained;

[0052] 3) Embedded porous Fe-N X Preparation of @Pd-NC nanorods: the green powder prepared in step 1) was heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com