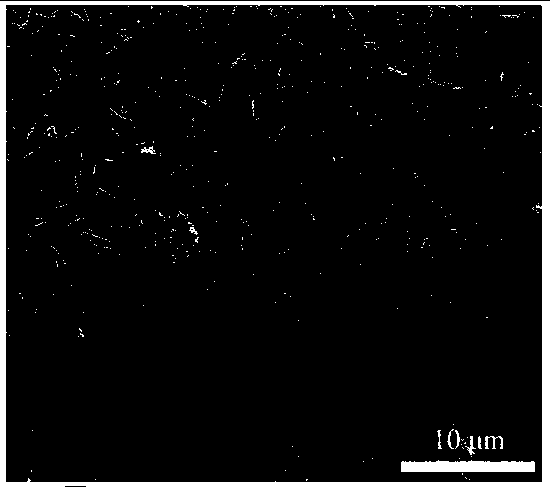

Preparation method of mutually staggered crescent bismuth vanadate composite material

A composite material, bismuth vanadate technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of simple operation, low cost, and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Cleaning of indium tin oxide (ITO) conductive glass: Put the indium tin oxide conductive glass into acetone, absolute ethanol, and secondary water for 10 minutes for ultrasonic treatment, and then put it in a 40 ℃ oven for 30 minutes to dry;

[0021] (2) Preparation of precursor solution: Weigh 0.3638 g of bismuth nitrate and 6.6404 g of potassium iodide and dissolve in 100 mL of nitric acid solution with pH=1.2, stir for 5 min to fully dissolve and mix, add 45 mL of 0.3 M p-benzoquinone Ethanol solution, stirred for 30 min;

[0022] (3) Electrodeposition of bismuth iodide oxide: place the indium tin oxide conductive glass treated in (1) in the precursor solution prepared in (2), and use the point-site dissolution analysis method of the electrochemical workstation to first adjust The parameter is -0.3 V, 5 s for pretreatment, then adjust the parameter to -0.1 V, 15 min for electrochemical deposition, take it out, wash it with secondary water three times, and dry it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com