Patents

Literature

37 results about "Tin(II) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin(II) oxide (stannous oxide) is a compound with the formula SnO. It is composed of tin and oxygen where tin has the oxidation state of +2. There are two forms, a stable blue-black form and a metastable red form.

Method for producing composite powders based on silver-tin oxide, the composite powders so produced, and the use of such powders to produce electrical contact materials by powder metallurgy techniques

A method for producing composite powders based on silver-tin oxide, by chemically reductive precipitation of silver onto particulate tin oxide. A solution of a silver compound and a solution of a reducing agent are simultaneously added in stoichiometrically equivalent amounts, separately and continuously with intensive mixing, to an aqueous suspension of tin oxide. The resulting composite powders have very high homogeneity, and can be processed to make electrical contact materials. The method is particularly suitable for producing composite powders based on silver-tin oxide doped with indium oxide, to be used in the manufacture of electrical contact materials.

Owner:UMICORE AG & CO KG +1

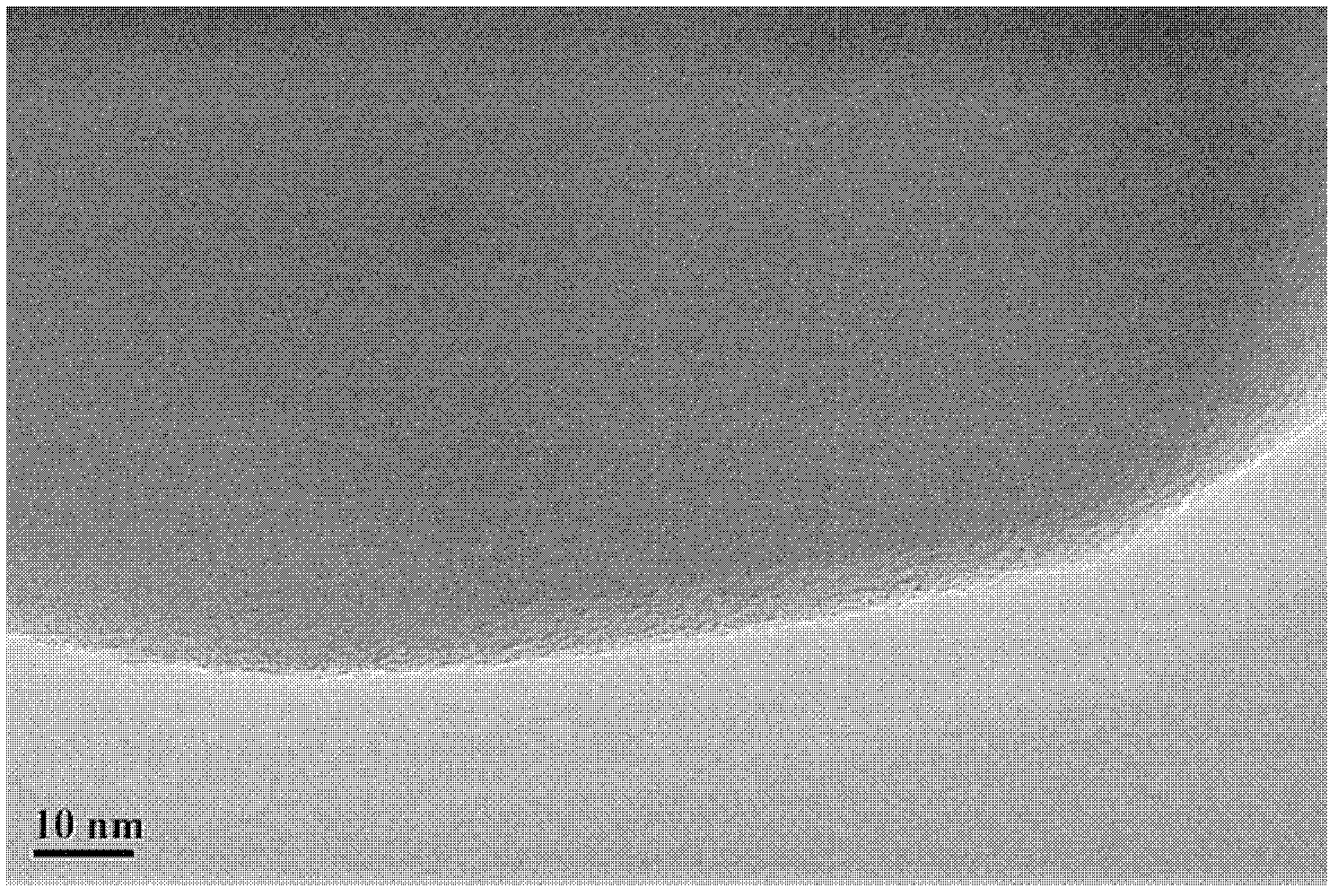

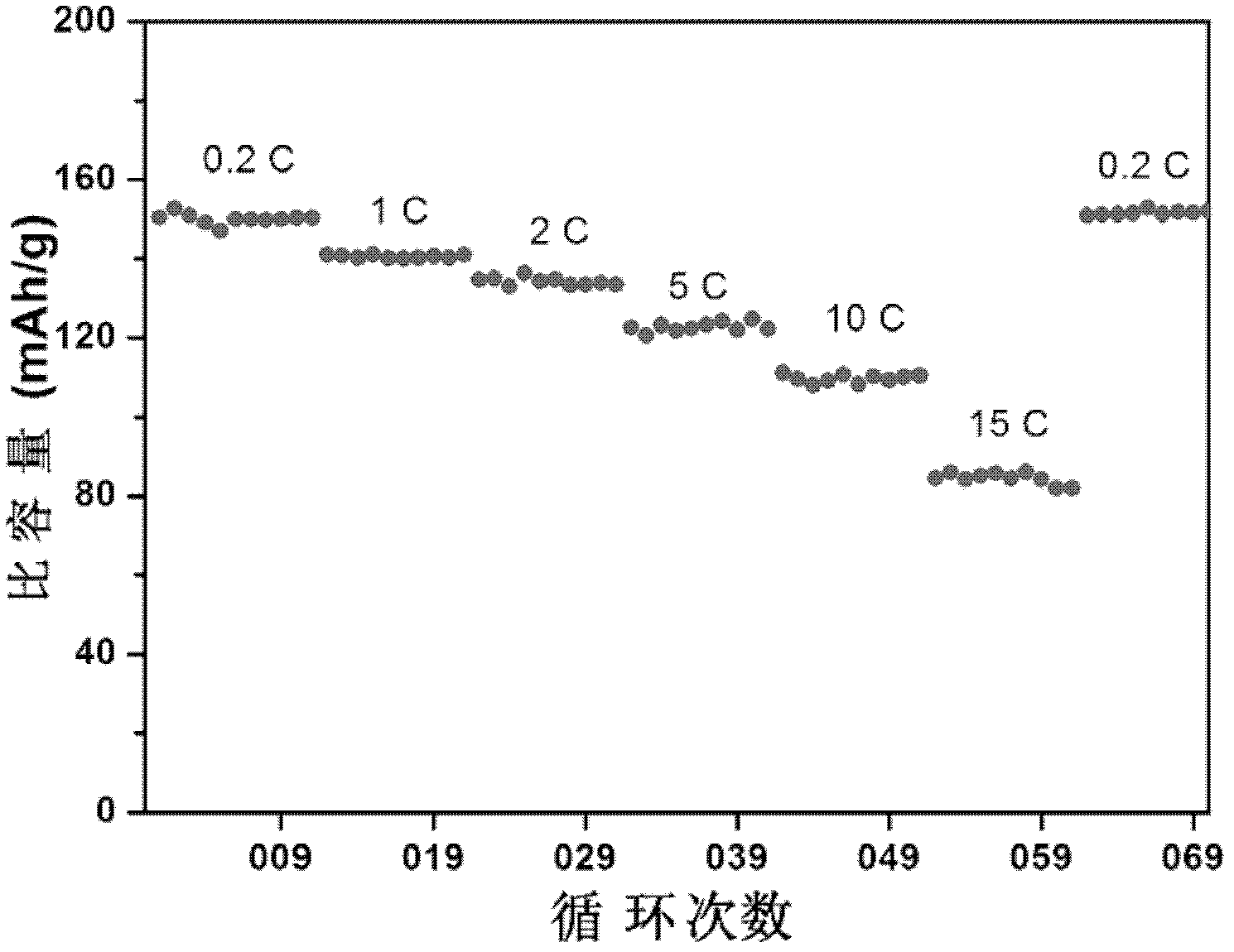

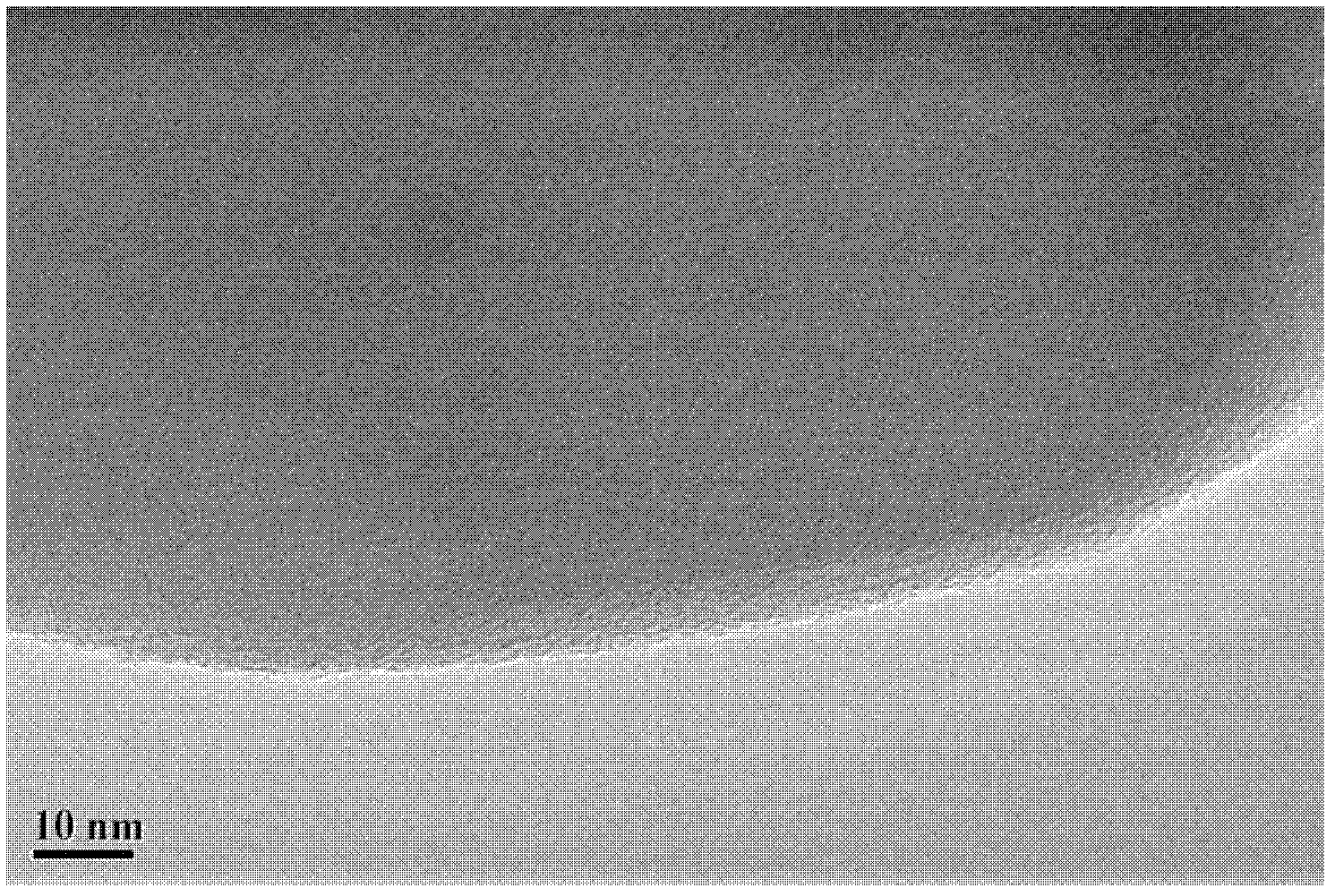

Lithium iron phosphate material wrapped by fluorine-doped tin oxide and preparation method of lithium iron phosphate material

ActiveCN102610817AImprove securityImprove stabilityCell electrodesMixed materialsLithium-ion battery

The invention discloses a lithium iron phosphate material wrapped by fluorine-doped tin oxide and a preparation method of the lithium iron phosphate material. The preparation method includes dissolving polymer of a fluorine source and a tin source in organic liquor according to the molar ratio of F:Sn ranging from 0.3 to 1; adding polymer of an iron source, a phosphorus source and a lithium source, and sufficiently mixing the polymer of the iron source, the phosphorus source and the lithium source with the polymer of the fluorine source and the tin source; and drying mixed materials, leading the mixed materials to react in inertia atmosphere at the temperature ranging from 550 DEG C to 700 DEG C for 5 to 10 hours, cooling and grinding the reacted mixed materials to obtain the fluorine-doped tin oxide and lithium iron phosphate composite material for an anode of a lithium ion battery. The molar ratio of P:Fe:Li:Sn of the elements is 1:1:X:Y, wherein the X is larger than or equal to 1.02 and smaller than or equal to 1.10, and the Y is larger than or equal to 0.005 and smaller than or equal to 0.05. The fluorine-doped tin oxide is wrapped on the surface of the lithium iron phosphate material, accordingly, conductivity of the lithium iron phosphate material is improved, the rate capacity is enhanced, electrolyte is prevented from dissolving and corroding internal active substances, and stability and safety of the material during rate and circulation are enhanced.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

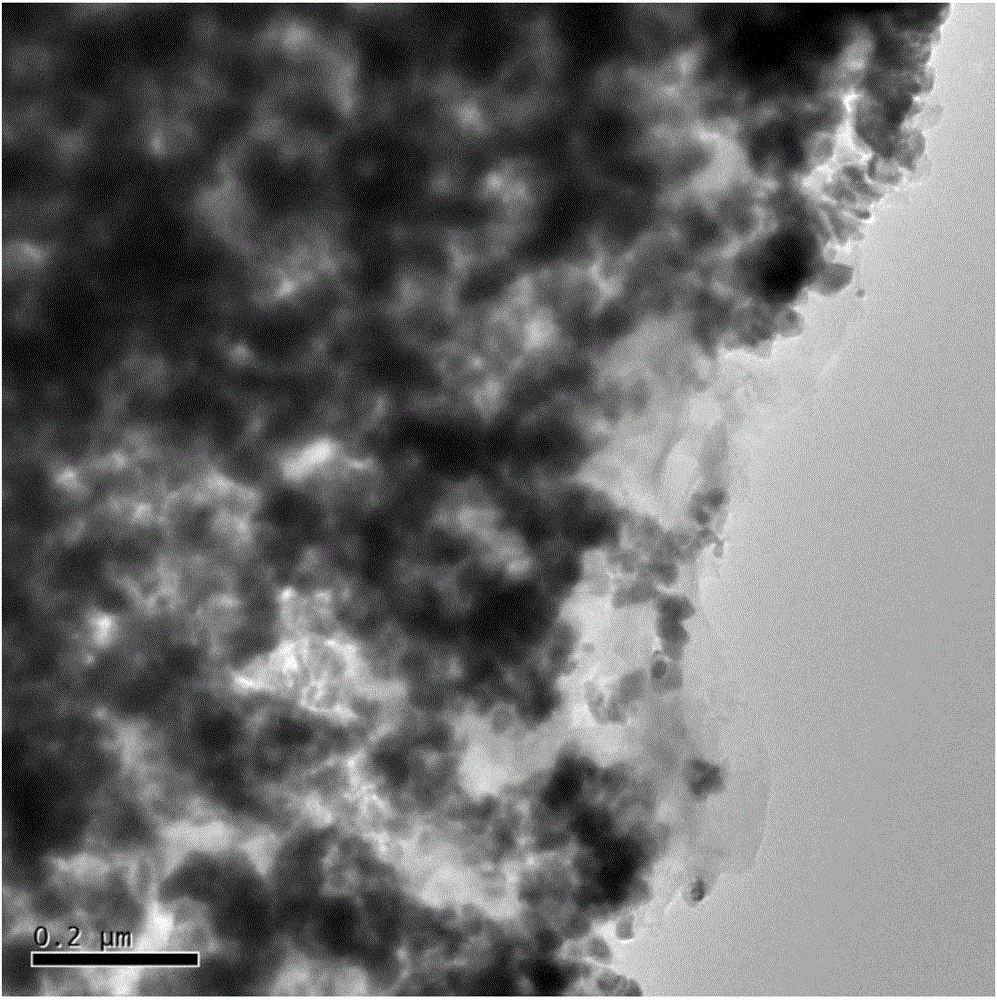

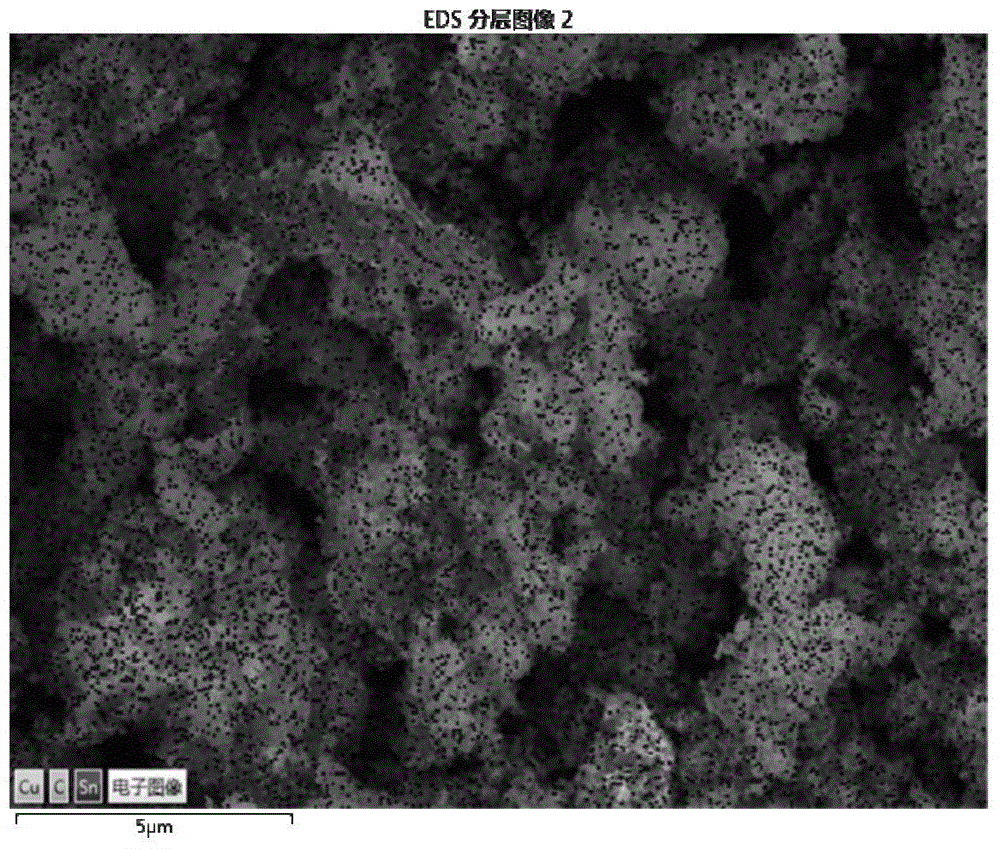

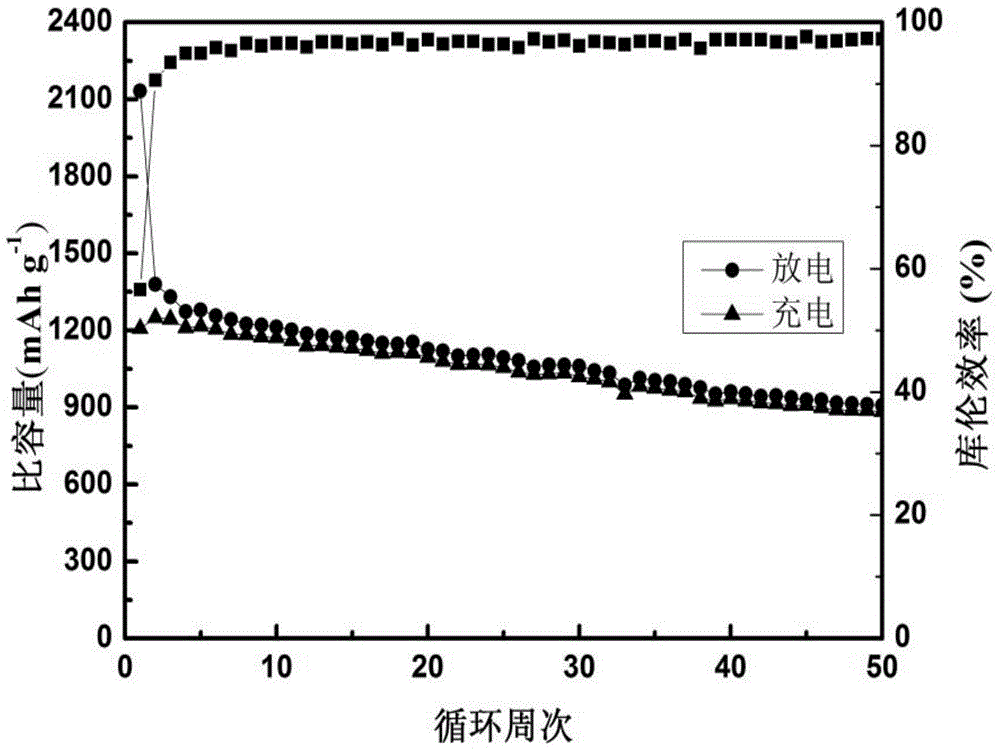

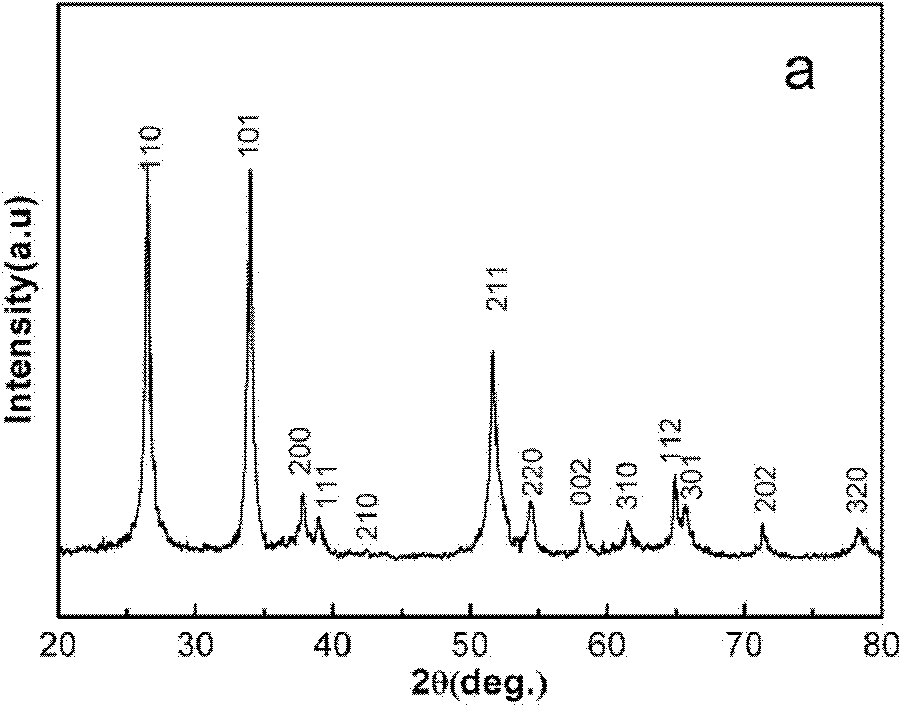

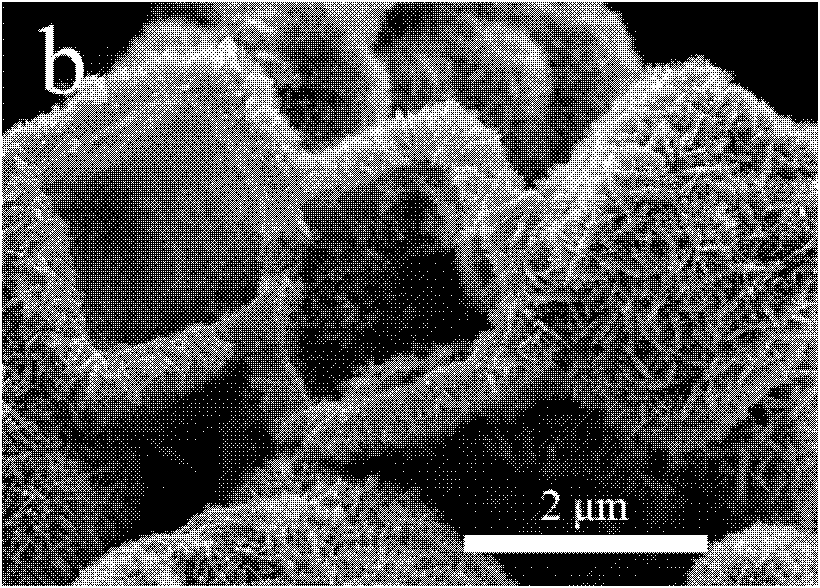

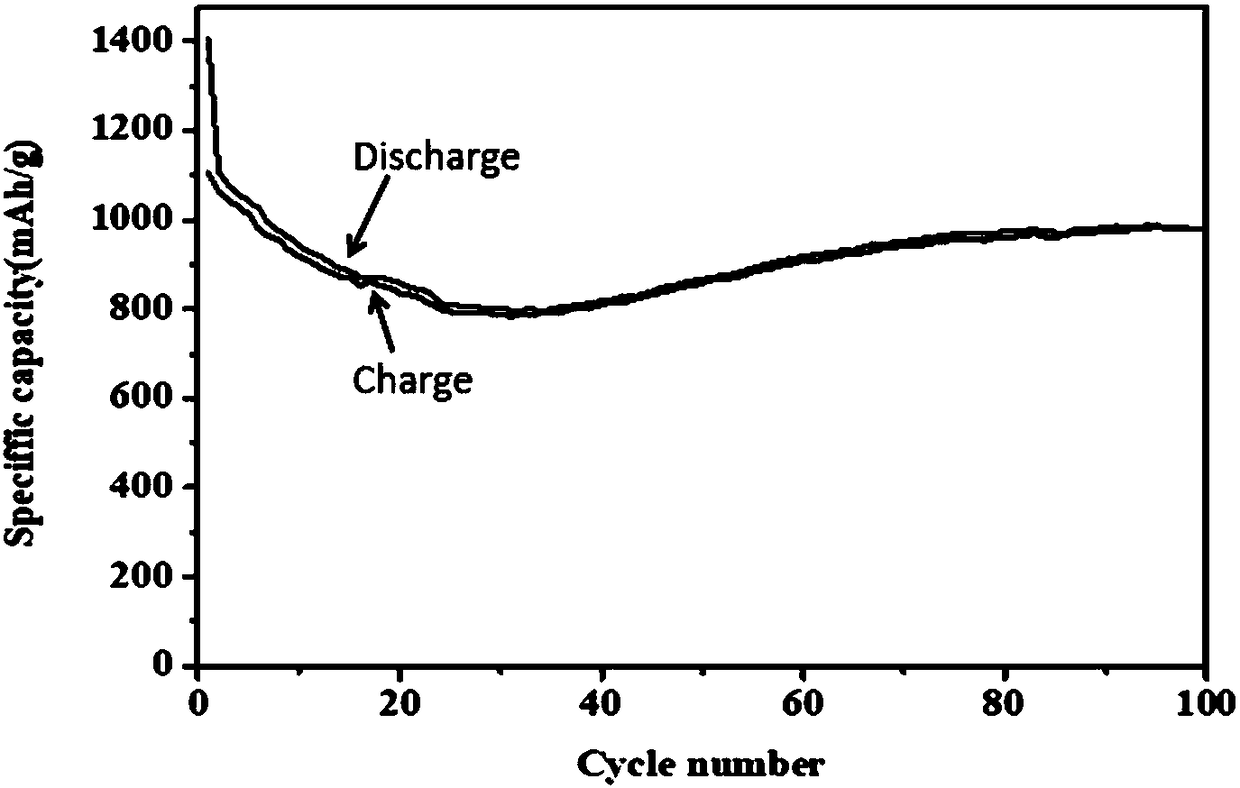

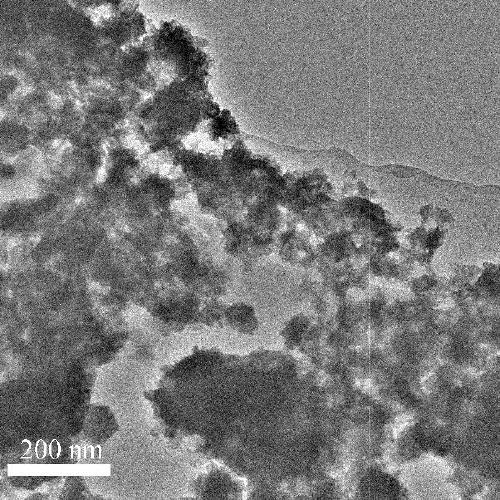

Tin oxide and porous carbon composite lithium ion battery anode materials

Disclosed is a production method of tin oxide and porous carbon composite lithium ion battery anode materials. The production method comprises the following steps of step 1, producing HKUST-1; step 2, activating HKUST-1, removing an organic solvent, adding a tin chloride solution by an injection method under the condition that the air is isolated and fully impregnating a pore passage, wherein the pore passage is occupied by the organic solvent; step 3, removing the solvent to obtain a precursor, performing 600 DEG C of firing of a muffle furnace under the protection of the argon gas, performing trimesic acid ligand carbonization, performing copper and tin reduction and alloying and obtaining a high dispersion of copper and tin alloy and carbon compound; step 4, selectively removing copper through nitric acid, converting tin oxide into tin dioxide to be stored in the pore passage in the form of nanocrystallization and obtaining the high performance composite materials. The tin oxide and porous carbon composite materials produced by the production method are firm in compositing, simple in operation and uniform in product; the tin oxide and porous carbon composite materials are large in capacity, high in current density, high in coulomb efficiency and high in rate performance current density when being applied to the lithium ion battery anode materials; the mass production can be achieved and the production cost is low.

Owner:NANKAI UNIV

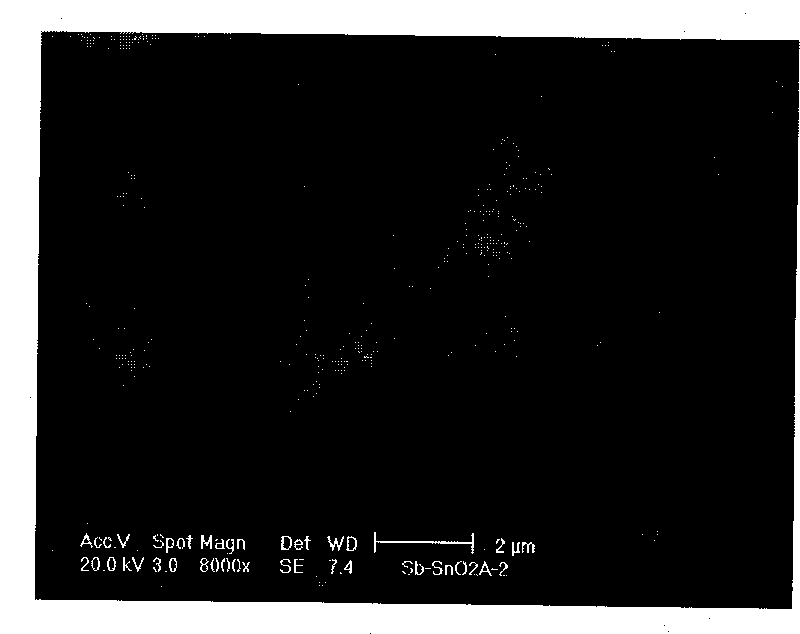

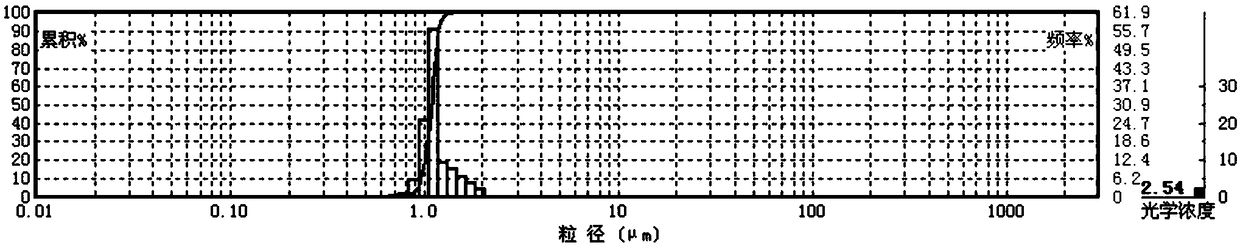

Method for manufacturing nano antimony doped tin oxide

InactiveCN101708820ANo emissionsSimple processNanostructure manufactureTin oxidesTin(II) oxideOrganic solvent

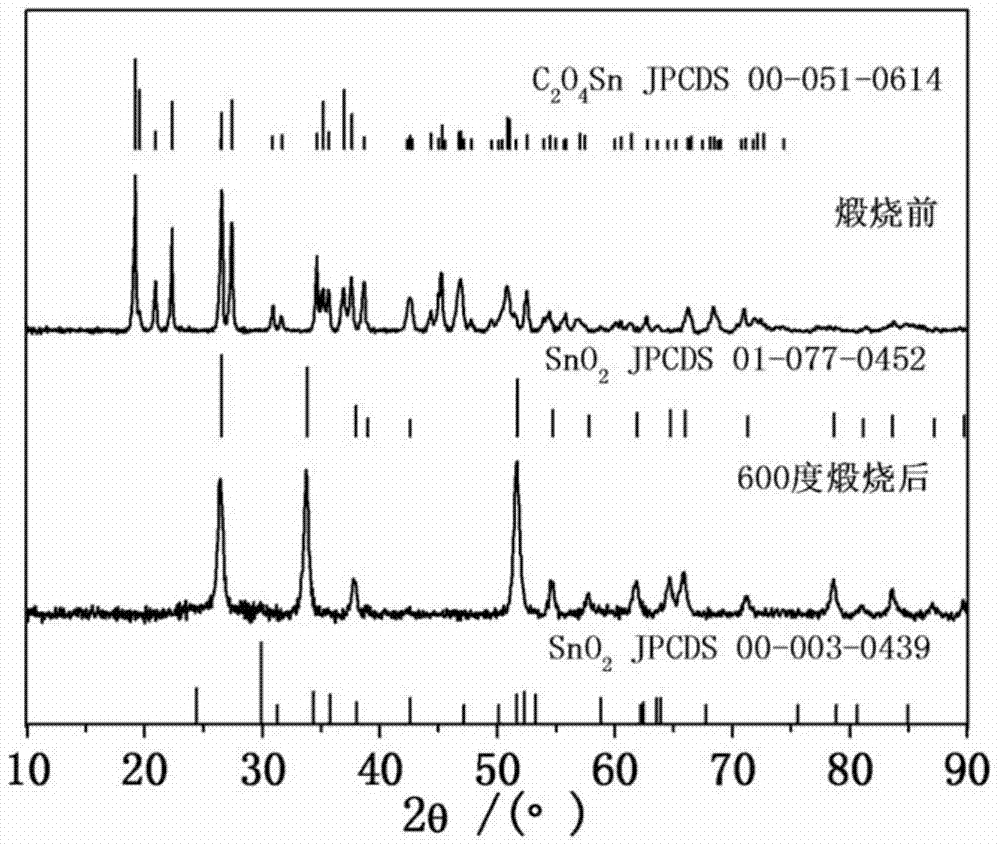

The invention relates to a method for manufacturing nano antimony doped tin oxide, which comprises the following steps of: performing complete thermal decomposition on a mixture of organic precursor tinoxalate of a tin and an antimonial substance at 250 to 800 DEG C; oxidizing and baking the rough product of the antimony doped tin oxide after the thermal decomposition at 800 to 1,500 DEG C for 15 to 90 minutes after completely and uniformly stirring the rough product to obtain the blue nano antimony doped tin oxide. The method avoids toxic hazardous chemical, such as chlorine and nitric acid, and a combustible and explosive organic solvent, so no pollutant is discharged in the whole production process. The method has the advantages of simple process and equipment, safe and environmentally-friendly production process and low production cost, and creates conditions for the industrial production with safety and low cost.

Owner:GANZHOU RUIDE CHEM

Selective ITO (tin indium oxide) etching solution

ActiveCN103805203AEtch rate is fast and efficientUniform etchingSurface treatment compositionsEtchingIndium

The invention provides a selective ITO (tin indium oxide) etching solution. The etching solution is used for etching crystal and non-crystal ITO film layers, and is especially applicable to an ITO film of which the lower layer is a film substrate of organic polymers such as PET and the like and the upper layer is a monolayer or multilayer covering film consisting of copper or high-molecular compounds. The selective ITO etching solution is composed of the following components in percentage by weight: 15-25% of hydrochloric acid, 1-10% of acetic acid, 0.5-5% of a copper corrosion inhibitor, 5-500 ppm of a surfactant, and the balance of deionized water, wherein the copper corrosion inhibitor is at least one of a long-chain water-soluble amine compound and a triazole compound; the surfactant is a non-ionic surfactant. The etching solution is high in etching speed, effective, stable, free of residues and uniform in etching, and can be used for etching ITO completely, the edge of an ITO line is clear and has no lateral erosion, and the etching solution has no corrosion effect on copper layers.

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

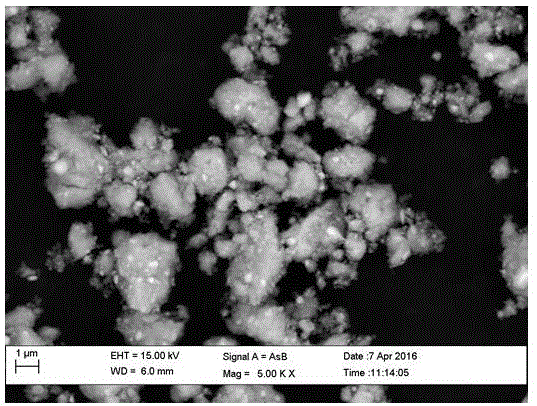

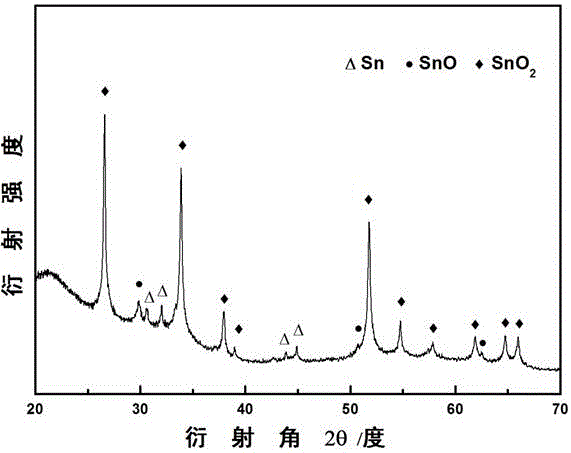

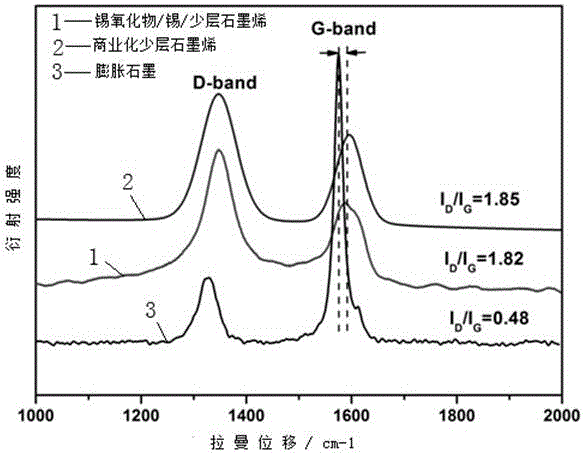

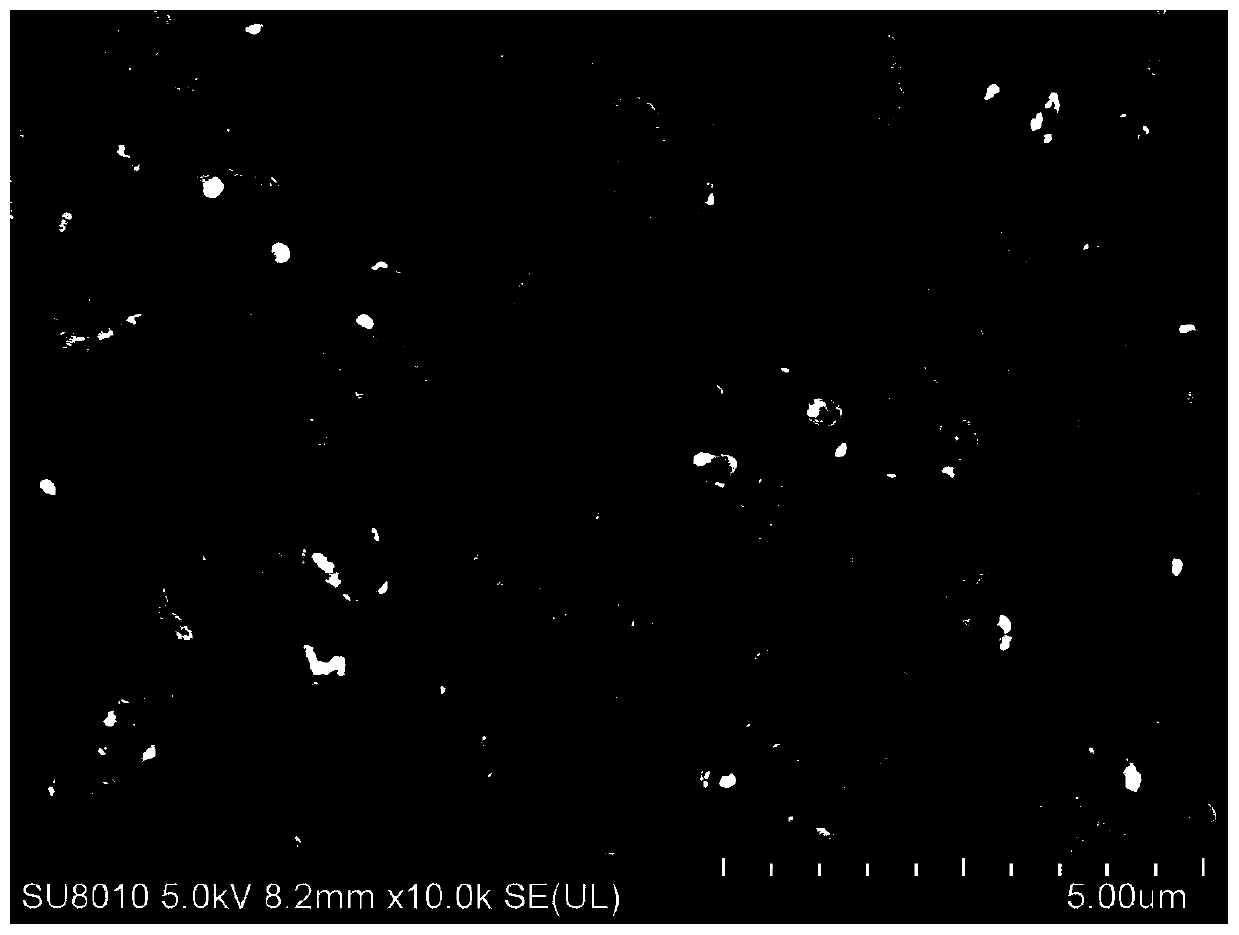

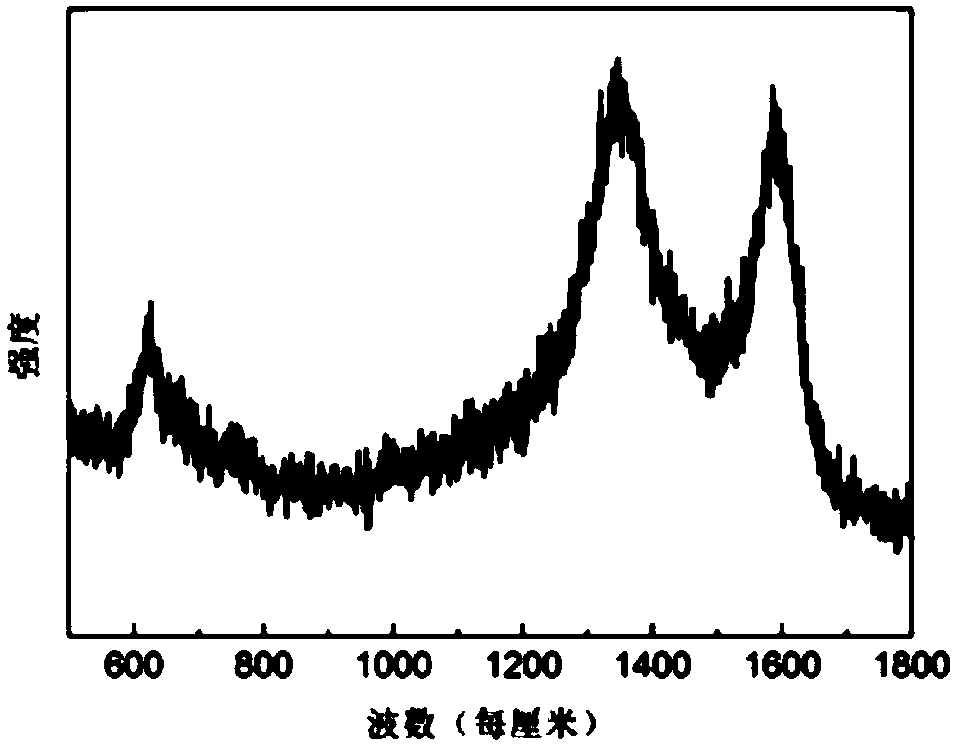

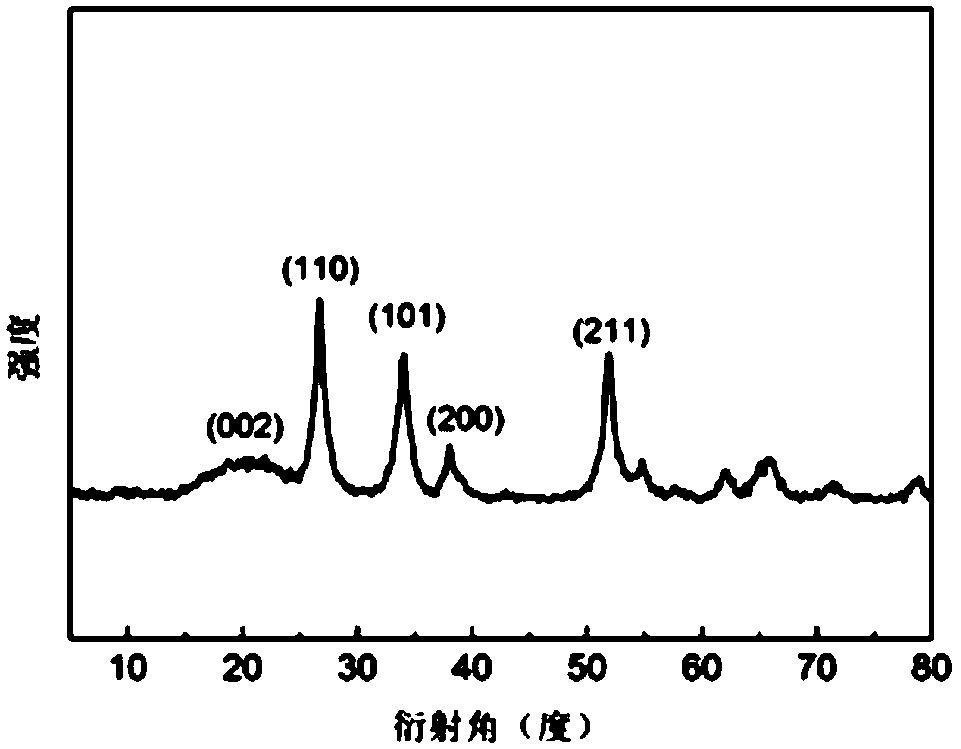

Tin oxide/tin/few-layer graphene composite material as well as preparation method and application thereof

InactiveCN106410166ANo pollution in the processImprove efficiencyMaterial nanotechnologyCell electrodesHigh energySodium-ion battery

The invention discloses a tin oxide / tin / few-layer graphene composite material as well as a preparation method and application thereof. A structure of the composite material is that nano-crystalline tin oxide and nano-crystalline tin are uniformly covered in a few-layer graphene carbon matrix. The method comprises: adding tin powder and expanded graghite into a ball mill and mixing; then vacuumizing and filling a gas medium; carrying out ball milling by adopting a dielectric barrier discharge plasma assisted high-energy ball milling method, so as to obtain the tin oxide / tin / few-layer graphene composite material. The composite material provided by the invention is used as a negative electrode material of a sodium-ion battery and has high capacity and excellent circulating performance; when the composite material is charged and discharged under a current density of 100mAg<-1>, an initial specific capacity is 448mAhg<-1>; after the composite material is circulated for 250 times, the capacity of 370mAg<-1> is still kept. The preparation method is simple, low in cost and high in powder yield; large-scale production is prone to realize and pollution to the environment is not caused.

Owner:SOUTH CHINA UNIV OF TECH

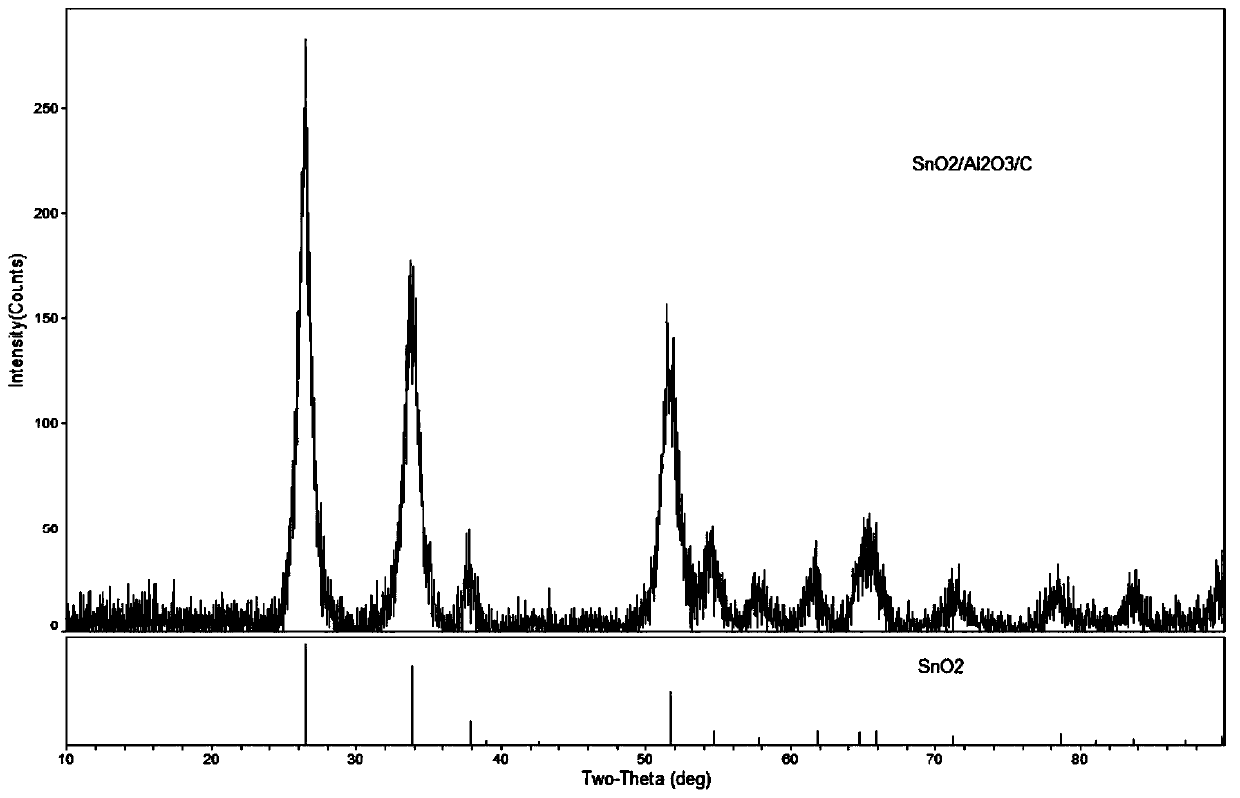

Tin oxide/alumina doped carbon composite material and preparation method thereof

ActiveCN110336035AAlleviate volume expansionImprove stabilitySecondary cellsNegative electrodesTin dioxideCarbon composites

The invention belongs to the technical field of electrochemistry, in particular to a tin oxide / alumina doped carbon composite material and a preparation method thereof. The invention provides a preparation method of a tin dioxide / alumina doped carbon composite material, which comprises the following steps: S1, mixing urea and a tin-containing precursor to complete dissolution to obtain mixed solution; and S2, carrying out hydrothermal reaction on the mixed solution and drying the product to obtain tin dioxide nanoparticles, carrying out dry grinding, and adding carbon for ball milling to obtain a tin dioxide / alumina doped carbon composite material. The invention also provides a tin dioxide / alumina doped carbon composite material prepared by the method. The invention provides the tin dioxide / alumina doped carbon composite material and the preparation method thereof, which solve the problem that the existing lithium-ion battery anode material causes quick capacity depletion and poor cycle performance of batteries due to serious volume expansion effect.

Owner:GUANGDONG UNIV OF TECH

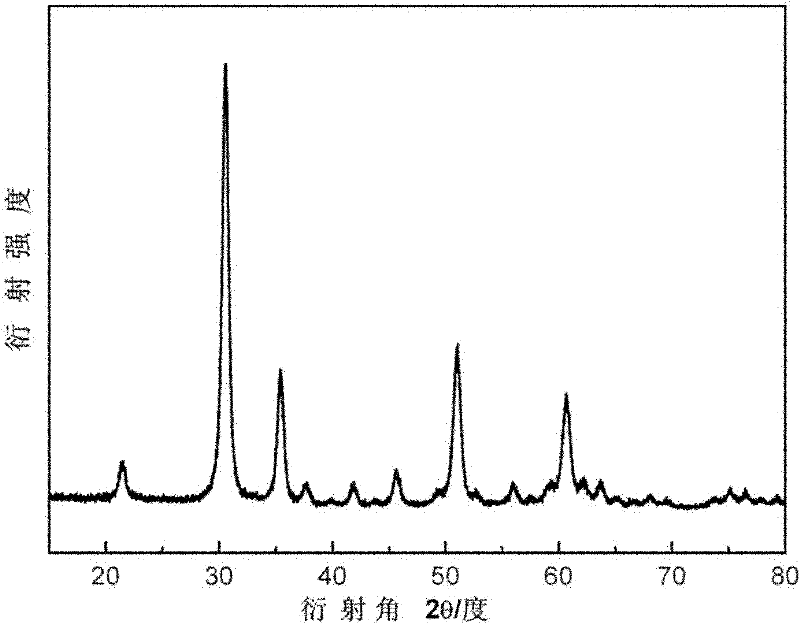

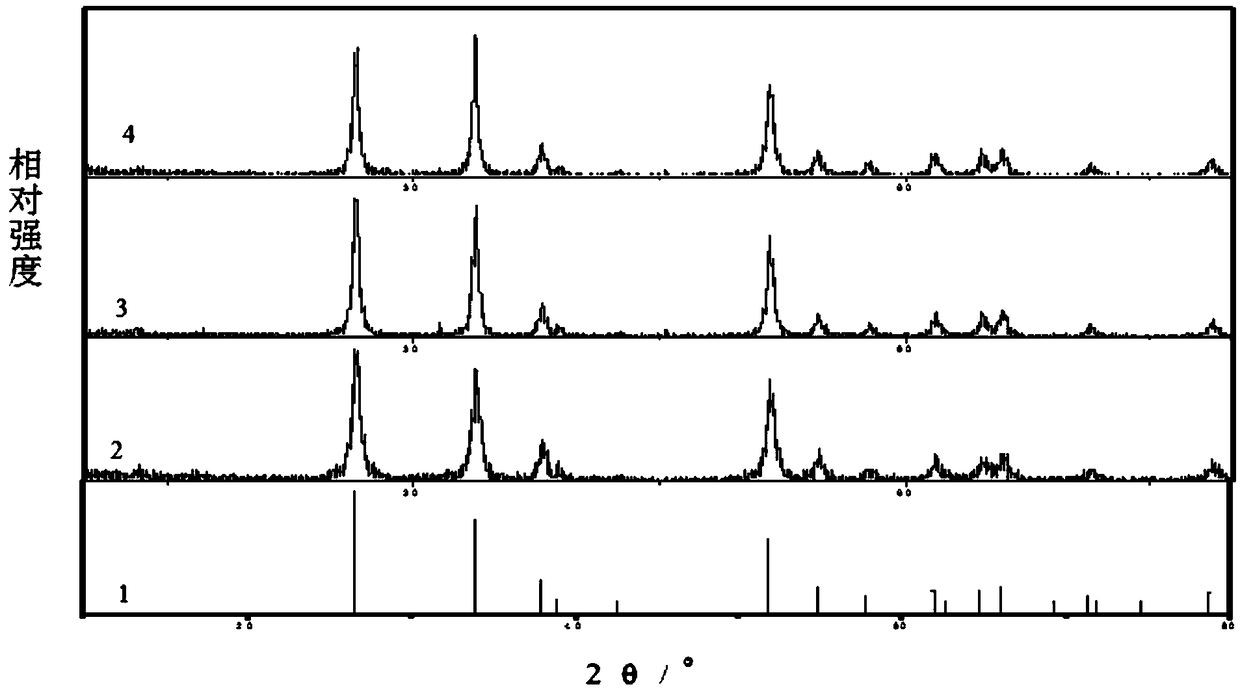

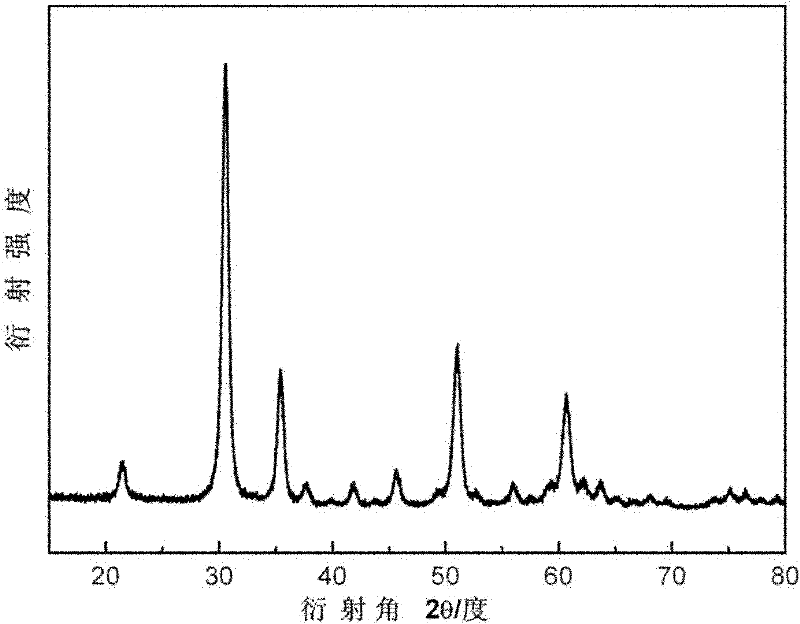

Hydrothermal synthesis method of zinc-doped tin oxide with hollow cubic structure

The invention provides a hydrothermal synthesis method of zinc-doped tin oxide with a hollow cubic structure, comprising the following steps: dropwise adding a mixed aqueous solution of SnCl4 and Zn(NO3)2 to a NaOH aqueous solution with a certain concentration, wherein, the volume ratio of the mixed aqueous solution of SnCl4 and Zn(NO3)2 to the NaOH aqueous solution is 1:3-1:15, the concentration of SnCl4 is 0.1094-0.1144mol / L, the concentration of Zn(NO3)2.6H2O is 0.0106-0.0156mol / L, and the concentration of NaOH is 1.875mol / L; evenly stirring and transferring the mixed solution to a hydrothermal reaction kettle so that the filling degree reaches 80%; carrying out isothermal reaction at the temperature of 180-190 DEG C for 25 hours; and finally centrifuging, washing and drying the obtained reaction product to obtain the zinc-doped tin oxide. The hydrothermal synthesis method has simple process and easy operation; and the synthesized zinc-doped tin oxide particles have controllable size and high purity, and the obtained product has excellent electrical property.

Owner:WUHAN UNIV OF TECH

Method for preparing carbon nano tube composite material loaded with nano indium-tin oxide

InactiveCN101792119ASimple processSolve complex processNanostructure manufactureCarbon nanotubeSodium hydroxide

The invention relates to a method for preparing a carbon nano tube composite material, in particular to a method for preparing a carbon nano tube composite material loaded with nano indium-tin oxide. The invention solves the problem of complicated process of the traditional method for preparing the carbon nano tube composite material loaded with nano indium-tin oxide. The method comprises the following steps of: preparing an organic phase solution by using indium nitrate, stannic chloride and ethylene glycol methyl ether; preparing an aqueous phase solution by using resorcinol, formaldehyde, sodium carbonate and water; dropwise adding the organic phase solution into the aqueous phase solution to obtain a precursor solution; soaking a porous aluminum oxide template into the precursor solution and standing; then sintering; finally, removing the template by using sodium hydroxide, washing and drying to obtain the carbon nano tube composite material loaded with the nano indium-tin oxide. The invention has simple process and can be used for preparing a hydrogen sensitive element.

Owner:HARBIN INST OF TECH

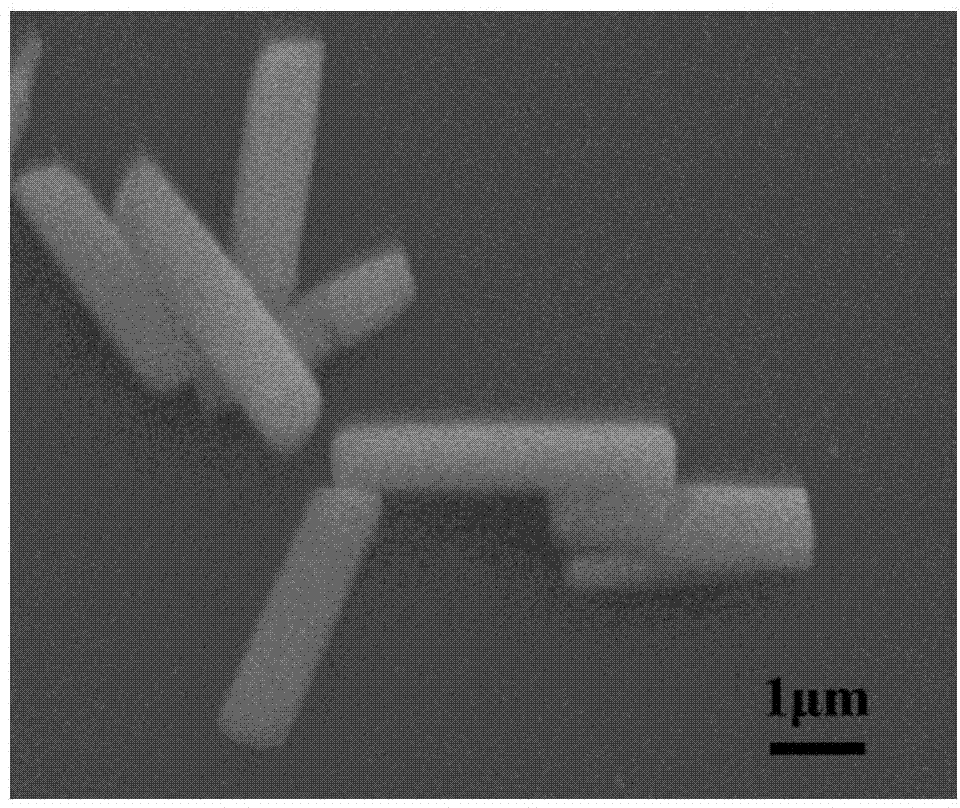

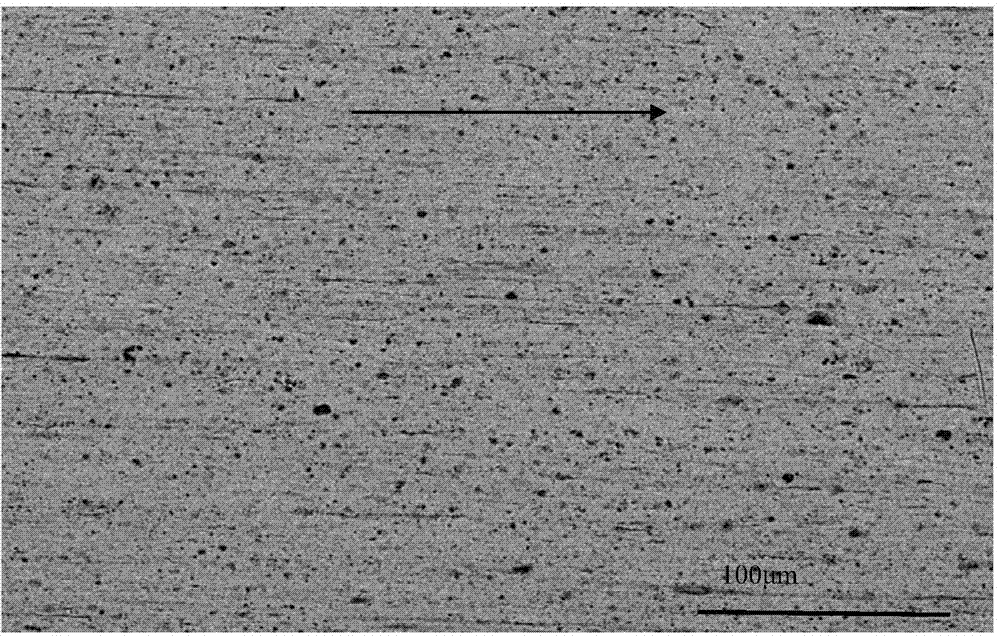

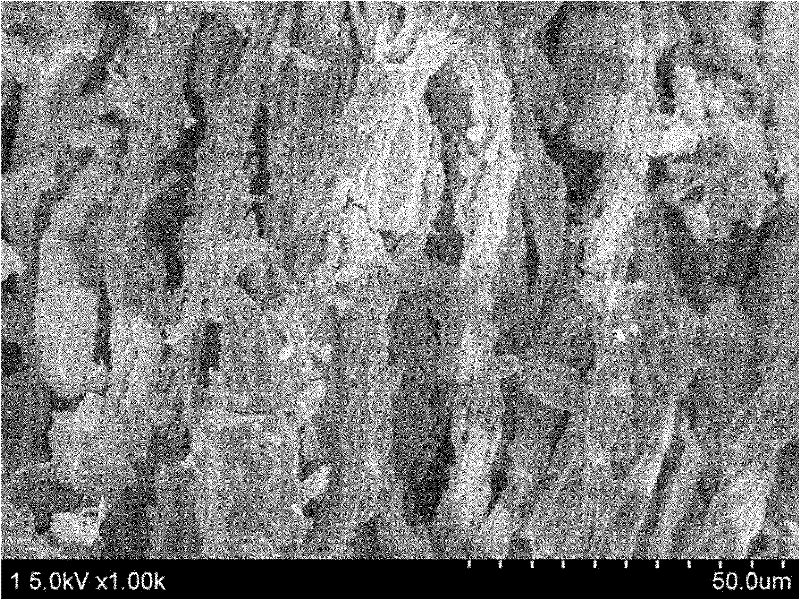

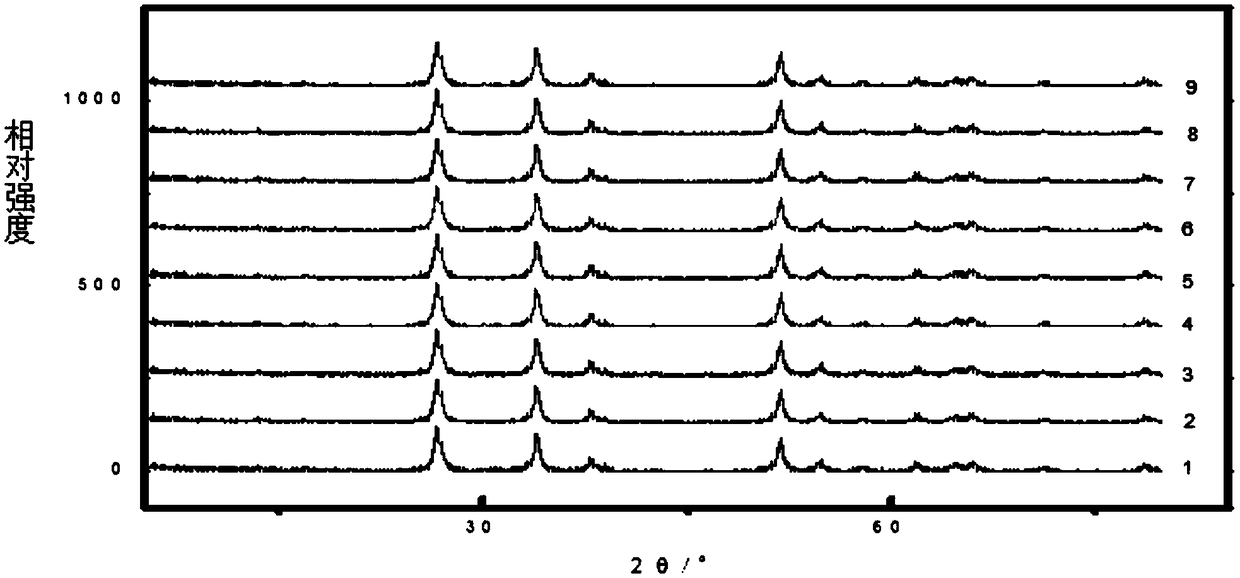

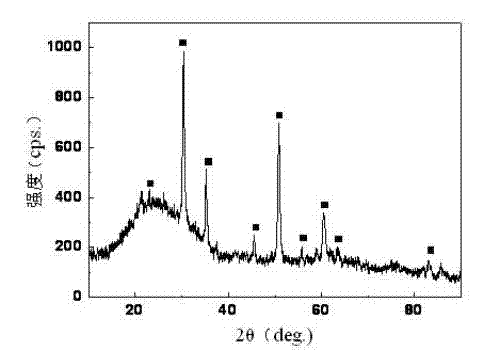

Preparation method of rod-shaped tin oxide-reinforced silver-based electric contact material

ActiveCN104505287AHigh yieldHigh purityTransportation and packagingMetal-working apparatusElectric contactRaw material

The invention provides a preparation method of a rod-shaped tin oxide-reinforced silver-based electric contact material. The preparation method comprises the following steps: (1), preparing a stannous salt solution with certain concentration and an oxalic acid solution with certain concentration; (2), taking a certain amount of stannous salt solution and oxalic acid solution according to the molar ratio of stannous salt to oxalic acid, and mixing to react for certain time; (3), separating out reaction precipitates by centrifugation, and drying the reaction precipitates to obtain a stannous oxalate precursor; (4) incinerating the stannous oxalate precursor to obtain putty powder; (5), preparing silver-coated tin oxide compound power by taking the putty powder and silver nitrate as raw materials according to a chemical coating method; (6) hot-pressing the compound powder into a blank; (7), hot-extruding the blank into a rod; and (8) drawing the rod into a wire material. According to the method, the rod-shaped putty powder is high in yield and high in purity, and the process is simple; the rod-shaped tin oxide is distributed in a electric contact wire material in an oriented manner along the drawing direction; the prepared electric contact material is high in rigidity and has favorable electric conductivity, welding resistance and arc erosion resistance.

Owner:NORTHEASTERN UNIV +1

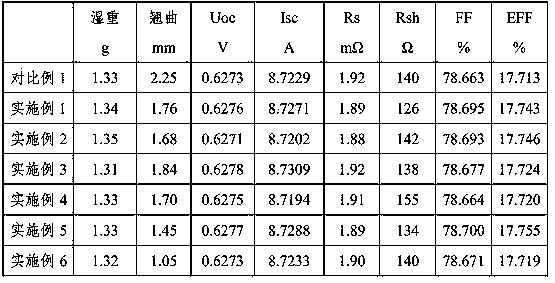

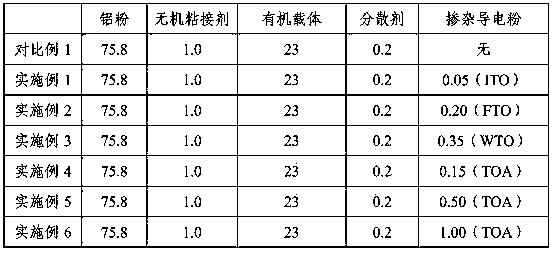

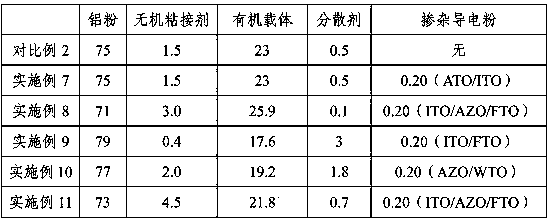

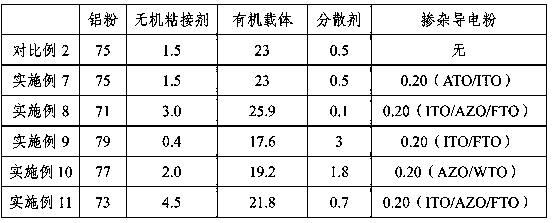

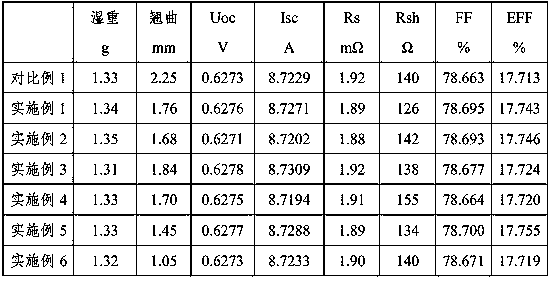

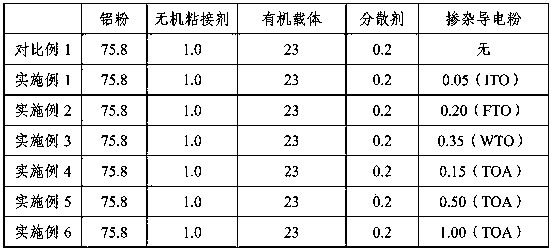

Efficient low-warpage crystalline silicon solar cell conducive aluminium paste

ActiveCN105374411AReduce warpageImprove conductivityNon-conductive material with dispersed conductive materialSemiconductor devicesTin dioxideTin(II) oxide

The invention discloses efficient low-warpage crystalline silicon solar cell conducive aluminium paste. The conducive aluminium paste comprises the components of aluminium powder, an organic carrier, at least one inorganic binder, and tin oxide doped conductive powder, wherein the tin oxide doped conductive powder is selected from at least one of antimony doped tin oxide (ATO), indium doped tin oxide (ITO), fluorine doped tin oxide (FTO), wolfram doped tin oxide (WTO), or aluminium doped tin oxide (TOA). The doped tin oxide conductive powder is uniformly dispersed in the aluminium paste; the doped tin oxide conductive powder becomes an out-phase stress releasing center in a sintered aluminium conducive layer; the warpage of a cell piece can be reduced; the doped tin oxide conductive powder is good in the conductivity; the doped tin oxide conductive powder is introduced as the out-phase stress releasing center, however, the conductivity of the aluminium conducive layer is not influenced; and the warpage of the silicon-based solar cell piece is reduced, and the photoelectric conversion efficiency of the solar cell is ensued as well.

Owner:JIANGSU HOYI TECH

Carbon/tin oxide/graphene composite material and preparation method and application thereof

ActiveCN109065864AHigh charge and discharge capacityImprove electrochemical performanceCell electrodesSecondary cellsTin(II) oxideAcid washing

The invention relates to a carbon / tin oxide / graphene composite material and a preparation method and application thereof. A preparation method of carbon / tin oxide / graphene composite material comprisesthe following steps of: hydrothermally reacting rice husk in alkaline solution at 160 DEG C to 180 DEG C to obtain a first precipitate; Carrying out acid washing on the first precipitate, and then washing the first precipitate with water to neutrality to obtain a carbon skeleton; hydrothermally reacting the carbon skeleton with tin source and graphene to obtain a second precipitate at 180 DEG C to 200 DEG C; calcining the second precipitate at 500 to 550 degree centigrade in a protective gas atmosphere to obtain carbon / tin oxide / graphene composite. The carbon / tin oxide / graphene composite prepared by the preparation method of the carbon / tin oxide / graphene composite material has the advantages of low cost and good electrochemical performance.

Owner:JILIN UNIV +3

Preparation method of mutually staggered crescent bismuth vanadate composite material

InactiveCN109395736AIncrease surface areaEnhanced light absorptionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIndiumBismuth vanadate

The invention discloses a preparation method of mutually staggered crescent nickel: iron hydroxide / bismuth vanadate composite material deposited on tin indium oxide (ITO) conducting glass, and belongsto the field of material preparation. The method includes the steps: substrate cleaning; precursor solution preparation; bismuth oxyiodide electro-deposition; bismuth vanadate generation; nickel: iron hydroxide / bismuth vanadate composite material synthesis. The preparation method has the advantages that a large-area crescent composite material structure is formed, technological process is simple,the tin indium oxide conducting glass with high light transmittance and good conductivity is selected as a substrate, environmental pollution is avoided, the operation process is simple, the cost islow, and reaction conditions are easily implemented. The nickel: iron hydroxide / bismuth vanadate composite material can be formed only by a two-step method, visible light absorption can be enhanced, photoelectric conversion efficiency can be improved, and the composite material has a wide application prospect in the fields of photocatalysis, solar batteries and the like.

Owner:UNIV OF JINAN

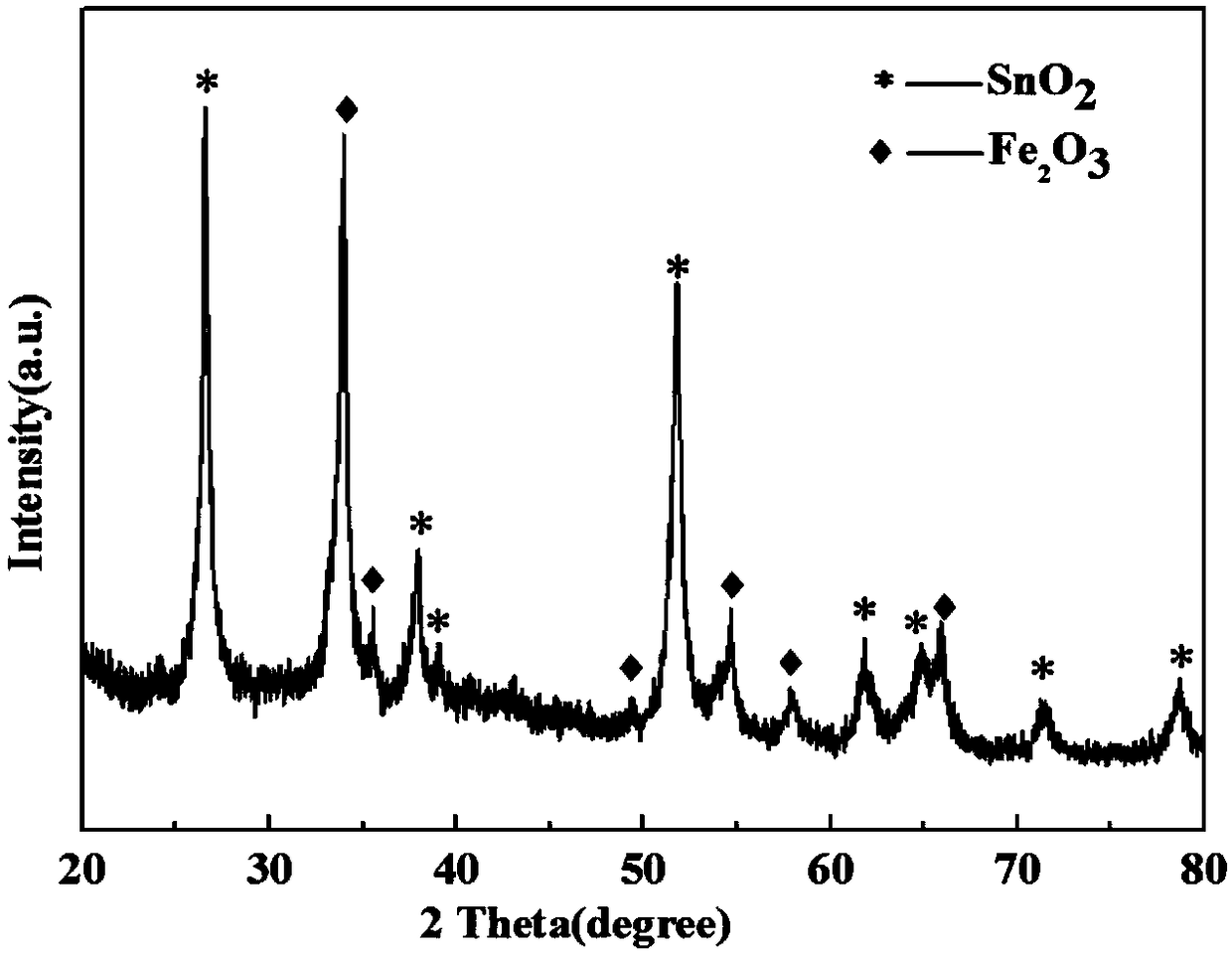

Carbon-doped nitrogen-coated tin oxide/iron oxide composite material, preparation method thereof, and lithium battery material

ActiveCN108598411AImprove chemical reactivityFully contactedCell electrodesSecondary cellsCarbon layerShielding gas

The invention provides a carbon-doped nitrogen-coated tin oxide / iron oxide composite material, a preparation method thereof, and lithium battery material, relating to the technical field of preparation of lithium battery material, comprising the steps of: dissolving binary lithium salt in an anhydrous alcohol solution; adding salt and tin salt to the above solution; adding a nitrogen source and acarbon source to the solution after 10 to 60 minutes; drying the solution to obtain a solid; calcining the solid to obtain a powder; washing and centrifuging the powder; drying the solid obtained by centrifugation to obtain a red solid powder; and calcining the red powder in a protective gas to obtain a carbon-doped nitrogen-coated tin oxide / iron oxide composite material. By using the binary lithium with lower boiling point as the molten salt reagent, the low-boiling molten salt can be used as a high-strength solvent during the reaction process to increase the ion diffusion rate, accelerate the formation of SnO2 and Fe2O3, and control the growth of product grains. After calcination, nitrogen atoms are introduced into the carbon layer to form structural defects, which facilitates rapid deintercalation of lithium ions and improves the charge and discharge rate and stability of the material.

Owner:HUBEI ENG UNIV

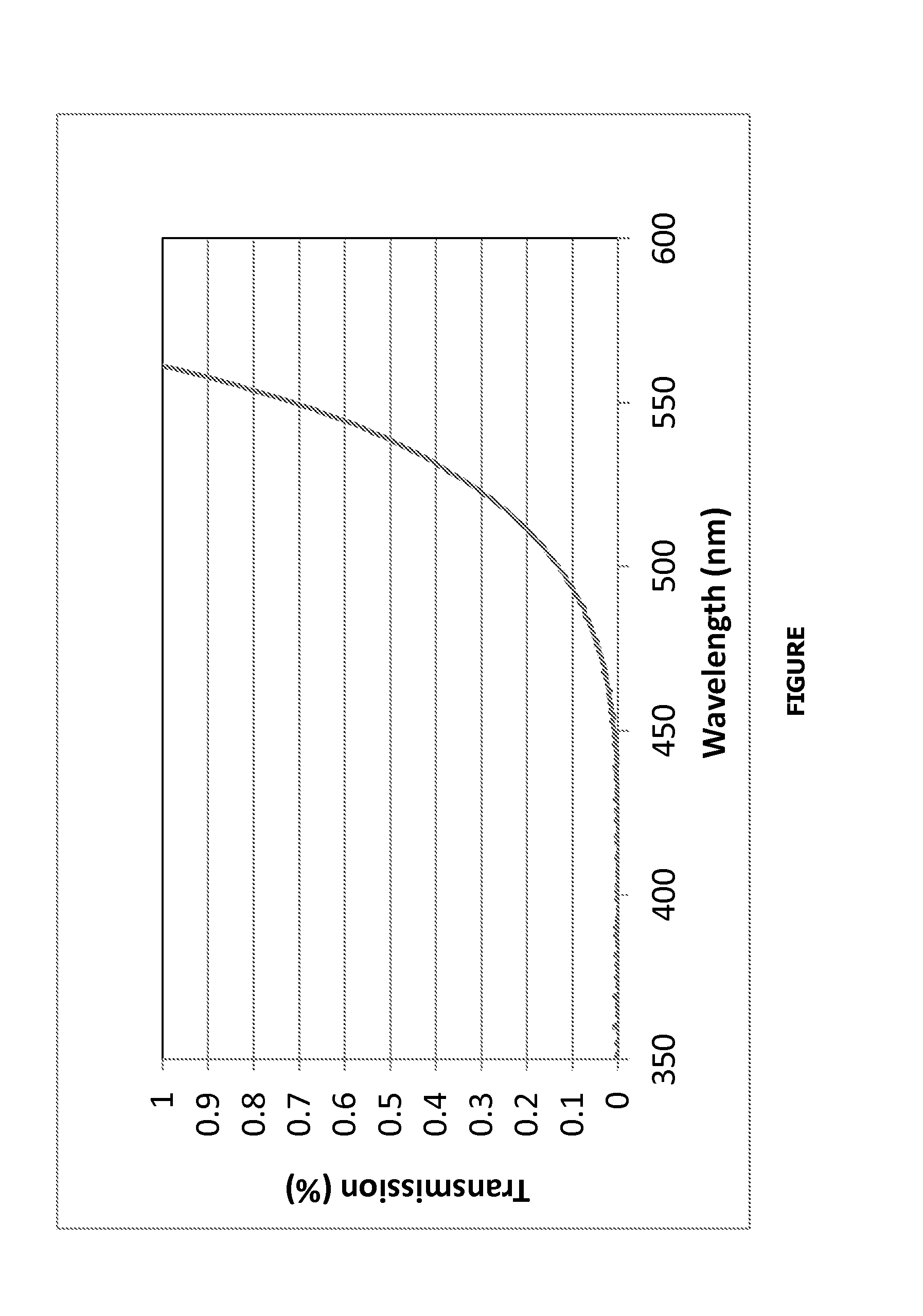

Beta-quartz glass-ceramics with a controlled transmission curve and a high content of iron oxide and of tin oxide; articles in said glass-ceramics, precursor glasses

β-quartz lithium aluminosilicate (LAS) glass-ceramics contain neither arsenic oxide nor antimony oxide, are fined with tin oxide and include vanadium oxide, chromium oxide and a high iron oxide content (>1500 ppm), and have a controlled transmission curve. Articles such as cook-tops can be made from such glass-ceramics.

Owner:EUROKERA SOC & NOM COLLECTIF

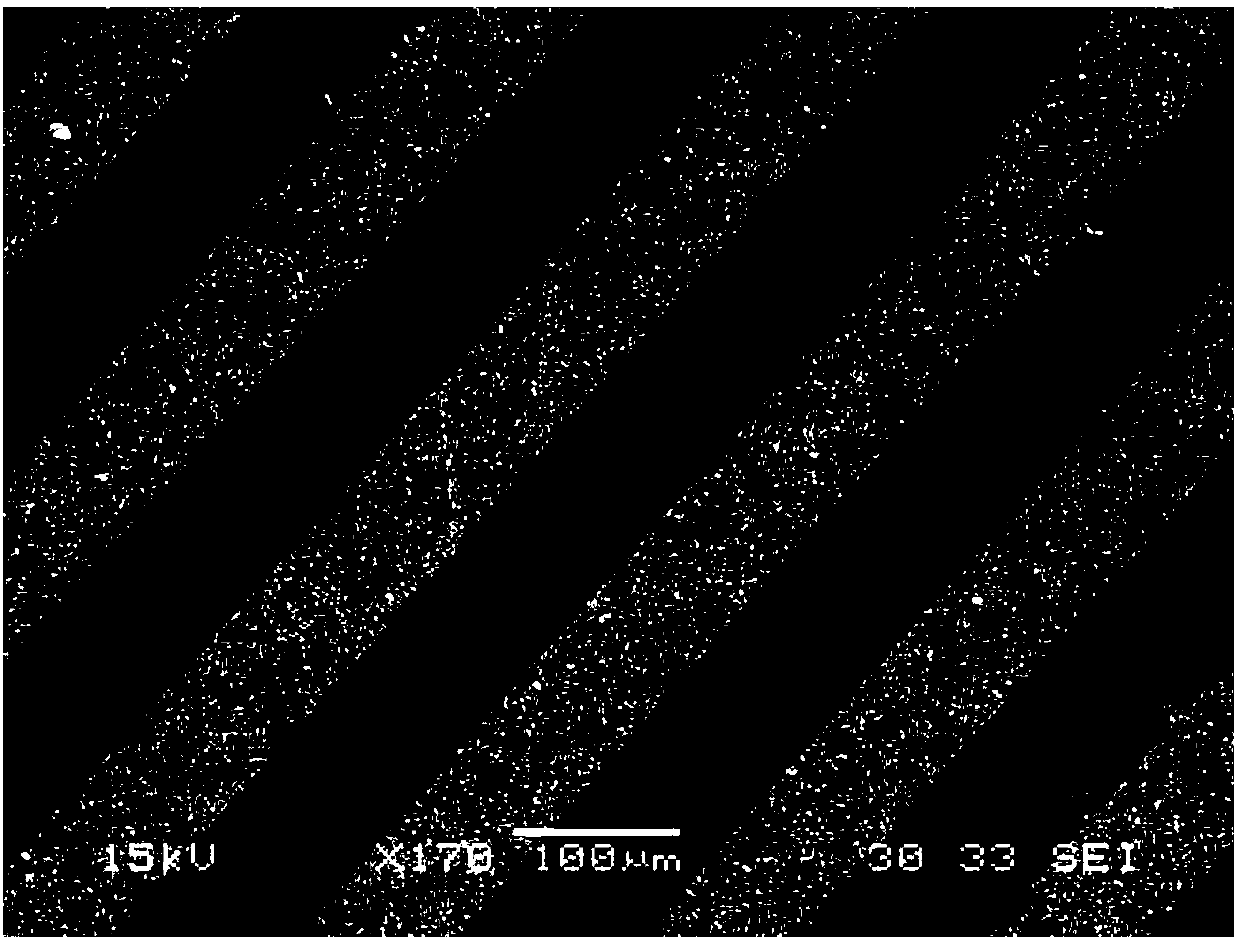

Preparation of indium-tin oxide/PDMS(polydimethylsiloxane) resin conducting material based on textile template

InactiveCN102176348AImprove conductivityGood mechanical propertiesConductive layers on insulating-supportsOxide conductorsTin(II) oxideIndium tin oxide

The invention relates to a method for preparing an indium-tin oxide / PDMS(polydimethylsiloxane) resin conducting material based on a textile template, which comprises the steps of: (1) preparing a precursor solution of an indium-tin oxide; (2) under a vacuumized environment, soaking a textile in the precursor solution, then taking out and drying, and calcining to obtain the indium-tin oxide conducting material; and (3) evenly mixing PDMS with a curing agent in a mass ratio of 10:1, then flatly laying the indium-tin oxide conducting material obtained in step (2) on the top of the mixture, curing at the temperature of 100 to 120 DEG C for 10 to 20min, and obtaining the indium-tin oxide / PDMS resin composite conducting material. The method provided by the invention has the advantages of simple preparation process, low cost and easiness for realization of industrial production, and the prepared indium-tin oxide / PDMS resin composite flexible conducting material has the advantages of compact structure, fine electrical conductivity, fine foldable performance and broad market prospects.

Owner:DONGHUA UNIV

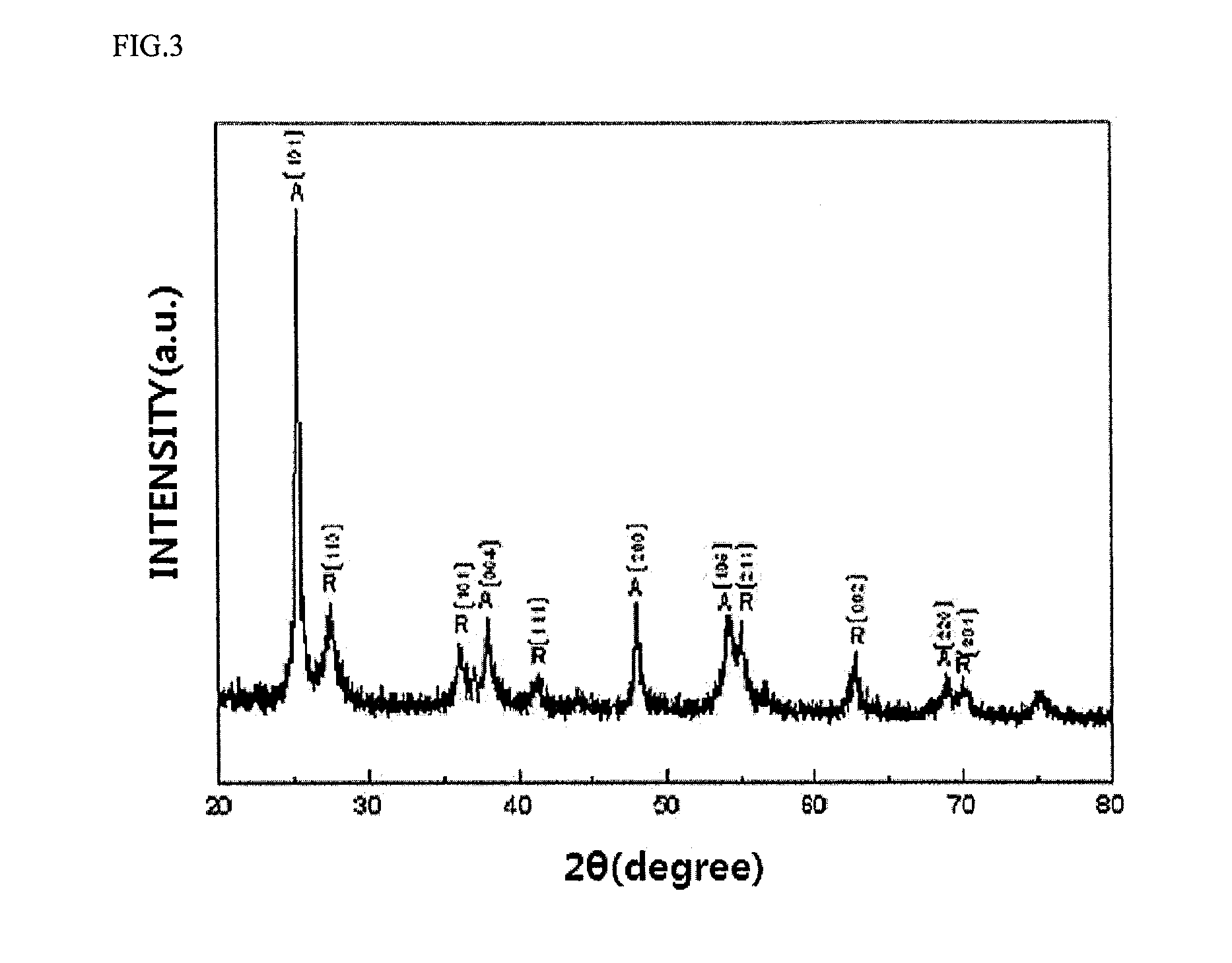

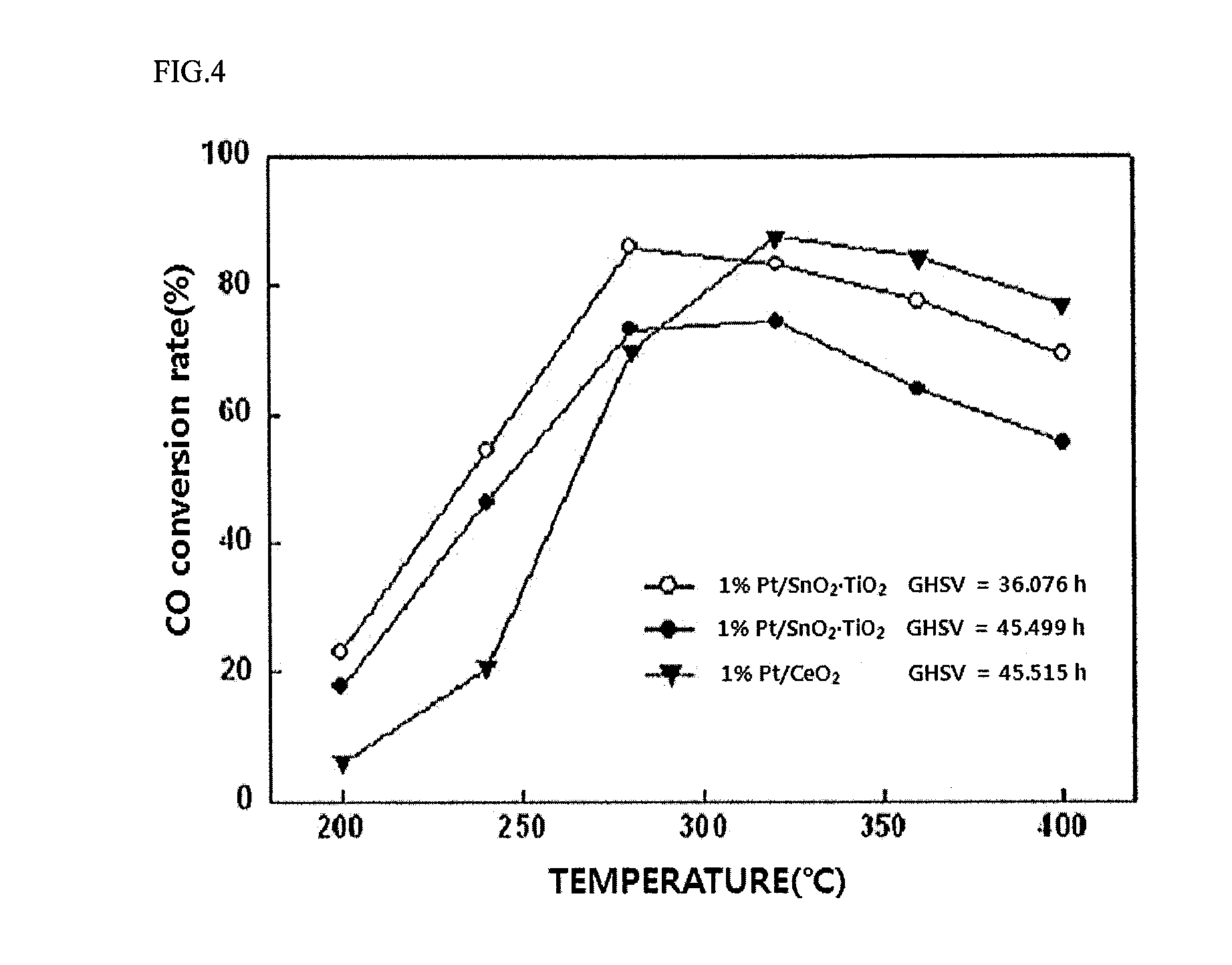

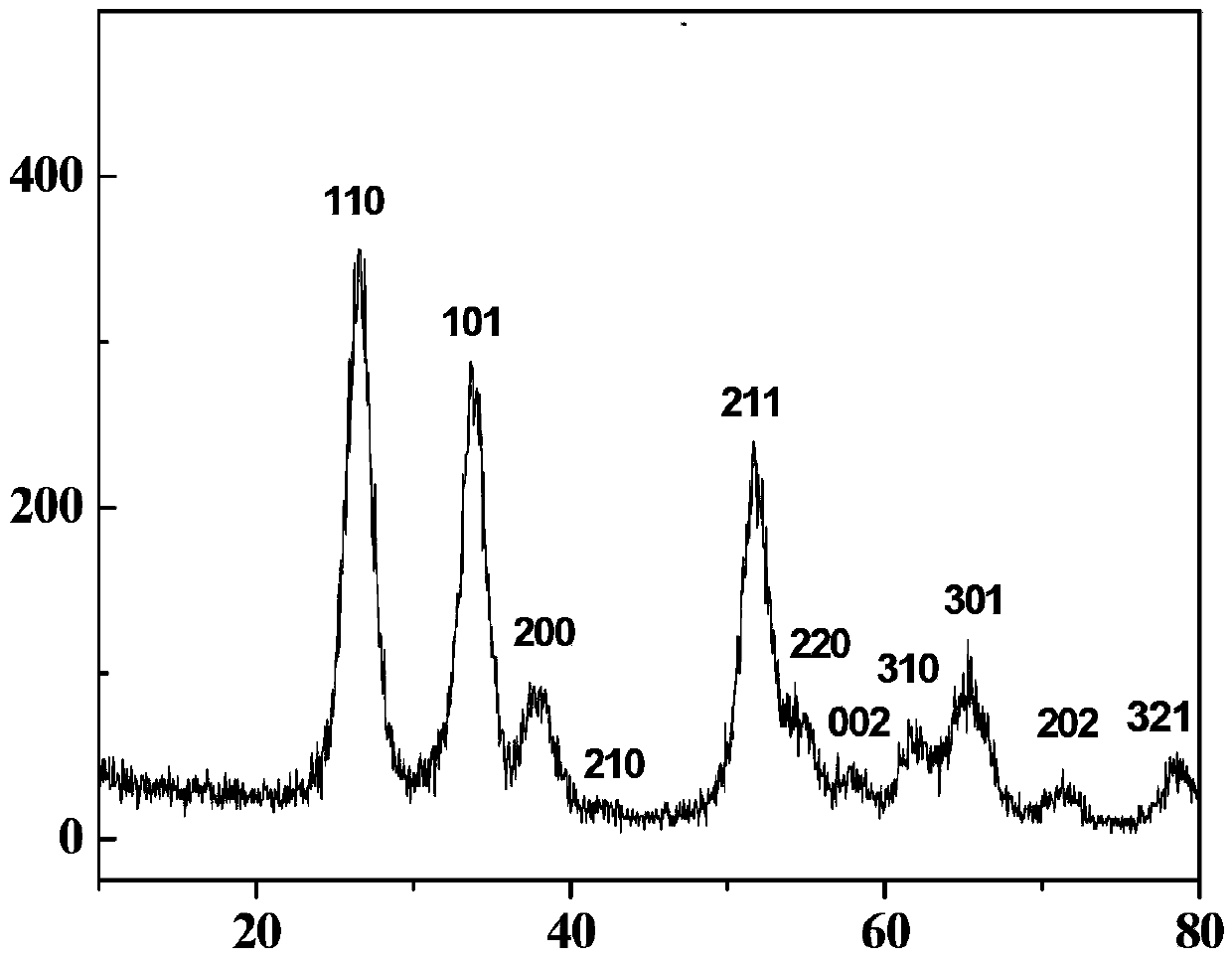

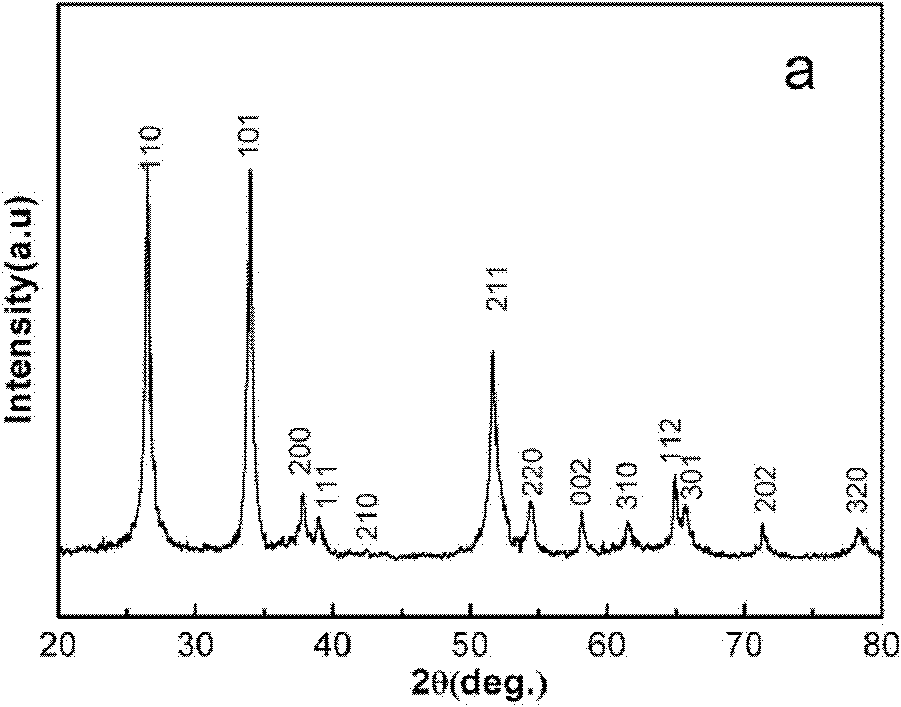

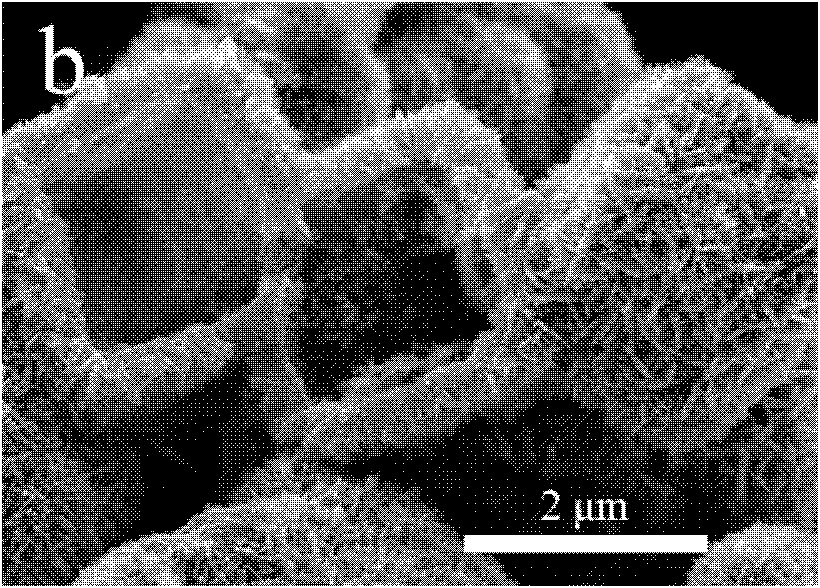

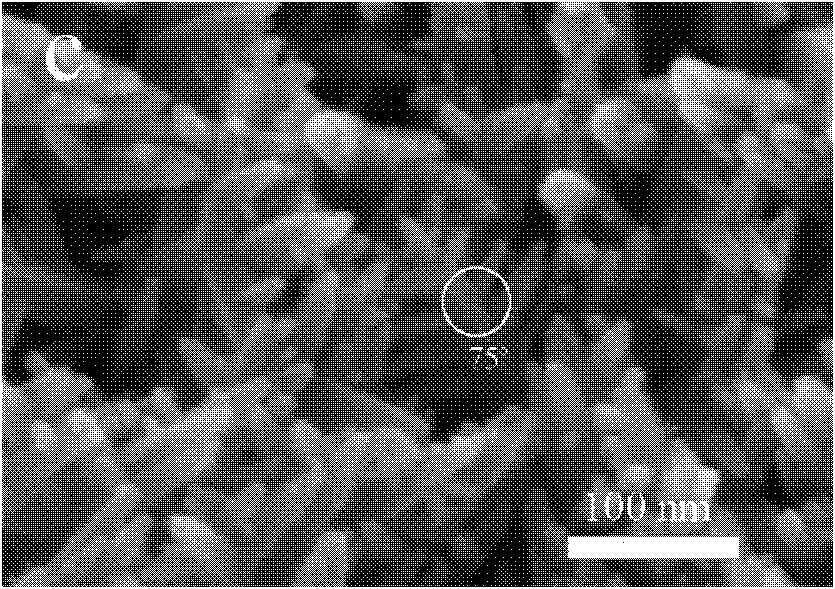

Metal complex of fluorinated tin oxide and titanium oxide and preparation method thereof

Disclosed is a metal complex including: a tin oxide; titanium oxide nanorods in a rutile phase formed on the tin oxide; and titanium oxide nanoparticles in an anatase phase formed on the titanium oxide nanorods in a rutile phase, and a preparation method thereof, and can be used as a catalyst support in various forms.

Owner:KOREA INST OF ENERGY RES

Preparation method of silver-tin oxide-wolfram carbide composite electric contact material and product thereof

InactiveCN107502768AImproved resistance to arc erosionImprove welding resistanceTransportation and packagingMetal-working apparatusChemical reductionContactor

The invention discloses a preparation method of silver-tin oxide-wolfram carbide composite electric contact material and a product thereof. The technical scheme is characterized in that a basis material of a contact comprises, by weight, 1-20% of tin oxide, 0.01-10% of wolfram carbide, less than 5% of additives and the balance silver. The preparation method of the silver-tin oxide-wolfram carbide composite electric contact material and the product thereof has the advantages and the positive effects as follows: 1, a chemical reduction coating method is adopted, so that the uniformity of mixed powder is better and the sintering strength is higher; 2, the surfaces of the WC powder body and the SnO2 powder body are uniformly coated with a silver layer, so that the electric arc erosion resistance and the melt welding resistance of the electric contact material are improved, and the reliability of a contactor is improved; and 3, the Ag-SnO2-WC contact material with appropriate components is selected, so that the arc burning resistance and the fusion welding resistant performance of the contact are improved, and meanwhile, the silver content of the contact is reduced, so that the silver-saving effect is achieved.

Owner:FUDA ALLOY MATERIALS

High performance manganese zinc magnetic material used for photovoltaic inverters, and preparation method thereof

InactiveCN107162581ASuit one's needsImprove work efficiencyInorganic material magnetismInductances/transformers/magnets manufactureRare earthManganese oxide

The invention discloses a high performance manganese zinc magnetic material used for photovoltaic inverters. The high performance manganese zinc magnetic material used for photovoltaic inverters comprises, by weight, 105 to 110 parts of ferric oxide, 18 to 22 parts of zinc oxide, 44 to 48 parts of manganese oxide, 2 to 3 parts of nickel oxide, 0.06 to 0.18 part of cobaltic oxide, 0.08 to 0.16 part of zirconium dioxide, 0.05 to 0.07 part of niobium pentoxide, 0.03 to 0.11 part of tin oxide, 0.01 to 0.07 part of alumina, 0.08 to 0.14 part of titanium dioxide, 0.1 to 0.3 part of europium oxide, and 1 to 3 parts of a rare earth oxide. The high performance manganese zinc magnetic material possesses higher magnetic permeability and excellent high frequency characteristics because of reasonable improvement of raw material formula; indexes including power consumption, Curie point, and saturation magnetic flux density are improved greatly; a preparation method and the raw materials are low in cost; the raw materials are easily available; the preparation method is simple; and relative application value and promising application prospect are achieved.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

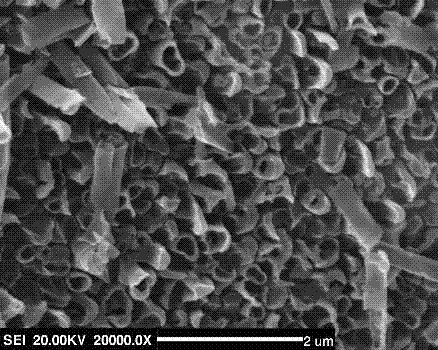

Solid-phase method for preparing tin oxide-tin sulfide heterojunction nanoflowers

InactiveCN110255605ALarge specific surface areaHigh reactivityMaterial nanotechnologyTin oxidesDispersityHeterojunction

The invention relates to a solid-phase method for preparing tin oxide-tin sulfide heterojunction nanoflowers, and belongs to the field of nano material preparation. The preparation method comprises the following steps: (1) putting stannic chloride into an agate mortar; (2) carrying out grinding, and then adding lauryl sodium sulfate; (3) carrying out grinding, and then adding thioacetamide; and (4) carrying out grinding, then adding sodium hydroxide, fully carrying out grinding, carrying out standing to complete a solid-phase reaction, carrying out washing with deionized water and absolute ethyl alcohol, carrying out suction filtration, and carrying out drying in a drying oven at 60 DEG C for 2 hours to prepare the tin oxide-tin sulfide heterojunction nanoflowers. The solid-phase chemical method for preparing the tin oxide-tin sulfide heterojunction nanoflowers has the advantages that the operation is simple, no solvent is used, the yield is high, cost is low, the synthesis process is simple and the like, and a high yield of the product is ensured. Moreover, characteristics of the sodium dodecyl sulfate surfactant are utilized, so that the product has relatively good dispersity; and meanwhile, interaction between tin oxide and tin sulfide is enhanced, so that the prepared tin oxide-tin sulfide heterojunction nanoflowers have a large specific surface area and high reaction activity, and have a potential application prospect in the fields of photoelectric devices, photocatalysis and the like.

Owner:XINJIANG UNIVERSITY

Method for producing a contact material on the basis of silver-tin oxide or silver-zinc oxide, and contact material

ActiveUS20190035563A1Improve mechanical propertiesAdvantageous heating behaviourContactsTin oxidesTin dioxideTin(II) oxide

A method for producing a contact material on the basis of silver-tin oxide or silver-zinc oxide is disclosed. Tin oxide particles and / or zinc oxide particles are mixed with a powder of a metal different from silver. The mixture is heated beyond the melting point of the metal powder such that the tin oxide particles and / or zinc oxide particles are wetted with liquid metal. The mixture is exposed to an atmosphere containing oxygen and the metal is thereby oxidized. Thereafter, the mixture product formed by the oxidation step is embedded as a powder into a silver matrix. The product further relates to a corresponding contact material.

Owner:DODUCO CONTACTS & REFINING GMBH

A kind of low warpage crystalline silicon solar cell conductive aluminum paste

ActiveCN105374411BReduce warpageImprove conductivityNon-conductive material with dispersed conductive materialSemiconductor devicesTin dioxideSilicon solar cell

Owner:JIANGSU HOYI TECH

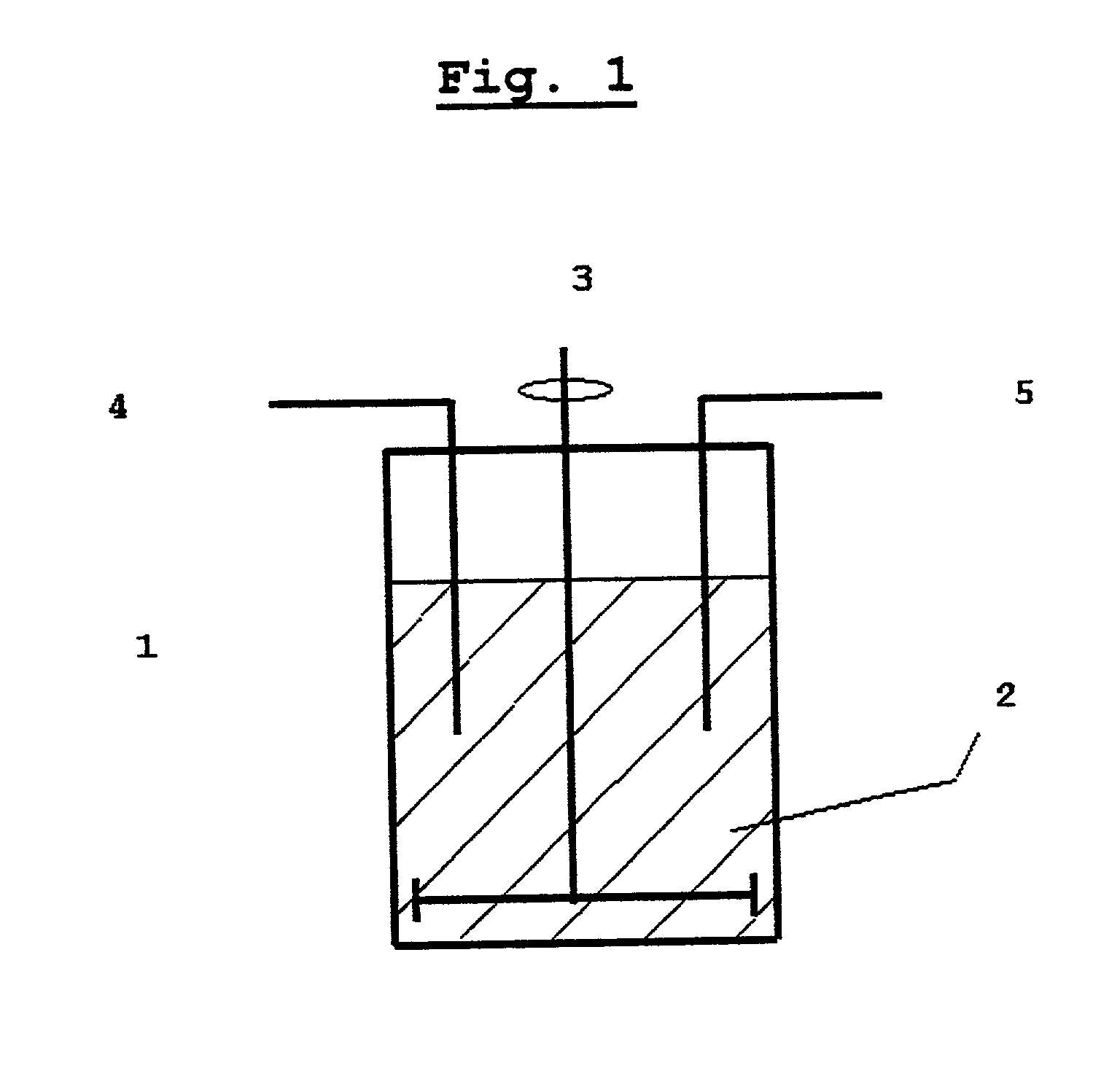

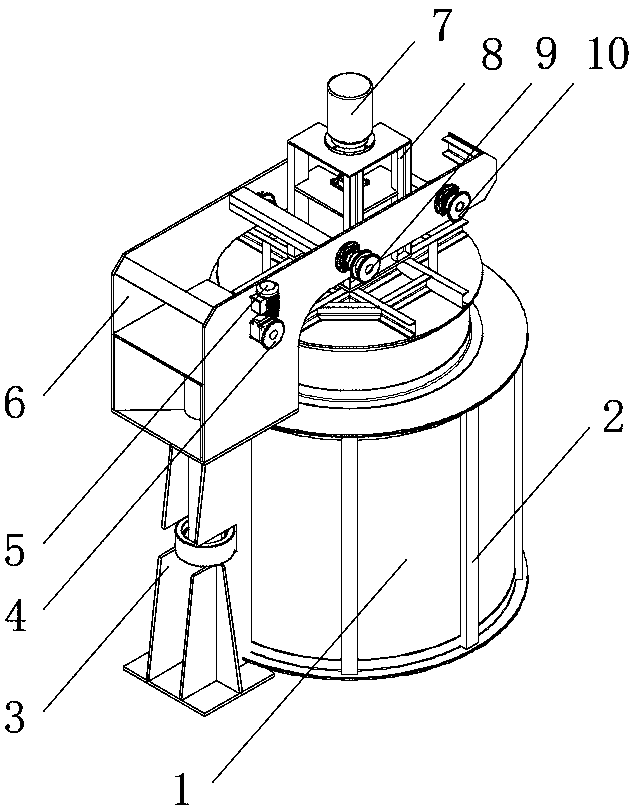

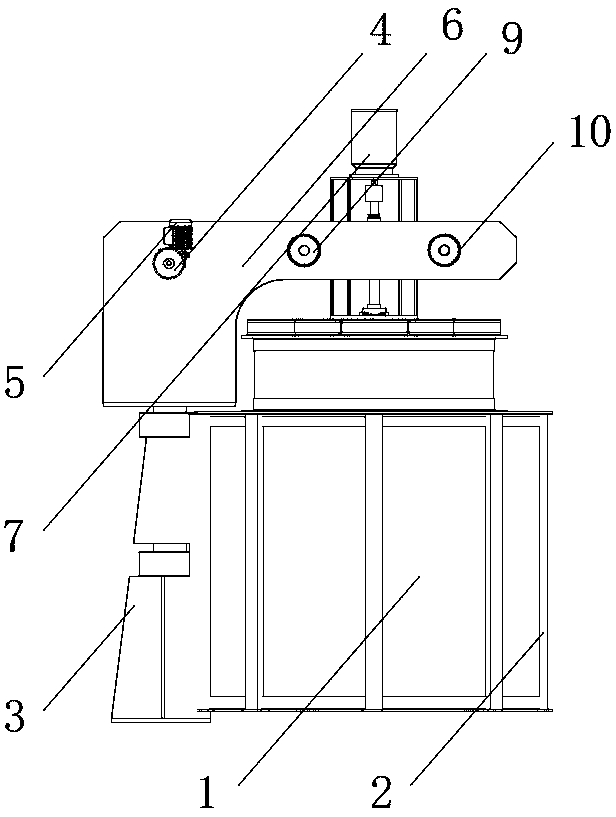

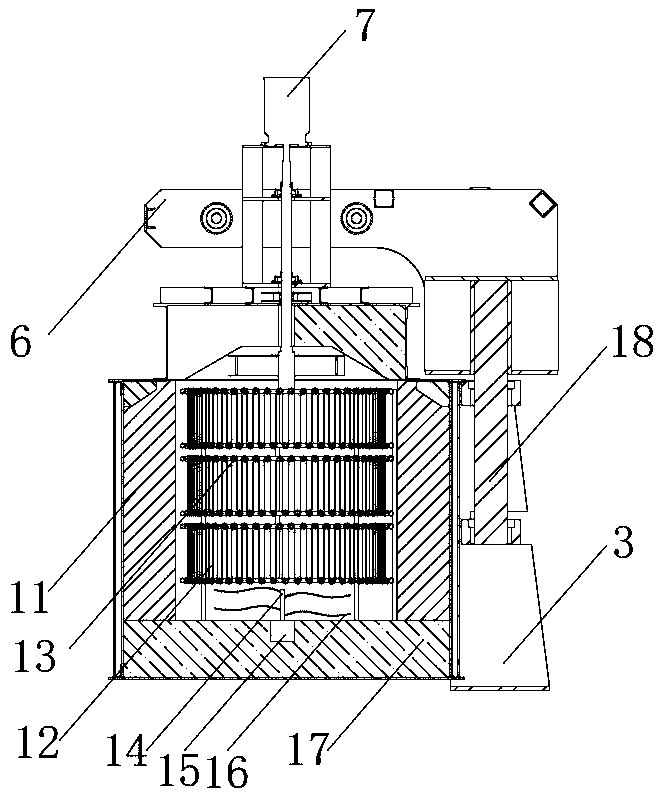

Efficient antimony doped tin oxide (ATO) production equipment adopting solid-phase method

ActiveCN109806829AReduce lossWell mixedChemical/physical/physico-chemical stationary reactorsTin oxidesTin(II) oxideEngineering

The invention discloses efficient antimony doped tin oxide (ATO) production equipment adopting a solid-phase method. The efficient ATO production equipment comprises a heat preservation main box, anda positioning main vertical column is arranged on the position, parallel to a generatrix of the heat preservation main box, of the side face of the heat preservation main box; the top of the positioning main vertical column is in fixed bolting connection with a supporting bracket, the side face of the supporting bracket is in fixed bolting connection with a power motor, the output end of the powermotor is in key connection with a driving gear, a first driven gear and a second driven gear are arranged on the position, on the same plane with the axis of the driving gear, of the supporting bracket at the equal distance, and a feeding funnel is vertically embedded in the middle of the top of the supporting bracket. According to the efficient ATO production equipment, the novel structure is used, a plurality of chain wheels are adopted for parallel transmission, thus a top cover of the whole equipment can be stably opened, meanwhile, stirring blades are additionally arranged in the equipment, thus reaction raw materials are fully mixed, complete reaction is ensured, waste is avoided, and the material loss is reduced.

Owner:柳州呈奥科技有限公司

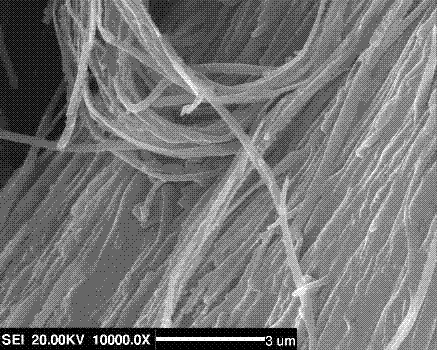

Preparation method of tin oxide-bacterial cellulose composite supported palladium-based fuel cell catalyst

ActiveCN107017413BGood dispersionHigh catalytic activityMaterial nanotechnologyCell electrodesDispersityNano catalyst

The invention discloses a method for preparing a tin oxide-bacterial cellulose composite supported palladium base fuel-cell catalyst and belongs to the technical field of preparation of fuel-cell catalytic materials. The preparation materials comprise the following components: SnCl4.5H2O, bacterial cellulose, chloropalladic acid and a reducing agent. The method comprises the following steps: dissolving SnCl4.5H2O and pretreated bacterial cellulose into water, fully dispersing and stirring, drying and calcining to obtain a tin oxide-bacterial cellulose composite carrier; and adding the carrier into a chloropalladic acid solution for fully stirring, and supporting palladium nano-catalyst particles through a liquid phase reduction method. The composite carrier is capable of obviously improving the dispersity of the palladium particles, so that the catalytic activity and stability of the catalyst on alcohols are improved. The method disclosed by the invention is simple and readily available in preparation materials and stable in process and has industrialization prospects.

Owner:FUZHOU UNIV

Rare earth-doped tin oxide as well as preparation method and application thereof

InactiveCN109482170AOrganic compound preparationCarboxylic acid esters preparationTin(II) oxideRare earth

The invention relates to rare earth-doped tin oxide as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a rare earth salt solution with tin oxide, so as to obtain a mixture; and calcining the mixture at 500-900 DEG C, so as to obtain rare earth-doped tin oxide. The preparation method is simple and easy in implementation, and rare earth-doped tin oxide prepared by virtue of the method is stable, large in specific surface area and high in catalytic activity to acetylsalicylic acid.

Owner:HUAIHUA UNIV

Method for preparing carbon nano tube composite material loaded with nano indium-tin oxide

The invention relates to a method for preparing a carbon nano tube composite material, in particular to a method for preparing a carbon nano tube composite material loaded with nano indium-tin oxide. The invention solves the problem of complicated process of the traditional method for preparing the carbon nano tube composite material loaded with nano indium-tin oxide. The method comprises the following steps of: preparing an organic phase solution by using indium nitrate, stannic chloride and ethylene glycol methyl ether; preparing an aqueous phase solution by using resorcinol, formaldehyde, sodium carbonate and water; dropwise adding the organic phase solution into the aqueous phase solution to obtain a precursor solution; soaking a porous aluminum oxide template into the precursor solution and standing; then sintering; finally, removing the template by using sodium hydroxide, washing and drying to obtain the carbon nano tube composite material loaded with the nano indium-tin oxide. The invention has simple process and can be used for preparing a hydrogen sensitive element.

Owner:HARBIN INST OF TECH

A metal-doped tin oxide transparent dispersion and its preparation method

The invention discloses a metal-doped tin oxide transparent dispersion and its preparation method. The dispersion contains metal-doped tin oxide, a surfactant and a solvent. The solid content is 5-40wt%; particle size distribution is narrow, and particle size of particles is 5-30nm; and the dispersion is in a stable transparent state. The method comprises the following steps: 1) tin salt and salt of metal A are dissolved in acid to form a mixed salt solution; aqueous alkali is added into the mixed salt solution to generate a hydroxide precipitate; 2) the hydroxide is dispersed in an organic solvent, the surfactant is added to carry out reflux so as to obtain modifier-coated hydroxide; 3) the modifier-coated hydroxide is dispersed in water to obtain a hydroxide dispersion liquid, and the dispersion liquid reacts by a hydrothermal method; and 4) a product of the reaction by the hydrothermal method is dispersed in an organic solvent or water so as to obtain the metal-doped tin oxide dispersion. Synthesized raw materials are easily available, price is low, and production cost is low. At low hydrothermal temperature and pressure, crystal transfer of a nano-powder is realized. The prepared particles have good conductivity and dispersibility, and the dispersion has good stability and transparency.

Owner:BEIJING UNIV OF CHEM TECH +1

Hydrothermal synthesis method of zinc-doped tin oxide with hollow cubic structure

The invention provides a hydrothermal synthesis method of zinc-doped tin oxide with a hollow cubic structure, comprising the following steps: dropwise adding a mixed aqueous solution of SnCl4 and Zn(NO3)2 to a NaOH aqueous solution with a certain concentration, wherein, the volume ratio of the mixed aqueous solution of SnCl4 and Zn(NO3)2 to the NaOH aqueous solution is 1:3-1:15, the concentrationof SnCl4 is 0.1094-0.1144mol / L, the concentration of Zn(NO3)2.6H2O is 0.0106-0.0156mol / L, and the concentration of NaOH is 1.875mol / L; evenly stirring and transferring the mixed solution to a hydrothermal reaction kettle so that the filling degree reaches 80%; carrying out isothermal reaction at the temperature of 180-190 DEG C for 25 hours; and finally centrifuging, washing and drying the obtained reaction product to obtain the zinc-doped tin oxide. The hydrothermal synthesis method has simple process and easy operation; and the synthesized zinc-doped tin oxide particles have controllable size and high purity, and the obtained product has excellent electrical property.

Owner:WUHAN UNIV OF TECH

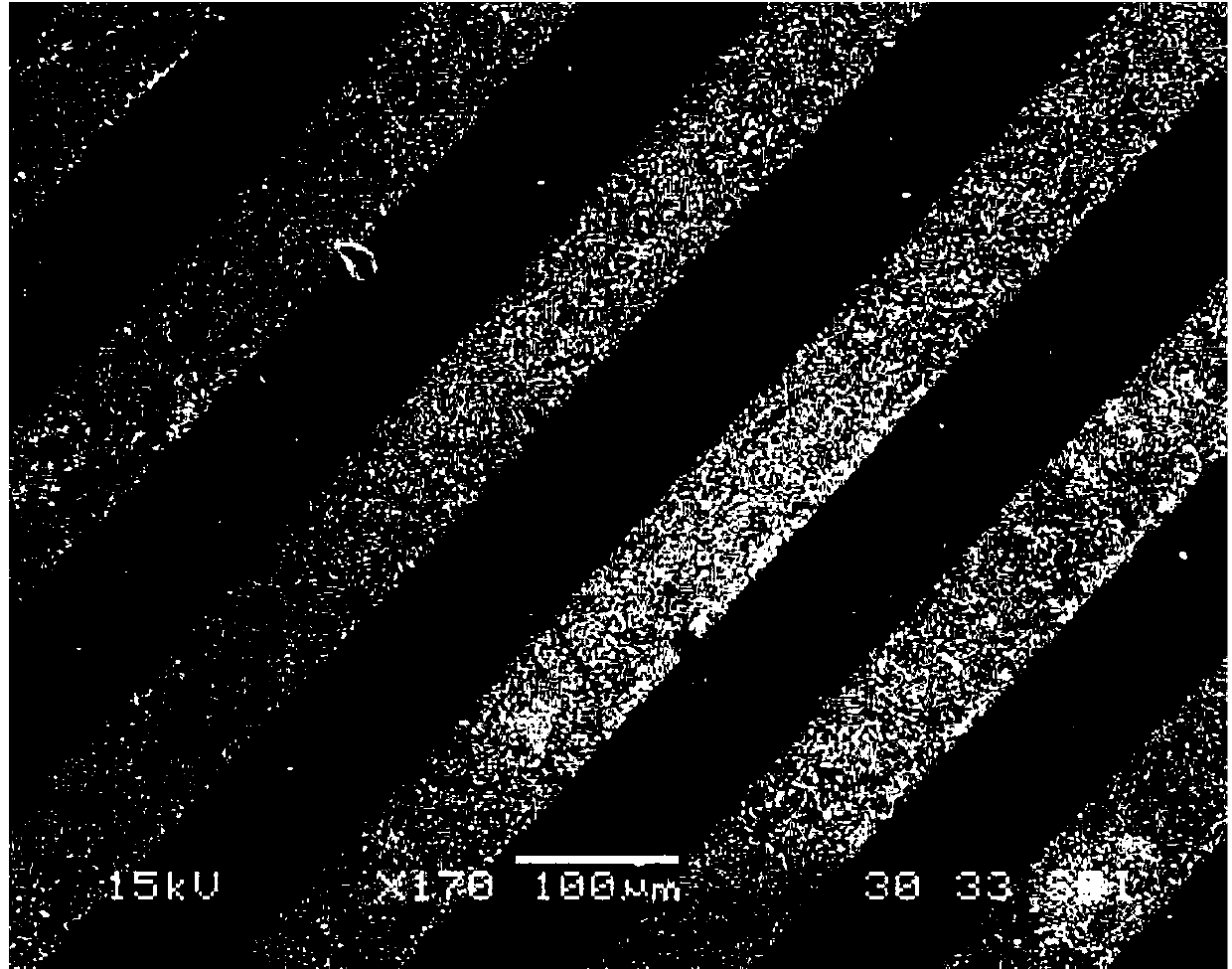

Preparation of indium-tin oxide/PDMS(polydimethylsiloxane) resin conducting material based on textile template

InactiveCN102176348BImprove conductivityImprove mechanical propertiesConductive layers on insulating-supportsOxide conductorsTin(II) oxideIndium tin oxide

The invention relates to a method for preparing an indium-tin oxide / PDMS(polydimethylsiloxane) resin conducting material based on a textile template, which comprises the steps of: (1) preparing a precursor solution of an indium-tin oxide; (2) under a vacuumized environment, soaking a textile in the precursor solution, then taking out and drying, and calcining to obtain the indium-tin oxide conducting material; and (3) evenly mixing PDMS with a curing agent in a mass ratio of 10:1, then flatly laying the indium-tin oxide conducting material obtained in step (2) on the top of the mixture, curing at the temperature of 100 to 120 DEG C for 10 to 20min, and obtaining the indium-tin oxide / PDMS resin composite conducting material. The method provided by the invention has the advantages of simplepreparation process, low cost and easiness for realization of industrial production, and the prepared indium-tin oxide / PDMS resin composite flexible conducting material has the advantages of compact structure, fine electrical conductivity, fine foldable performance and broad market prospects.

Owner:DONGHUA UNIV

Preparation method of antimony-doped zinc oxide and tin oxide-coated silicon oxide conductive powder

ActiveCN107967967BHigh whitenessNo impuritiesOxide conductorsCable/conductor manufacturePeristaltic pumpTin dioxide

The invention, which belongs to the technical field of functional material preparation, in particular relates to a preparation method of conductive powder with antimony-doped zinc oxide and stannic oxide coating monox. Pure silica powder is put into a beaker containing distilled water with the pH valued adjusted by hydrochloric acid and stirring is carried out to obtain a monox suspension; mixed liquid with Zn<2+>, Sn<4+> and Sb<3+> and an alkaline solution are controlled by a peristaltic pump to be dripped into the monox suspension simultaneously, and after dripping completion of the mixed liquid, heating and stirring are carried out continuously; ageing, suction filtration, and washing are carried out successively, an obtained precursor is dried, and then the dried precursor is placed ina muffle furnace to carry out heat treatment, so that conductive powder is obtained. The conductive powder not only has the conductive property but also has chemical stability not possessed by materials like metal and has the good antistatic performance; and the coverage rate and whiteness are high. The conductive power serving as a functional filler applied to a preparation process like of a plastic, coating, ceramic material has a wide application range.

Owner:山东电盾科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com