Preparation method of rod-shaped tin oxide-reinforced silver-based electric contact material

A technology of electrical contact material and tin oxide, which is applied in the direction of circuits, electrical switches, electrical components, etc., can solve the problems of affecting electrical performance and service life, the decline of electrical performance of contacts, and non-wetting of liquid silver to achieve good electrical conductivity The effect of high stability, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is to prepare the rod-shaped tin oxide-reinforced silver-based electrical contact material containing 90% silver and 10% tin oxide (mass percentage content), and proceeds according to the following steps:

[0032] 1. Prepare appropriate amounts of 0.1mol / L tin protochloride aqueous solution and 0.1mol / L oxalic acid aqueous solution respectively for standby;

[0033] 2. Mixed solution: According to the molar ratio of stannous chloride and oxalic acid 1:1, take a certain amount of stannous chloride aqueous solution and oxalic acid aqueous solution, quickly pour the stannous chloride aqueous solution into the oxalic acid aqueous solution, and use magnetic stirring to make Mix well and react at room temperature for 30 minutes;

[0034] 3. Separate the precipitate in step 2 by centrifugation, put it in an oven, and dry it at 60°C for 24 hours to obtain the stannous oxalate precursor;

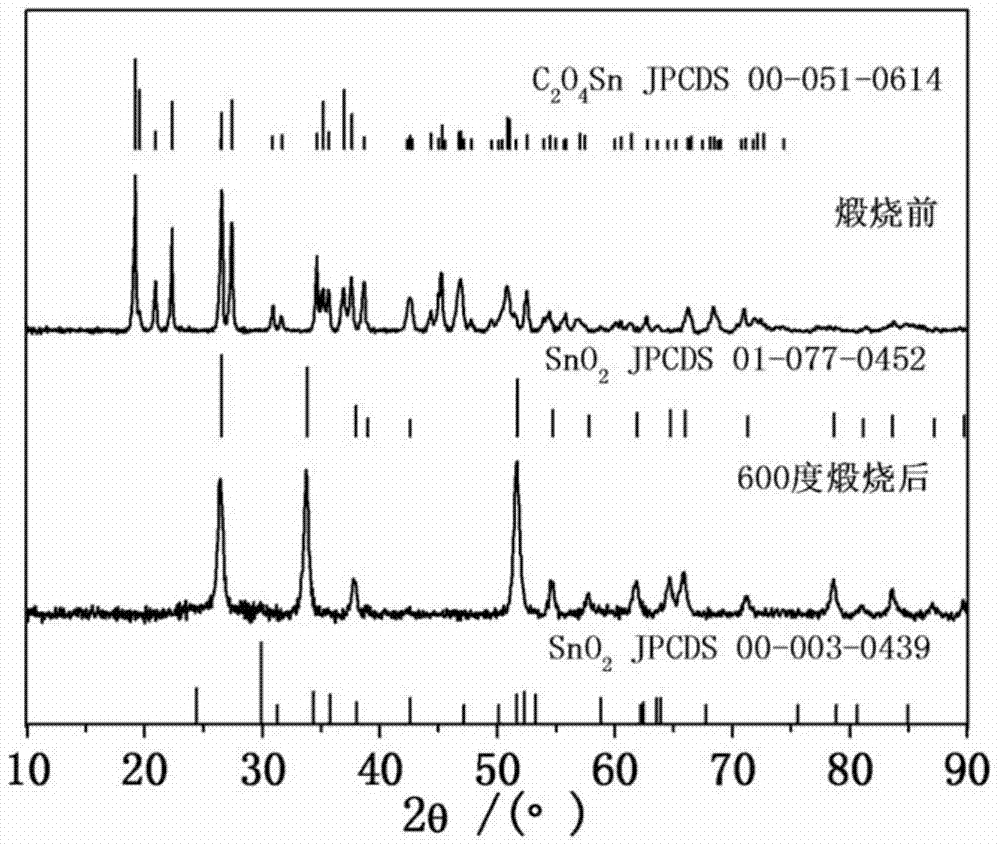

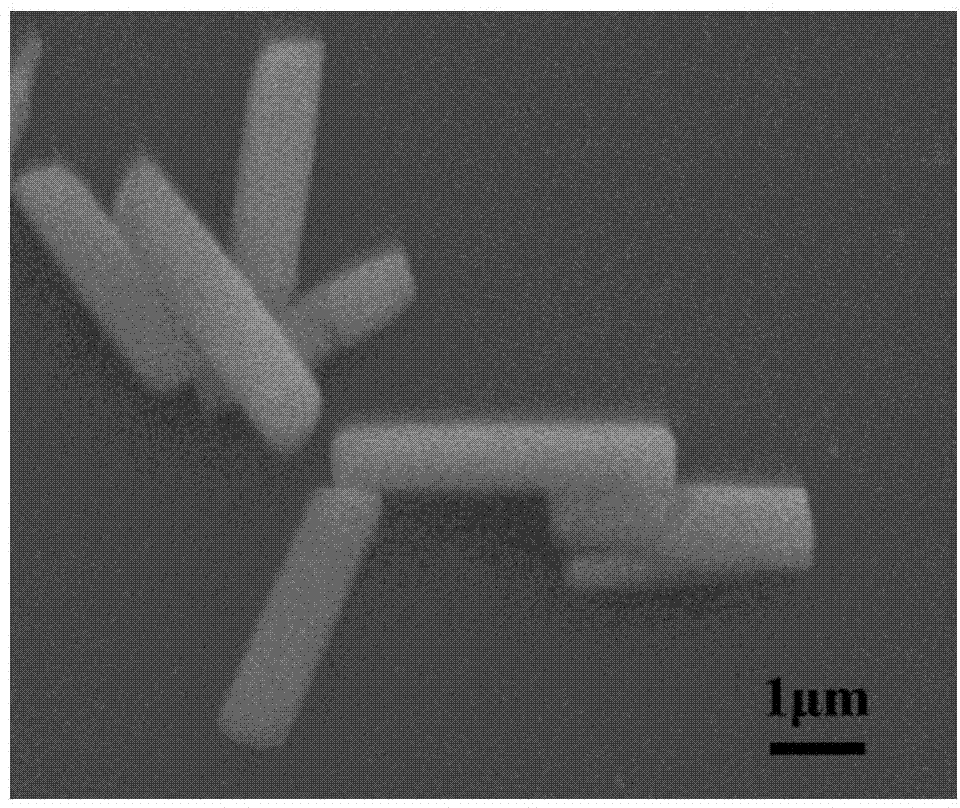

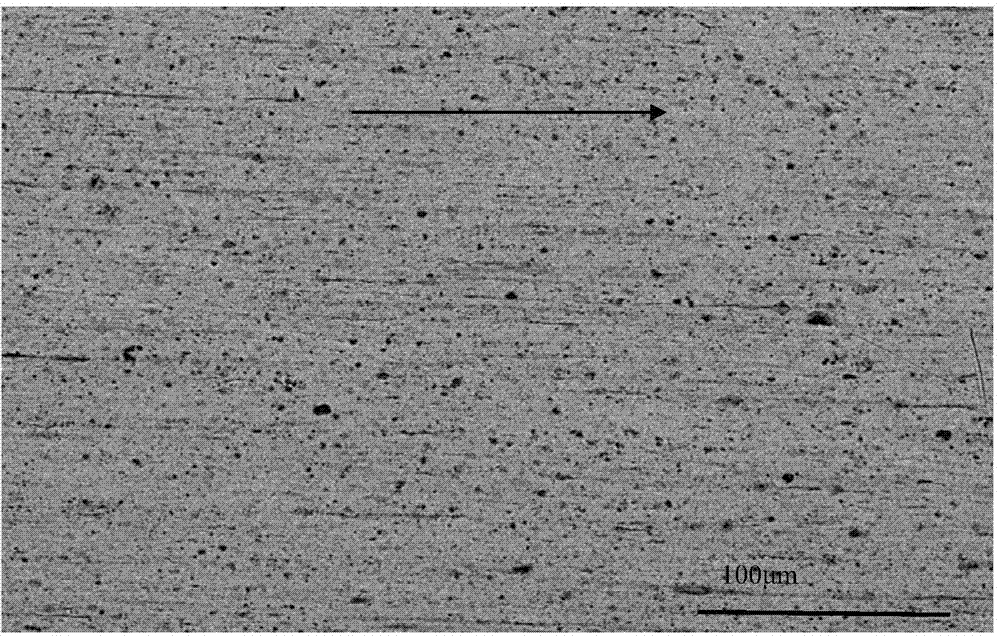

[0035] 4. Put the stannous oxalate precursor into a muffle furnace and ca...

Embodiment 2

[0042] This embodiment is to prepare the rod-shaped tin oxide-reinforced silver-based electrical contact material containing 90% silver and 10% tin oxide (mass percentage content), and proceeds according to the following steps:

[0043] 1. Prepare appropriate amounts of 0.2mol / L stannous chloride aqueous solution and 0.3mol / L oxalic acid aqueous solution respectively for use;

[0044] 2. Mixed solution: According to the molar ratio of stannous chloride and oxalic acid 1:1, take a certain amount of stannous chloride aqueous solution and oxalic acid aqueous solution, quickly pour the stannous chloride aqueous solution into the oxalic acid aqueous solution, and use magnetic stirring to make Mix well, react at room temperature for 120min;

[0045] 3. Separate the precipitate in step 2 by centrifugation, put it in an oven, and dry it at 40°C for 48 hours to obtain the stannous oxalate precursor;

[0046] 4. Put the stannous oxalate precursor into a muffle furnace and calcinate at ...

Embodiment 3

[0053] This embodiment is to prepare the rod-shaped tin oxide-reinforced silver-based electrical contact material containing 90% silver and 10% tin oxide (mass percentage content), and proceeds according to the following steps:

[0054] 1. Prepare suitable amounts of ethanol solution of 0.1mol / L stannous chloride and ethanol solution of 0.2mol / L oxalate respectively for use;

[0055]2. According to the molar ratio of stannous chloride and oxalic acid 1:2, take a certain amount of stannous chloride ethanol solution and oxalate ethanol solution, drop the stannous chloride ethanol solution into the oxalate ethanol solution, and react for 40 minutes;

[0056] 3. Separate the precipitate in step 2 by centrifugation, put it in an oven, and dry it at 60°C for 12 hours to obtain the stannous oxalate precursor;

[0057] 4. Transfer the stannous oxalate precursor into a muffle furnace and calcinate at 500°C for 3 hours to obtain tin oxide powder;

[0058] 5. Use the tin oxide powder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com