Patents

Literature

43results about How to "Good arc corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-based electric contact composite material and preparing method thereof

The invention discloses a copper-based electric contact composite material and a preparing method thereof, and belongs to the technical field of metal composite material preparing. The copper-based electric contact composite material comprises, by mass percentage, 10%-30% of chromium, 1%-5% of tungsten carbide and the balance copper. The copper-based electric contact composite material is high in compactness and even in structure and has high specific conductance and good anti-arc erosion performance. According to the preparing method, after chromium powder, tungsten carbide powder and copper powder are mixed, the spark plasma sintering technology is utilized for preparing a copper-chromium-tungsten carbide composite material. The obtained composite material has the high strength and high smelting point of chromium, good electrical conductivity and abrasion resistance of tungsten carbide and high electric conductivity and thermal conductivity of copper. The preparing method is controllable and environment-friendly, the technology is simple, cost is low, and the production period is short. The preparing of the electric contact composite material which has high anti-arc erosion performance, anti-welding capability, strength and electric conductivity performance is achieved, and the copper-based electric contact composite material is suitable for application and popularization.

Owner:HENAN UNIV OF SCI & TECH

A making method of silver/graphite electrical contact

The invention provides a method of producing high performance Argentine / graphite electronic contactor material, it includes following steps: 1) expanded graphite and Argentine are combined to produce raw material powder, the weight ratio of expanded graphite is 3-10%, the weight ratio of Argentine is 90%-97%; 2) Argentine / graphite raw material powder obtained in step 1) is sintered, and pressed to molding. The craftwork of the invention is easy, it convenient to operate, requirement of equipment is low, cost of production is low; the performance of product produced is well, nanophase graphite piece is even in material, resistivity is low, density is high, it possesses perfect performance of anti-arc corrosion.

Owner:HARBIN ENG UNIV

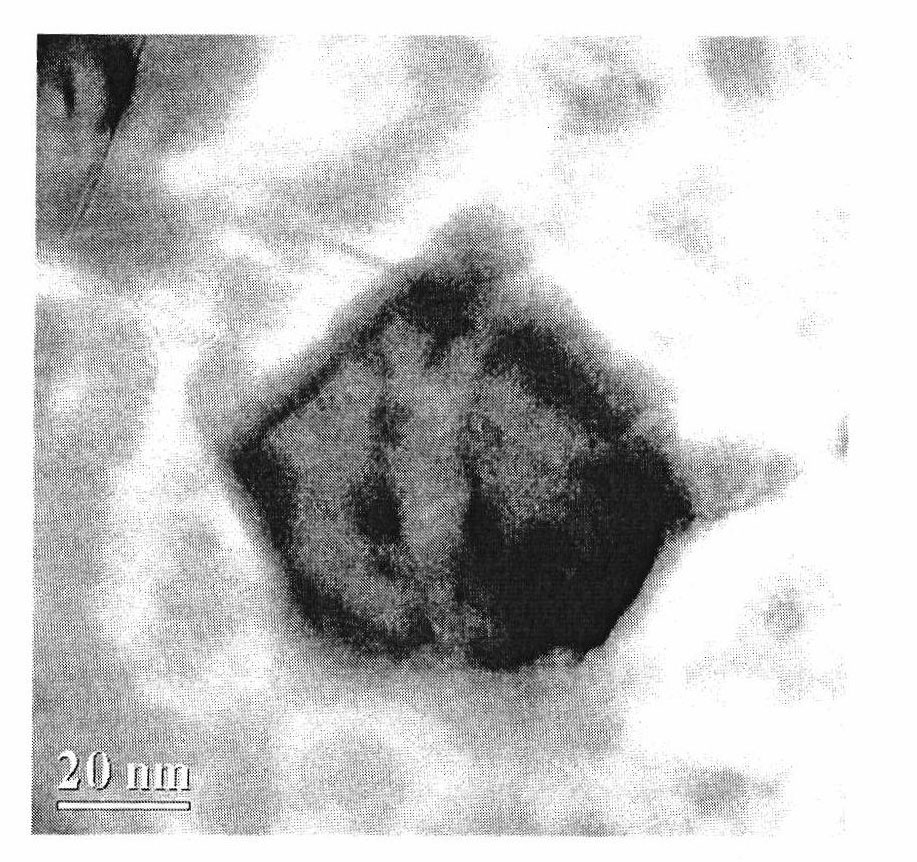

Technology for preparing silver rare earth oxide electric contact material for low voltage electric apparatus with liquid phase method

InactiveCN103233136ARaw materials are easy to getLow costRare earth metal compoundsContactsPowder metallurgyOxide

The invention relates to a technology for preparing a silver rare earth oxide electric contact material for a low voltage electric apparatus with a liquid phase method. According to the method, a chemical reduction method is combined with a homogeneous precipitation method to prepare nano-silver and rare earth oxide powder, and the silver rare earth oxide electric contact material is prepared by adopting a powder metallurgy technology, so that the contact material has high hardness, density and electric conductivity. The material used in the technology is easily available and little, and the cost is low; the chemical reduction method is combined with homogeneous precipitation method to prepare nano-silver and rare earth oxide powder, so that the technology is simple, the nano-silver and rare earth oxide powder are easy for industrial production, and the technology is environment-friendly and meets the currently recommended requirement of low-carbon production; and the contact material has good electrical property, 10%-30% of silver can be saved, and the contact material is a novel silver-saving electrical contact material.

Owner:HEBEI UNIV OF TECH

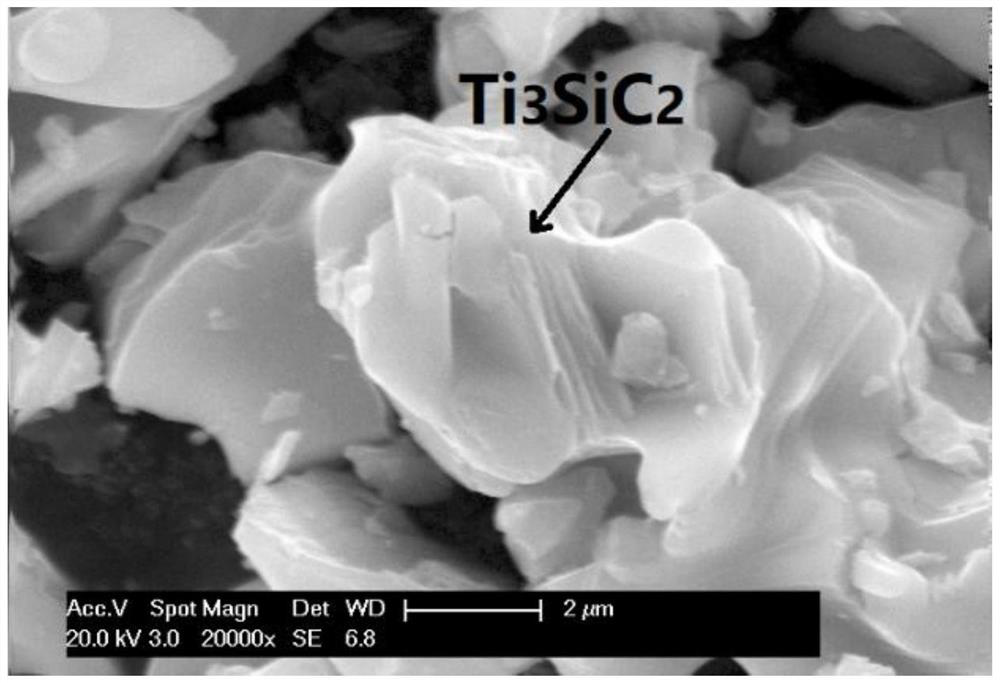

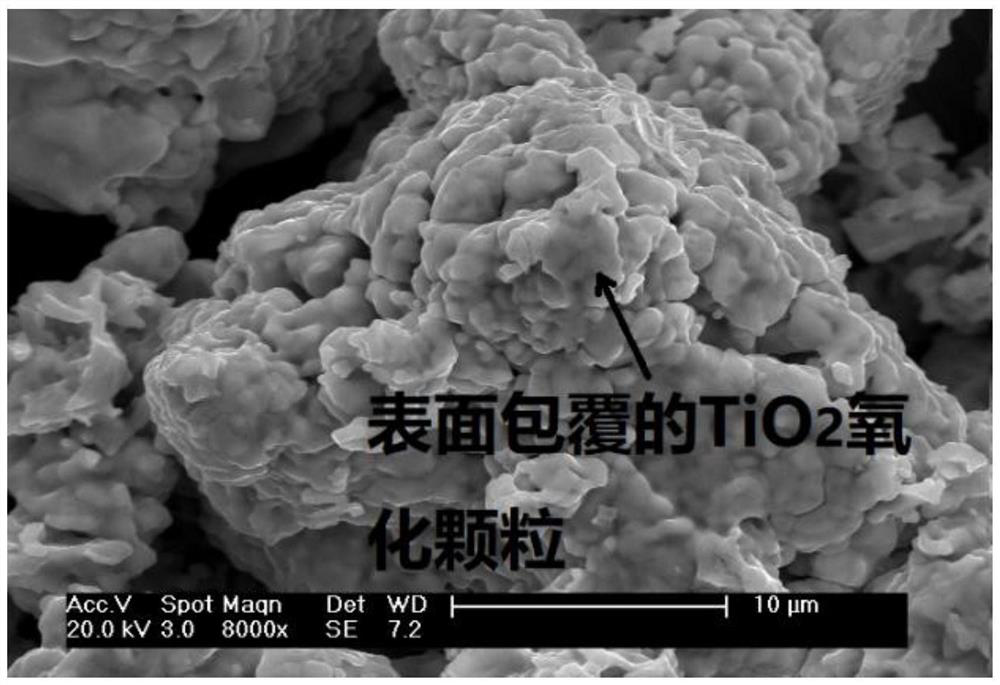

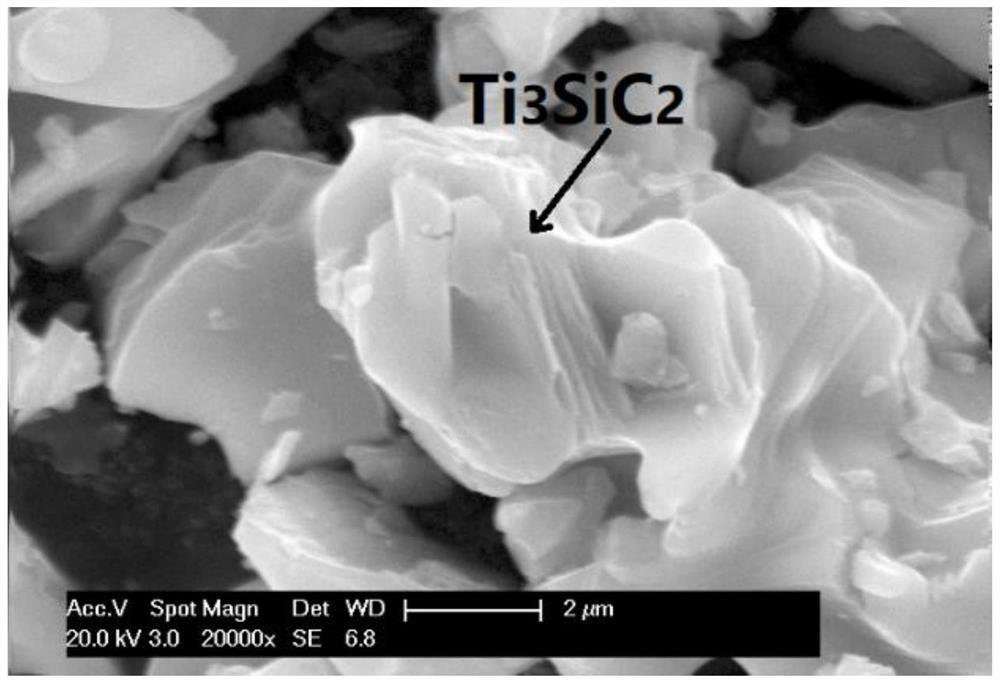

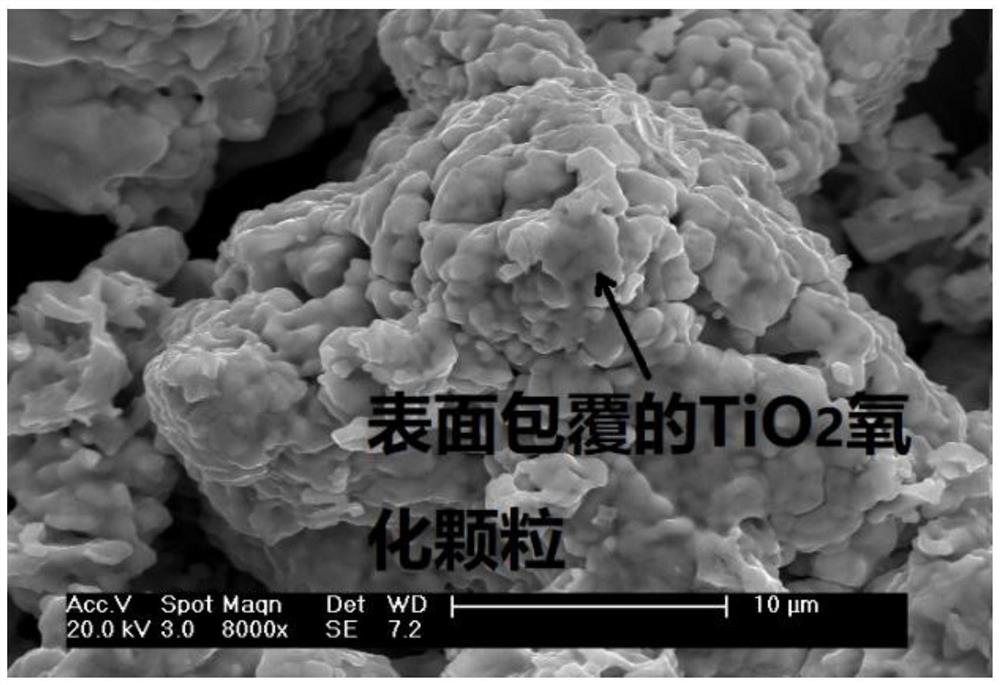

Shell-core-structure MXene@MAX composite contact reinforcing phase material and preparation method thereof

The invention discloses a shell-core-structure MXene@MAX composite contact reinforcing phase material and a preparation method thereof. The MXene@MAX composite contact reinforcing phase material is ofa multi-dimensional core-shell structure, an inner core is a MAX-phase material, and the shell is a MXene material corresponding to the MAX-phase material of the inner core. An Ag / MXene@MAX composite contact reinforcing phase material using the MXene@MAX and a preparation method thereof are disclosed. According to the MXene@MAX composite contact reinforcing phase material, after compounding withthe Ag matrix, the three-dimensional MAX plays a role of a supporting structure, the two-dimensional MXene plays the role of conducting electricity and heat and enhancing bonding with an Ag-based interface, the density, the conductivity, the heat conduction and the anti-arc erosion performance of an Ag-based electrical contact are improved, and the surface temperature rise, the contact resistanceand the material loss rate of the electrical contact are reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Silver-tungsten carbide-nickel contact material and preparation method thereof

The invention discloses a silver-tungsten carbide-nickel contact material and a preparation method thereof. The silver-tungsten carbide-nickel contact material is prepared from the following components in percentage by weight: 20-30% of tungsten carbide, 0.1-5% of nickel and the balance of silver. The preparation method of the material comprises the following steps: weighing tungsten carbide powder, nickel powder and silver powder, mixing evenly, putting the silver-tungsten carbide-nickel mixed powder, high-purity nickel balls and water into a ball mill for ball milling, and performing drying, annealing, forming, sintering, re-pressing and re-annealing on the ball-milled powder, thereby obtaining the silver-tungsten carbide-nickel contact material; the weight ratio of the high-purity nickel balls to the silver-tungsten carbide-nickel mixed powder is (4-10): 1; the dosage of the water is calculated according to that 130-220ml of water is added to the silver-tungsten carbide-nickel mixed powder per 1kg; the time of the ball milling is 12-48 hours; and as the nickel lost in ball milling is mixed with the powder, the weight of the weighed nickel powder is 0-92% of that of the nickel in the final silver-tungsten carbide-nickel mixed powder obtained after ball milling.

Owner:桂林金格电工电子材料科技有限公司

MAX@MOm/AOn electrical contact reinforced phase material, composite electrical contact material and preparation method

The invention discloses an MAX@MOm / AOn electrical contact reinforced phase material, a composite electrical contact material and a preparation method. The material is MAX@MOm / AOn with a core-shell structure, the inner core of the MAX@MOm / AOn is a three-dimensional material MAX phase, and the outer shell of the MAX@MOm / AOn is oxide particles MOm, AOn or a composite oxide layer MOm / AOn correspondingto the material of the inner core MAX phase. The Ag / MAX@MOm / AOn composite electrical contact material prepared by adopting the MAX@MOm / AOn prepared by the invention as a reinforcing phase is used forpreparing the Ag / MAX@MOm / AOn composite electrical contact material, the composite material is excellent in electrical conductivity, moderate in hardness and good in processability, can be processed into various electrical contact shapes according to actual application requirements, is excellent in arc erosion resistance and remarkable in silver-saving effect, and the content of a reinforcing phase MAX@MOm / AOn in an Ag matrix accounts for 40 wt% of the composite material at most. The preparation process is simple, good in practicability and suitable for large-scale production, is suitable forlow-voltage switch equipment such as contactors, circuit breakers and relays, and brings social and economic values.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

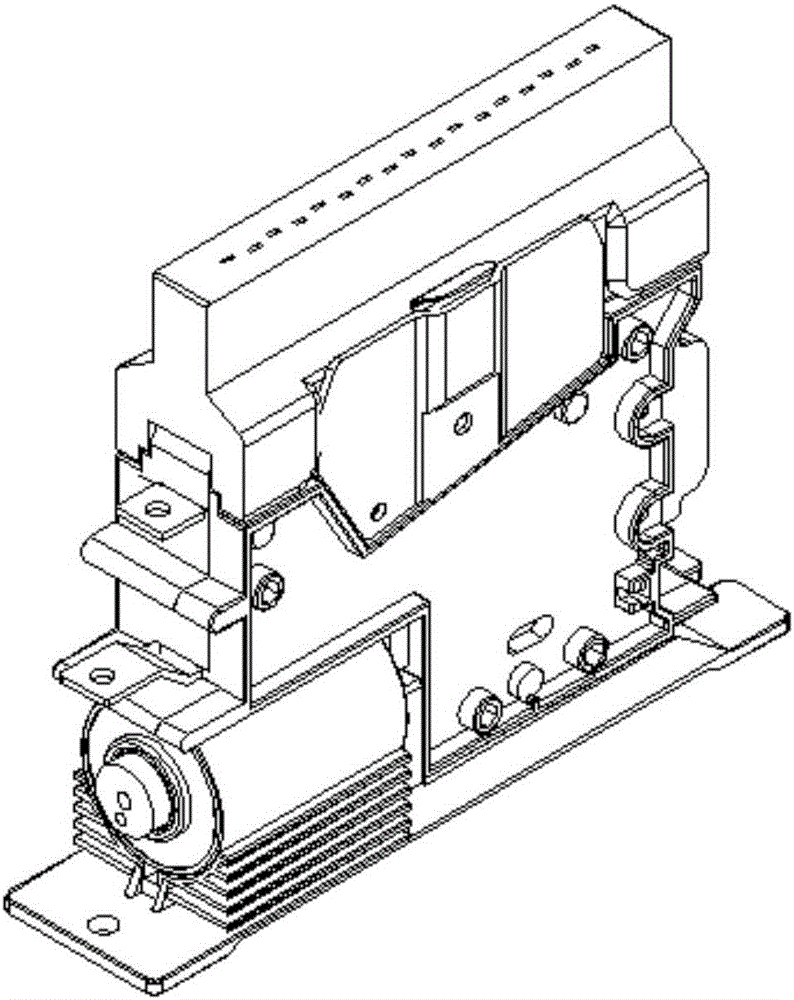

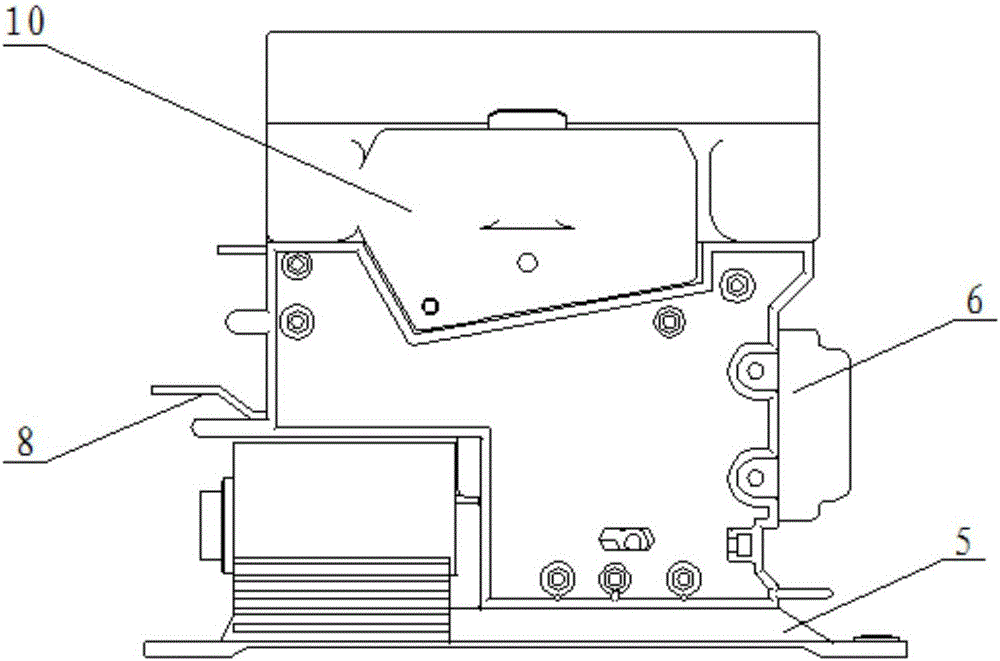

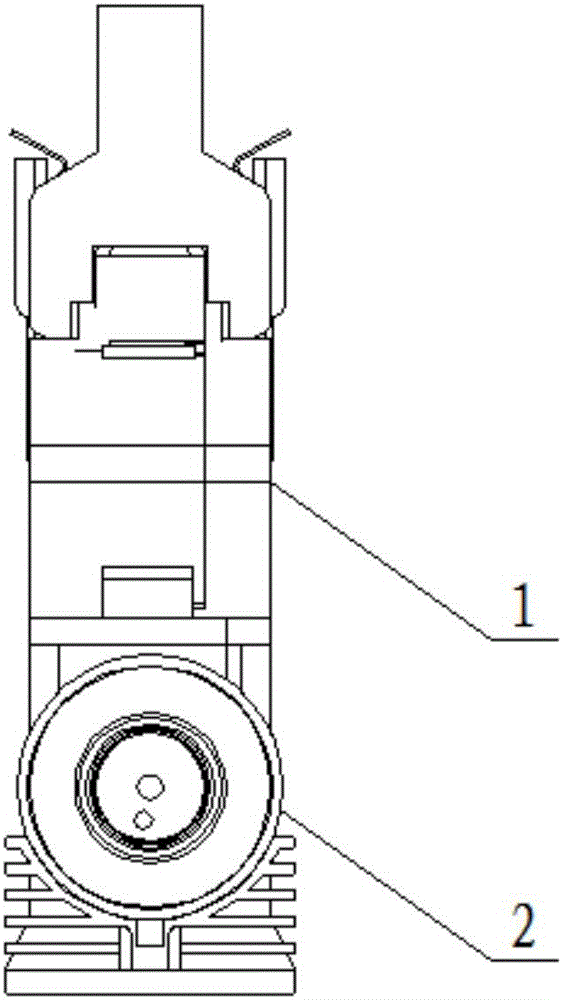

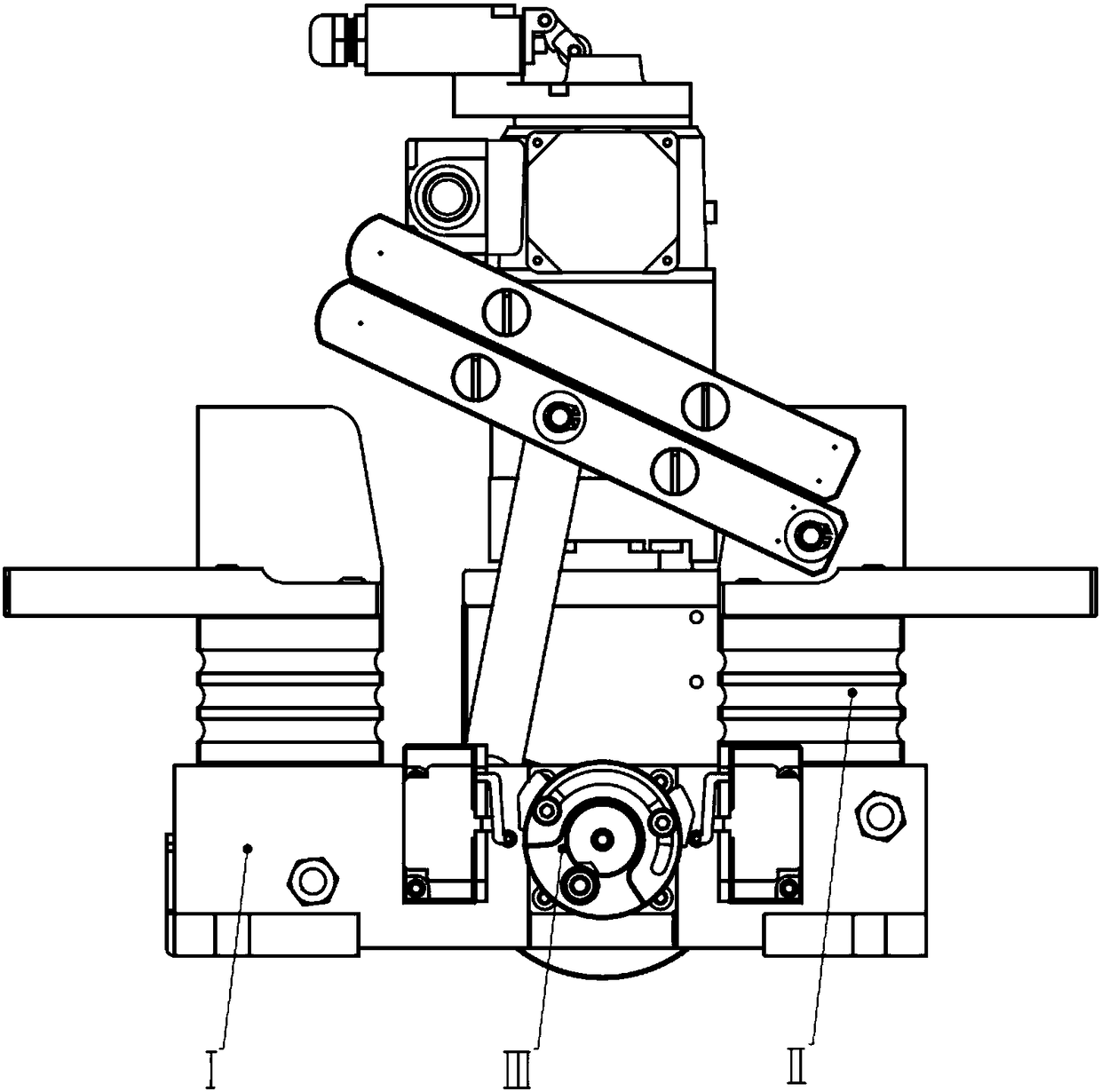

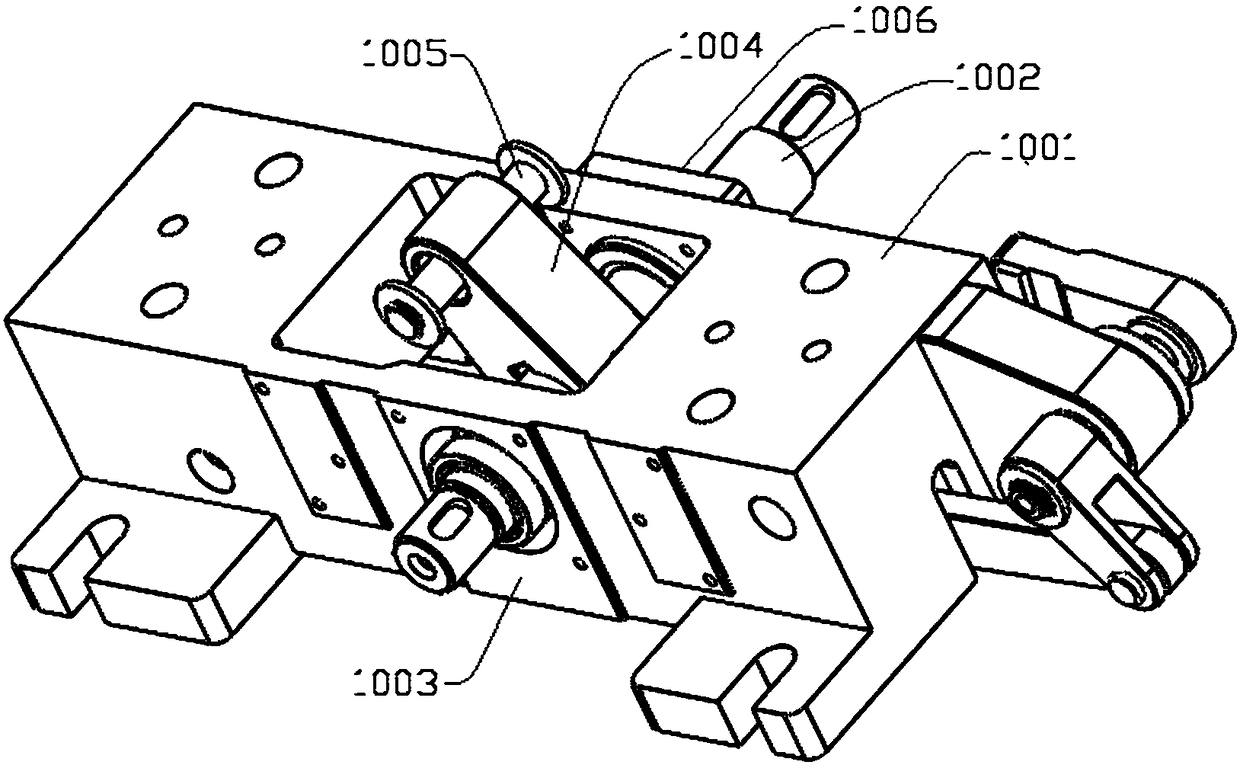

High voltage direct current contactor with magnetic coil arc quenching

InactiveCN106098477ASo as not to damageInduced magnetic field enhancementElectromagnetic relay detailsHigh-voltage direct currentHigh pressure

The invention discloses a high voltage direct current contactor with magnetic coil arc quenching, and belongs to the contactor technical field. The high voltage direct current contactor with the magnetic coil arc quenching comprises a shell and a base, wherein the shell is fixedly connected with the base. A magnetic ring coil assembly and a swinging rod are arranged in the shell. A moving contact pin 2 is fixed on the top of the swinging rod. An electromagnet assembly is arranged under the shell. A movable end of the electromagnet assembly is connected to one end of the swinging rod through a pushing rod. The pushing rod can push the swinging rod to rotate around an installation shaft. The technical scheme adopts magnetic ring winding coils to generate an induced magnetic field so as to provide a magnetic blow-out arc quenching system. The induced magnetic field generated in the winding coils correspondingly changes along with the high- low of an instantaneous voltage level, so that the magnetic blow-out force is different. The magnetic field is guided in a vertical direction of a current flowing direction of a contact through a baffle, and an electric arc is more effectively blown to a cavity of a specified arc quenching room for segment arc quenching. The damage of the contact in a product is prevented.

Owner:GUIZHOU TIANYI ELECTRICAL

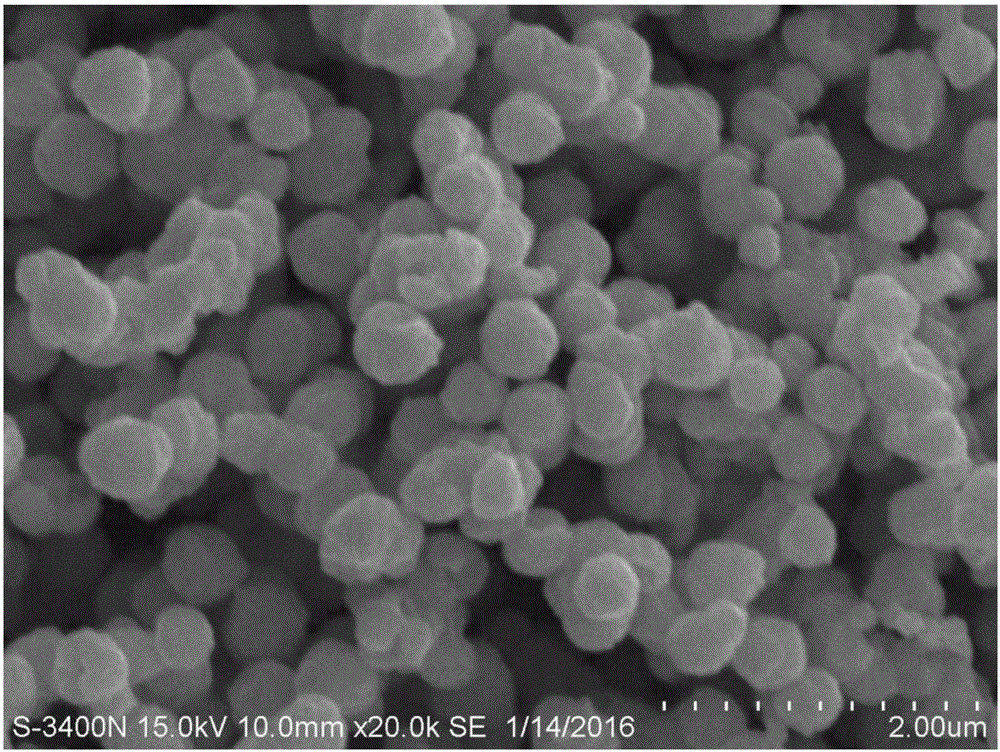

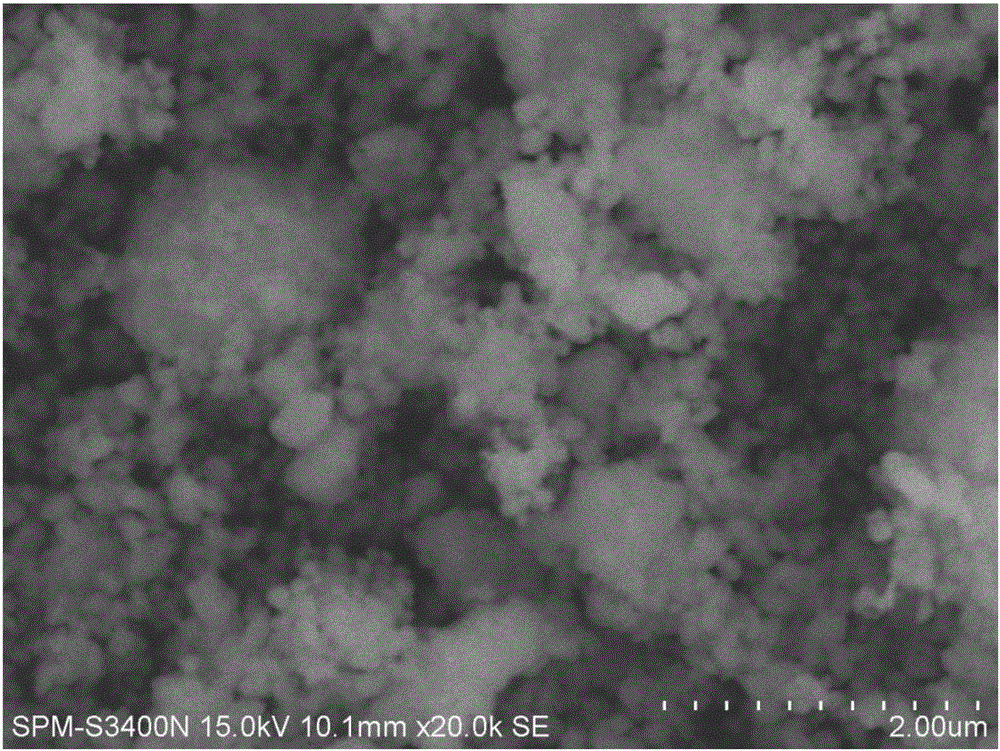

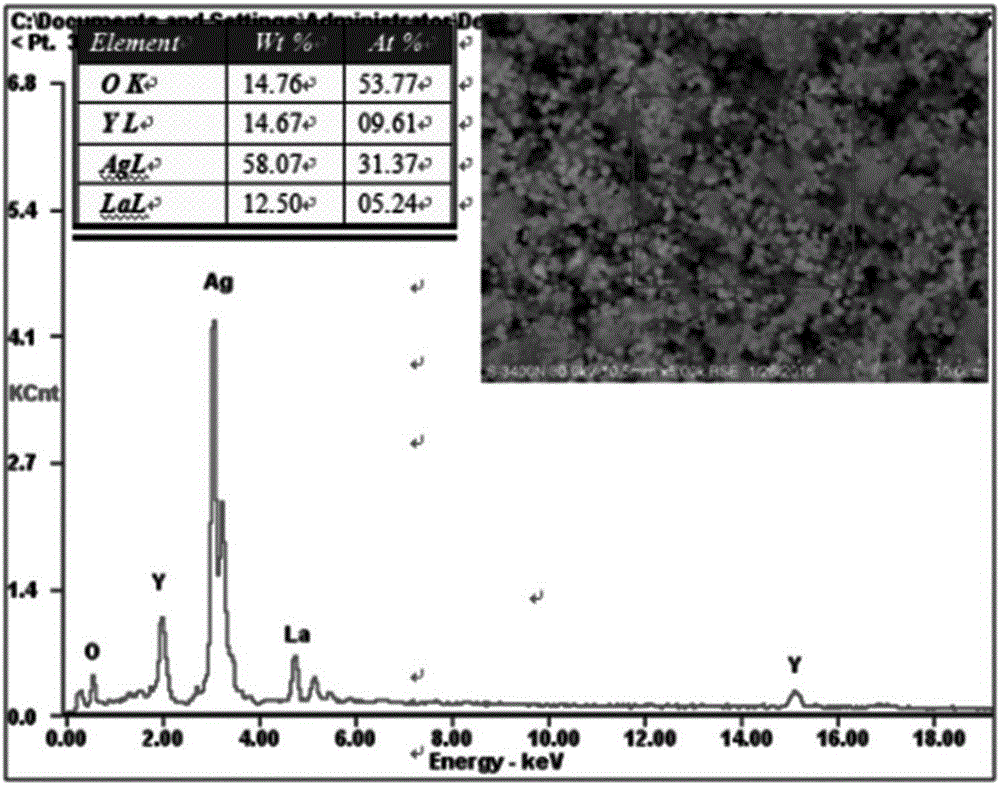

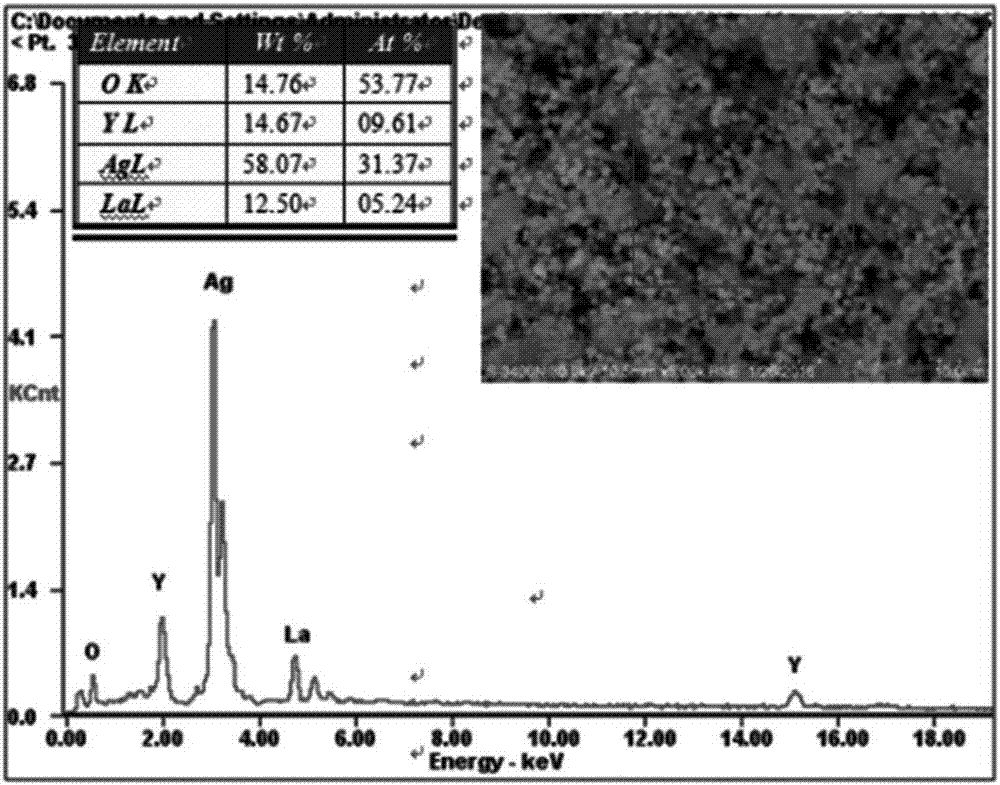

Novel silver rare earth oxide alloy and preparing method thereof

InactiveCN105695791AEase of industrial productionLow costTransportation and packagingMetal-working apparatusAlloyElectric properties

The invention discloses a novel silver rare earth oxide alloy and a preparing method thereof. According to the method, a chemical reduction method and a high-energy ball milling method are combined to prepare nano silver and rare earth oxide powder, and a powder metallurgy technology is used for preparing a novel silver rare earth oxide electric contact material; and the contact material has the higher hardness, density and specific conductance. The silver rare earth oxide electric contact material comprises, by weight percent, 3.0% to 8.0% of Y2O3, 2.0% to 8.0% of La2O3 and the balance Ag. Raw materials used in the method are easily obtained and few, and the cost is low; the technology for combining the chemical reduction method and the high-energy ball milling method to prepare the nano silver and rare earth oxide powder is simple, industrialized production is easily achieved, the method is environment-friendly, the service life of a contact is long, and the higher hardness and density are achieved; and the contact material has the excellent electric performance, meanwhile, the electric contact properties of wear resisting, corrosion resisting, electric arc burning loss resistance, fusion welding resistance and the like are achieved, and therefore the contact performance and the reliability of an electric appliance are improved.

Owner:KUNMING INST OF PRECIOUS METALS

Silver-boron nitride-cerium switch apparatus contact material and preparation method thereof

InactiveCN102031409ASimple preparation processGood arc corrosion resistanceContactsElectricityLiquid state

The invention discloses a silver-ceramic series electric contact material and a preparation method thereof. The material consists of 1 to 15 weight percent of boron nitride (BN), 0.5 weight percent of cerium (Ce) and the balance of silver (Ag). The silver-boron nitride-cerium contact material prepared by the method is second-phase boron nitride (BN) particles which are dispersed and distributed in a silver matrix to reinforce the contact material, and the addition of the cerium improves wettability of liquid-state silver on the boron nitride to prevent the second-phase particles from clustering and more compactly combine the silver with the boron nitride. Experimental results of electric life after 2 hundred thousand times of action at direct current of 12V and lamp load of 8*21W+5*5W (impact current of 33A and steady current of 16A) can show that the pitting of a contact is not serious, and the contact material is not obviously transferred and the material has the advantages of high arc erosion resistance, material transfer resistance and comprehensive performance.

Owner:HEBEI UNIV OF TECH

Silver-borazon switching apparatus contact material and preparation method thereof

InactiveCN102163505ASimple preparation processGood arc corrosion resistanceContactsElectricityMetallurgy

The invention provides a silver-borazon switching apparatus contact material and a preparation method thereof. The material consists of the following materials in percentage by weight: 1 to 15 percent of borazon and the balance of silver. The silver-borazon contact material prepared by the method is a silver-based ceramic compound contact material in which second-phase borazon (BN) particles are dispersed in a silver base body; under the condition that the direct-current is 12V and the lamp load is 8*21W+5*5W (the impact current is 33A and the stable current is 16A), after 200,000 electrical endurance tests, the contact is eroded slightly, and no obvious contact material is transferred; therefore, the silver-borazon contact material has high arc erosion resistance and material transferring resistance as well as comprehensive performance.

Owner:HEBEI UNIV OF TECH

Electric contact material and preparation method thereof

ActiveCN104741616ASolve the problem that it is difficult to achieve uniform dispersionEvenly dispersedContactsMicro nanoMetal particle

The invention discloses a preparation method of electric contact material and the electric contact material prepared by the method. The method includes the steps of firstly, respectively dissolving intermediate phase containing metal precursor and biomass derived carbon and reducing agent into alcohols solvent to obtain alcoholic solution; secondly, well mixing and allowing sufficient reaction; thirdly, centrifuging and drying to collect composite micro-nano metal powder, with biomass carbon intermediate film layers covering surfaces, obtained in the reaction of the second step; fourthly, heat processing the composite micro-nano metal powder collected in the third step under non-oxidizing atmosphere to allow the biomass carbon intermediate film layers to be converted into thin films containing diamond phase or diamond-like phase. By the method, the electric contact material with uniform metal particle size, small particle size, compactly-combined diamond phase or diamond-like phase, and good performance can be obtained.

Owner:SCHNEIDER ELECTRIC IND SAS

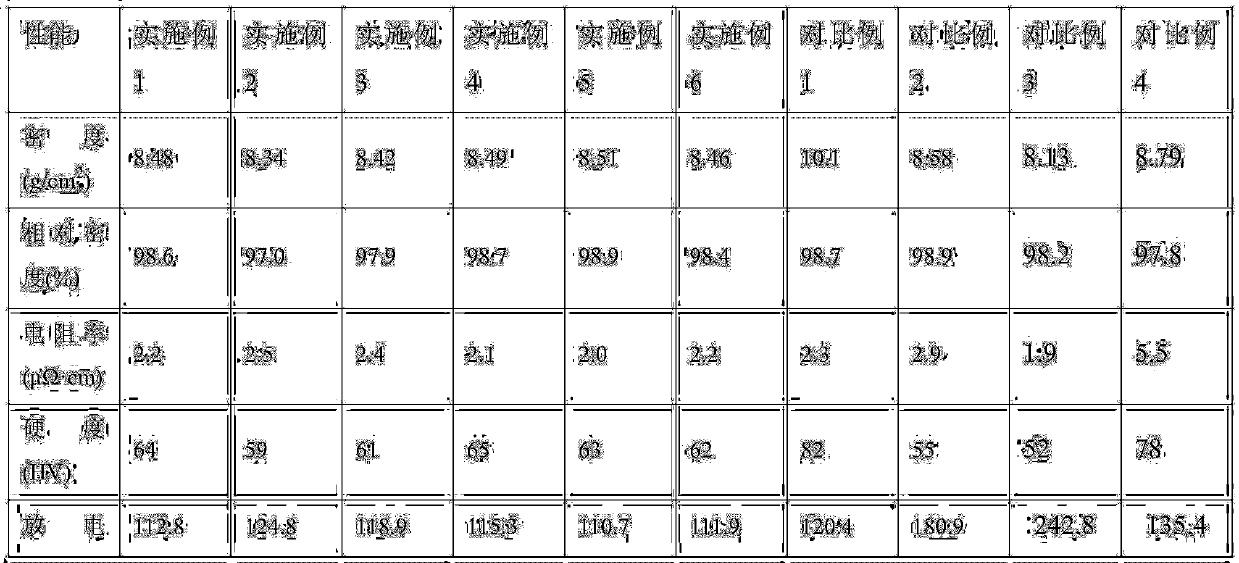

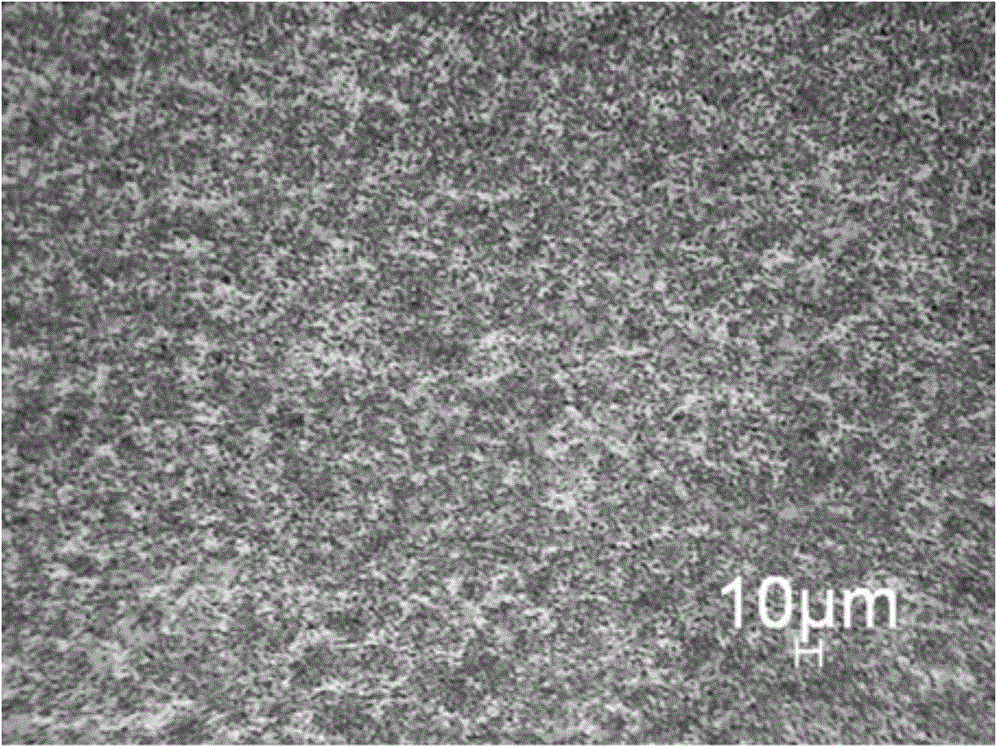

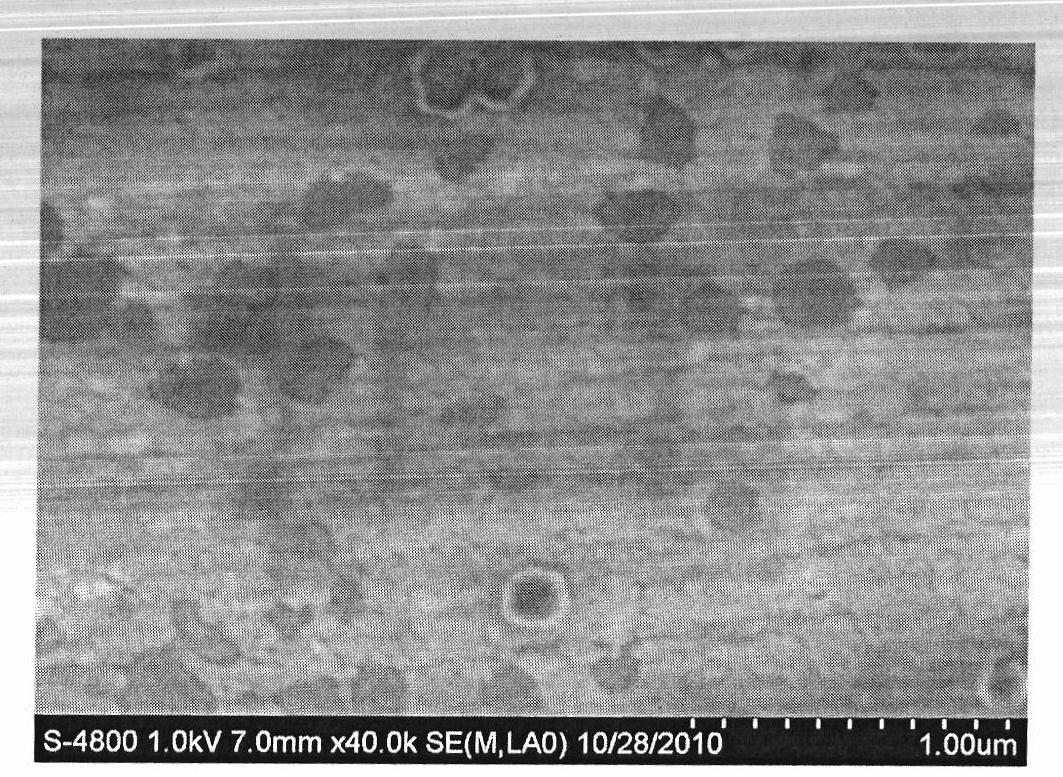

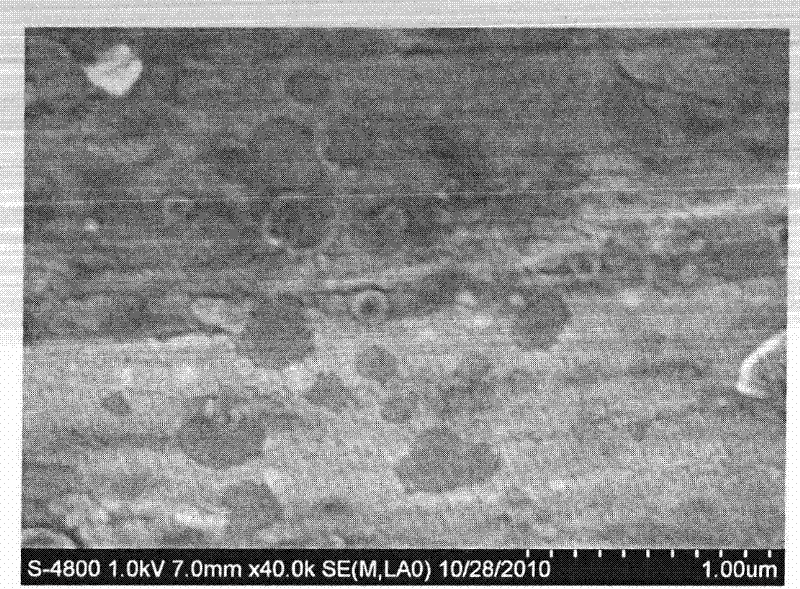

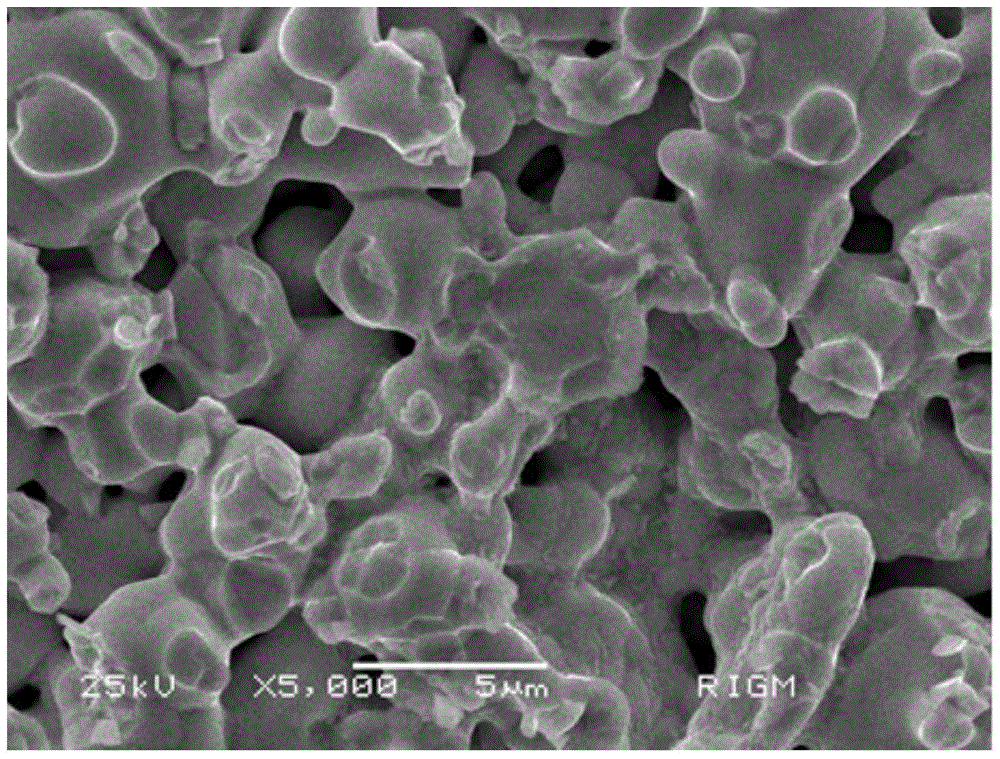

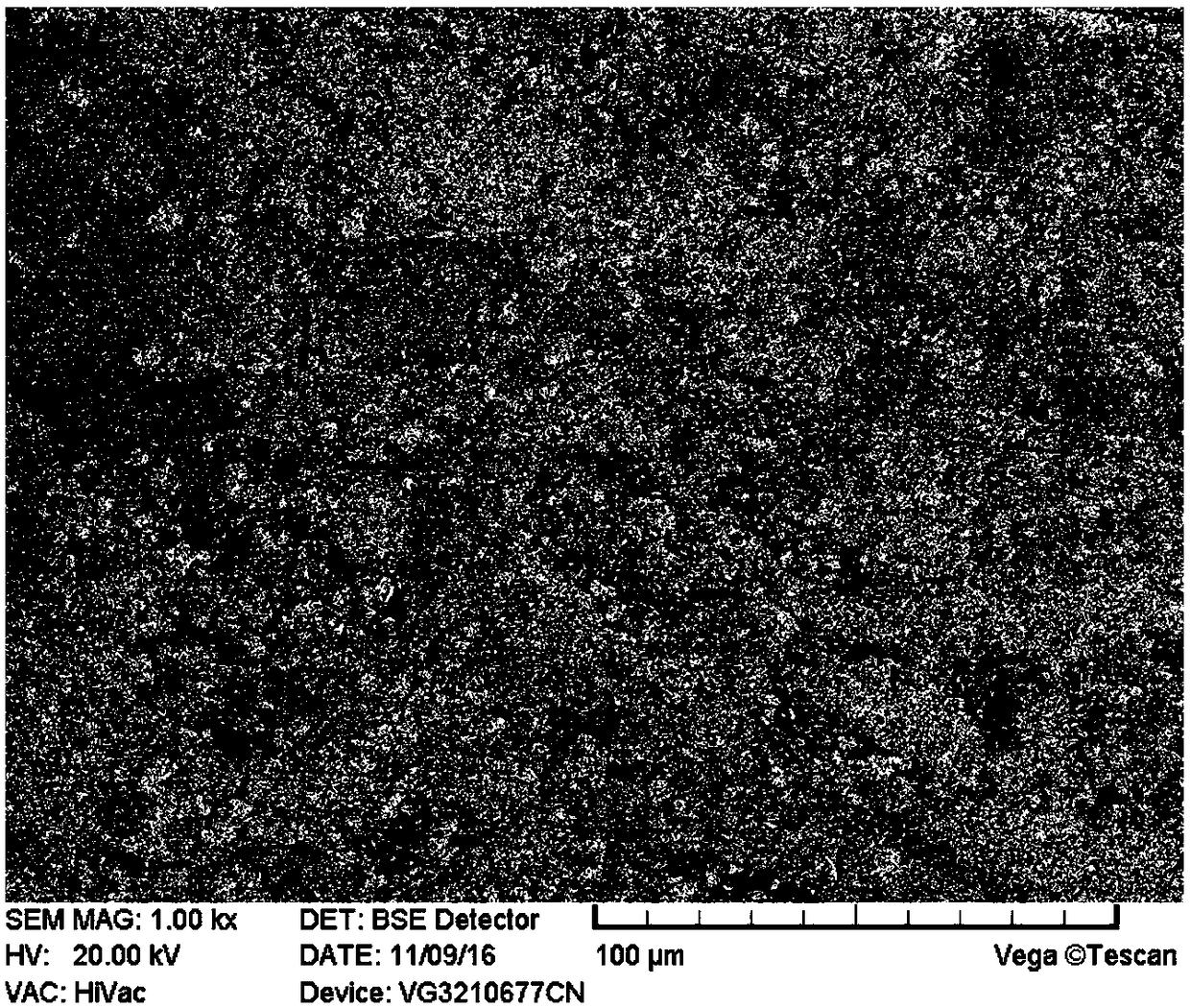

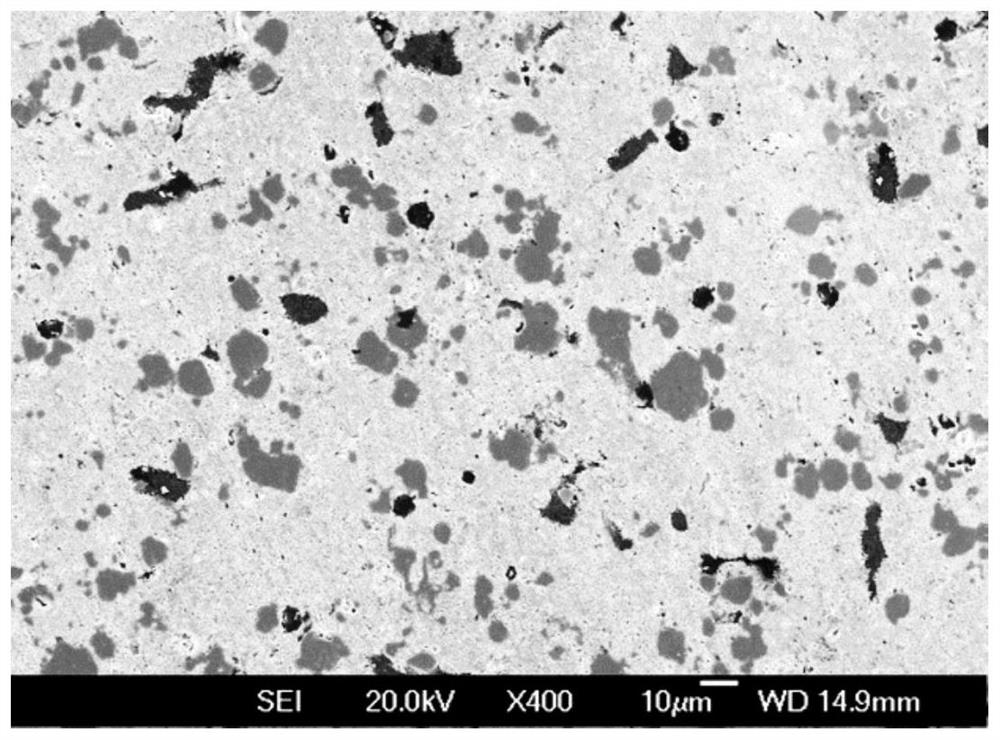

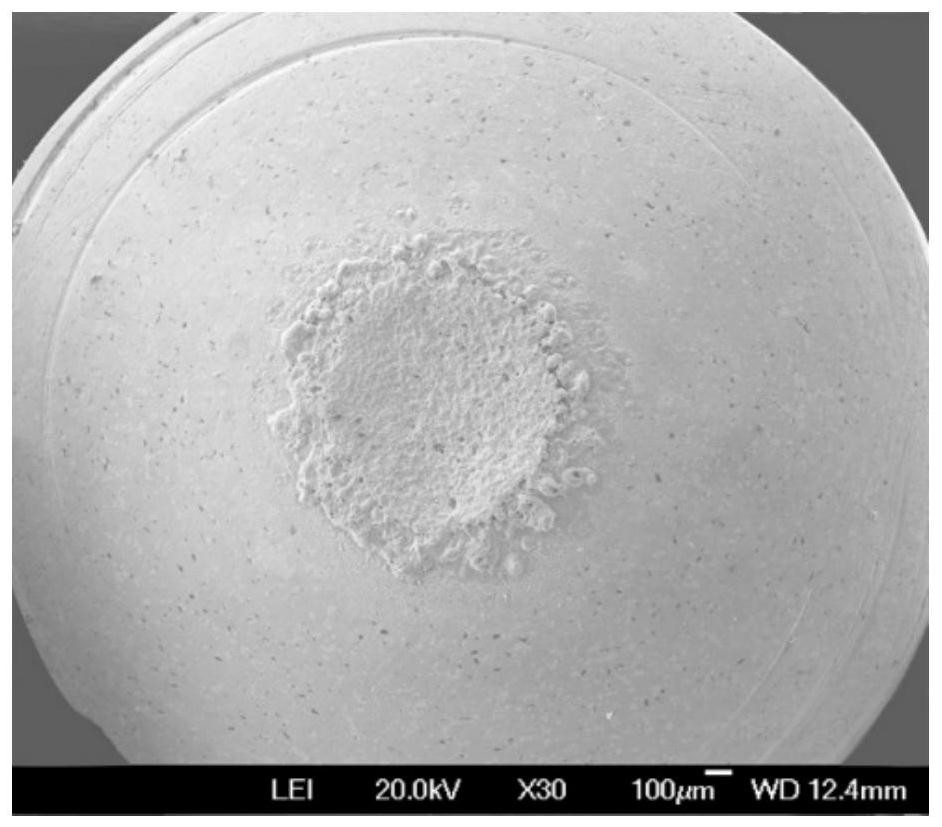

Copper-chromium contact material for vacuum circuit breaker and preparation method thereof

The invention discloses a copper-chromium contact material for a vacuum circuit breaker and a preparation method thereof. The copper-chromium contact material comprises the following components of, byweight, 20-60% of Cr and the balance Cu, and comprises the following raw materials of, by weight, 30-350 microns of chromium powder and 350 or below microns of copper powder, wherein the chromium powder is electrolytic chromium powder or aluminothermic reduction chromium powder, the copper powder is electrolytic copper powder or atomized copper powder, the purity of the chromium powder is 99.00%-99.98%, and the purity of the copper powder is 99.00%-99.98%. Compared with an existing mold pressing and sintering process, the preparation method of the copper-chromium contact material for the vacuum circuit breaker, mass stabilization production can be achieved, and large-specification copper-chromium contacts can be produced in a batched mode. According to the preparation method, the technological process is simple, the heating process is only 30-90 minutes, and time and energy are greatly saved compared with a mold pressing sintering process which is as long as 15-30 hours. The producedcontacts are compact in structure, free of air holes and other defects and good in electric arc erosion resistance.

Owner:HENAN CHANGZHENG ELECTRIC

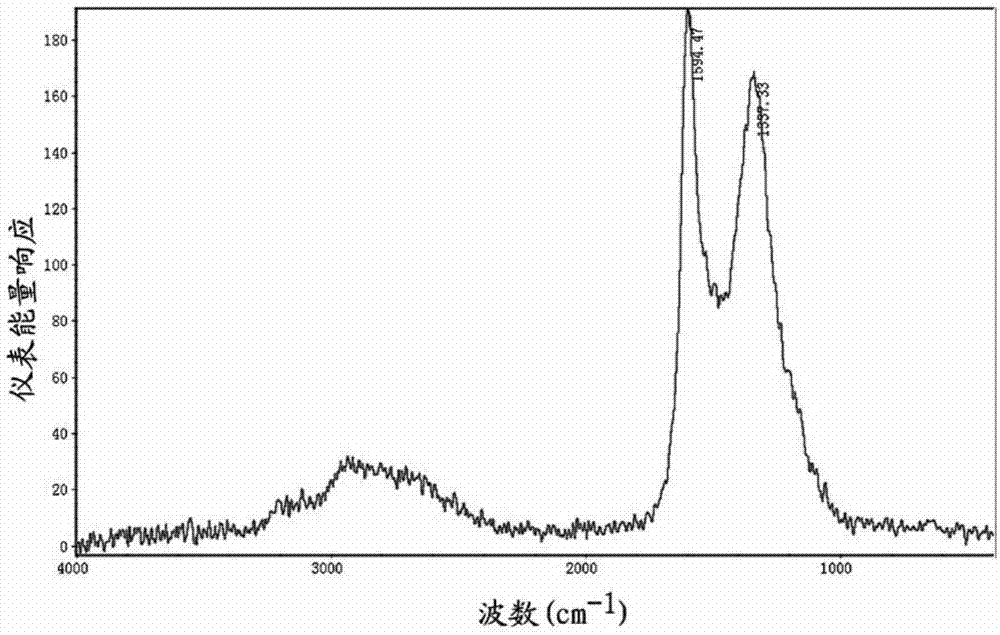

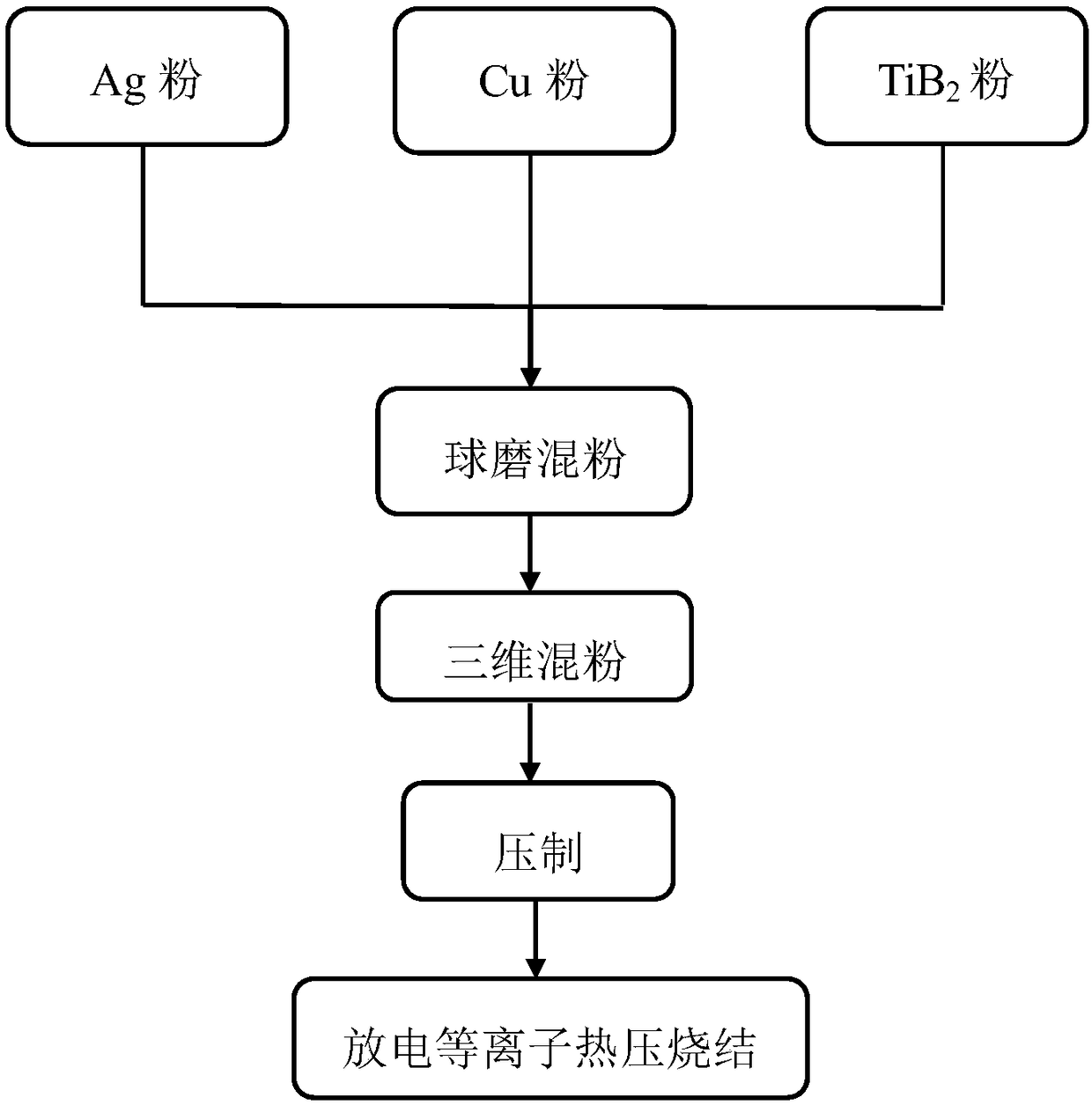

Silver based electrical contact material resistant to arc erosion and preparation method thereof

The invention discloses a silver based electrical contact material resistant to arc erosion. The material comprises following components in percentage by weight: 5 to 20% of Cu, 2 to 10% of TiB2, and70 to 93% of Ag, wherein the total percentage by weight is 100%. The invention also discloses a preparation method of the electrical contact material. The preparation method comprises following steps:weighing Ag powder, Cu powder and TiB2 powder according to a ratio, mixing the powder in advanced to obtain premixed powder; placing the premixed powder in a three dimensional powder mixing machine,mixing the premixed powder again to obtain mixed powder; filling obtained powder into a mould, pressing the powder to obtain a pressed blank; placing the pressed blank in a sintering furnace, carryingout sintering, and finally naturally cooling the blank in the furnace to the room temperature to obtain the AgCu-TiB2 electrical contact material. Through the aforementioned method, TiB2 is introduced into an Ag-Cu alloy electrical contact material, and the low cost AgCu-TiB2 electrical contact material is prepared by a powder metallurgic method and has the advantages of good thermal conductivityand electrical conductivity, excellent performance on resisting arc erosion and material transfer, and good mechanical properties.

Owner:XIAN UNIV OF TECH

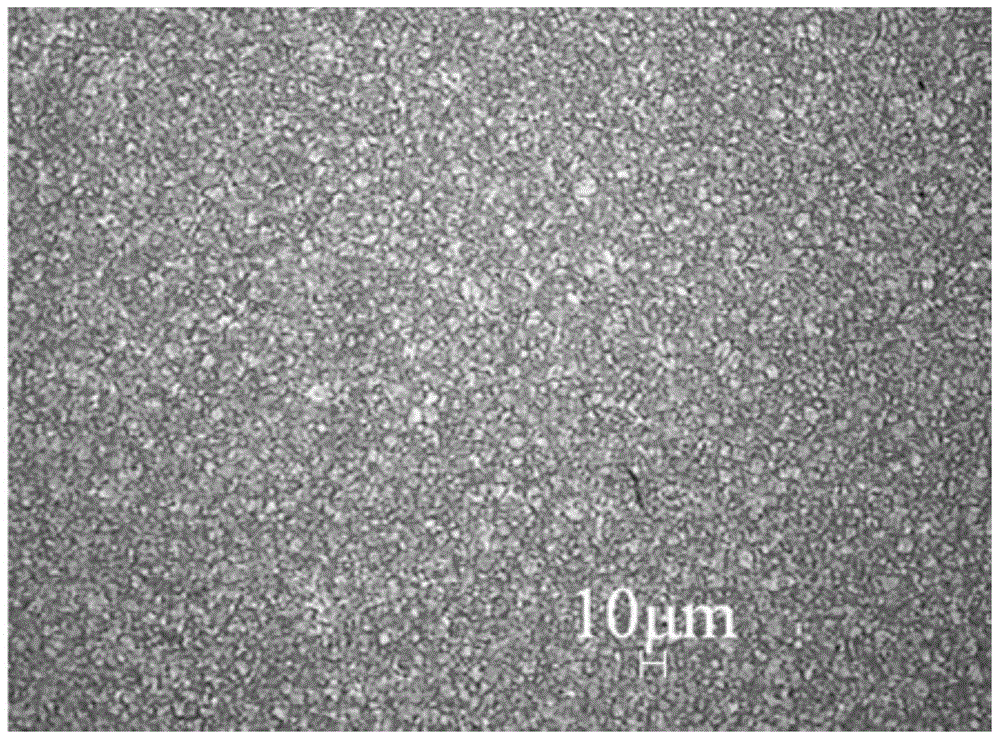

A copper-based electrical contact composite material and its preparation method

The invention discloses a copper-based electrical contact composite material and a preparation method thereof, belonging to the technical field of metal composite material preparation. The copper-based electrical contact composite material is composed of the following components in mass percentage: 10%-30% of chromium, 1%-5% of tungsten carbide, and the balance is copper. The copper-based electrical contact composite material of the invention has high density, uniform structure, high electrical conductivity and good arc erosion resistance. In the preparation method of the present invention, after mixing chromium powder, tungsten carbide powder and copper powder, a copper-chromium-tungsten carbide composite material is prepared by using a discharge plasma sintering process; Electrical conductivity and wear resistance, as well as high electrical conductivity and thermal conductivity of copper; the preparation method is controllable and environmentally friendly, the process is simple, the cost is low and the production cycle is short, and the arc erosion resistance, welding resistance, strength and conductivity are achieved. The preparation of the electrical contact composite material with high performance is suitable for popularization and application.

Owner:HENAN UNIV OF SCI & TECH

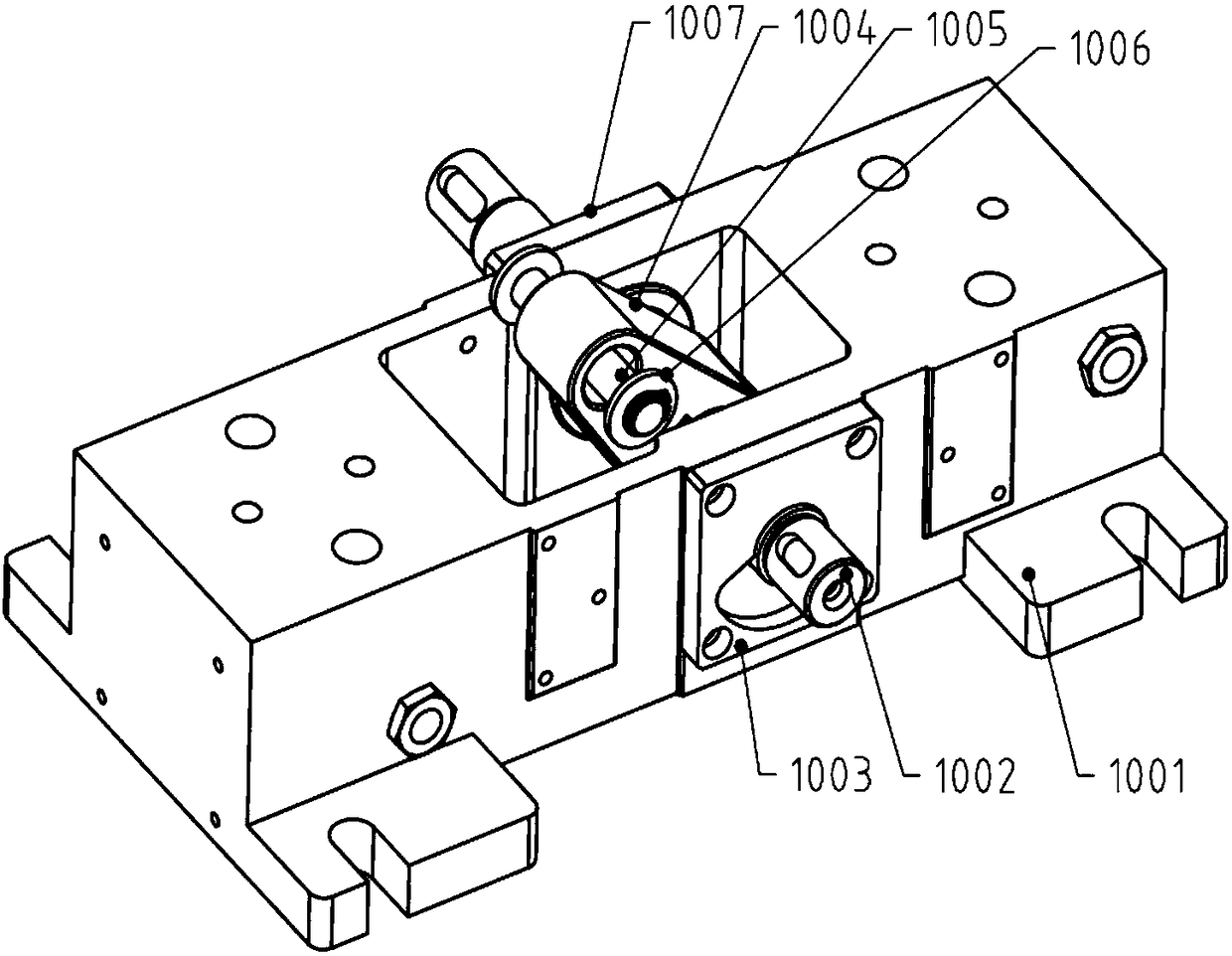

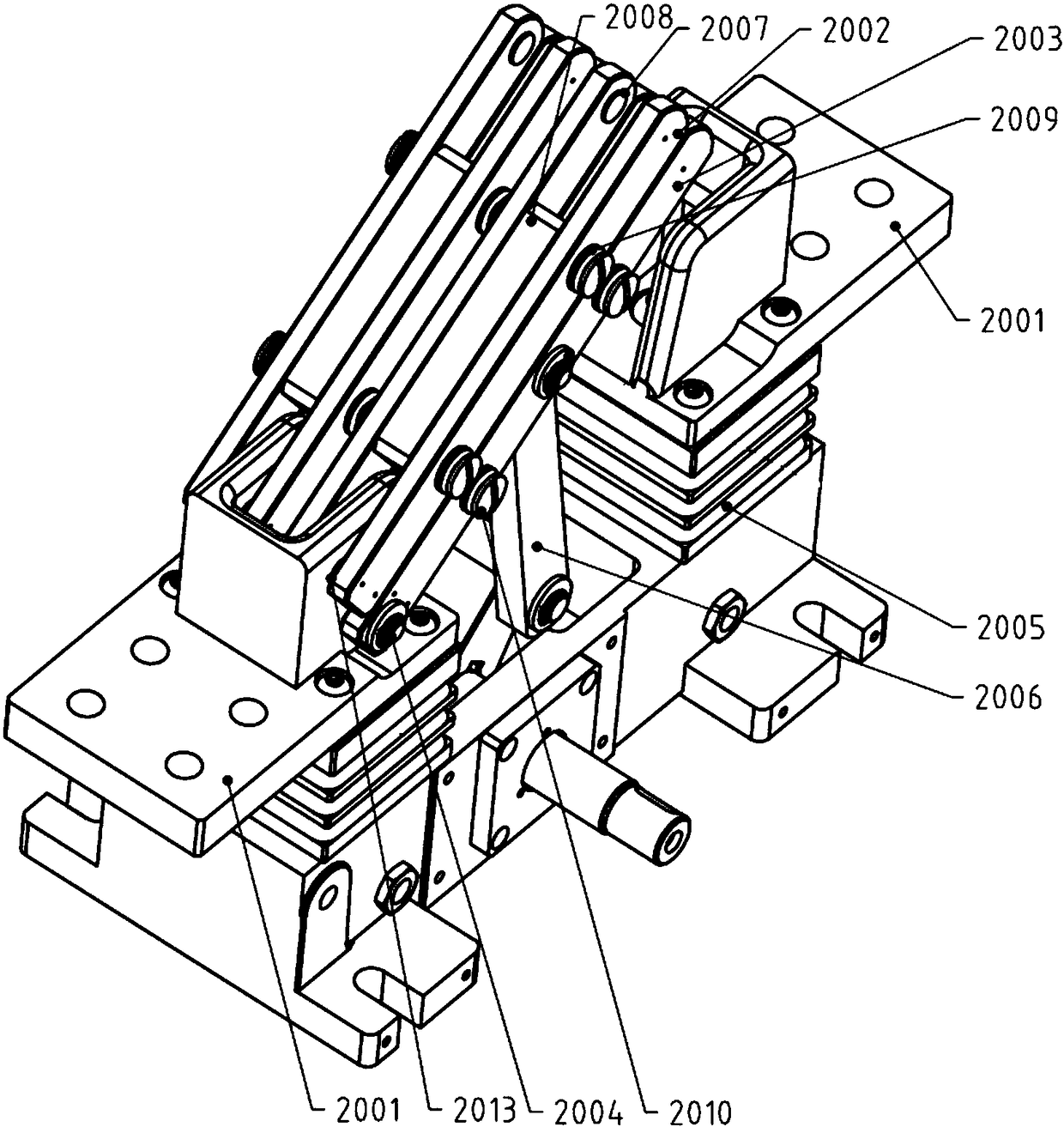

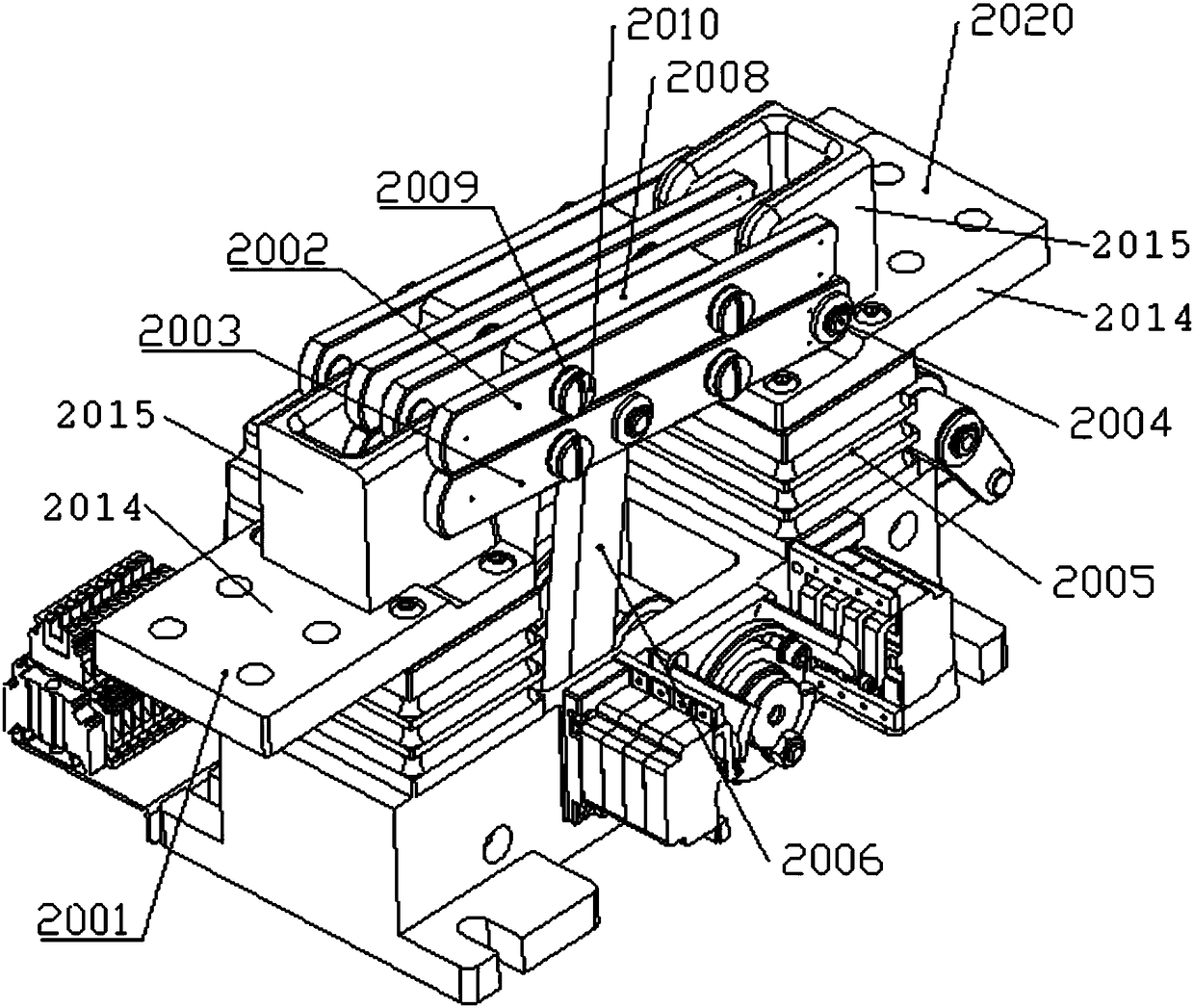

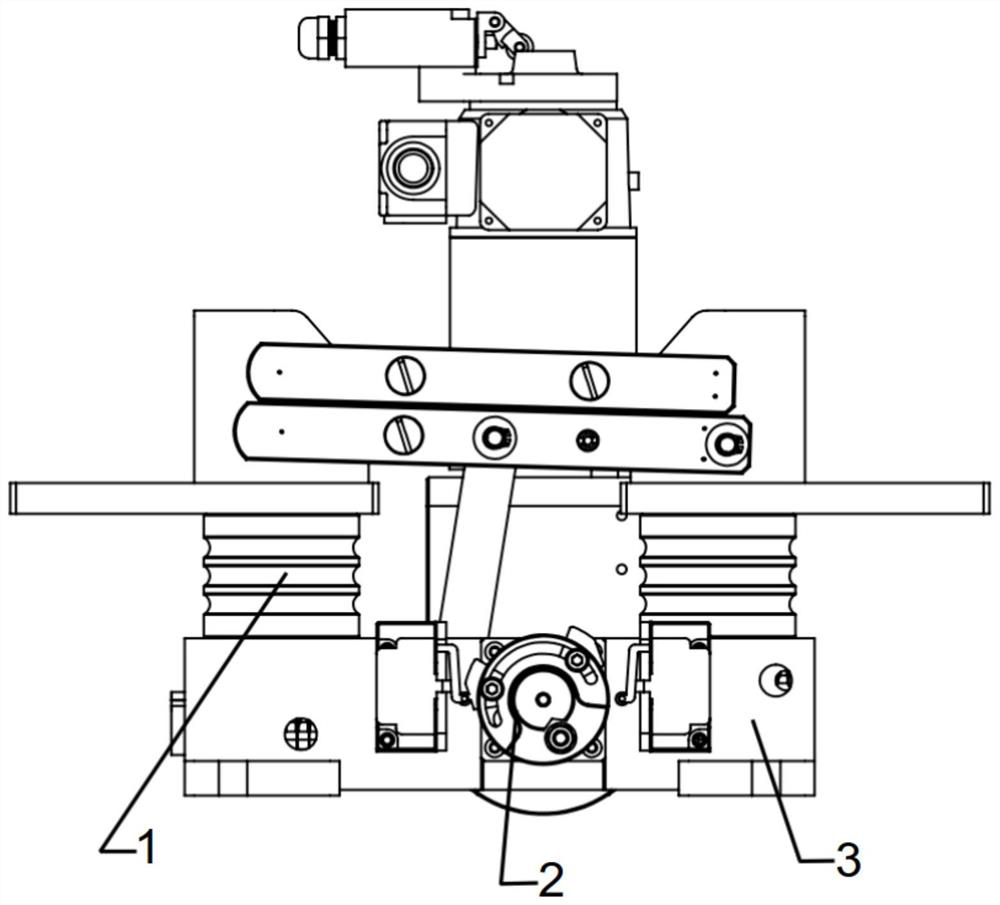

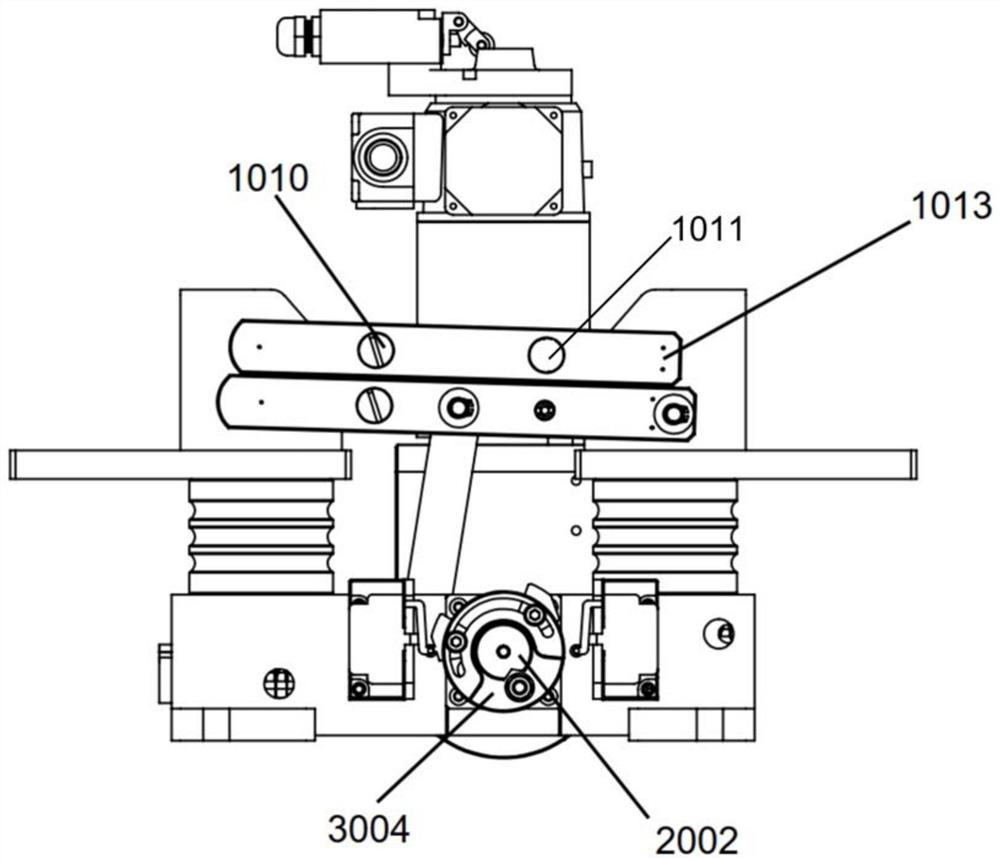

Medium-voltage AC-DC dual-purpose high-power isolation switch

PendingCN108962663AGood arc corrosion resistanceReduce contact resistanceAir-break switch detailsEngineeringTraction power supply

The invention discloses a medium-voltage AC-DC dual-purpose high-power isolation switch, which comprises a base and conductive and insulating components arranged on the base, wherein the conductive and insulating components include an insulator and a conductive component arranged on the insulator, the conductive component includes an input terminal, an output terminal and a movable knife switch assembly with one end being in articulated connection with the output terminal which are arranged on the insulator, the movable knife switch assembly includes multiple copper bars, two ends of each copper bar are respectively provided with contacts, and the contacts adopt beryllium bronze with the hardness being HRC42-44. The isolation switch has the characteristics of stable performance, low cost,long service life and the like, and can meet great demands of traction power supply systems such as metros, light rails and cloud rails in urban rail transit in China and high-power three-phase four-wire AC power grids.

Owner:金晓亮 +2

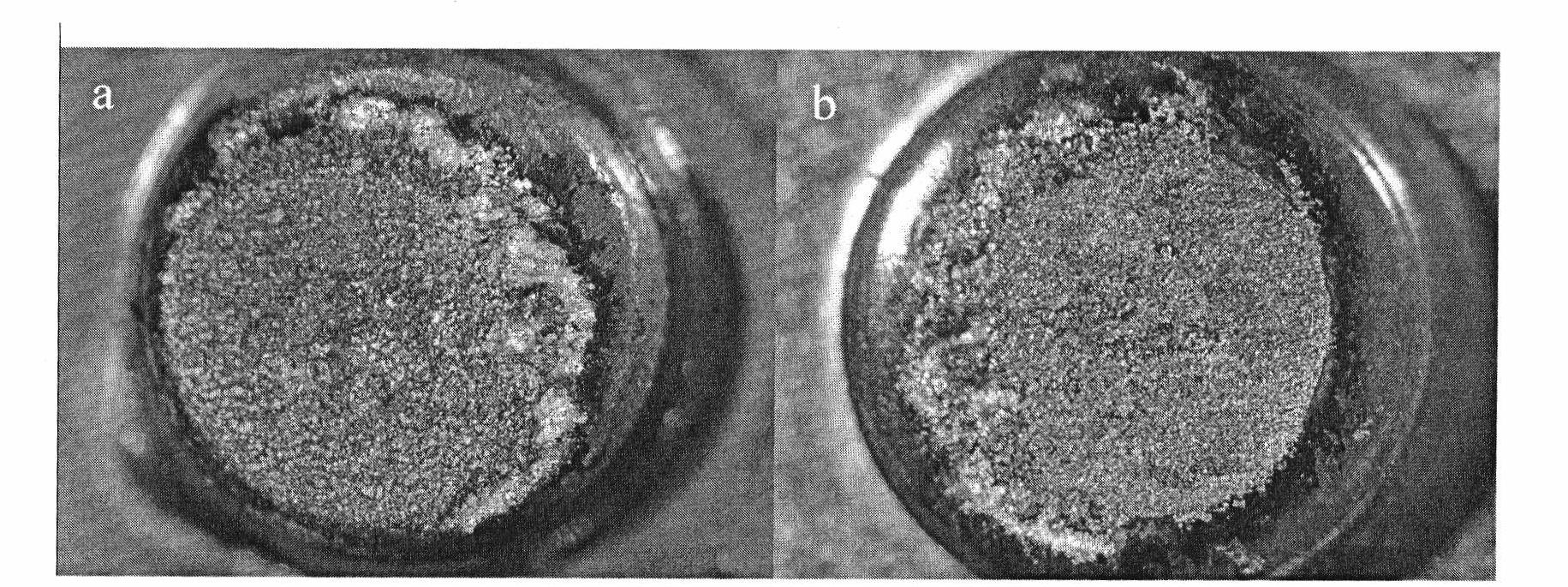

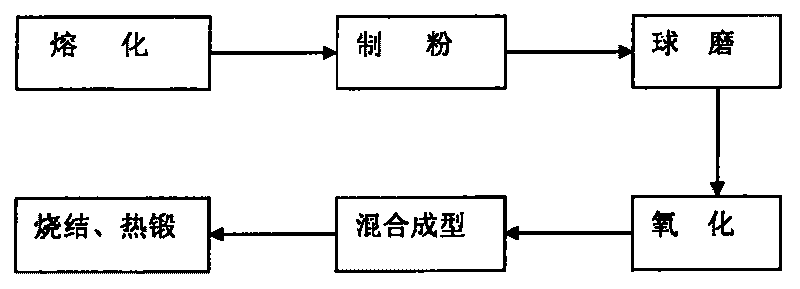

A silver-ZnO electric contact and its making method

InactiveCN101241804BGuaranteed uniformity of distributionChange the internal microstructureContactsElectrical resistance and conductanceAlloy

The present invention provides a silver-zinc oxide electrical contact and the preparing method thereof. The electric contact related by the invention is composed of silver, zinc oxide and additive. The preparing method comprises the following procedures: preparing Ag and Zn in proportion, preparing Ag-Zn alloy powder with gas atomizing after melting, oxidizing the alloy powder after abrasive processing, adding additive, and preparing the thread material or sheet material after the techniques of molding, sintering and hot processing. The silver-zinc oxide prepared with the invention has the advantages of sufficient zinc oxidizing, high oxidation efficiency, dispersed arrangement of zinc oxide at the inner part of the power particle, uniform formation, excellent combination property, excellent fusion welding resistance, excellent electrical arc corrosion resistance, low and stable contact resistance, easy soldering, and no danger to the human body and environment. The invention is suitable for industrial production and can replace the poisonous silver-cadmium oxide contact.

Owner:CENT SOUTH UNIV

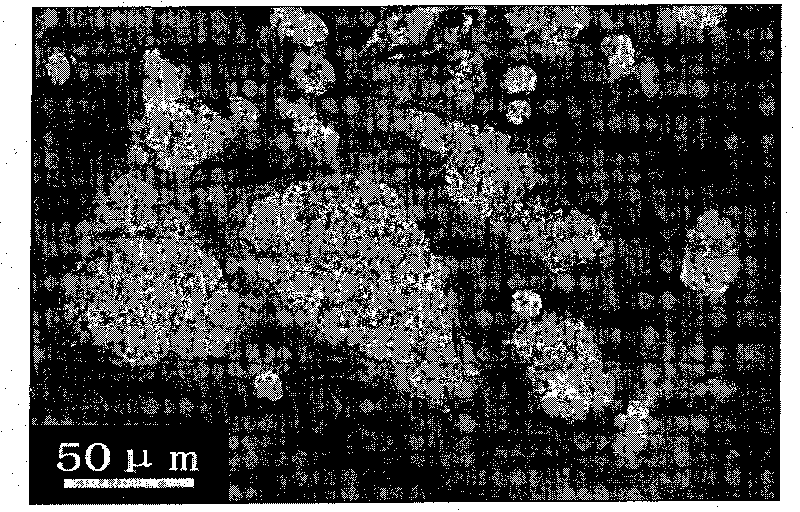

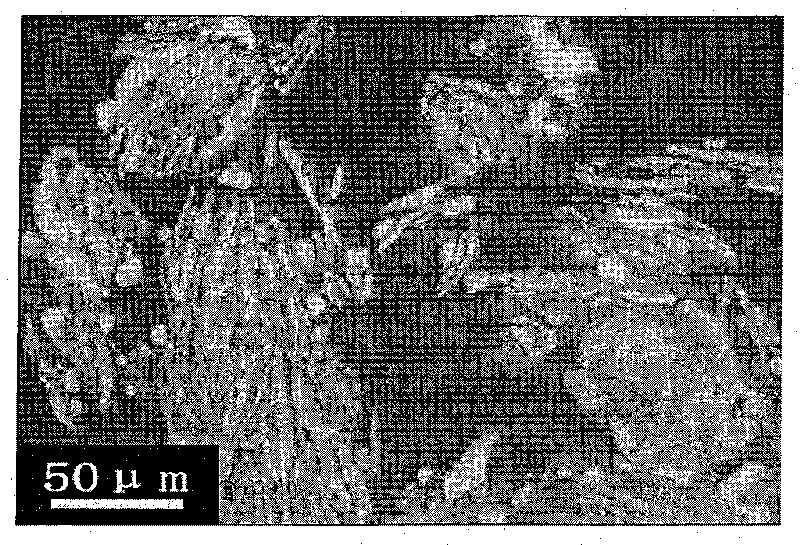

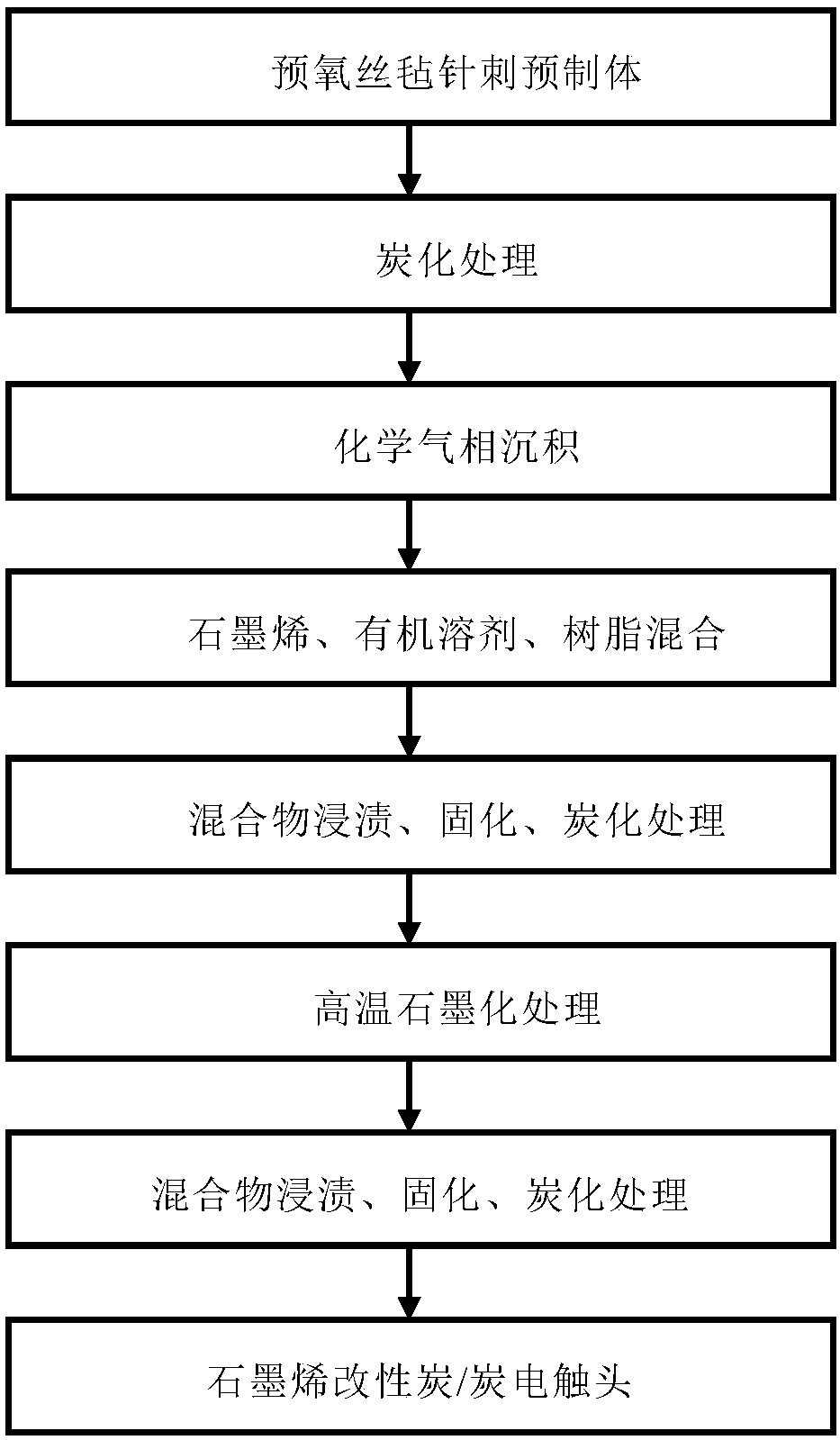

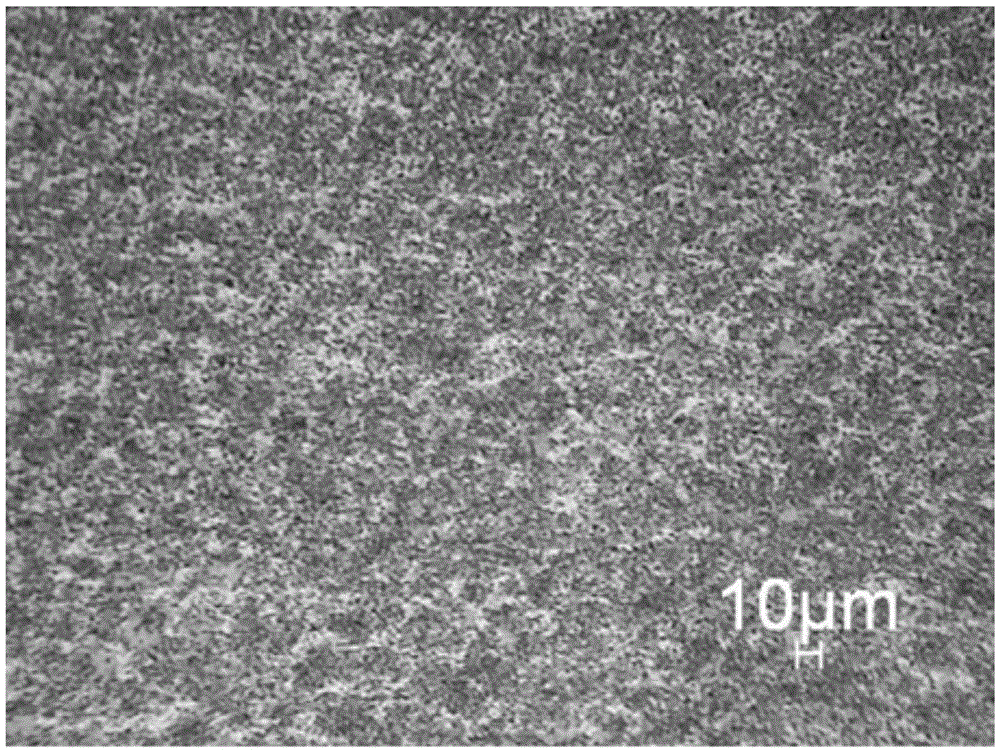

Preparation method for graphene modified carbon/carbon electrical contact

ActiveCN108484196AGood mechanical propertiesHigh mechanical strengthContact materialsCvd grapheneCarbon composites

The invention relates to an electrical contact material and a preparation method thereof, and a graphene modified carbon / carbon electrical contact and a preparation method thereof. According to the invention, by utilization of the characteristics of high strength, high electrical conductivity and high thermal conductivity of graphene, the graphene is adopted for functional modification of a carbon / carbon composite material; the graphene and resin are mixed and diluted through an organic solvent, and pressurized to be immersed into a porous chemical-vapor-deposition treated carbon / carbon composite green body; and the processes of curing, carbonization and graphitization are adopted to prepare a graphene-modified carbon / carbon composite electrical contact which has the advantages of excellent mechanical properties, high mechanical strength, low electrical resistivity, good wear resistance, good arc-erosion resistance, etc.

Owner:内蒙古栢特新材料科技有限公司

A kind of silver tungsten carbide nickel contact material and its preparation method

Owner:桂林金格电工电子材料科技有限公司

A kind of preparation method of copper tungsten contact material

ActiveCN104362015BImprove activation sintering effectImproved arc erosion resistanceElectric switchesEmergency protective device manufactureUltimate tensile strengthBall mill

The invention discloses a preparation method of a copper-tungsten contact material. The method comprises the steps of performing ball grinding on tungsten powder, high-purity nickel balls and water in a ball grinding machine, and performing drying, annealing, forming, pre-sintering and infiltration treatment on the tungsten powder subjected to ball grinding, wherein the weight ratio of the high-purity nickel balls to the tungsten powder is (4-10) to 1; the use amount of the water is calculated according to a fact that every 1kg of tungsten powder is added to 120-150ml of water; and the ball grinding is executed for 12-48 hours. By the adoption of the special ball grinding technology, adding of nickel and ball grinding are simultaneously executed; furthermore, the added nickel can uniformly cover the surface of the tungsten particles, so that the activated sintering effect of a tungsten framework is effectively enhanced, and a tungsten framework with high performance can be obtained; the copper-tungsten contact material prepared by performing infiltration treatment on the tungsten framework and a copper sheet has a tissue structure that the tungsten particles are uniformly distributed on a copper base body, so that the prepared contact material is perfect in arc erosion resistance and high in high-temperature mechanical strength.

Owner:桂林金格电工电子材料科技有限公司

Multi-ingredient oxide enhanced silver-based electric contact material and preparation method thereof

InactiveCN108220650AOxide particles are fineDispersionContactsChemical IngredientsVacuum induction melting

The invention discloses a multi-ingredient oxide enhanced silver-based electric contact material and a preparation method thereof. The material is prepared from the following chemical ingredients in percentage by mass: 6 to 10 percent of Sn, 2 to 6 percent of In,0 to 5 percent of La, 0 to 5 percent of Bi, 0 to 3 percent of Zn, 0 to 3 percent of Sm, 0 to 3 percent of Hf and the balance of Ag. The method comprises the following process steps of proportionally weighing metal with the ingredient proportion; putting the metal into a zirconium oxide crucible; performing vacuum sensing melting and casting to obtain an alloy ingot blank; performing turning processing on the alloy ingot blank to obtain a rod blank; putting the rod blank into a special inner oxidization furnace for pressurization inner oxidization to obtain the multi-ingredient oxide enhanced silver-based electric contact material; performing heat extrusion, room temperature pulling processing to obtain the multi-ingredient oxide enhanced silver-based electric contact material. The multi-ingredient oxide enhanced silver-based electric contact material prepared by using the method has the advantages that the pulling resistantintensity reaches 280 to 340 MPa; the electric life reaches 150 thousand times under the test conditions of AC / 220V / 15A.

Owner:KUNMING INST OF PRECIOUS METALS

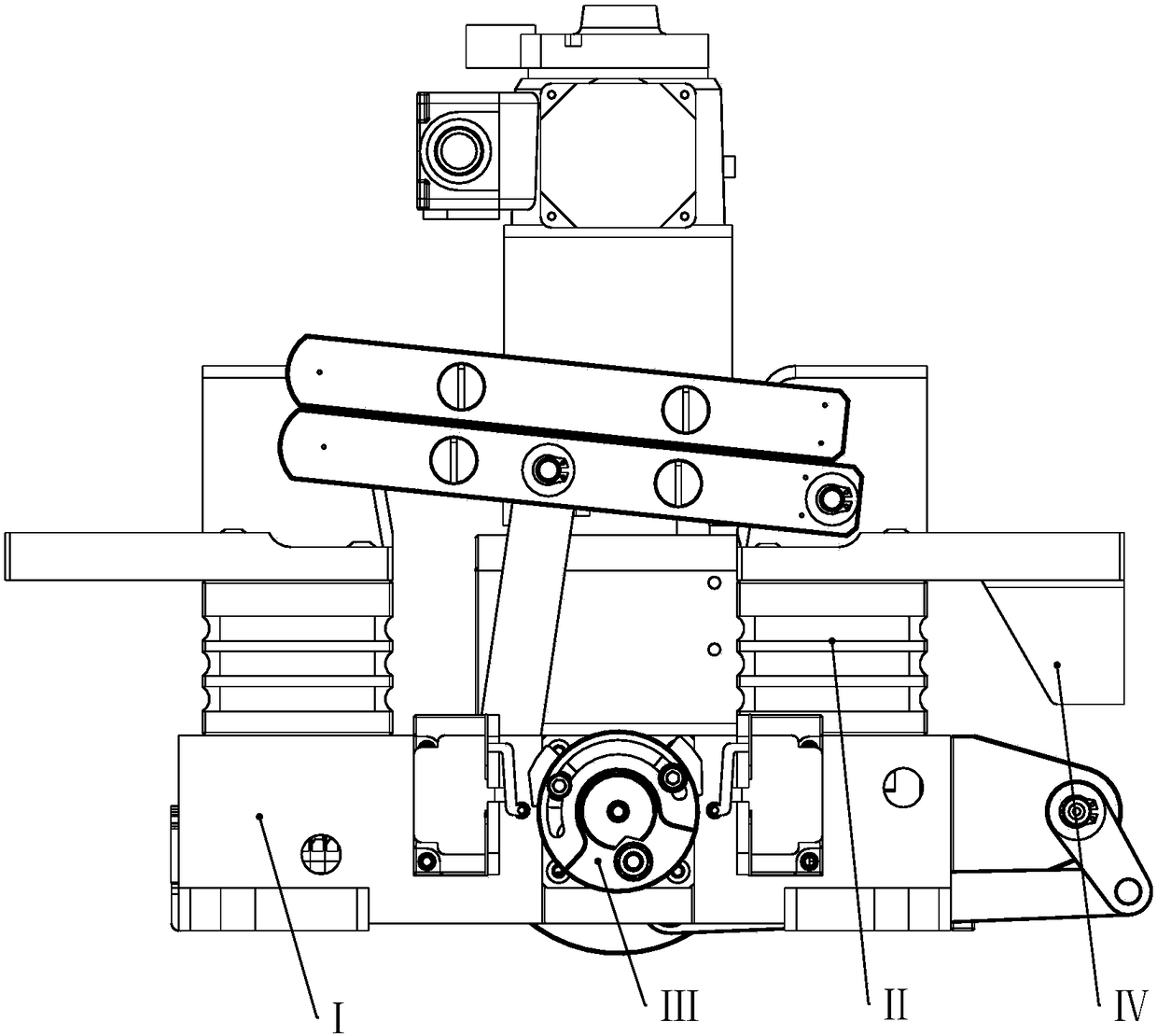

Intermediate-voltage AC-DC high-power isolating switch with grounding function

PendingCN108933058AGuarantee the safety of lifeAchieve groundingContact driving mechanismsSwitch power arrangementsVoltage

The invention discloses an intermediate-voltage AC-DC high-power isolating switch with a grounding function. The isolating switch comprises a base, transmission components, conductive components, insulating components, driving and control components and a grounding switch component. The grounding switch components comprises the components of a static contact which is arranged on an output terminal, a moving contact which can move relative to the static contact, and a static driving mechanism for driving the moving contact to move. The moving contact can realize on-and-off with the static contact in a motion process. The transmission components drive a contact driving mechanism to act in an action process. Furthermore when a moving knife switch is on with a wire inlet terminal, the moving contact is separated from the static contact. When the moving knife switch assembly is separated from the wire inlet terminal, the moving contact is on with the static contact. The insulating switch performs on-off controlling on the moving knife switch assembly and furthermore can realize on-off operation on the grounding switch component, thereby realizing switching-on of the grounding switch when the moving knife switch of the isolating switch is switched off, realizing a grounding function, and ensuring life safety of maintenance personnel in a locomotive.

Owner:金晓亮 +2

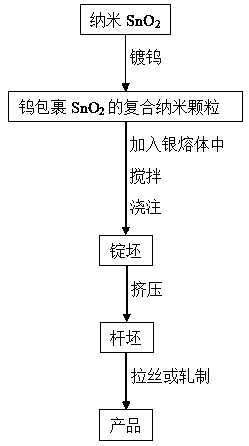

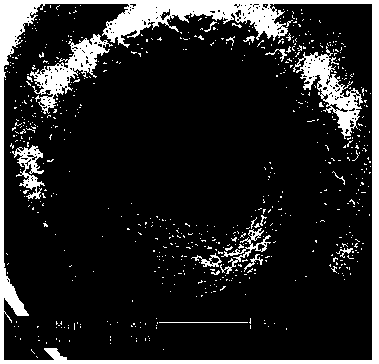

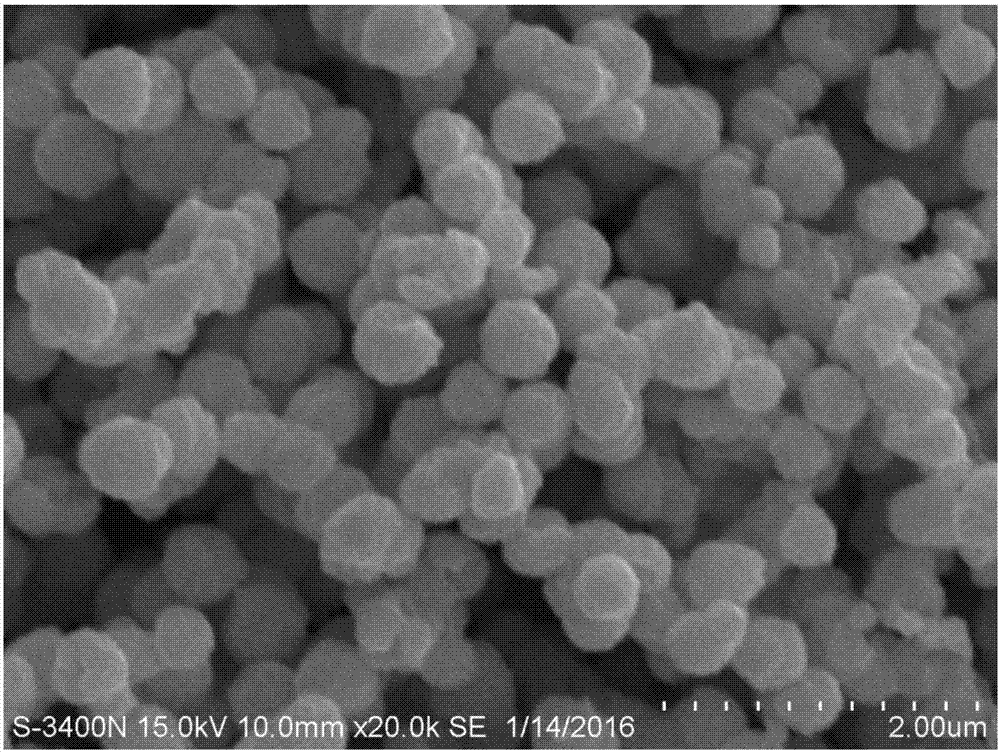

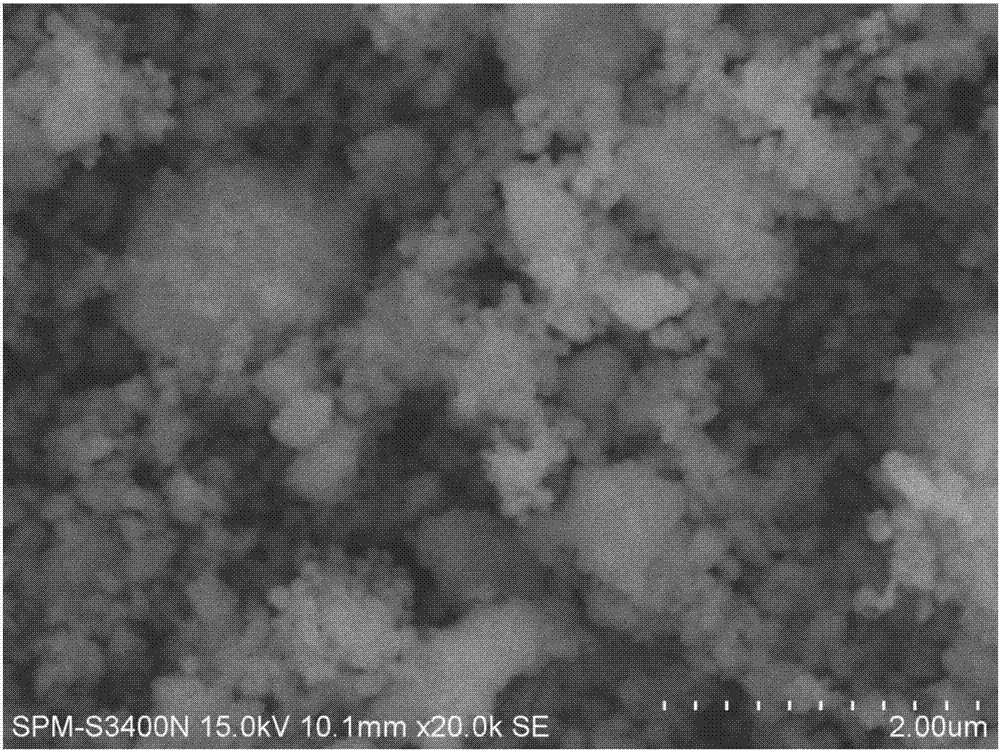

Preparation method of composite nanoparticle-reinforced silver-based electrical contact material

InactiveCN108565156AIncrease green densityImprove conductivityElectric switchesComposite nanoparticlesViscosity

The invention discloses a preparation method of a composite nanoparticle-reinforced silver-based electrical contact material. The method comprises the following steps: firstly, plating tungsten on a surface of spherical nano-SnO2; then putting the obtained tungsten-coated SnO2 composite nanoparticles into a silver melt; and preparing the material by stirring, pouring, extruding, drawing or rollingprocess. The invention has the advantages that density of the material is greatly increased and the composite nanoparticles can be uniformly distributed on a silver base; compared with a traditionalsilver metal oxide electrical contact material, the composite nanoparticle-reinforced silver-based electrical contact material prepared in the invention has low resistivity, high viscosity of a moltenpool during electrical contact, and good arc erosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

A kind of shell-core structure mxene@max composite contact reinforcement phase material and preparation method thereof

ActiveCN110699568BImprove conductivityEasy to processElectric switchesElectrical resistance and conductanceContact resistance

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A preparation method of silver tin oxide electrical contact alloy with uniform structure

Owner:XI'AN POLYTECHNIC UNIVERSITY

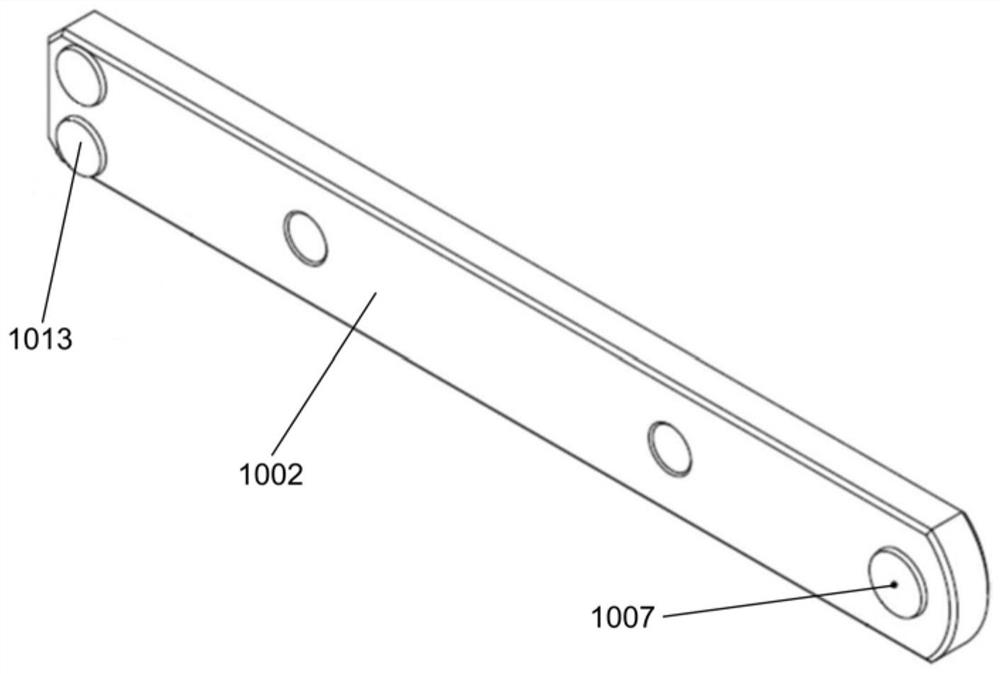

Conductive structure of isolation switch of direct-current cabinet of tracked (trackless) street car carriage

PendingCN111816489AFully contactedGuaranteed conductivityAir-break switch detailsContact electric connectionAlloyRail transit

The invention discloses a conductive structure of an isolation switch of a direct-current cabinet of a tracked (trackless) street car carriage. The conductive structure comprises a conductive and insulating part, a machine base and transmission part and a driving and control part. The conductive structure is a conductive part on insulators arranged at two ends of the base, the conductive part is composed of a bipolar double-phase incoming line, an output terminal and two groups of movable knife switches of eight copper bars connected with the output terminal, an alloy copper contact is arranged at the copper bar end, and the hardness of the contact is HRC 43-46 after the contact is subjected to heat treatment by a special process. And the movable knife switch and a copper terminal are pressed by a belleville spring. A nylon insulating cap is creatively mounted on a large-head screw outside the disc spring of the movable knife switch, so that 6000 A current can be insulated to the maximum extent. The switch with the conductive structure is stable in performance, safe and durable, can be used for a direct current cabinet of a tracked (trackless) street car, and can also meet the widerequirements of three-phase four-wire system alternating current power grids of traction power supply systems of subways, light rails, intercity and the like in urban rail transit.

Owner:金晓亮 +1

A kind of max@mom/aon electrical contact reinforcement phase material, composite electrical contact material and preparation method

The invention discloses a MAX@MO m / AO n Electrical contact reinforcement phase material, composite electrical contact material and preparation method, which are MAX@MO with core-shell structure m / AO n , the inner core is the three-dimensional material MAX phase, and the outer shell is the oxide particle MO corresponding to the inner core MAX phase material m , AO n or complex oxide layer MO m / AO n ; MAX@MO prepared by the present invention m / AO n Ag / MAX@MO prepared as reinforcement phase m / AO n The composite electrical contact material has excellent electrical conductivity, moderate hardness and good workability. It can be processed into various electrical contact shapes according to actual application requirements. It has excellent arc erosion resistance and significant silver saving effect. The reinforced phase in the Ag matrix is MAX. @MO m / AO n The content accounts for up to 40wt% of the composite material; the preparation process is simple, the practicability is good, it is suitable for mass production, and is suitable for low-voltage switchgear such as contactors, circuit breakers, relays, etc., bringing social and economic value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of novel silver rare earth oxide alloy and preparation method thereof

InactiveCN105695791BEase of industrial productionLow costTransportation and packagingMetal-working apparatusHigh energyRare earth

The invention discloses a novel silver rare earth oxide alloy and a preparation method thereof. The method adopts a combination of chemical reduction method and high-energy ball milling method to prepare nano silver and rare earth oxide powder, and uses powder metallurgy technology to prepare a novel silver rare earth oxide electrical contact material with high hardness, density and electrical conductivity. The weight percent chemical composition of the silver rare earth oxide electrical contact material is: 3.0-8.0% Y2O3, 2.0-8.0% La2O3, and the balance is Ag. The raw materials used in the invention are easy to obtain, few raw materials and low cost; the preparation of nano silver and rare earth oxide powder by the combination of chemical reduction method and high-energy ball milling method is simple, easy to industrialize production, green and environmental protection, prolongs the service life of the contact, and has the advantages of High hardness and density, and the contact material has excellent electrical properties, as well as electrical contact properties such as wear resistance, corrosion resistance, arc burn resistance and anti-welding resistance, thereby improving the contact performance and reliability of electrical appliances.

Owner:KUNMING INST OF PRECIOUS METALS

Silver-nickel electric contact producing technology

ActiveCN100452259CImprove arc extinguishing effectGood arc corrosion resistanceContactsManufacturing technologyManufactured material

Owner:哈尔滨东大高新材料股份有限公司

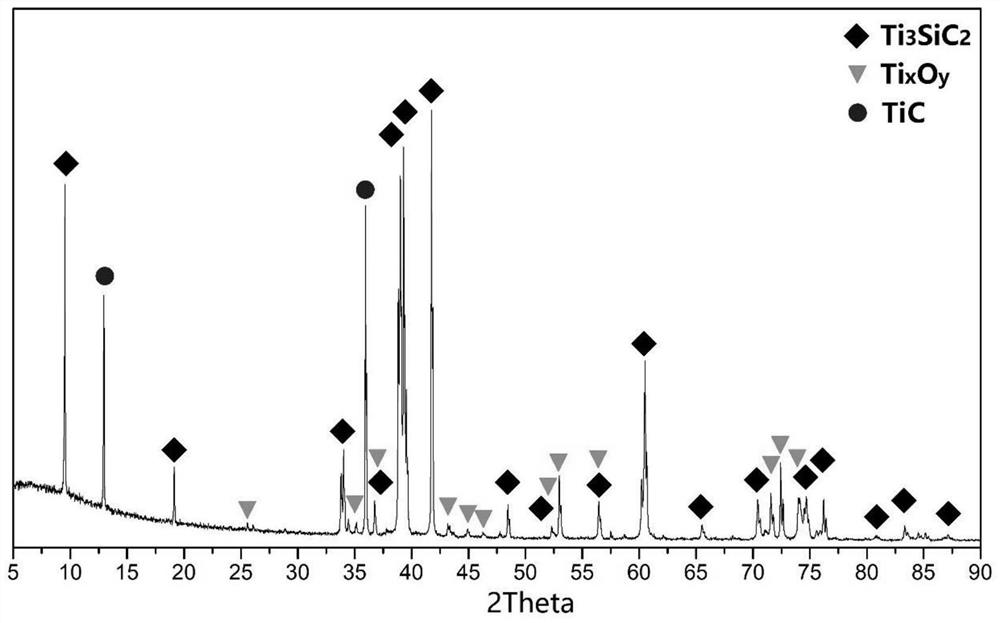

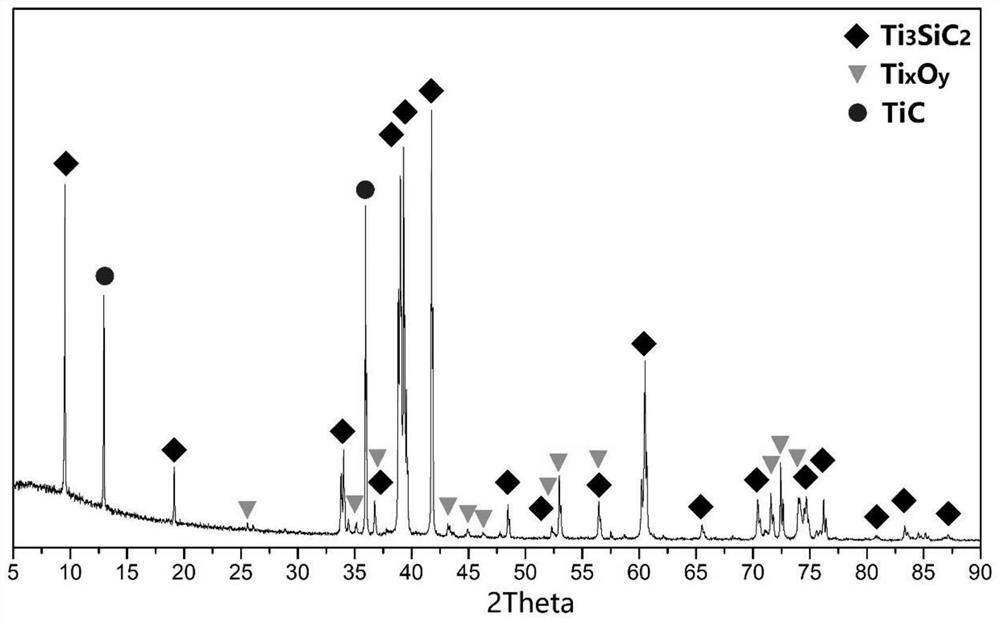

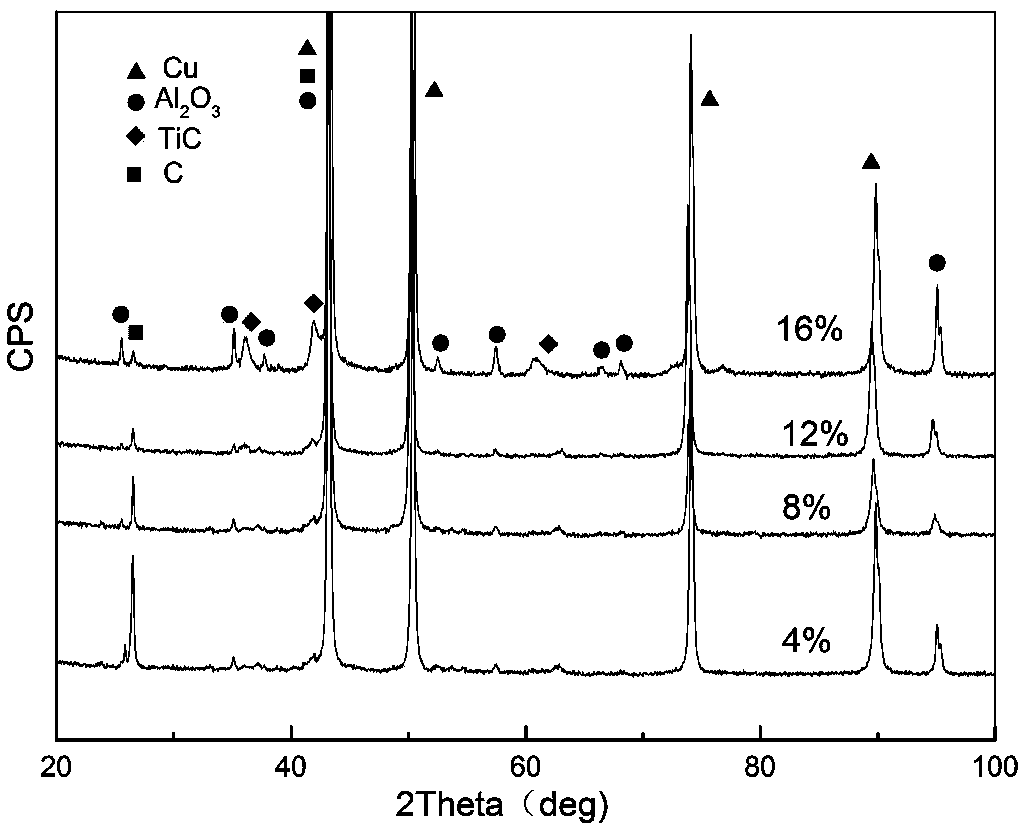

A kind of al2o3-tic copper-based composite material and preparation method thereof

The invention discloses a Al2O3-TiC copper-based composite which is prepared by Cu powder, Al powder, TiO2 powder and C powder through an in-situ preparation method, wherein a ratio of a weight percent of the Al powder to a weight percent of the TiO2 powder to a weight percent of the C powder is equal to (8-10):(18-22):(2-5), and a sum of the weight percent of the Al powder, the weight percent of the TiO2 powder and the weight percent of the C powder is 1-10%. The prepared Al2O3-TiC copper-based composite comprises three phases, namely, Cu, Al2O3 and TiC and the particle sizes of Al2O3 and TiC reinforcement body particles are less than 100 nanometers. The Al2O3-TiC copper-based composite has the advantages of high strength, high hardness, good arcing erosion resistance, high wear resistance and high conductivity, and can meet the industrial development requirements at the present stage. The invention further discloses a preparation method of the Al2O3-TiC copper-based composite.

Owner:JIANGXI UNIV OF SCI & TECH +1

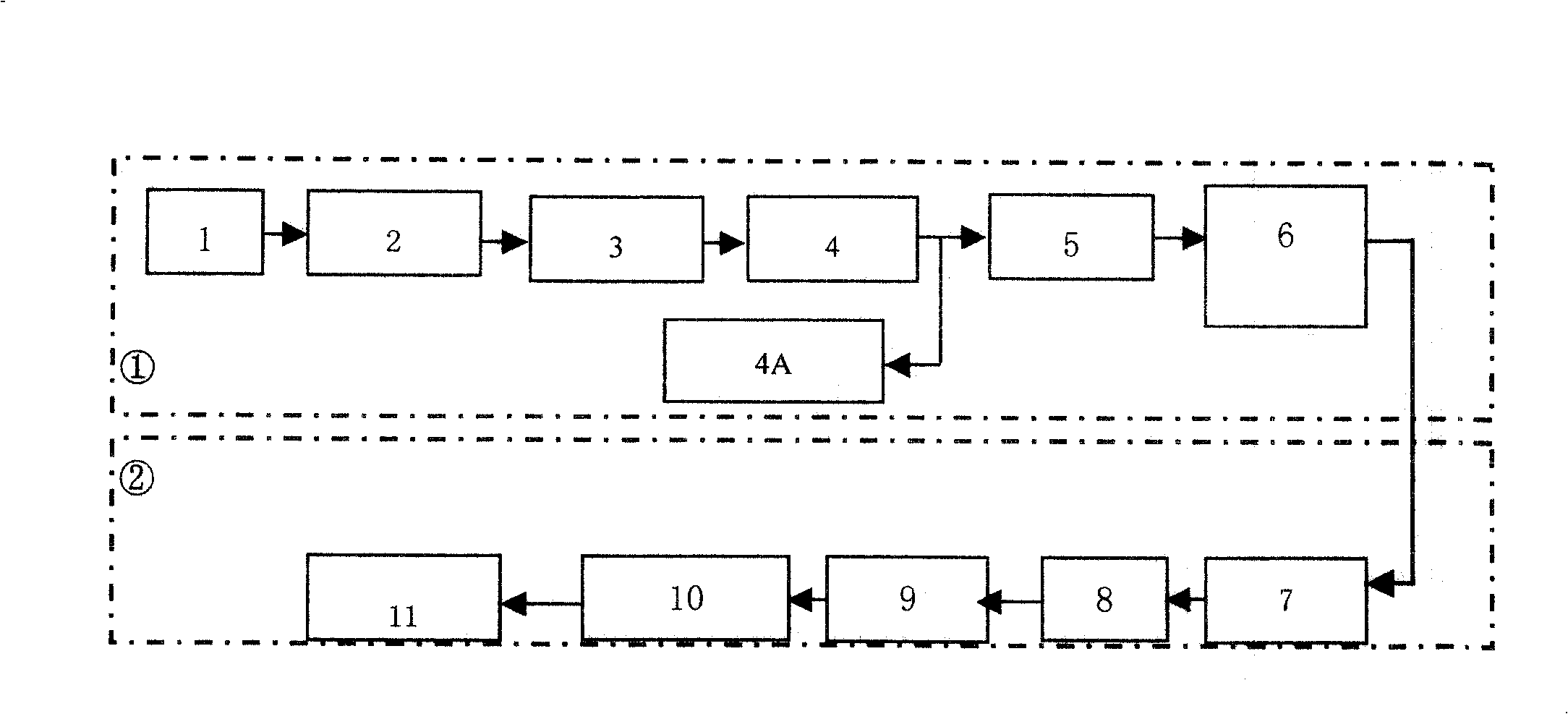

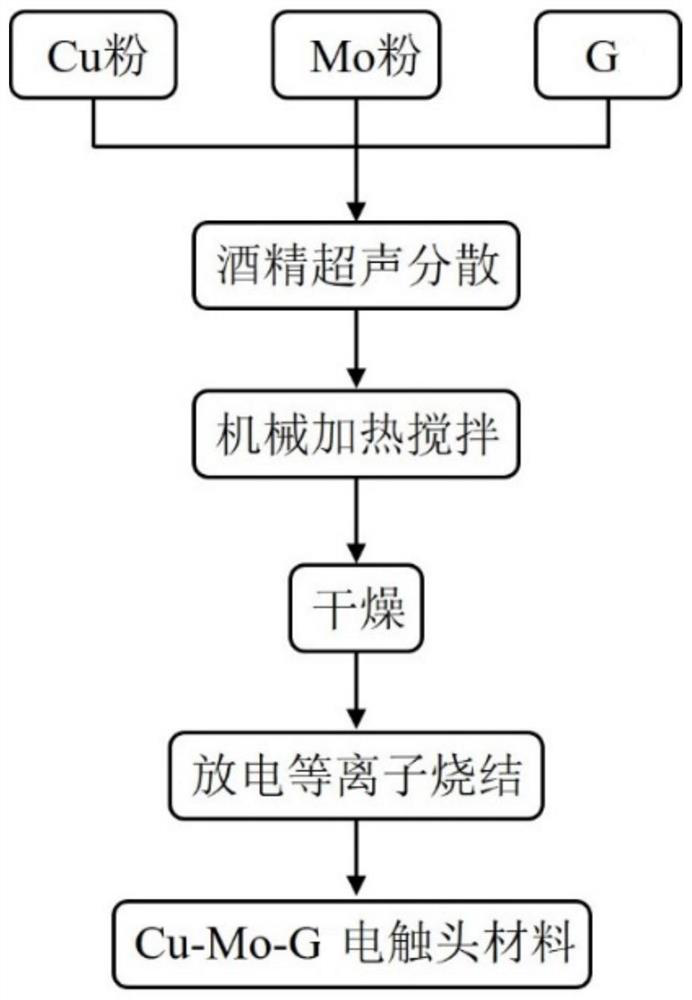

A kind of cu-mo-g electrical contact material and preparation method thereof

ActiveCN113913641BImprove conductivityImprove mechanical propertiesTransportation and packagingMetal-working apparatusGraphiteUltrasonic dispersion

The invention discloses a Cu-Mo-G electrical contact material, which comprises the following components by mass percentage: 88.8-93.8%; Mo 6.0-10.0%; and graphite 0.2-1.2%. The invention also discloses a preparation method of a Cu-Mo-G electrical contact material, which comprises the following steps: adding Cu powder, Mo powder and graphite powder weighed in proportion to an ethanol solution for ultrasonic dispersion, then adding grinding balls and Move to a heating and stirring device for mechanical stirring, then put the mixture into an oven to evaporate to dryness to obtain Cu-Mo-G mixed powder, and finally put the mixed powder into a graphite mold for pre-pressing, transfer it to a discharge plasma furnace for sintering, and cool it with the furnace At room temperature, the Cu-Mo-G electrical contact material is obtained. The Cu-Mo-G electrical contact material of the present invention has excellent mechanical-electrical properties, and also has good resistance to material transfer and arc erosion.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com