Silver based electrical contact material resistant to arc erosion and preparation method thereof

An electric contact material and arc-resistant technology, applied in contacts, circuits, electric switches, etc., can solve problems such as poor arc corrosion resistance, and achieve stable performance, good electrical and thermal conductivity, and good electrical and thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

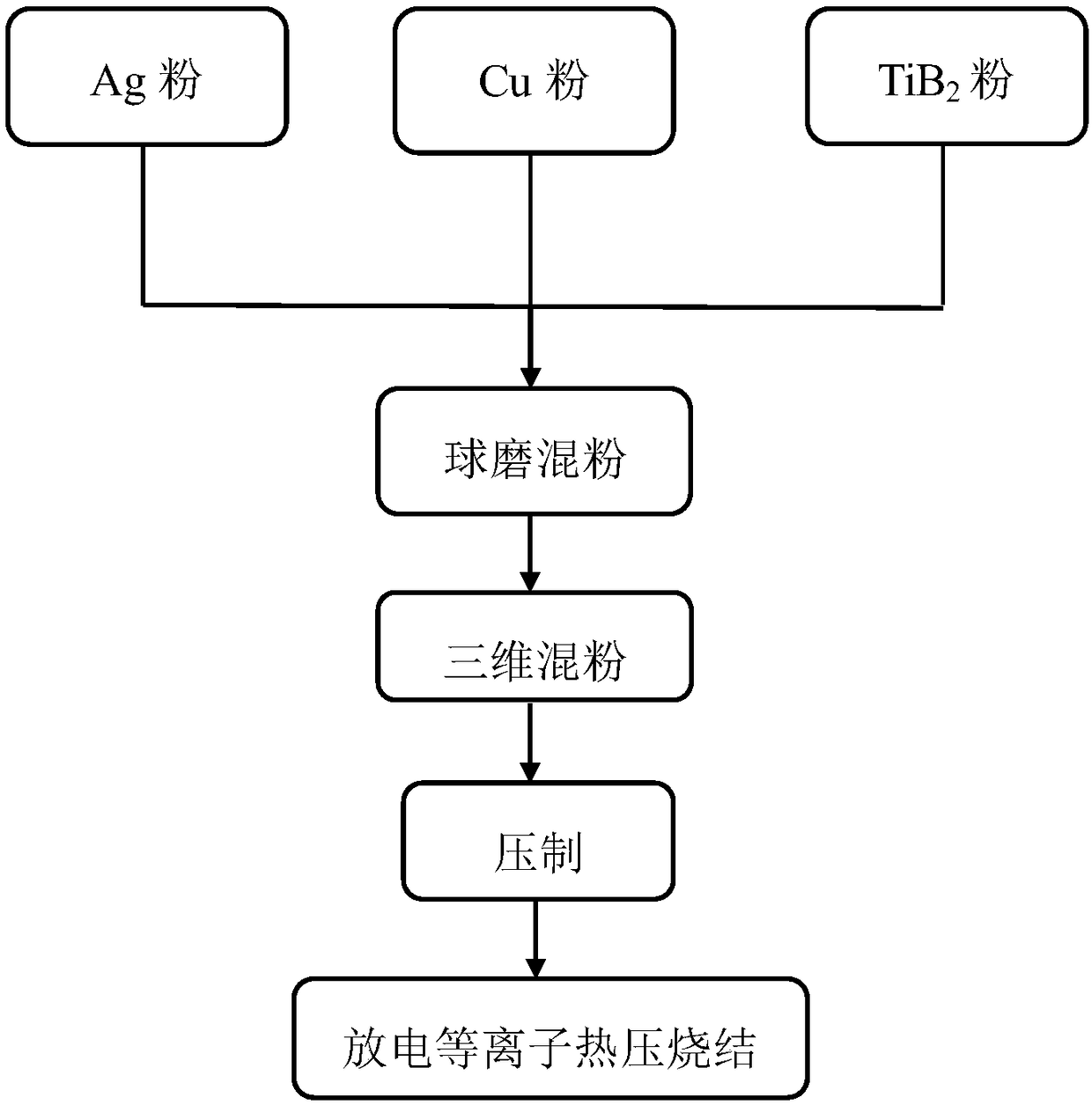

[0025] A kind of preparation method of the silver-based electric contact material of resistance to electric arc corrosion The specific process is as follows figure 1 As shown, the specific operation steps are as follows:

[0026] Step 1, weigh the following materials according to the mass percentage: 5%-20% of Cu powder with a purity of not less than 99.9%, TiB with a purity of not less than 99.9% 2 2%-10% Ag powder and 70%-93% Ag powder with a purity of not less than 99.9%, the sum of the mass percentages of the above components is 100%;

[0027] Step 2, the weighed Ag powder, Cu powder and TiB 2 Put the powder into a ball mill, and add control agent absolute ethanol and dispersant polyvinylpyrrolidone to pre-mix the powder. The amount of absolute ethanol added is Ag powder, Cu powder and TiB powder 2 0.5-1.2% of the total mass of the powder, the amount of polyvinylpyrrolidone added is Ag powder, Cu powder and TiB 2 0.5-2.0% of the total mass of the powder, the speed of th...

Embodiment 1

[0033] Step 1, weigh the following materials according to the mass percentage: Cu powder with a purity of not less than 99.9% 5%, and a purity of not less than 99.9% TiB 2 Ag powder 2% and purity not less than 99.9% Ag powder 93%, the sum of the mass percentages of the above components is 100%;

[0034] Step 2, the weighed Ag powder, Cu powder and TiB 2 Put the powder into a ball mill, and add control agent absolute ethanol and dispersant polyvinylpyrrolidone to pre-mix the powder. The amount of absolute ethanol added is Ag powder, Cu powder and TiB powder 2 0.5% of the total mass of powder, the amount of polyvinylpyrrolidone added is Ag powder, Cu powder and TiB 2 0.5% of the total mass of the powder, the speed of the ball mill is 250r / min, and the powder is mixed for 4 hours to obtain the premixed powder;

[0035] Step 3, put the pre-mixed powder into the three-dimensional powder mixer for re-mixing, the vibration frequency is 30Hz, and the mixing time is 4h to obtain the ...

Embodiment 2

[0039] Step 1, weigh the following materials according to the mass percentage: 20% of Cu powder with a purity of not less than 99.9%, TiB with a purity of not less than 99.9% 2 Ag powder 3% and purity not less than 99.9% Ag powder 77%, the sum of the mass percentages of the above components is 100%;

[0040] Step 2, the weighed Ag powder, Cu powder and TiB 2 Put the powder into a ball mill, and add control agent absolute ethanol and dispersant polyvinylpyrrolidone to pre-mix the powder. The amount of absolute ethanol added is Ag powder, Cu powder and TiB powder 2 1.2% of the total mass of the powder, the amount of polyvinylpyrrolidone added is Ag powder, Cu powder and TiB 22.0% of the total mass of the powder, the speed of the ball mill is 350r / min, and the powder is mixed for 8 hours to obtain the premixed powder;

[0041] Step 3, put the premixed powder into a three-dimensional powder mixer for re-mixing, the vibration frequency is 40 Hz, and the mixing time is 8 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com