Silver-nickel electric contact producing technology

A manufacturing process and technology of electric contacts, applied in the direction of contacts, circuits, electric switches, etc., can solve problems such as slow work, poor anti-welding performance, and difficult breakthrough in electrical performance, so as to improve comprehensive electrical performance and working life Long, excellent effect of arc erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

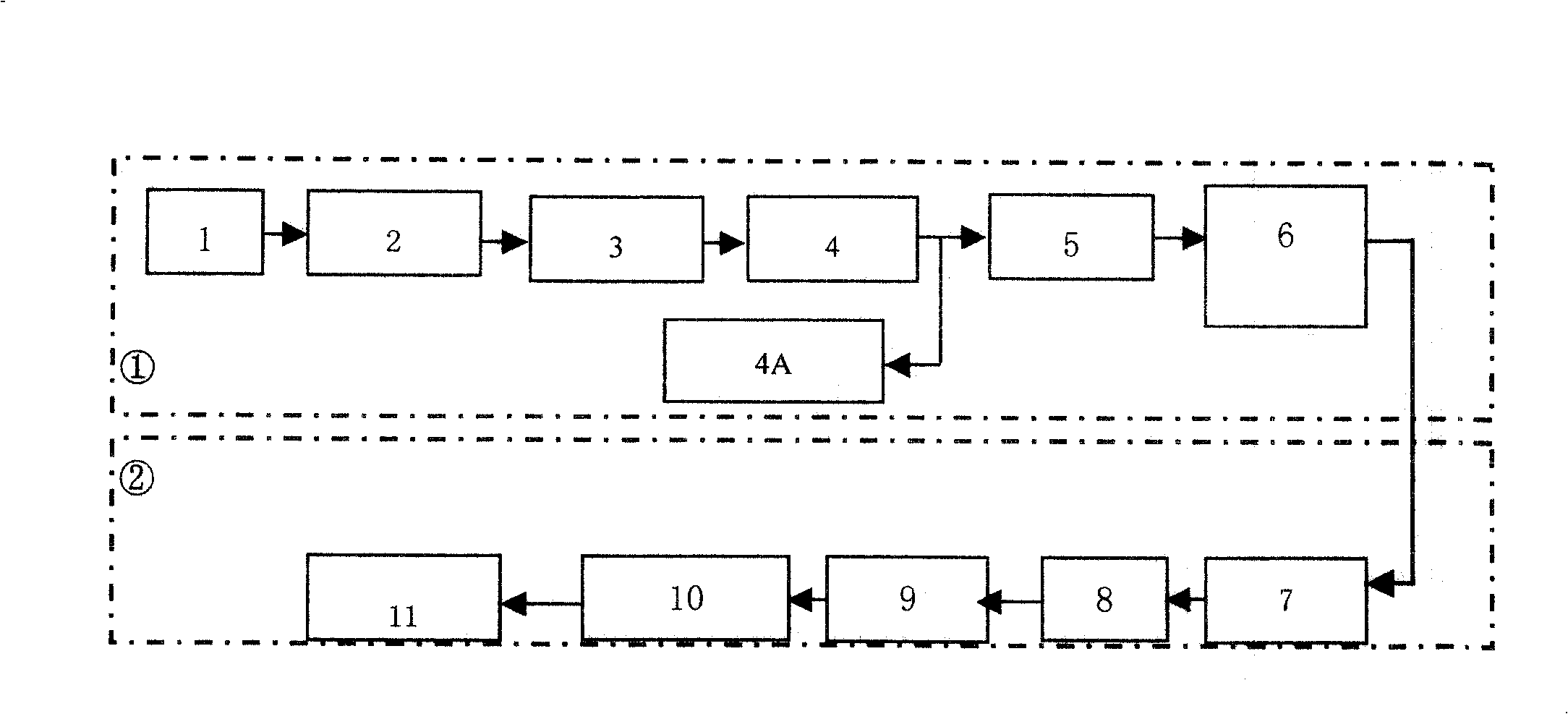

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] figure 1 One embodiment of the silver-nickel electrical contact manufacturing process of the present invention is shown.

[0019] Silver-nickel contact material is an environmentally friendly material developed in recent years. It has good welding resistance and arc erosion resistance, which can meet the requirements of high reliability and long life in electrical operation. With the enhancement of people's awareness of environmental protection, it will be the general trend to replace AgCdO electrical contact materials with silver-nickel electrical contact materials in the fields of low-power thermostats and relays.

[0020] There are mainly three mature processes for the production of silver-nickel electrical contact materials: powder mixing, ball milling, and co-precipitation. Among them, the raw materials of silver-nickel contacts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com