Conductive structure of isolation switch of direct-current cabinet of tracked (trackless) street car carriage

A technology of isolating switch and conductive structure, applied in the direction of electric switch, air switch parts, circuits, etc., can solve the problem of large dimensional tolerance of product assembly, increased contact resistance, and the operator cannot see the correct position of the moving knife component, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is specifically described below by the examples, the examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-compliances made by those skilled in the art based on the content of the above-mentioned patent of the present invention Essential improvements and adjustments also belong to the protection scope of the present invention.

[0041] combine Figure 1 to Figure 6 .

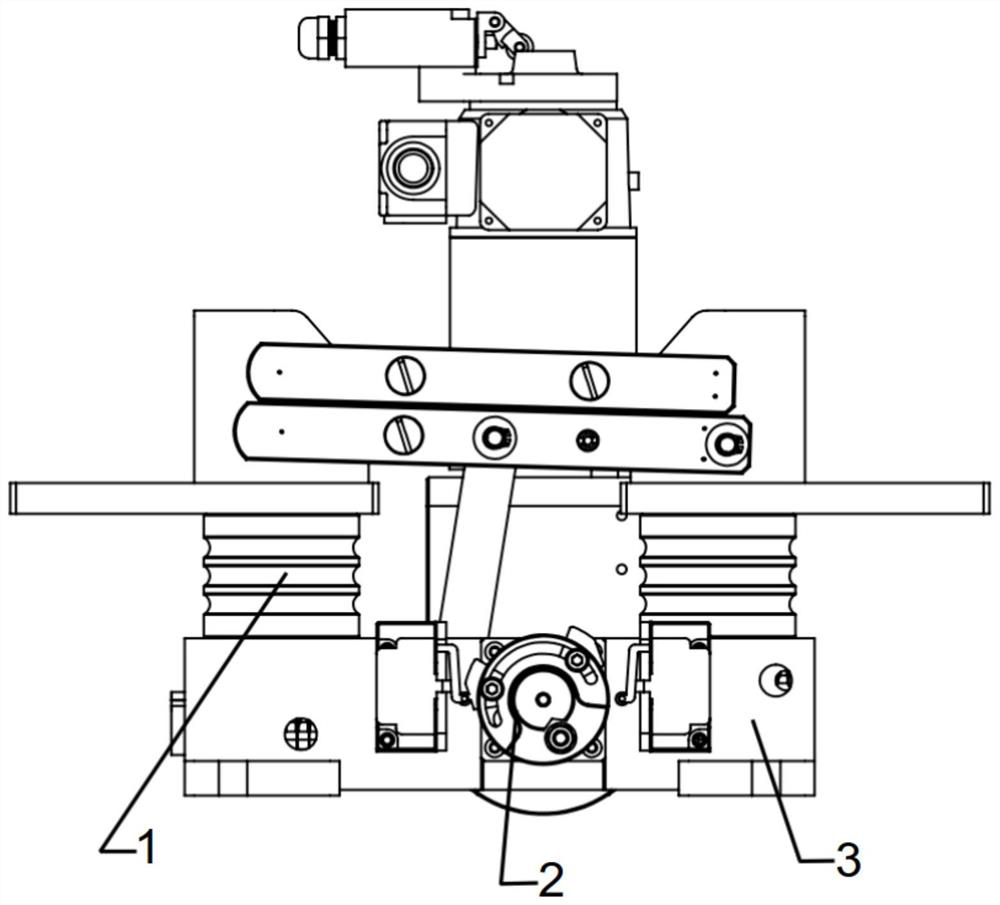

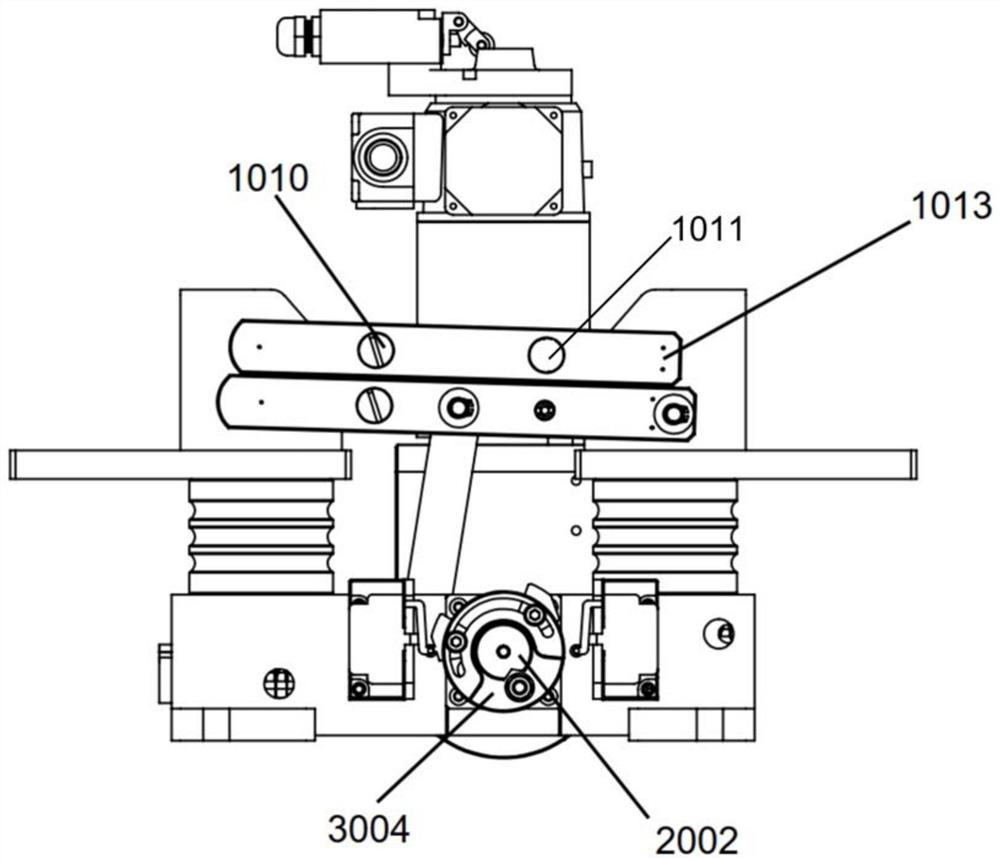

[0042] Such as figure 1 As shown, the isolating switch among the present invention is mainly composed of conductive and insulating parts 1, a frame and a transmission part 2, and a drive and control part 3, three major parts. The components of the isolating switch will be described in detail below in conjunction with the accompanying drawings.

[0043] Conductive and insulating parts 1

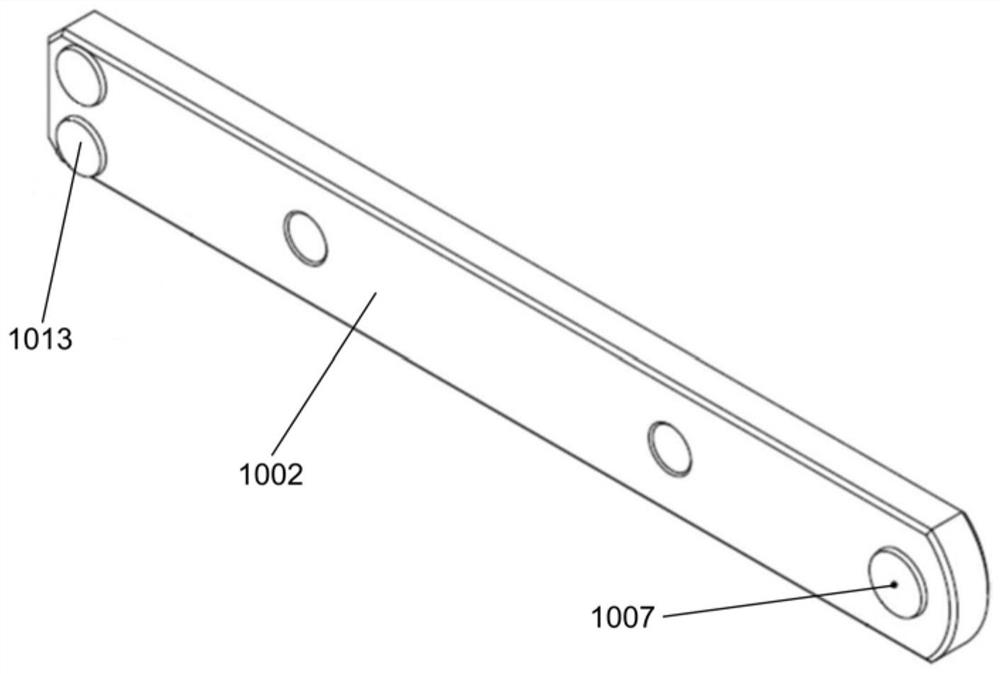

[0044] Such as Figure 4 , four insulators 1005 are arranged on the above-mentioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com