A kind of cu-mo-g electrical contact material and preparation method thereof

An electrical contact material, cu-mo-g technology, applied in contacts, circuits, electrical switches, etc., can solve the problems of uneven dispersion of graphite, poor interface between graphite and metal matrix, etc., and achieves less impurities and good quality. Resistance to material transfer, effect of reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

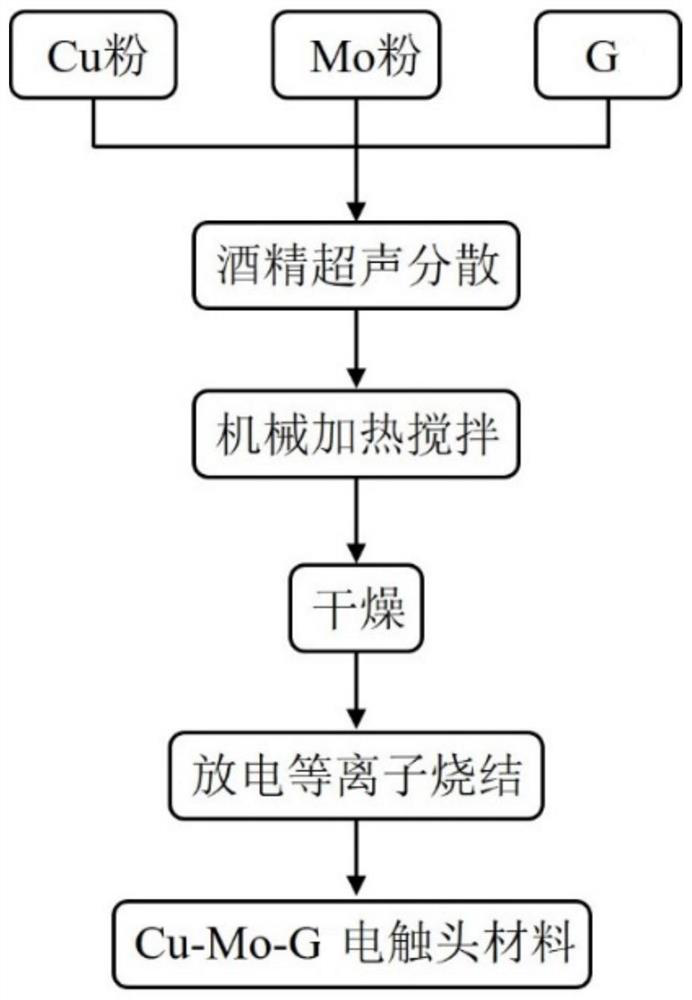

Method used

Image

Examples

Embodiment 1

[0033] Step 1, respectively weigh Cu: 89.8%, Mo: 10.0%, G: 0.2% by mass percentage, and the corresponding masses of Cu, Mo, and G are 161.64g, 18g, and 0.36g, respectively. Among them, Cu is 38μm dendritic powder, Mo is 10μm quasi-spherical powder, G is 10μm quasi-spherical powder, and the purity of each powder is ≥99.9%;

[0034] Step 2, mix the weighed Cu, Mo, G powders and ethanol according to a mass ratio of 9:1, and ultrasonically disperse them in an ultrasonic processor for 40 min to obtain a mixed solution;

[0035] Step 3, adding agate balls with a diameter of 5mm in the mixed solution according to the mass ratio of grinding ball:powder=1.5:1, then transferring to the heating and stirring device for mechanical stirring for 4h, the temperature is 100°C, and the stirring rate is 300rpm;

[0036] Step 4, put the above mixture into an oven with a temperature of 55° C. for 20 minutes to obtain a mixed powder of Cu-Mo-G;

[0037] Step 5, put the mixed powder into a graphite...

Embodiment 2

[0040] Step 1, respectively weigh Cu: 89.4%, Mo: 10.0%, G: 0.6% by mass percentage, and the corresponding masses of Cu, Mo and G are 160.92g, 18g and 1.08g respectively. Among them, Cu is 38μm dendritic powder, Mo is 10μm quasi-spherical powder, G is 10μm quasi-spherical powder, and the purity of each powder is ≥99.9%;

[0041] Step 2, mix the weighed Cu, Mo, G powders and ethanol according to a mass ratio of 9:1, and ultrasonically disperse them in an ultrasonic processor for 40 min to obtain a mixed solution;

[0042] Step 3, adding agate balls with a diameter of 5mm in the mixed solution according to the mass ratio of grinding ball:powder=1.5:1, and then transferring to the heating and stirring device for mechanical stirring for 4h, the temperature is 100°C, and the stirring rate is 300rpm;

[0043] Step 4, put the above mixture into an oven with a temperature of 55° C. for 20 minutes to obtain a mixed powder of Cu-Mo-G;

[0044]Step 5, put the mixed powder into a graphite...

Embodiment 3

[0047] Step 1, respectively weigh Cu: 89.0%, Mo: 10.0%, G: 1.0% by mass percentage, and the corresponding masses of Cu, Mo, and G are 160.2 g, 18 g, and 1.8 g, respectively. Among them, Cu is 38μm dendritic powder, Mo is 10μm quasi-spherical powder, G is 10μm quasi-spherical powder, and the purity of each powder is ≥99.9%;

[0048] Step 2, mix the weighed Cu, Mo, G powders and ethanol according to a mass ratio of 9:1, and ultrasonically disperse them in an ultrasonic processor for 40 min to obtain a mixed solution;

[0049] Step 3, adding agate balls with a diameter of 5mm in the mixed solution according to the mass ratio of grinding ball:powder=1.5:1, and then moving to the heating and stirring device for mechanical stirring for 4h, the temperature is 100 ° C, and the stirring rate is 300rpm;

[0050] Step 4, put the above mixture into an oven with a temperature of 55° C. for 20 minutes to obtain a mixed powder of Cu-Mo-G;

[0051] Step 5, put the mixed powder into a graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com