Silver-tungsten carbide-nickel contact material and preparation method thereof

A silver tungsten carbide and contact material technology, applied in contacts, electrical components, electrical switches, etc., can solve the problems of short electrical life of circuit breakers, difficult electrical life, and low resistance to arc erosion of AgNiC static contacts. The effect of improving wettability, high density and excellent arc erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

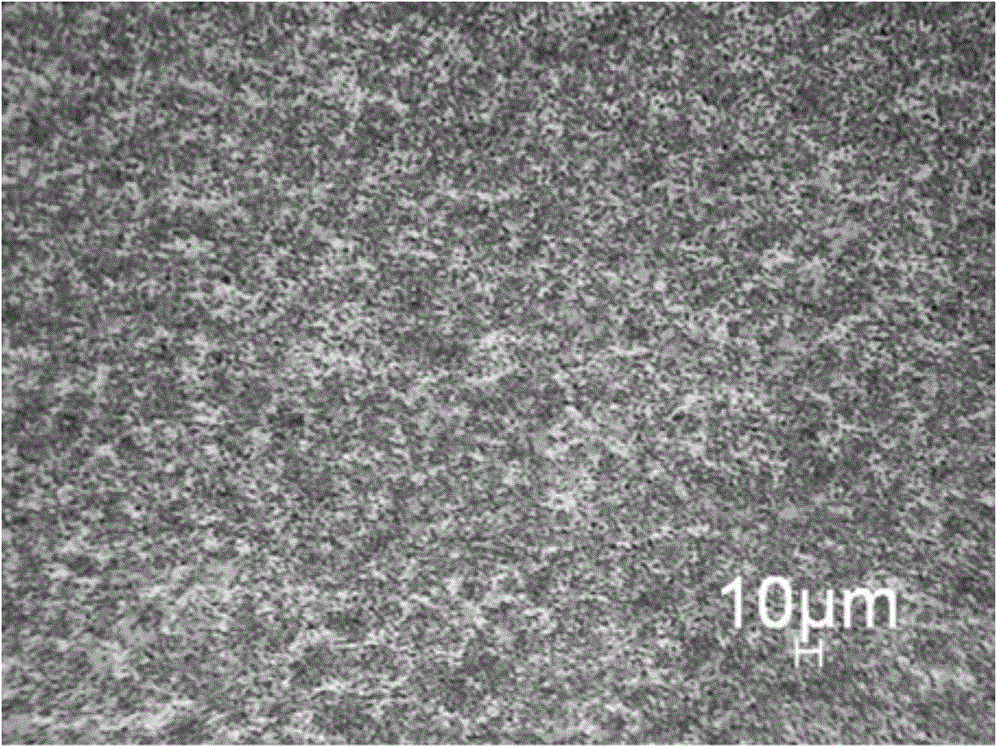

Image

Examples

Embodiment 1

[0028] Select tungsten carbide powder with an average particle size of 1 μm, -200 mesh silver powder and -300 mesh nickel powder, and weigh the silver tungsten carbide nickel with a total weight of 20kg according to the following weight percentages (25% tungsten carbide, 1.55% nickel, and silver as the balance) Powder, powder is put into 30 liters of V type mixers and mixes 2.5 hours, the silver tungsten carbide nickel powder after mixing, the high-purity nickel ball of the φ 6mm of 180kg, 4400ml deionized water are put into 100 liters of roller mills together and carry out ball milling ( Rotation speed is 45 rpm), ball milling time is 30 hours, the powder is taken out and dried at 120°C for 3 hours (after testing, the nickel content in the obtained powder material is 2%), and the dried powder is placed in a hydrogen atmosphere Anneal at 700°C for 2 hours, use 6T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact in a hydrogen atmosphere and sinte...

Embodiment 2

[0031] Select tungsten carbide powder with an average particle size of 3 μm, -100 mesh silver powder and -300 mesh nickel powder, and weigh the silver tungsten carbide nickel with a total weight of 20kg according to the following weight percentages (27% tungsten carbide, 0.9% nickel, and silver as the balance) Powder, powder is put into 30 liters of V-shaped mixers and mixes 3 hours, the silver tungsten carbide nickel powder after mixing, the high-purity nickel ball of the φ 20mm of 80kg, 3000ml deionized water are put into 100 liters of roller ball mills together and carry out ball milling ( Rotation speed is 45 rpm), ball milling time is 12 hours, the powder is taken out and dried at 150°C for 3 hours, and the dried powder is placed in a hydrogen atmosphere and annealed at 750°C for 1 hour (after testing, the obtained powder material Nickel content is 1%), with 4T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact in a hydrogen atmosphere and si...

Embodiment 3

[0033] Select tungsten carbide powder with an average particle size of 1 μm, -120 mesh silver powder and -300 mesh nickel powder, and weigh the silver tungsten carbide nickel with a total weight of 20kg according to the following weight percentages (20% tungsten carbide, 4.2% nickel, and silver as the balance) Powder, powder is put into 30 liters of V-shaped mixers and mixes 2 hours, the silver tungsten carbide nickel powder after mixing, the high-purity nickel ball of the φ 30mm of 200kg, 2600ml deionized water are put into 100 liters of roller ball mills together and carry out ball milling ( Rotation speed is 45 rpm), ball milling time is 48 hours, the powder is taken out and dried at 130°C for 2 hours, the dried powder is placed in a hydrogen atmosphere and annealed at 720°C for 2 hours, (after testing, the obtained powder material The nickel content is 5.0%), with 7T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact in a hydrogen atmosphere a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com