A kind of al2o3-tic copper-based composite material and preparation method thereof

A copper-based composite material, al2o3-tic technology, applied in the field of copper-based composite materials, can solve the problem of insufficient resistance to high temperature, high pressure, large arc load, harsh application environment of current density in contact area, and reinforced copper-based composite materials that cannot meet special requirements. Performance and service life and other issues, to achieve good anti-arc erosion performance, easy control of process conditions, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, Al powder, TiO 2 The sum of the percentages by weight of powder and C powder is 1%;

[0042] The average particle size is 300 mesh Al powder 0.084g, 300 mesh Cu powder 29.7g, 300 mesh rutile ultrafine TiO 2 0.188g of powder and 0.028g of graphite powder with a particle size of 800 mesh were manually ground in a mortar for 5 minutes, then put into a ball mill pot and wet ball milled on a planetary ball mill for 10 hours;

[0043] Then dry;

[0044] Then put the dried product into a graphite mold and sinter it in an SPS spark plasma sintering furnace. Cool to get Al 2 o 3 -TiC copper-based composite material.

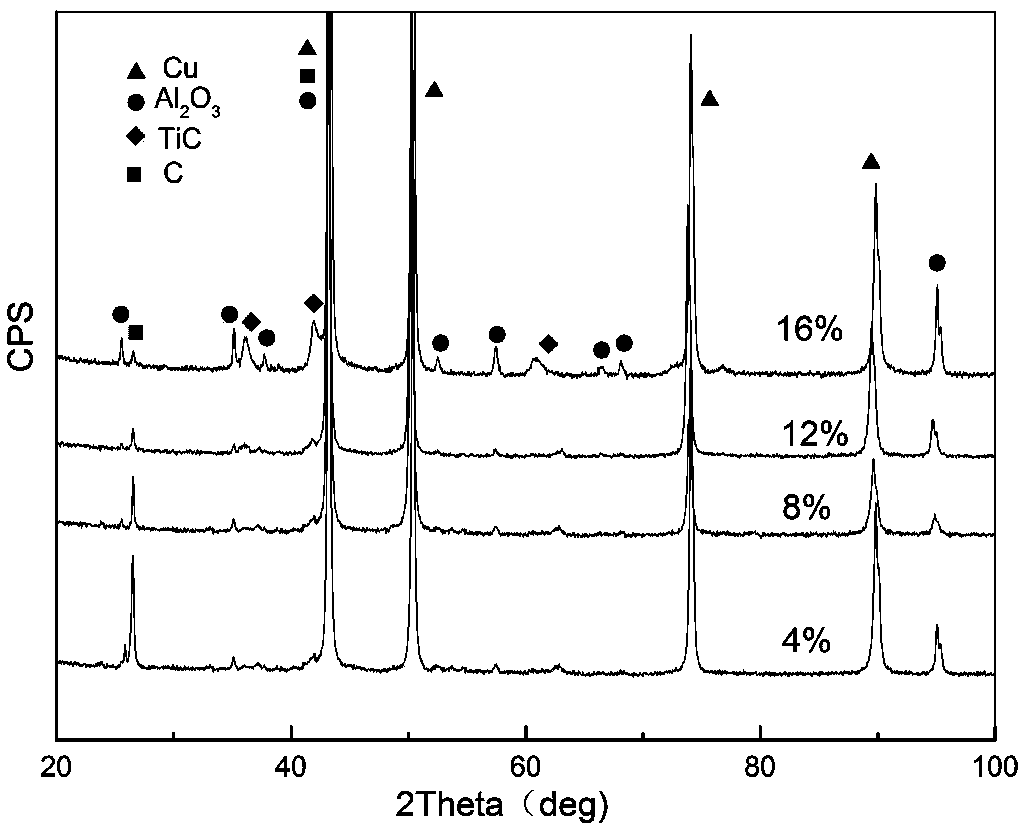

[0045] The sintered product is Cu, Al by XRD phase analysis 2 o 3 , TiC three-phase, prepared Al 2 o 3 - The Vickers hardness of the TiC copper matrix composite is 170HV, the tensile strength is 551MPa, the elongation is 20%, and the electrical conductivity is 87% IACS.

Embodiment 2

[0047] In this embodiment, Al powder, TiO 2 The sum of the percentages by weight of powder and C powder is 2%;

[0048] The average particle size is 300 mesh Al powder 0.169g, 300 mesh Cu powder 29.4g, 300 mesh rutile ultrafine TiO 2 0.375g of powder and 0.056g of graphite powder with a particle size of 700 mesh were manually ground in a mortar for 5 minutes, then put into a ball mill pot and wet ball milled on a planetary ball mill for 8 hours;

[0049] Then dry;

[0050] Then put the dry product into a graphite mold and sinter it in an SPS discharge plasma sintering furnace. Cool to get Al 2 o 3 -TiC copper-based composite material.

[0051] The sintered product is Cu, Al by XRD phase analysis 2 o 3 , TiC three-phase, prepared Al 2 o 3 -TiC copper matrix composite material has a Vickers hardness of 172HV, a tensile strength of 558MPa, an elongation of 18%, and an electrical conductivity of 85% IACS.

Embodiment 3

[0053] In this embodiment, Al powder, TiO 2 The sum of the percentages by weight of powder and C powder is 3%;

[0054] The average particle size is 300 mesh Al powder 0.253g, 300 mesh Cu powder 29.1g, 400 mesh rutile ultrafine TiO 2 0.563g of powder and 0.084g of graphite powder with a particle size of 700 mesh were manually ground in a mortar for 5 minutes, then put into a ball mill pot and wet ball milled on a planetary ball mill for 12 hours;

[0055] Then dry;

[0056] Then put the dried product into a graphite mold and sinter it in a SPS spark plasma sintering furnace. Cool to get Al 2 o 3 -TiC copper-based composite material.

[0057] The sintered product is Cu, Al by XRD phase analysis 2 o 3 , TiC three-phase, prepared Al 2 o 3 -TiC copper matrix composite material has a Vickers hardness of 176HV, a tensile strength of 563MPa, an elongation of 17%, and an electrical conductivity of 83% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com