Shell-core-structure MXene@MAX composite contact reinforcing phase material and preparation method thereof

A core-shell structure and composite contact technology, which is applied in the direction of electrical components, circuits, electric switches, etc., can solve the problems of inability to strengthen the Ag matrix, find no electrical contact materials, and not Ag/CdO, etc., and achieve arc erosion resistance Excellent performance, moderate hardness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

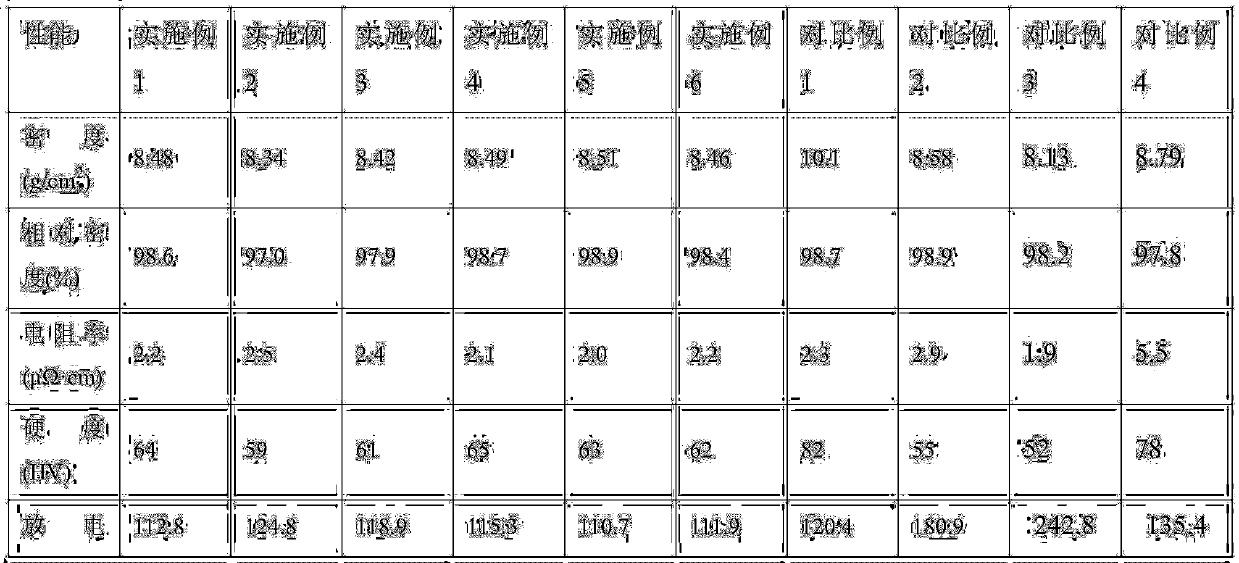

Embodiment 1

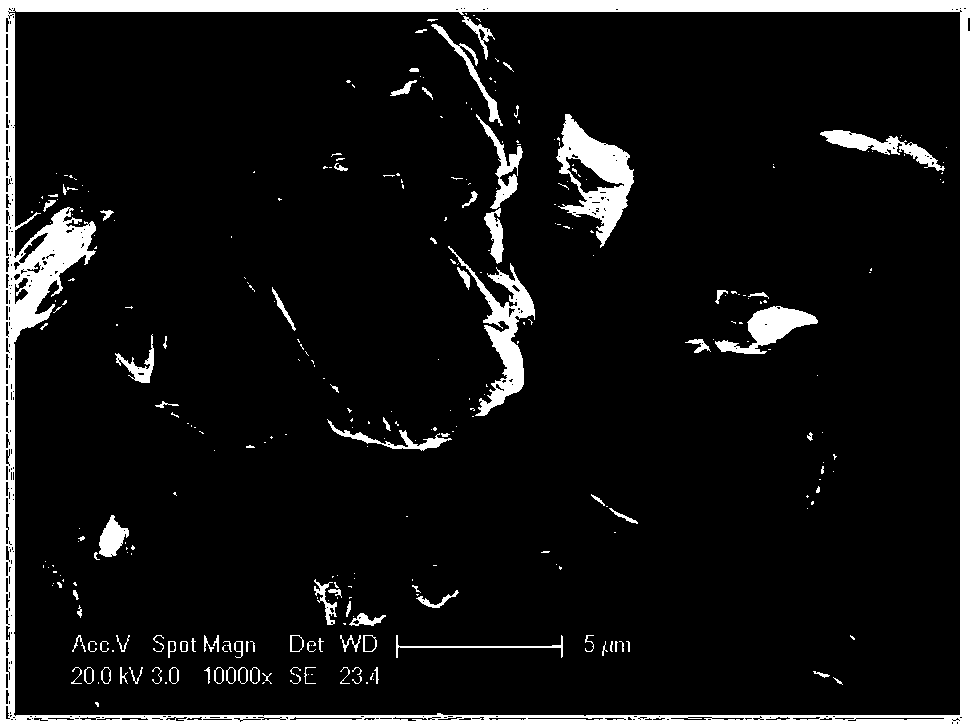

[0039] 10g Ti 3 SiC 2 The powder is added into the HF acid solution with a concentration of 20wt% according to the mass ratio of liquid: solid = 20:1, and stirred at a speed of 50rpm in a magnetic stirrer at a temperature of 30°C for 1 hour; the mixed solution is poured into a centrifuge tube with a size of 10mL In the centrifuge, it was centrifuged at a set speed of 1000rpm for 1 hour, and the centrifuged mixture was placed in a freeze dryer for 1 hour to freeze-dry to obtain Ti with a core-shell structure. 3 SiC 2 @Ti 3 C 2 Powder; Ti will account for 5% by mass of the overall material 3 SiC 2 @Ti 3 C 2 The powder and the Ag powder of mass fraction 95% were wet-mixed 0.5 hour (ball: alcohol: powder material=2:1:1) in the ball mill tank that medium is housed, then dried 2 hours to obtain mixed powder; The press was pressed at a pressure of 800MPa and kept for 10 minutes; the block sample was placed in a sintering furnace, and the temperature was raised to 600°C at a h...

Embodiment 2

[0041] 25g Ti 3 SiC 2 The powder is added into the HF+FLi acid solution with a concentration of 25wt% according to the mass ratio of liquid: solid=30:1, and stirred at a speed of 78rpm in a magnetic stirrer for 1.8 hours at a temperature of 38°C; the mixed solution is poured into a 25mL container In a centrifuge tube, centrifuge at a set speed of 1800rpm for 1.5 hours in a centrifuge, and the centrifuged mixture is placed in a freeze dryer for 1.5 hours to freeze-dry to obtain Ti with a core-shell structure. 3 SiC 2 @Ti 3 C 2 Powder; will account for 8% Ti of the overall material mass fraction 3 SiC 2 @Ti 3 C 2 The powder and the Ag powder of mass fraction 92% were wet-mixed for 1 hour (ball: alcohol: powder = 2.5:1.5:1) in a ball mill tank equipped with a medium, and then dried for 3 hours to obtain a mixed powder; Compress molding with a pressure of 750MPa in a press for 9 minutes; place the block sample in a sintering furnace, N 2 Under atmosphere protection, the t...

Embodiment 3

[0043] 48g Ti 3 SiC 2 The powder is added into the HF acid solution with a concentration of 28wt% according to the mass ratio of liquid:solid=38:1, and stirred at a speed of 90rpm in a magnetic stirrer for 2.5 hours at a temperature of 42°C; the mixed solution is poured into a centrifuge tube with a size of 50mL In the centrifuge, it was centrifuged at a set speed of 2000rpm for 2 hours, and the centrifuged mixture was placed in a freeze dryer for 2 hours to freeze-dry to obtain Ti with a core-shell structure. 3 SiC 2 @Ti 3 C 2 Powder; Ti will account for 10% of the overall material mass fraction 3 SiC 2 @Ti 3 C 2 Powder and the Ag powder of massfraction 90% were wet-mixed 1.5 hours (ball: alcohol: powder material=2.8:2:1) in the ball mill tank that medium is housed, then dried 3.5 hours to obtain mixed powder; Compress molding with a pressure of 700MPa in a press for 8 minutes; place the block sample in a sintering furnace, N 2 Under the protection of the atmosphere,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com