A kind of preparation method of copper tungsten contact material

A contact material, copper tungsten technology, applied in the manufacture of emergency protection devices, electrical components, circuits, etc., can solve the problems of reduced probability of tungsten particles capturing nickel, discounted tungsten skeleton activation and sintering effect, and insufficient dispersion of tungsten particles. , to achieve excellent arc erosion resistance, improve the activation sintering effect, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 20kg of tungsten powder with an average particle size of 2μm, combine tungsten powder, 200kg of φ6~φ30mm (the weight ratio is φ6mm:φ10mm:φ20mm:φ30mm=3:5:1:1) high-purity nickel balls, and 3000ml of deionized water Put them together into a 100-liter roller ball mill for ball milling (rotation speed is 45 rpm), the ball milling time is 24 hours, take out the powder and dry it at 150°C for 2 hours, and place the dried powder in a hydrogen atmosphere at 700°C Anneal for 2 hours (after testing, the nickel content in the obtained powder material is 0.55%), use 2T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact in a graphite boat, and sinter at 1300°C for 1 hour in a hydrogen atmosphere to obtain a tungsten skeleton. Put the tungsten skeleton blank in the graphite boat and add Corresponding mass of copper sheet (57% of the weight of the tungsten skeleton) is infiltrated in a hydrogen atmosphere at 1200° C. for 2 hours, thereby producing a...

Embodiment 2

[0030] Weigh 20kg of tungsten powder with an average particle size of 9 μm, put tungsten powder, 80kg of φ20mm high-purity nickel balls, and 2400ml of deionized water together into a 50-liter roller mill for ball milling (the speed is 50 rpm), and the ball milling time is 12 hours. Take out the powder and dry it at 80°C for 4 hours, place the dried powder in a hydrogen atmosphere and anneal at 850°C for 1 hour (the nickel content in the obtained powder material is 0.15% after testing), use 4T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact in a graphite boat, sinter at 1450°C for 1 hour in an ammonia decomposition gas atmosphere to obtain a tungsten skeleton, and place the tungsten skeleton blank in a graphite boat And add the corresponding quality of copper sheet (24% of the weight of the tungsten skeleton), and infiltrate it at 1250°C for 1 hour in the atmosphere of ammonia decomposition gas, so that the copper-tungsten 85 contact can be produ...

Embodiment 3

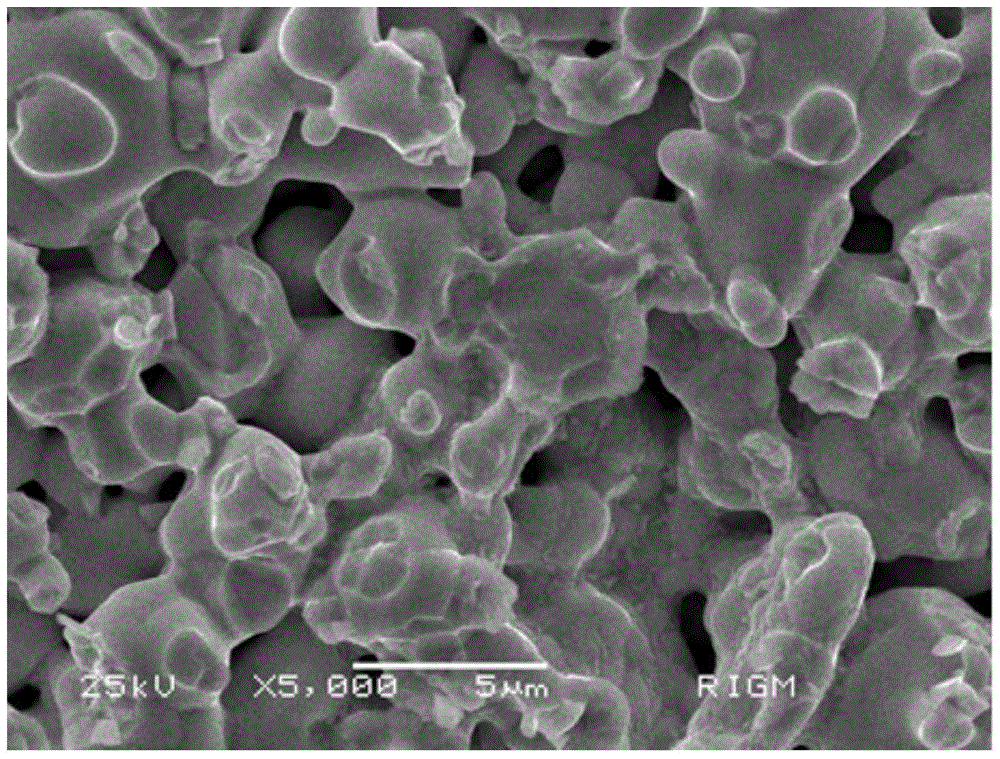

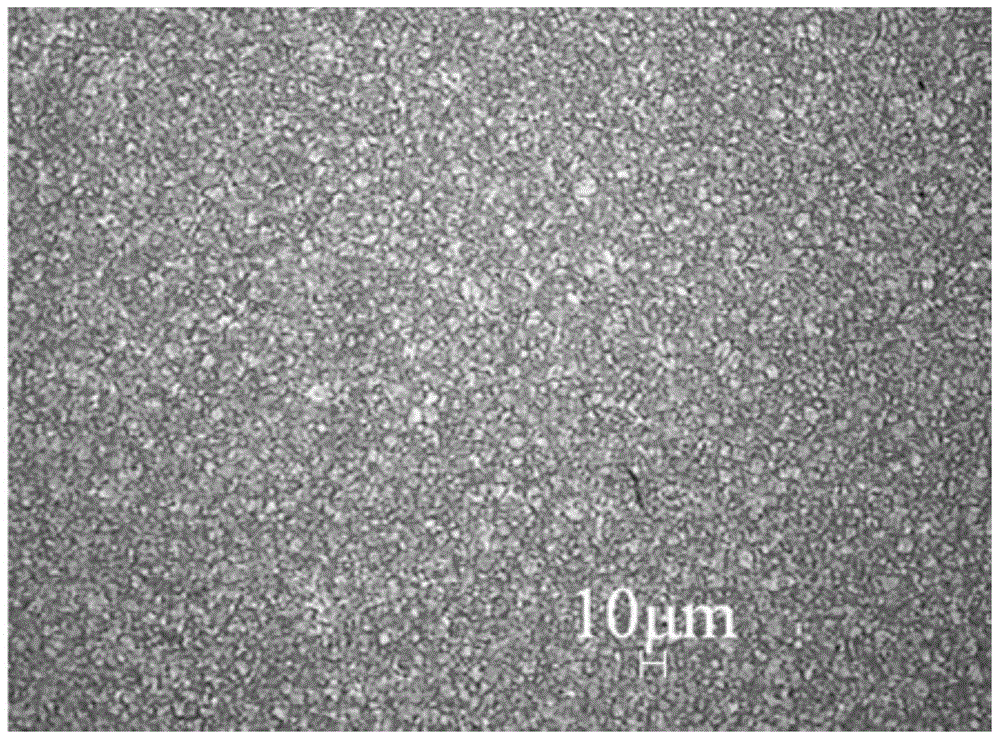

[0032] Weigh 20kg of tungsten powder with an average particle size of 6μm, put the tungsten powder, 160kg of φ10mm high-purity nickel balls, and 2600ml of deionized water into a 100-liter roller ball mill for ball milling (rotational speed is 45 rpm), and the ball milling time is 48 hours , take out the powder and dry at 100°C for 3 hours, place the dried powder in an ammonia decomposition gas atmosphere and anneal at 800°C for 1.5 hours (after testing, the nickel content in the obtained powder material is 0.96%), use 3T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact in a graphite boat, and sinter at 1400°C for 2 hours in a hydrogen atmosphere to obtain a tungsten skeleton (such as figure 1shown), put the tungsten skeleton billet in the graphite boat and add the corresponding mass of copper sheet (31% of the weight of the tungsten skeleton), and infiltrate it at 1250°C for 1 hour in the hydrogen atmosphere, thus the copper tungsten 80 contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com