Complex conductive oxide-modified copper-based electric contact material and preparation method thereof

A technology of conductive oxides and electrical contact materials, applied in contacts, circuits, electrical switches, etc., can solve the problems of short life of breaking contacts of low-voltage electrical switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

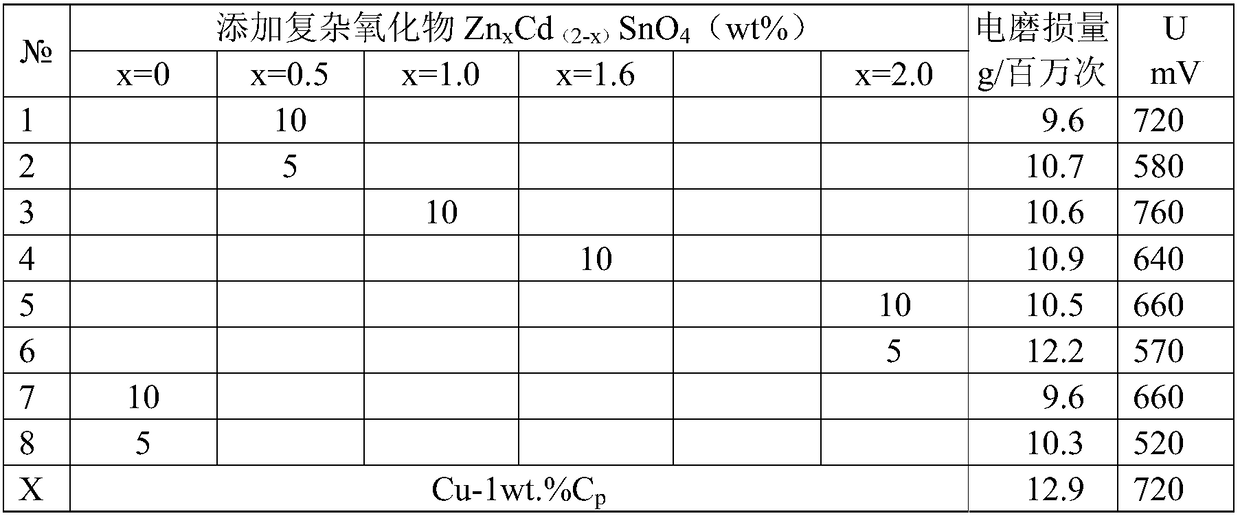

[0031] Specific Embodiment 1: The complex conductive oxide modified copper-based electrical contact material in this embodiment is characterized in that the complex conductive oxide-modified copper-based electrical contact material is composed of 2% to 15% complex conductive oxide, 0.004% to 0.01% of lanthanum, 0.1% to 0.3% of zirconium and the balance of copper; the molecular formula of the complex conductive oxide is Zn x Cd (2-x) SnO 4 , x in the molecular formula is 0-2.

[0032] The beneficial effects of this embodiment are:

[0033] 1. This embodiment adopts the principle of complex conductive oxide as the second phase and matrix alloying for material design, and realizes material preparation through liquid phase in-situ synthesis, co-deposition and subsequent heat treatment to obtain high arc ablation resistance, A new type of copper-based electrical contact material with low and stable contact resistance; the complex conductive oxide modified copper-based electrical...

specific Embodiment approach 2

[0041] Specific embodiment two: the preparation method of complex conductive oxide modified copper-based electrical contact material in this embodiment is specifically carried out according to the following steps:

[0042] 1. Weigh cadmium acetate dihydrate, zinc acetate dihydrate, five Tin chloride hydrate and copper alloy powder; said complex conductive oxide has the molecular formula Zn x Cd (2-x) SnO 4 , x in the molecular formula is 0~2;

[0043] 2. Dissolve the cadmium acetate dihydrate, zinc acetate dihydrate and tin chloride pentahydrate in the step 1 respectively in distilled water to obtain a concentration of 1.55M~1.65M cadmium acetate solution and a concentration of 1.55M~1.65M acetic acid Zinc solution and tin chloride solution with a concentration of 0.75M ~ 0.85M; mix cadmium acetate solution, zinc acetate solution and tin chloride solution, then add copper alloy powder and distilled water, in a water bath with a temperature of 60°C ~ 85°C Stir to obtain a s...

specific Embodiment approach 3

[0049] Embodiment 3: This embodiment differs from Embodiment 2 in that: the particle size of the copper alloy powder in step 1 is 25-44 μm. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com