Preparation method of composite nanoparticle-reinforced silver-based electrical contact material

A technology of composite nanoparticles and electrical contact materials, which is applied in circuits, electrical switches, electrical components, etc., can solve the problems that AgMeO electrical contact materials cannot be achieved, AgMeO electrical contacts cannot achieve comprehensive performance, etc. The effect of good arc erosion, improved plastic deformation and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

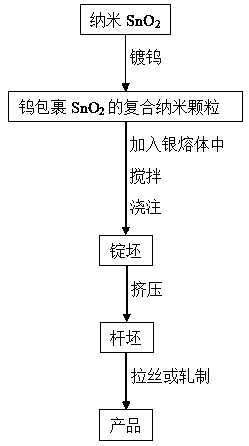

[0021] Such as figure 1 The process flow, using the traditional tungsten plating process, in the commercially available 20nm spherical nano-SnO 2 The surface is coated with a layer of tungsten with a thickness of 12nm; then in a vacuum of 10 -5 Under vacuum conditions, the tungsten-coated SnO 2 The composite nanoparticles were added to the silver melt at a temperature of 1100 ° C, and the tungsten-coated SnO 2 The mass percentage of the composite nanoparticles and the silver melt is 10%, and the stirring rate is 600r / min for mechanical stirring; then after mechanical stirring for 5min, the pouring temperature is 1000°C to pour into an ingot; then the ingot Extruded into a billet at an extrusion temperature of 820°C and an extrusion pressure of 1000MPa; finally, a tungsten-coated SnO 2 Composite nanoparticle-reinforced silver-based electrical contact materials.

[0022] The tungsten-coated SnO prepared in this embodiment 2 Electrical contact erosion pits of composite nano...

Embodiment 2

[0024] Such as figure 1 The process flow, using the traditional tungsten plating process, in the commercially available 100nm spherical nano-SnO 2 The surface is coated with a layer of tungsten with a thickness of 8nm; then in a vacuum of 10 -5 Under vacuum conditions, the tungsten-coated SnO 2 The composite nanoparticles were added to the silver melt at a temperature of 1000 °C, and the tungsten-coated SnO 2 The mass percentage of the composite nanoparticles and the silver melt is 12%, and the stirring rate is 500r / min for mechanical stirring; then after mechanical stirring for 3 minutes, the pouring temperature is 980 ℃ to pour into an ingot; then the ingot Extruded into a billet at an extrusion temperature of 750°C and an extrusion pressure of 1500MPa; finally, a tungsten-coated SnO was obtained using a traditional drawing process. 2 Composite Nanoparticle Reinforced Silver-Based Electrical Contact Filaments.

Embodiment 3

[0026] Such as figure 1 The process flow, using the traditional tungsten plating process, in the commercially available 10nm spherical nano-SnO 2 The surface is coated with a layer of tungsten with a thickness of 10nm; then in a vacuum of 10 -5 Under vacuum conditions, the tungsten-coated SnO 2 The composite nanoparticles were added to the silver melt at a temperature of 980 ° C, and the tungsten-coated SnO 2 The mass percentage of the composite nanoparticles and the silver melt is 17%, and the stirring rate is 1400r / min for mechanical stirring; then after mechanical stirring for 8 minutes, the pouring temperature is 970 ℃ to pour into an ingot; then the ingot Extruded into a billet under the condition of extrusion temperature of 800°C and extrusion pressure of 1200MPa; finally, the traditional rolling process was used to obtain tungsten-coated SnO 2 Composite nanoparticle-reinforced silver-based electrical contact materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com